E-T-A PowerPlex CM500 User manual

Compact Module CM500

Installation and Operating Instructions

2

User Manual PowerPlex®

Issue: M_PP-M-CM500-E –Index: -

Date of publication: October 2020

Reference document: -

Editor:

E-T-A Elektrotechnische Apparate GmbH

Industriestraße 2-8

90518 Altdorf

GERMANY

Phone: +49 (0) 91 87 / 10-0

Facsimile: +49 (0) 91 87 / 10-397

Web: ww.e-t-a.com

Copyright ©2020 E-T-A GmbH

The contents of this document is the property of E-T-A GmbH. No part of this publication must in any we be

reproduced or distributed without prior written consent of E-T-A GmbH. Any person acting illegally with regard to

this publication can be prosecuted.

Limitation of liability

Although all provisions were taken when creating this document, the editor does not accept any responsibility for

errors or omissions or for damages caused by using the information contained in this document. The information

contained in this document may be revised at any time without pre-advise.

Brands

All references to software and hardware in this document are generally protected by brands or patents.

© E-T-A GmbH 2020. All rights reserved.

3

About this manual

This manual describes start-up of the PowerPlex®Compact Module (PP-M-CM500) in connection with compatible

PowerPlex®components. We assume that all PowerPlex®compatible components and devices were installed

correctly. The instruction is meant to be used by all professional electricians who want to integrate this control

panel into an E-T-A PowerPlex®system. The PowerPlex®keypads allow easy and intuitive operation and

monitoring of the PowerPlex®installations.

Besides this document further information on the E-T-A PowerPlex®can be found on E-T-A’s Website.

All manuals contain important instructions for connection and safe operation of the PowerPlex®devices. Safety

instructions have to be observed. All users have to be informed about all safety instructions. The documents have

to be accessible for the user.

4

Qualified personnel

The system must only be installed, connected and configured in connection with this document.

Installation and operation of the device/system must only be carried out by qualified personnel. With

regard to the safety instructions of this documentation, qualified persons are persons authorised to

operate devices, systems and circuits according to the standards and rules of safety engineering.

Safety instructions

Please follow the installation and configuration instructions given in this document carefully. Failure to

comply may lead to serious damages of the product or the system. E-T-A is unable to accept

responsibility for customer or third-party liability, warranty claims or damage caused by incorrect

installation or improper handling in disregard of the Installation and Operating Instructions.

5

Content

About this manual 3

Content 5

List of pictures 6

List of tables 6

Symbols 6

1. Introduction 7

2. System components: Overview 8

3. PowerPlex®system: General 11

3.1. PowerPlex®Modules 11

3.2. PowerPlex®CAN Bus 11

3.3. Put down the serial number 13

3.4. The CAN bus address 13

4. General: PowerPlex®Compact Module CM500 13

4.1. Technical data 14

4.2. Scope of delivery 15

4.3. Inputs, outputs and interfaces 15

5. Mounting 17

5.1. Installation check list 17

5.2.

Recommended installation site 17

5.3. General notes on wiring 18

5.4.

Required installation dimensions - mounting cut-out 18

5.5. Dimensions and space requirements 19

5.6. Mounting of the device 19

6. Connection to power supply 21

7. Integration of the device in the CAN bus network 21

8. PowerPlex®Configuration Software 23

8.1. Computer Requirements 23

8.2. Software installation 23

9. CAN/USB converter and driver 24

10.Important information and safety instructions 24

Notes 25

6

List of pictures

Fig. 1: Exemplary system design of a recreational vehicle ......................................................................................8

Fig. 2: Exemplary system design –Boat..................................................................................................................8

Fig. 3: Overview of PowerPlex® components..........................................................................................................9

Fig. 4: Two PowerPlex® modules connected via CAN bus cable..........................................................................12

Fig. 5: Various PowerPlex® modules connected via serial CAN bus topology......................................................12

Fig. 6: PowerPlex® Compact Module CM500........................................................................................................13

Fig. 7: Pin assignment of the PowerPlex® Compact Module.................................................................................15

Fig. 8: Dimensions of the PowerPlex® Compact Module.......................................................................................19

Fig. 9: Installation dimensions of the PowerPlex® Compact Module.....................................................................19

Fig. 10: Connection of the PowerPlex® components in the CAN bus system.......................................................21

Fig. 11: CAN/USB converter (example: Peak) .......................................................................................................24

