6

the native soil is sand or if a

high, uctuating water table

is expected. Class I, angular

crushed stone, oers an added

benet in that it needs minimal

compaction. Class II, naturally

rounded stone, may require

more compactive eort, or

tamping, to achieve the proper

density.

If the native soil condition

consists of clean, compactible

soil with less than 12% nes,

free of ice, rocks, roots, and

organic material, it may be

an acceptable backll. Such

soil must be compacted in

lifts not to exceed one foot to

reach a nal Proctor Density

between 85% and 90%. Non-

compactable clays and silts

are not suitable backll for this

or any underground structure

such as inlet or discharge

lines. If you are unsure of

the consistency of the native

soil, it is recommended that a

geotechnical evaluation of the

material be obtained before

specifying backll.

Another option is the use of

a owable ll (i.e., low slump

concrete). This is particularly

attractive when installing

grinder pump stations in

augured holes where tight

clearances make it dicult to

assure proper backlling and

compaction with dry materials.

Flowable lls should not be

dropped with more than 4

feet between the discharge

nozzle and the bottom of the

hole because this can cause

separation of the constituent

materials.

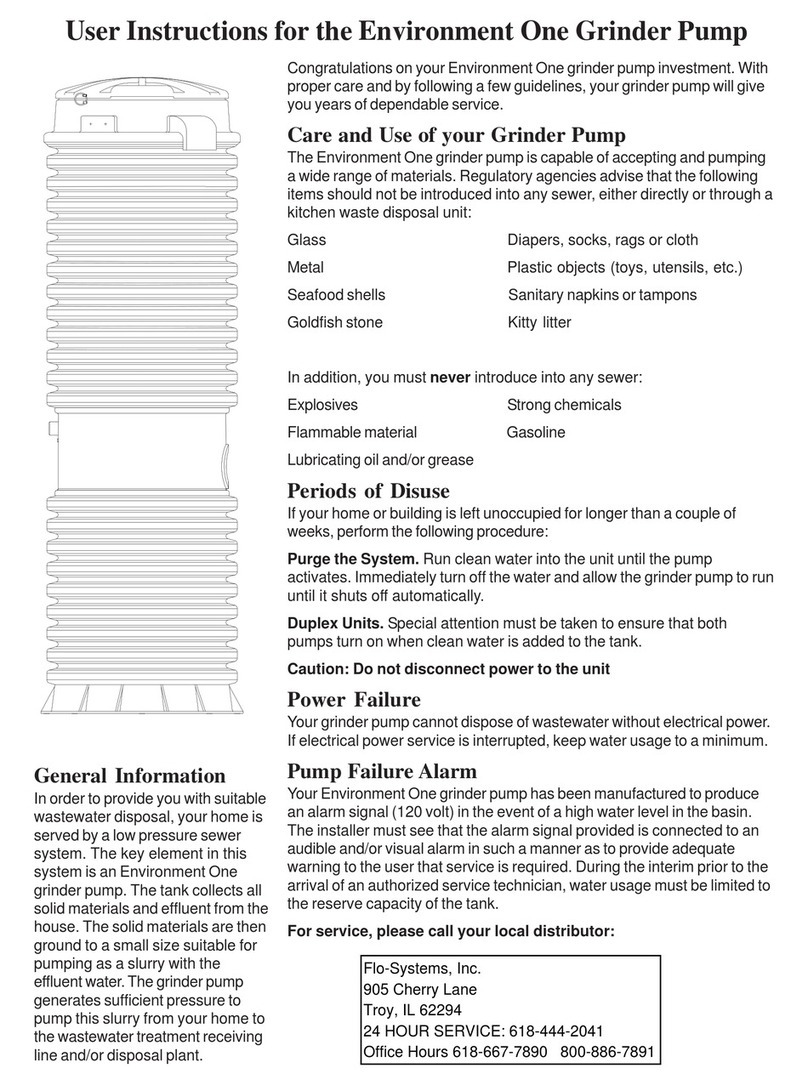

6. VENTING: The unit must

be properly vented to assure

correct operation of the pump.

If you have an indoor unit, it

can be vented through the

2” port supplied at the top of

the wetwell or through the

incoming sewer line with a 2”

pipe (the vent must be within

4 feet of the grinder pump,

and before the rst change of

direction tting).

Outdoor units are supplied

with a vent pipe from the

wetwell to the top of the

accessway. Failure to properly

vent the tank will result in faulty

operation and will void the

warranty.

7. ELECTRICAL

CONNECTION: (Supply panel

to E/One Alarm Panel) Before

proceeding, verify that the

service voltage is the same as

the motor voltage shown on the

name plate. An alarm device is

to be installed in a conspicuous

location where it can be readily

seen by the homeowner. An

alarm device is required on

every installation. There shall

be no exceptions.

Wiring of supply panel and

alarm panel shall be per

Figures 2a and 2b, alarm panel

wiring diagrams and local

codes. A dedicated 30 amp

breaker is required before all

simplex alarm panels.

8. ELECTRICAL

CONNECTION: (Pump to

Panel) (Fig. 4) The grinder

pump station is provided

with a cable for connection

between the station and the

alarm panel (supply cable).

The supply cable is shipped

inside the station with a small

portion fed through the cable

connector mounted on the

wall of the berglass shroud.

The supply cable, a six

conductor tray cable, meets

NEC requirements for direct

burial as long as a minimum of

24” burial depth is maintained.

Those portions of the cable

which have less than 24” of

cover must be contained in

suitable conduit. This includes

the vertical portion dropping

to a 24” depth at the station

and the length rising out of the

ground at the control panel.

NOTE: Wiring must be installed

per national and local codes.

Conduit must enter panel from

bottom and be sealed per NEC

section 300.5 & 300.7.

8a. Installing E/One supply

cable:

1) Open the lid of the

station. Locate the cable and

the feed-thru connector on

the wall of the shroud. If the

station has a eld joint and

was delivered in two pieces,

be sure both halves of the

EQD are securely assembled

together. Loosen the nut on

the connector and pull the

supply cable out through

the connector until it hits the

crimped-on stop feature on the

cable, approximately 24” from

the EQD. **IMPORTANT: All

but 24” of the cable must be

pulled out of the station, and

the EQD and Equalizer should

be hung as high in the station

as possible to ensure that the

pump functions properly. Do

not leave the excess cable in

the station.

2) Retighten the nut. This

connection must be tight or

ground water will enter the

station.

3) Feed the wire through the

length of conduit (contractor

provided), which will protect it

until it is below the 24” burial

depth.

4) Position the conduit

vertically below the cable

connector along side of the

station reaching down into the

burial depth. Attach the small

berglass guard (protective

shroud) provided with the