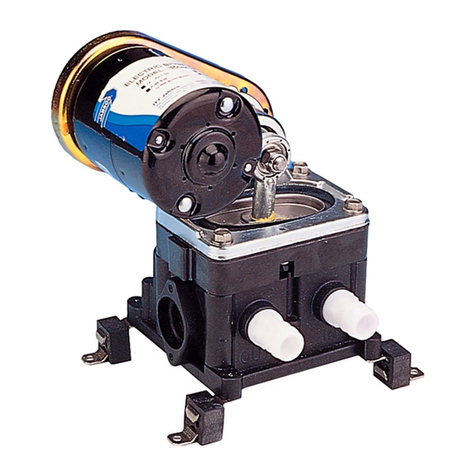

. DISASSEMBLYSTEPS

CAUTIONi PUMPS

WHICH HAVE HANDLE9 CORBO-

SIVE, CAUSTIC OR TOXIC FLUIOS SHOULD BE

DRAINED

AND COMPLETELYFLUSHEDPRIORTOSER.

VICING, FAILURE TO DO SO MAY CAUSEINJURY.

TOREPLACE

IMPELLER

a Hemovewinsnutsandend

cover.

a Graspimpellerhub with water pump pliers

andwithdraw

impellerfrom body-Checksealand

internal

parts

for wear.

Feplace

worn parts

if necessary.

E Coatbody boreandendof impetlerextendedinsert

with a

lightfilm of water

pumpgrease.

Align

detent

in impeller

extended insen with keyway in shaft. Depressrhe two

impeller

bladeswhichfit underthecam,

andcarefully

push

the impellerinto the body bore. Use

a screwdriver

in the

drainslot6rea

to posh

theneopreneslingerup onto theend

of the extendedinsert.Rotate

the impellerin a clockwise

direction to assurethe impellerbladesarein the correct

position

for easystarting.

E F€placeendcover

and

securewith wihqnuts.

TOREPLACESEALASSEMBLY

a Loolenadaptorclamp

nut and

remove

pump

headfrom

motor.Usea screwdriverto spreadtheclampslightlyto

facilitate

removal,

a Removewing nuts,end cover,top and bottom bolts.

a Unscrewr€mainingtwo boltsfrom body.Remove

body

6nd w€arplate

from adaptor,Pushimpellerfrom body

O Removesealliner

andrealbypresring

frommotofendof

a Remove

s€alfromliner.Checkall

pa(s

for

wear.Replace

I ASSEMBLY

STEPS

D tnstatl

sea liner

in boreof adaptor,aligningbolt holes

D Dlp iip sealin waterfor lubrication

andpush

intoseal

line>r'

bore with lip of sealfacing

outwards.

Wipe

a thin film of

qrease

on lip of seal.

E Installwearplateagainstliner.Alignboltholes-

fl rn" booy hasfour bolts in eachflanseface.Two of the

bolt holes

just below the pofts on the front or end cover

flange

of the body arethreaded.The flangefacewith the

four clearanceboll holes locatesagainstthe wearplale.

Push

the imp€llerinto the bodyand

rotatethe impellerin a

clockwisedirectionto alignthe bladesfor correctdirection

of rotation. l\Iakesurethe O-ringsarein rhe

grooves

irrthe

flangefaces

of the body. Place

the body on the wearplate

while carefullyinse(ing the impellerextendedinsert

O Installthe lwo boltsthroughthe adaptor

llange

andscrew

into threadedholes in front body flange.Tighten bolts

eventlyandse€urely,

E tnstatttop and bottom bolts through adaptorflangeand

body. lvake sLrreO.ring isin place

in body groove.

Install

endcover

overfour boltsandsecurewith wingnots.

nAllgn thetab in lhe slingerborewith the keyway

in the

shaft

and

push

theslinger

part

wayonto theshaft.

EAlign thedetent

in theimpeller

extendedinsertwiththe

keyway in the shaft and push the pump headonto the

moto, huo.firmly agairstthemotor.

Tight€n

thesdapror

clsmpnur juste^ough

ro prele^r

rhe pump head

f.om v

turningon themotorhub.lf too tight,motor

besringwill

seizethe shaf! and becomedamagedduring operation.

Attach short lengthsof hose

to suctionanddischarge

ports

and place both hoseends in a bucket of water before

plugging

motorin,

tocheckoperation.

www.PumpAgents.com - Click here for Pricing/Ordering