List of tables

Table 1: Symbols used 6

Table 2: Additional accessories 10

Table 3: Different PowerPlex® Modules 11

Table 4: Selection of technical data 14

Tabel 5: Inputs, outputs and interfaces of the PowerPlex® Compact Module 16

Table 6: Installation check list 17

Table 7: General requirement of the installation site 17

Table 8: General notes on wiring 18

Table 9: Mounting of the device 20

Table 10: Pin assignment on the 2-pole connector (X1) 20

Table 11: Pin assignment on the 10-pole connector (X2) 20

Tabel 12: Pin assignment on the 22-pole connector (X3) 20

Table 13: Major properties of the CAN bus cable to be used 22

Table 14: Requirements of the configuration PC 23

Table 15: Important information 24

Symbols

The following conventions and symbols will accompany you throughout the entire manual. They are defined as

follows:

Warning

You are in a situation which might cause injury. Before working with one of the devices you have to be

aware of the risks of electrical circuitries and you ought to be familiar with standard procedures of

accident prevention.

Caution

There is a risk in this situation to do something which might cause damage of the devices or data loss.

Information

Here you receive information which might be particularly useful for the application.

Table 1: Symbols used

7

1. Introduction

You chose PowerPlex®, a comprehensive, future-oriented on-board system which combines safety, user

convenience and reliability. It is a decentralised power distribution and control system, regulating, controlling and

monitoring various loads, switches and sensors and connecting them via CAN. All PowerPlex®modules ensure

reliable control and monitoring of the electrical installations on board, either alone or in combination with other

PowerPlex®components. Besides the protection against overcurrent they allow readout of data of the connected

level sensors and temperature sensors as well as of shunts.

By means of the PowerPlex®configuration software, the application-specific logics for power distribution, power

control and power monitoring will be defined, stored or adjusted. Communication takes place via the PowerPlex®

CAN, based on SAE J1939.

Thanks to its system properties PowerPlex®is the perfect solution for smart electrical networks on boats and in

vehicles. Typical applications include:

•Buses, special vehicles, mobile homes etc.

•Watercraft, e.g. leisure boats, workboats

Benefits for the OEM

The E-T-A PowerPlex®system allows switching and controlling of various loads, timer functions, real load status

indication, overcurrent protection and wire break detection. Each function can be configured separately to meet

the requirements of the loads.

Based on the CAN communication the PowerPlex®system allows to make individual wiring between load and

control unit a thing of the past. The transmission of switch commands and status information is based on the peer-

to-peer CAN bus communication. A direct cable connection between the actuator, e.g. a light switch, and the load,

e.g. a lamp, is no longer required. The obvious advantages for the OEM include the reduced wiring and production

costs as well as a convenient system setup by means of a Windows based configuration software. All control

functions of the system are freely configurable with regard to complexity and size of the system. Change or system

extension at a later date are also extremely easy.

PowerPlex®Scope of operation –PowerPlex®takes over the following tasks:

•Distributes the DC 12 V or DC 24 V power supply to all spots of the boat where loads are installed, such

as lighting and heating control, bilge and water pumps, windscreen wiper motors etc.

•Collects all status information of all sensors and actuators everywhere in the vehicle, such temperature

and tank level measuring points, ON/OFF status signals of the actuators.

•Switches devices and equipment ON and OFF, according to selectable, pre-set scenarios, at the touch

of a button.

•Monitors devices and equipment regarding their out-of-range conditions, indicates possible failures and

responds by reversing the pertinent control unit, as e.g. switching on a pump, if the water tank level falls

below a certain limit.

•Protects devices and equipment against hazardous overcurrent and short circuit by isolating the faulty

load from the system and failure indication to the system.

•Offers back-up protection and switching in the improbable case of a PowerPlex®system or component

failures.

8

2. System components: Overview

The PowerPlex®system of E-T-A is a comprehensive on-board system combining safety, convenience and

reliability. PowerPlex®allows individual and flexible concepts of switching the illumination, acoustic and special

signals and lots more. It automatically switches loads and immediately indicates undesired conditions of the

devices or of the entire electrical installation. Thus it is ensured, that everything works precisely - which is

reassuring, as the loads often are not in plain sight. E-T-A PowerPlex®is a decentralised power distribution system

with electronic protection –clearly reflecting trends of the future.

Fig. 1 and Fig. 2 show typically PowerPlex®solutions with an application-specific number of PowerPlex®

components - modules and control units –installed at various positions.

