E.T. Systems Drive 300 User manual

ET DRIVE300 INSTALLER 2016.001.001

Installer Instrucons

Low trac 300kg Slide Gate Operator

www.et.co.za

300

2

Introducon.

Page 3 Be Safe! Instrucons, warnings and obligaons.

Page 4 Technical specicaons.

Page 5 Component idencaon and operator dimensions.

Site preparaon.

Page 6 Gate preparaon and mechanical requirements.

Page 7 Duty cycle.

Page 7 Motor posioning.

Page 8 Cabling requirements.

Hardware installaon - Mechanical.

Page 9 Baseplate kit and installing the baseplate.

Page 10 Cable conduit height above baseplate.

Page 10 How to use the manual release override.

Page 11 Mounng the motor onto the baseplate.

Page 12 Installing the rack.

Hardware installaon - Electrical.

Page 14 Terminang the AC supply.

Page 15 Wiring and terminaon of the control card.

Page 16 Installing the limit actuator.

Control card programming and setup.

Page 17 Using the control card display and dashboard.

Page 18 Programming menu quick reference guide.

Page 19 Seng up the gate runme.

Page 20 Selecng a safety level.

Page 20 Safety infra-red beams setup.

Page 21 Selecng a BT operang mode and adjusng the BT auto-close me.

Page 22 Seng up the pedestrian open distance and pedestrian auto-close me.

Page 23 Receiver programming and setup.

Page 29 Switching the AC monitoring and/or built-in charger on or o.

Page 30 Adjusng the length of the slow speed at the ends of travel.

Page 30 Switching the posive close mode on or o.

Page 31 Selecng the Auxiliary relay’s mode of operaon.

Operang mode denions and examples.

Page 32 Collision sensing and safety overload rounes

Page 33 Safety infra-red beams funcon. All modes except P.I.R.A.C. auto-close mode.

Page 34 “BT” Buon triggers - Standard mode.

Page 35 “BT” Buon triggers - Simple auto-close mode.

Page 36 “BT” Buon triggers - Condominium auto-close mode.

Page 37 “BT” Buon triggers - P.I.R.A.C. auto-close mode.

Page 38 “PED” Pedestrian trigger. With no safety beams installed.

Page 39 “PED” Pedestrian trigger. With safety beams installed.

Page 40 Auxiliary relay modes - Strike lock mode.

Page 41 Auxiliary relay modes - Magnec lock mode.

Page 42 Auxiliary relay modes - Receiver relay mode.

Page 43 Auxiliary relay modes - Courtesy light mode.

Page 44 Auxiliary relay modes - Alarm mode.

Page 45 Posive close mode.

Page 46 Holiday lock-out mode.

Page 47 Auto-close override/party mode.

Troubleshoong.

Page 48 Status LED, buzzer and diagnoscs menu denions.

Page 49 Troubleshoong guide and display denions.

Page 50 Warranty.

3

Be Safe!

WARNING!! These are the general safety obligaons for the installers and users of ET Systems

automaon equipment. A copy of this document also appears in the user instrucons. Those

instrucons must be issued to the responsible end user during the handover and instrucon

meeng.

1. Only suitably qualied persons, may install, repair or service the product. Unless expressly indicated in the user instrucons, no

user serviceable components can be found inside any ET Systems automaon product.

2. It is important for personal safety to study and follow all the instrucons carefully. Incorrect installaon or misuse may cause

serious personal harm.

3. Keep the instrucons in a safe place for future reference.

4. This product was designed and manufactured, strictly for the use indicated in the accompanying documentaon. Any other use

not expressly indicated in the documentaon, may damage the product and/or be a source of danger. ET Systems cannot accept

responsibility for improper use or incorrect installaon of this product.

5. ET Systems cannot accept responsibility if the principles of good workmanship are disregarded by the installer.

6. ET Systems cannot accept responsibility regarding safety and correct operaon of the automaon, if other manufacturers’

equipment is added to this product.

7. Do not make any modicaons or alteraons to this product. Do not substute any component of this product with any other

component not expressly designed into this product.

8. Anything other than expressly provided for in the accompanying instrucons is not permied.

Prior to installaon:

1. All unnecessary ropes, chains and fasteners must be removed and all unnecessary latches or locks must be disabled from locking.

2. The gate or door must be balanced correctly where it, neither opens nor closes from any posion under its own load. When

operated by hand the gate or door should be free of hindrance and easily moved (In the case of a garage door if the balancing

springs need to be adjusted the adjustment should only be carried out by a qualied and experienced person).

3. The construcon of the gate or door must be sound and automatable. It is the responsibility of the installer to ensure that the

mechanical components of the gate or door system are sucient to withstand the necessary forces in cases of overload.