Fig. 1: Exemplary system design of a recreational vehicle

Fig. 2: Exemplary system design –Boat

9

PowerPlex®communication is based on the CAN bus principle by means of “nodes”, which communicate with

each other via a serial 2-wire connection. Hence the key components of a PowerPlex®system are these nodes

distributed over the vehicle or boat. The overall PowerPlex®term for these interconnected nodes is “module".

Various hardware components are required for installation and start-up of a PowerPlex®system:

Please check the delivered components upon receipt about completeness. You require the following hardware

components for installation and start-up of a PowerPlex®system:

•one or more PowerPlex® modules (e.g. DC Power Module, DC Mini Module) that meet application-specific

requirements

•USB-CAN converters (cable and driver) for transferring the configuration

•USB cables for the USB service interface for transferring application-specific user interfaces onto

PowerPlex®Touch Panels.

In addition, you require a CAN bus cable for connecting the PowerPlex®components to the bus. Many

manufacturers offer standard cables for this purpose. For more information on the required cable properties please

see chapter 7 of the manual.

PowerPlex®reliably and precisely connects, regulates, controls and monitors electrical loads, switches and

sensors via CAN. It controls status indications, operating conditions and execution of commands. Perfectly

matched software and hardware components offer a comprehensive total solution with maximum potential of

individualisation.

Each module protects the loads and cable harnesses against overcurrent. In addition the modules collect data of

level sensors and temperature sensors as well as of shunts. Usually a PowerPlex®system consists of several

modules of different kinds. The selection depends on the size of the electrical system to be monitored and

controlled as well as of the current ratings of the loads.

Use our PowerPlex®Configuration Software to “programme” various control configurations. As requested, you

can store them on the computer and load them into various PowerPlex®control systems. As soon as a

PowerPlex®configuration has been completed, it will be transferred to the PowerPlex®modules (”nodes”) via the

CAN bus interface. Via this CAN bus interface you also connect the PowerPlex®software for testing, analysing

and debugging purposes of the PowerPlex®installation.

Fig. 3 shows the entire PowerPlex®product range to enable you to design your own PowerPlex®system solution:

Fig. 3: Overview of PowerPlex® components

10

More components required for setting up a PowerPlex®system are shown in .

Accessories

Description

PowerPlex®Suite

Configuration software for defining addresses, characteristics and functions of the

PowerPlex®modules, assignment of the inputs and outputs to the modules and

execution of system tests and analyses.

CAN-USB converter plus driver

CAN-USB adapter for connecting the CAN bus hardware to the USB interface of the

computer with the PowerPlex®configuration software and/or to the USB interface of

a touch panel which could be connected to the PowerPlex®.

Terminating resistors

Two 120 Ω resistors terminate the CAN bus network, one on each end of the CAN

bus.

CAN bus cable

A trunk CAN bus cable in pairs with two conductors (CAN-H and CAN-L) and the

shield (SHLD) connect two PowerPlex®modules with each other.

Power supply

12 V DC or 24 V DC battery voltage supply

Line protection

Protection of the L (+) connection from a PowerPlex®module to the battery or to the

CAN bus.

Recommendation: Thermal-magnetic E-T-A 8345 circuit breaker type.

Table 2: Additional accessories

11

3. PowerPlex®system: General

3.1.PowerPlex®Modules

PowerPlex®modules are the key components of a PowerPlex®network. According to the CAN bus terminology

they are the “nodes” of the network and form the points of switching, transmission and control.

PowerPlex®for DC system include high-end power semi-conductors with integral protective elements for switching

and protection of electrical loads. The modules are free of mechanical components and thus insusceptible to wear

and shock and vibration resistant.

E-T-A offers various PowerPlex®modules for DC 12 V and DC 24 V systems. gives an example of the difference

between two modules.

DC Modules

Compact Module

CM500

Power Module

PM500

Voltage ratings

DC 12 V/24 V

DC 12 V/24 V

max. total current

60 A per module

102 A per module

Inputs

digital

8, configurable

8

analog

4

Outputs

4 (max. 3 A, dimmable)

10 (max. 10 A, dimmable)

4 (max. 1 A, dimmable)

6 (max. 8 A, FLPC)

2 (max. 25 A, FLPC)

Degree of protection

IP22

IP22

Part number

PP-M-CM500-000-0-Z-00

PP-M-PM500-000-0-0-00

Table 3: Different PowerPlex® Modules

3.2.PowerPlex®CAN Bus

A PowerPlex® network can embrace up to 30 different PowerPlex® modules. The smallest PowerPlex®system

would consist of two modules communicating via the CAN bus cable (see Fig. 4).