4. It is the responsibility of the installer to ensure the gate or door is suciently trapped within its range of travel by means of

mechanical ends of travel stoppers.

5. Ensure all xed mounng points, such as the wall above the door in a garage door system or the posts in a swing gate system, are

sound and strong enough to allow proper xing of the operator.

6. It is the responsibility of the installer to ensure the installed posion selected for this product, falls within the limitaons of the

products ingress protecon rang.

7. Ensure the area of installaon is not subject to explosive hazards. There should be no volale gasses or fumes as these can present

a serious safety hazard.

8. All ET Systems garage door operators are supplied with a sealed 15A safety plug on lead for use in an electrical code of pracce

approved plug point. Do not extend, modify or replace the plug lead unless duly qualied as an electrician. Before installing the

unit, ensure the mains supply is switched o.

9. ET Systems gate operators are supplied with a terminal connecon for the electrical supply beneath the screwed down cover of

the operator. In the case of a model requiring 220Vac supply at the operator, an all pole negavely biased switch, with a contact

opening of greater than 3mm must be installed within 1,5m of the operator. This switch must be clear of all workings of the system

and must be in a posion secure from public access. This switch and its connecons must be inspected and passed by a cered

electrician prior to using it.

10. It is the responsibility of the installer to ascertain that the designated persons (including children) intended to use the system,

do not suer reduced physical sensory or mental capabilies, or lack of experience and knowledge, unless they have been given

supervision or instrucon concerning the use of the system by a person responsible for their safety.

11. The drive may not be installed on a door incorporang a wicket door, unless the drive is disabled by the release of the wicket door.

(Wicket door :- A pedestrian door within the main gate or door)

1. Ensure the working area is clear of obstrucons and obstacles.

2. Install the safety warning scker within clear view of where the gate or door will be operated from. Typically this would be

adjacent to any xed trigger switches or on the gate or door itself.

3. The emergency manual release must be installed where it is no higher than 1,8m from the oor level. This would apply to the cord

in a garage installaon or the lockable lever in a gate installaon.

4. Any addional xed door control switches such as wall consoles or keypads, if installed, must be at a height of at least 1,5m, within

clear sight of the gate or door and away from any moving components of the system.

During installaon:

Connued overleaf.......

4

5. It is highly recommended that a set of safety infra-red beams be used in conjuncon with this product. The safety beams must be

installed in such a way that the product is prevented from running when anything is in the path of the door or gate.

6. Over and above the recommendaon to use safety infra-red beams with this product it is mandatory to install and use a safety

beam set when using the automac closing feature. It is recommended that a warning light be ed to any automaon system.

7. The emergency manual release instrucon label must be installed on or adjacent to the emergency manual release mechanism.

Aer installaon - It is the responsibility of the installer to ensure the users:

1. Is procient in the use of the manual emergency release mechanism.

2. Is issued with the documentaon accompanying this product.

3. Understands that the gate or door may not be operated out of clear sight.

4. Ensures that children are kept clear of the gate or door area at all mes, and that children do not play with the remote transmiers

or any xed trigger switches linked to the system.

5. Is instructed not to aempt to repair or adjust the automaon system and to be aware of the danger of connuing to use the

automaon system in an unsafe condion before a service provider aends to it.

6. Is procient in tesng the unit’s safety obstrucon sensing system.

7. Is aware of what to check for with regards to wear and tear that may need to be aended to from me to me by the service

provider.

8. Is aware that a fagued baery may not be disposed of in the general refuse and must be handed in at a baery merchant for safe

disposal. Before removing the baery from the system the household mains must be disconnected. In the case of the motor unit

being removed and scrapped, the baery must be removed rst.

Technical specicaons.

Rated gate mass. 300kg

Maximum gate leaf length. 25m

Primary power supply to gate. 220 – 240Vac @ 50Hz – 60Hz

(A low voltage plug-in transformer can be purchased and installed if required)

Peak power consumpon at gate 18W

Electrical class. Class 1

Motor voltage. 24Vdc

Motor current liming. 5A Starng / 3,5A Running

Rated duty cycle. 25% with 220Vac present (See determining your duty cycle on page 7)

Number of operaons on baery reserve

within 24 hours of power failure. 100 (Gate load and baery health dependent. Based on a gate opening of 4m)

Gate speed. 25m/min (Gate load and baery health dependent)

Rated Load. 300N Starng / 240N Running

Operang temperature range. -10 to 50° C (14F to 122F)