The loads controlled by the modules - in this case a light and bilge pump - are normally installed at some place in

the vehicle which may not be necessarily close to the input signal. The decentralised control structure of

PowerPlex®allows monitoring and switching of the devices anywhere on the vehicle or boat from any chosen

installation site.

A level sensor monitors the bilge and supplies the analog information on module 1. From there the information is

transferred to module 2 via the CAN bus. As soon as the measured analog input value (i.e. the “pumping level”)

has exceeded a pre-set limit value , module 2 will send a switch command to the load (i.e. the “bilge pump”) so

as to switch on the pump and to reduce the water level of the bilge back to an acceptable level. The status

information of the bilge pump will be sent back to module 1 to switch on the display “bilge pump running”.

In addition, module 2 monitors the position of a light switch –ON or OFF –at one of the digital inputs and sends

the switching signal to module 1, which switches the light ON or OFF depending on the switching status.

12

Fig. 4: Two PowerPlex® modules connected via CAN bus cable

An example demonstrates the principle of using the sensor and switching signal information at the module inputs

as well as the sending, switching or the display of commands to the outputs of the same or a different module.

A typical PowerPlex®control system will of course connect a much higher number of modules and their inputs

and outputs which will be distributed over the entire vehicle. Fig. 5 shows the electrical connection of several

PowerPlex®modules in a serial CAN bus topology. Each module must be connected to the DC voltage supply

and the CAN bus.

Fig. 5: Various PowerPlex® modules connected via serial CAN bus topology

Note

The first and last Modules of the CAN bus topology must be connected with a 120 Ω terminating resistor

between the CAN high and CAN low signals. This helps avoiding interferences on the bus.

13

3.3.Put down the serial number

Each PowerPlex®component has a unique serial number. Before mounting the PowerPlex®modules, we

recommend to prepare a list. This list should include: PowerPlex®component (module type), pertinent serial

number and installation area.

You find the serial number of the PowerPlex®Compact Module on the label attached to the housing. The serial

number consists of 7 letters and numbers. It is used as an identification for new, not yet projected modules which

have the CAN bus address “0” for a start. The serial numbers are required for system set-up. By means of the

PowerPlex®configuration software the pertinent CAN bus addresses will be assigned.

Note

Please note the 7-digit serial number of each PowerPlex®component. It is required for the subsequent

system configuration with the PowerPlex®configuration software.

Later, when you start configuring the modules and when you define their roles in the CAN network, the assignment

between serial number, CAN bus address and installation area must be made.

The use of CAN bus address labels helps keeping an overview for module identification, above all in the event of

comprehensive projects.

3.4.The CAN bus address

Any PowerPlex®component within a PowerPlex®network has its own, unique CAN bus address in a range of 1

to 30 for a clear identification. Assignment of the CAN bus addresses is during the system set-up by means of the

PowerPlex®Configuration Software (cf. PowerPlex®Manual Volume 3: System set-up and configuration).

We recommend to mark the modules in the PowerPlex®system with the corresponding CAN bus addresses so

as to be able to keep track.

4. General: PowerPlex®Compact Module CM500

Growing demands regarding safety and convenience lead to the installation of more and more electrical loads in

vehicles and boats. The PowerPlex® Compact Module (Fig. 6) is a multifunctional module that perfectly

complements the PowerPlex® product range. Like all the other PowerPlex®components it meets the special

requirements of marine and recreational vehicles applications.

It offers eight multifunctional inputs, which can be used for measuring current, voltage, temperature and/or liquid

levels, as well as 14 load outputs.

Fig. 6: PowerPlex® Compact Module CM500

14

4.1.Technical data

The technical information of the PowerPlex®Compact Module are summarised in Table 4.

Technical Data

Rated voltage

DC 12 V/24 V

Operating voltage

9 ... 32 V DC

Current consumption

typically 63 mA at 12 V

typically 44 mA at 24 V

Max. total current

60 A per module

Degree of protection

IP22 when mounted vertically with terminals pointing downwards

Operating temperature range

-30 … +70°C (-22 … 158 °F)

with derating above +50 °C (+122 °F)

Storage temperature range

-30 … +85°C (-22 … 185 °F)

mass

approx. 410 g

Interfaces:

CAN I*

PowerPlex® CAN, 250 kbit/s, galvanically isolated

CAN II*

CAN II galvanically isolated, protocol upon request

*) The CAN-terminals at each end of a CAN bus require a termination by a 120 Ω resistor.

LIN

LIN bus interface (CI-BUS) upon request

Inputs:

8 multifunctional inputs, configurable as

I1

I2

I3

I4

I5

I6

I7

I8

digital input:

0 … 8 kΩ: ON; > 10 kΩ OFF;

plus or minus switching

⚫

⚫

⚫

⚫

⚫

⚫

⚫

⚫

analog inputs:

a)

voltage monitoring:

0 … 32 V, Rin: 60 kΩ;

resolution: 10 Bit

⚫

⚫

⚫

⚫

⚫

⚫

⚫

⚫

b)

battery monitoring:

± 60 mV; battery current

measurement with external shunt

(I3 & I4)

+

-

c)

resistance measurement:

0 ... 750 Ω; for tank levels and

temperature

⚫

⚫

⚫

⚫

⚫

⚫

⚫

⚫

d)

frequency measurement:

0 … 10 kHz (I1 & I2)

⚫

⚫

Outputs

10 outputs with 10 A max. continuous current

load output

Power MOSFET, high side switching (HSS)

max. current rating

10 A, adjustable in 1 A steps

typical voltage drop UON at

rated current (25 °C):

60 mV

tripping range at overload

1.01 … 1.30 x IN

motor function:

Switching of 2 H-bridges possible

(X2: O1 & O2, X2: O6 & O7)

high current function

20 A outputs via parallel connection of two load outputs (X2: O1 … O10)

dimming function:

all outputs are high-frequency dimmable, frequency adjustable

4 outputs with 3 A max. continuous current

load output

Power MOSFET, high side switching (HSS)

max. current rating

3 A, adjustable in 1 A steps

typical voltage drop UON at

rated current (25 °C):

75 mV

tripping range at overload

1.01 … 1.30 x IN

dimmer function:

all outputs are high-frequency dimmable, frequency adjustable

Approvals

approval authority: KBA

Standard: ECE regulation No 10 (E1)

Rated voltage: DC 12/24 V

Part number

PP-M-CM500-000-0-Z-00

Table 4: Selection of technical data

*) For further information please see the relevant data sheet.

15

4.2.Scope of delivery

Standard scope of delivery of the PowerPlex®Compact Module is without accessories.

For completion we recommend the following accessories:

•USB/CAN Converter:

XPP-USBC0

XPP-USBC1 (opto-decoupled)

•Connection package:

XPP-CP-130

(contains a 2-, 10- and 22-pole connector, 10 x crimp contacts 14-16 AWG and

22 x crimp contacts 16 AWG))

•Temperature sensor

XPP-TS500R-HB

(-30 … +100 °C (-22 … +212 °F))

XPP-TS500R-PH

(-30 … +100 °C (-22 … +212 °F))