An-crushing safety sensing. Yes – Electronic gate proling

Auxiliary supply output. 12Vdc @ 400mA

Built in baery charger. Mulple stage auto-calibrang (350mA peak)

Receiver format. ET BLU MIX ® Backward compable with ET BLUE (Rolling code)

Receiver frequency. 433.92MHz

Receiver channels. 4CH (BT, PED, Aux relay, Holiday lock-out)

Receiver memory capacity. 32 users

All users can be allowed control of all channels. Yes

Ingress protecon. IPX4

5

1

2

3

4

5

6

77

8

9

10

12

11

13

14

15

16

17

18

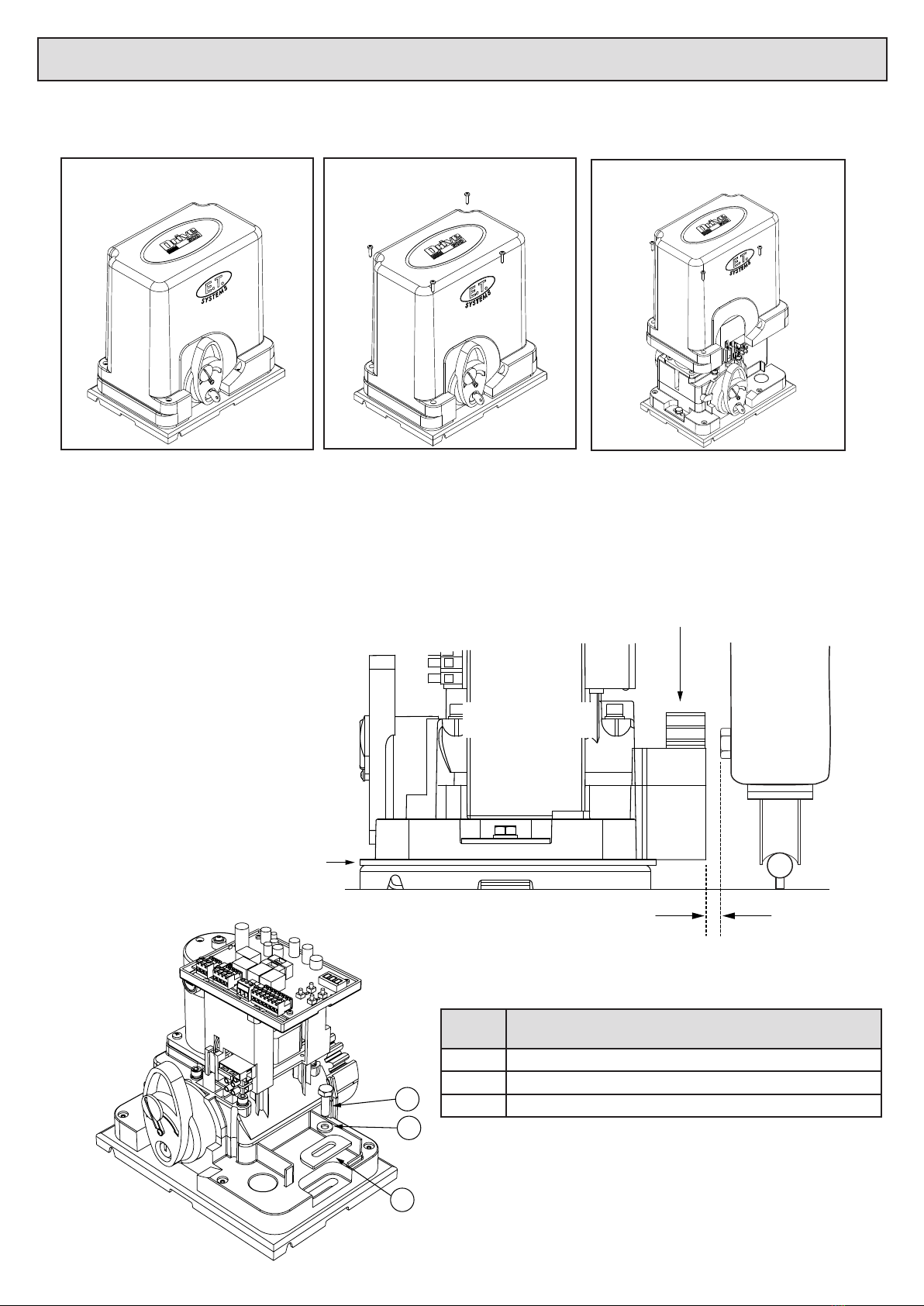

Component idencaon and descripons.