4.3.Inputs, outputs and interfaces

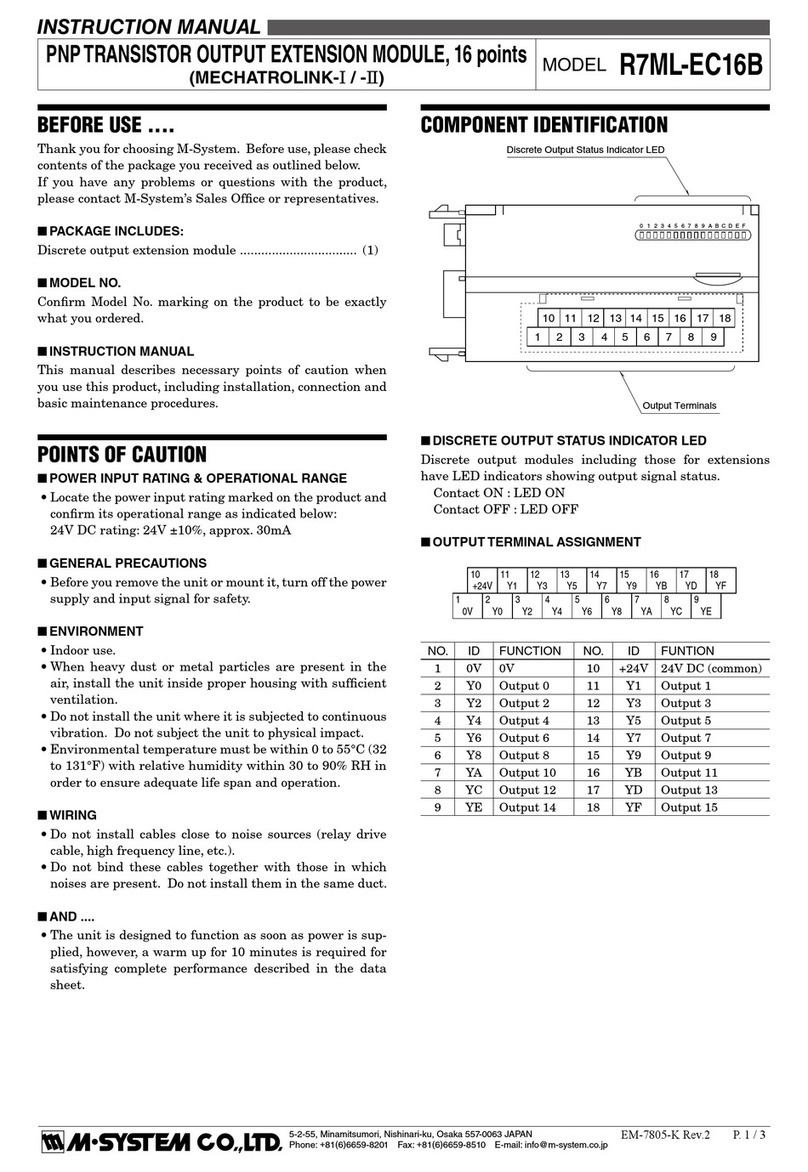

Fig. 7 shows an overview of the terminals and interfaces of the PowerPlex®Compact Module.

Fig. 7: Pin assignment of the PowerPlex® Compact Module

Explanation:

•Inputs (X3: I1 - I8) are multifunctional inputs which can be configured as a digital or analogue input.

•GNDIare ground terminals only for the multifunctional inputs (X3: I1 - I8). The outputs must be connected

to external ground GNDO.

•Outputs are dimmable outputs

owith max. 10 A continuous current, (X2:O1 - O10)

owith max. 3 A continuous current, (X3: O1 - O4)

•Outputs (X2: O1 & O2; O6 & O7) can be used for switching H-bridges (motor function).

•Ubatt+ and Ubatt- are for the connection of the power supply

•CAN-H, CAN-L, SHLD are the interfaces to the CAN buses (CAN I: PowerPlex® CAN; CAN II: other CAN

bus)

16

Input/ output/

interface

what is connected

connection

cable connection

protection & status

indication/comments

X1: 2-pole connection

voltage supply

DC 12 V/24 V

(DC 9 V … 32 V)

UBatt +

Ubatt ‒

BUZ 10.16IT/02/*

battery connection

X2: 10-pole connection

power output

10 A

loads

with max. 10 A

O1 - O8

crimp connector, 16

AWG

short-circuit and over-current

protection: Current limitation and

electronic safety shutdown; motor

function: two H-bridges (O1&O2,

O6&O7); high current function: 20

A outputs via parallel connection of

two load outputs; dimming function

with adjustable frequency

X3: 22-pole connection

PowerPlex® CAN

CAN bus cable

6-pole Molex

connector

crimp connector, 16

AWG

based on SAE J1939, galvanically

isolated

CAN II

CAN bus cable

input: digital

switch, momentary switch,

...

I1 - I8

crimp connector, 16

AWG

control inputs, switching to ground

input: analogue

battery, charger, sensor, ...

I1 - I8

crimp connector, 16

AWG

voltage measurement

external shunt

I3(+) & I4(-)

crimp connector, 16

AWG

battery current measurement

± 60 mV,

note: when monitoring the battery,

it must be ensured that

PLUS/MINUS are correctly

connected.

tank sensor

I1 - I8

crimp connector, 16

AWG

monitoring of tank levels

temperature sensor:

I1 - I8

crimp connector, 16

AWG

temperature monitoring

ground for

multifunctional

inputs

GNDI

GNDI

crimp connector, 16

AWG

caution: ground of load outputs

GNDOmust be connected

externally!

power output

3 A

loads

with max. 3 A

O1 - O4

crimp connector, 16

AWG

short-circuit and over-current

protection: Current limitation and

electronic safety shutdown;

dimming function with adjustable

frequency

LIN interface

LIN

LIN

crimp connector, 16

AWG

interface (CI-Bus)

Tabel 5: Inputs, outputs and interfaces of the PowerPlex® Compact Module

Caution

To avoid inadvertent short circuits, please ensure that the module is disconnected from the power

supply before you establish connections.

The ground connections GNDIon the module are only for the multifunctional inputs (X3: I1 - I8). The

ground connection GNDOfor an output (X2: O1 - O10; X3: O1 - O4) must be installed externally.

Please observe correct polarity for connection and wiring of the device.

17

5. Mounting

The PowerPlex®Compact Module has been designed for stationary installation. This PowerPlex®module is used

for loads up to 10 A. We recommend to install the modules in close proximity to the loads to be controlled.

5.1.Installation check list

When planning and installing the PowerPlex®system please observe the limited number of system components.

Our recommendation is some 30 PowerPlex®modules per system. Maximum values depend on the configuration

scope so that more modules per system could be possible. Mounting covers the following installation steps listed

in Table 6:

Step

Action

1

Application-specific system planning

2

Determine the installation site and prepare all necessary devices and tools

3

Put down the serial number

4

Run the cables

5

Prepare the necessary cut-outs for cables and device in the mounting plate

6

Connect the device for start-up

7

Mount and connect all remaining PowerPlex®components if not done before

8

Start the system by switching on

9

Check the system behaviour by a complete system test

Table 6: Installation check list

5.2.

Recommended installation site

All PowerPlex® components can be installed in any location. The PowerPlex® HMI devices should be installed in

an area which offers maximum benefit for the user. The PowerPlex®modules on the other hand should be installed

close to the connected loads to reduce wiring efforts.

Important

•Leave enough space for heat dissipation.

•Please make sure to install the PowerPlex®modules in enclosed rooms.

•Please observe the mounting version so as to reach the required degree of protection.

General requirements of installation site

When choosing the mounting site, various factors that might influence the performance of the device have to be

considered. Table 7 gives you an overview of the major factors.

Ventilation

Please ensure sufficient ventilation by leaving enough space at all sides of the device and ensure that

the vent holes are not blocked. Leave enough space between the devices.

Installation area

Ensure a tight installation on the mounting area. Please consider the vehicle-specific properties and

do not mount components in places where might affect the safety features of the vehicle. In addition,

make sure that the mounting surface is flat and even and not too rough so as to ensure the requested

protection degree.

Cable bushing

Ensure installation at a site where the cables can be laid and connected properly.

Electrical noise pulses

The installation site should provide sufficient distance to any devices that might emit noise pulses.

Table 7: General requirement of the installation site

18

5.3. General notes on wiring

The selection of the correct cable types is important for the reliable power distribution, control and monitoring by

means of a PowerPlex®system. Please ensure to use cables of superior quality with the suitable cross sections

to avoid voltage drops. Please also so the separate chapter 7 concerning the integration of the device into the

CAN bus network.

The cables should be laid very carefully to achieve the maximum performance of the PowerPlex®installation.

Table 8 gives general hints which must be observed regarding wiring of a PowerPlex®system and the connected

loads.

Item

Note

1

The cables should not be kinked or bent sharply. Please provide sufficient bending radii.

2

Cables must be protected against damages and heat. Avoid the proximity to moveable or hot parts and

to machines.

3

Cables should be secured by means of brackets or cable clips. Excessive cable lengths should be

disposed of appropriately.

4

Depending on the site of the cables, waterproof bushings might be useful.

5

Ensure a suitable strain relief.

6

Check cables about intact insulation, above all after cable laying.

Table 8: General notes on wiring

If AC and DC current is used for installation, an adequate insulation must be ensured.

Note

Please do not forget the 120 Ω terminating resistor when the PowerPlex®Compact Module is

connected as first and/or last participant on the CAN bus.

5.4.

Required installation dimensions - mounting cut-out

The PowerPlex®Compact Module are meant for front panel mounting. The modules are screwed onto the

mounting plate from the front, e.g. in the side trim panel. The required dimensions are shown in Fig. 8.

19

Fig. 8: Dimensions of the PowerPlex® Compact Module

All cables are connected to the module from below. This has to be considered in the planning stage and ensures

ease of mounting, preventing a possible kinking of the cables.