Diagram

number Descripon Diagram

number Descripon

1Control card 10 Baseplate

2Dashboard 11 220V connector

3Plug-in terminal connectors 12 Manual release

4Manual release monitoring reed switch 13 Manual release lock

5Baery 14 Electric motor

6Transformer housing 15 Electric motor brush ports

7Mounng bolts 16 Revoluon counter ring magnet

8Gearbox 17 Ends of travel limits, reed switch

9Cable inlets 18 Output drive pinion

260213

15

91

258

Operator dimensions.

6

BEFORE ATTEMPTING TO INSTALL A SLIDE GATE OPERATOR, PLEASE BE CERTAIN YOU HAVE READ AND

UNDERSTOOD THE FOLLOWING TO ENSURE CONTINUED SATISFACTORY SAFE SERVICE FROM THIS PRODUCT:

The following are points to note before installing your new slide gate operator:

1. Gate mechanics.

2. Duty cycle.

3. Where to posion the gate motor with regards to ingress protecon.

4. Cabling requirements.

Gate mechanics.

Gate Leaf:

Gate leaf must be sound and of sucient construcon to accommodate an operator of this type (see technical specicaons).

Gate leaf should be straight and true with minimal deviaon to the fascia that the rack must aach to (no ‘banana-eect’).

Wheels and track:

The track must be secure, straight, level and free of all obstrucons.

Recommended wheel type and size for this automaon is steel or steel alloy, machined or cast wheels of at least 100mm diameter using sealed roller

bearings. The larger the wheel the less rolling resistance generated. Larger wheels also maintain their plumb and momentum longer. When wheels

are xed in the gate, and not able to pivot, binding can occur if the gate is bowed. (Banana eect) For wheel prole and matching track types, see the

three examples below:

Recommended Less problemac Problemac

Guides:

• It is recommended that a roller guide consisng of a sealed roller bearing clad in nylon be used.

• The guidance system should be installed at the top edge of the gate whenever possible. In cases where this is not possible the guidance system

should never be below the halfway point of the total gate height when the gate is in posion on its track.

• In the case of a single guide roller running in a guide channel, ensure the guide never touches both inside walls of the channel simultaneously. This

causes the roller to snag as it tries to roll in both direcons at once.

• In the case of 2 guide rollers being used on either side of the gate leaf, ensure that both wheels never touch the leaf simultaneously.

• Avoid using more than 1 guide roller on the same side of the gate leaf to prevent binding.

• As with the wheels the larger the guide the less rolling resistance generated.

Gate Travel:

Using a sherman’s pull scale, as shown below, pull the gate fully open and fully closed at approximately the same speed as the operator you intend to

use (see technical specicaons). For opmum performance, ensure that the maximum resistance does not exceed 30kgF starng and 24kgF running.

The starng resistance should fall away within 300 to 500mm. Note the recommended track, wheel and guide types menoned b) and c) above.

NB! Install physical stoppers at the ends of the gate travel to prevent the gate over-running the ends of the track as shown here. (Naonal safety

standard requirement)

End of travel stopper!

End of travel stopper!

Gate preparaon and mechanical requirements.

7

Duty Cycle.

The Formula used to determine duty cycle is:

Run me x 100 = Duty cycle

Run me + rest me

Working example 1: (Low duty cycle)

Run me: 12 seconds.

Rest me: 36 seconds.

12 ÷ 48 x 100 = 25

Thus the duty cycle in example 1 is said to be 25%

Working example 2: (High duty cycle)

Run me: 12 seconds.

Rest me: 1 second.

12 ÷ 13 x 100 = 92.3

Thus the duty cycle in example 2 is said to be 92.3%

The above examples do not factor in resistance and gate mass. These two elements contribute greatly to the amount of heat generated in your gate

automaon system.

Below are the maximum allowed duty cycles based on the gate mass and rolling resistance for the ET motor models. These are calculated to conform

to the standards set out in the SANS 60335-95-1:2011 safety code.

Duty cycle capabilies guideline of the ET Drive series motor models:

Model Gate Mass Starng resistance Rolling resistance Max Duty Cycle

Drive 300 ≤ 300kg ≤ 30kgf ≤ 24 kgf 25%

Where to posion the gate motor.

Liquid ingress:

The ET Drive series motor models all carry an ingress protecon rang of IPX4. This means they are protected from splashing water. They are not

water ght as there are sensive electronic and electrical circuits that require uninhibited airow to remain cool and dry.

When deciding on an installaon posion, be aware of water collecon points around and near the desired mounng posion of the motor unit. If

the water does not ow away quickly enough, it can seep into the system and cause expensive and possibly hazardous damage. Always install the unit

higher than the highest level that any water owing past the motor unit can reach.