5.5. Dimensions and space requirements

According to EMC conditions there must always be sufficient space between the different electrical devices. Space

requirement of a device depends on its dimensions shown in Fig. 9.

Delivery of a standard PowerPlex®Compact Module does not include any mating plugs. They can be ordered

separately as accessories XPP-CP-130:

Information

The protection degree IP22 is achieved when the PowerPlex®Compact Module is installed vertically

with the terminals pointing downwards.

Fig. 9: Installation dimensions of the PowerPlex® Compact Module

5.6. Mounting of the device

Before you start installation, please make sure that

•the installation site was selected under consideration of the product-specific requirements

•the cable connections were identified correctly and cable laying was thoroughly planned

•the power supply was disconnected and protected against inadvertent reset

20

Step

Action

1

Mark the intended installation site following the installation dimensions

2

Drill the mounting holes into the wall with an adequate tool.

5

Depending on the accessibility of the cable connections we recommend to connect all cables (current,

CAN etc.) before mounting the device.

Important: A cable connection must only be established if the main switch is OFF. Check the cables

with regard to correct polarity and ensure that the max. permissible operating voltage is not exceeded.

Please do not forget the terminating resistor if the device is the first or last participant on the CAN bus.

Table 9: Mounting of the device

Pin assignment

The pins of the PowerPlex®Compact Module are on the bottom side. The pin assignment is shown in Table 10.

Please note that the mating connectors are not included in the delivery scope as standard.

2-pole connection (X1)

interface

assignment

pin

voltage supply

(DC 12V/24V; DC 9 … 32V)

UBatt +

1.1

UBatt -

1.2

Table 10: Pin assignment on the 2-pole connector (X1)

10-pole connection (X2)

interface

assignment

pin

10 A outputs, dimmable

(motor function [H1/H2]: O1 & O2, O6 & O7; high current function: 20

A via parallel connection; GNDOmust be connected externally.)

O1 (H1)

2.1

O2 (H1)

2.2

O3

2.3

O4

2.4

O5

2.5

O6 (H2)

2.6

O7 (H2)

2.7

O8

2.8

O9

2.9

O10

2.10

Table 11: Pin assignment on the 10-pole connector (X2)

22-pole connection (X3)

interface

assignment

pin

CAN I: PowerPlex® CAN, galvanically isolated

CAN-H

3.1

CAN-L

3.2

SHLD

3.3

CAN II: galvanically isolated

CAN-H

3.12

CAN-L

3.13

SHLD

3.14

10 A outputs, dimmable

(note: parallel connection possible; GNDOmust be connected

externally.)

O1

3.4

O2

3.5

O3

3.15

O4

3.16

multifunctional inputs

(note: when monitoring the battery, it must be ensured that PLUS/

MINUS are correctly connected.)

I1

3.6

I2

3.7

I3

3.8

I4

3.9

I5

3.17

I6

3.18

I7

3.19

I8

3.20

GND for multifunctional inputs

(note: only use GNDIfor multifunctional inputs (X3: I1 –I8), not for

GNDOof the load outputs (X2: O1 –O10; X3: O1 –O4)

GND I

3.10

GND I

3.21

LIN bus interface

LIN

3.22

GNDLIN

3.11

Tabel 12: Pin assignment on the 22-pole connector (X3)

This manual suits for next models

1

Table of contents

Other E-T-A Control Unit manuals

Popular Control Unit manuals by other brands

Tanda

Tanda TX7211 Installation and operation manual

EOS

EOS ECON D4 Assembly and operation instruction

STATUS SCIENTIFIC CONTROLS

STATUS SCIENTIFIC CONTROLS MCU3 Installation and Hardware Configuration Manual

Allen-Bradley

Allen-Bradley POINT I/O 1734-VHSC5 user manual

Eneo

Eneo VHM/H24W Mounting instructions

hager

hager h3 h400 User instructions

Sentiotec

Sentiotec Pro B3 Instructions for installation and use

ST

ST ACEPACK DMT-32 Mounting instruction

TechNexion

TechNexion FLEX-IMX8M-Mini product manual

KYL

KYL KYL-300I quick start guide

HVAC Controls

HVAC Controls iO-ESP-400 Installation & operation instructions

Siemens

Siemens HOTEL SOLUTION HTC3.2 Series quick start guide