Physical protecon:

Whenever possible, always install the gate motor on the opposite side of the gate’s guide/emergency post, to the driveway itself. This way it is out of

the path of the motor vehicles as they pass through the entrance/exit.

8

Cabling requirements.

• Before mounng the operator ensure your cables and conduing are in place to prevent any inconvenience at a later stage.

• All household mains cabling and circuits need to be installed by a qualied electrician and signed o by a registered electrician.

• Allow for spare cabling in case of faulty cable & breakages (especially important when using low specicaon cable).

• As automaon systems vibrate when in use, it is highly recommended that only mul-stranded, exible cables be used.

• If installing an intercom, remember to allow for sucient cable cores for all the users of the system as per manufacturers cabling requirements.

• The Drive 300 motor is designed to facilitate 1 x 20mm conduit going directly into its housing from below. If more cabling needs to be routed to the

motor, we suggest that a weatherproof electrical box be installed as a distribuon box. All of the circuits can then be extended to the distribuon

box and terminated there.

1

29V

3

Alarm

panel

2

11 4

10

8

9

1

6

5

7

1. Courtesy lights twin + earth 1.0mm back to motor housing and

isolator switch.

7. Free exit loop 1.5mm silicone insulated single core exible stranded

cable back to loop detector that is typically installed in the motor

housing.

2. Intercom gate staon (check with intercom supplier for cable

specicaons)

8. From intercom internal equipment (check with intercom supplier

for specicaons) + 5 cores 0,5mm stranded for status LED, BT and

Pedestrian triggers.

3. (220Vac) - twin + earth: 2,5mm stranded (An all pole negavely

biased isolator must be installed within 1,5m of the motor unit, in

circuit with the 220Vac supply)

9. Alarm monitoring circuit. 2 cores 0,5mm stranded back to motor

housing.

4. Safety infra-red beam RX power & switch. 4 cores 0,5mm stranded

back to motor housing.

10. Oponal plug in transformer for low trac sites (29Vac) - twin +

earth. Min 0,5mm stranded (1Amp)

5. Safety infra-red beam TX power. 2 cores 0,5mm stranded back to

motor housing.

11. Lock power supply. Twin + earth 2,5mm stranded from isolator

switch.

6. Electric lock power. 2 cores 0,5mm stranded back to independent

lock power supply via motor housing.

9

Baseplate and fastener kit assembly.

1

1

1

1

2

5

1

1

3

3

4

3

2

2

Diagram

number Descripon

1M10 Machine nuts.

2M10 Flat washers.

3M10 J-Bolts for concrete casng method.

4Cabling conduit piping.

5Baseplate.

Installing the baseplate.

There are a number of dierent fastening techniques that can be used to fasten the baseplate in posion. The standard kit is supplied with J-bolts

so that the baseplate can be cast in concrete. While this method oers a nice solid base it takes more than 48hrs to install as the concrete must cure

properly before connuing with the installaon. Whichever mounng method you opt for, the posion of the base plate will always remain the same.

Below are the dimensions to use when posioning the baseplate. The baseplate should be installed above the highest point of ooding that may occur

with the run o of water down the driveway.

PLAN VIEW OF THE BASEPLATE INSTALLED

Proudest component of

the gate on the motor side

Edge of the baseplate

nearest to the gate

Required space

30 - 50mm

Gate positioned where the proudest component

is opposite the base plate of the operator.

Base plate positioned on the opposite

side of the gate guide/emergency post,

to the driveway.

Gate guide/

emergency post

Driveway

Required space

> 50mm to allow for

the optional security

bracket.

Cable inlet.

10

Cabling conduits height:

Trim the conduits o where the ends are level

with the top of the baseplate. If any part of the

conduits protrude above the top of the basepate,

it will be dicult to adjust the position of the gearbox

on top of the baseplate.

How to use the manual release.

Move gate open and closed by hand.

1. Unlock the manual release lever lock using the key supplied. 2. Swing the manual release lever upright to disengage the

gearbox.

To re-engage the gearbox lower the manual release lever and lock it once again. Gently pull or push the gate by hand unl the gears fall into

place before triggering the unit to run.

Referencing the closed posion

On the rst trigger subsequent to the gearbox being engaged aer a manual release, the gate will close at half speed. The system is looking for the

closed posion which is the origin point. This is known as referencing the closed posion. If any of the trigger inputs are acvated or the safety

overload sensing is acvated while the gate is busy “referencing” then the gate will simply stop. The next trigger will cause the unit to connue

“referencing”. While referencing the closed posion the display will show ref. Referencing the closed posion will also occur on the rst trigger

aer exing programming or powering up a previously programmed control card.

11

Mounng the operator onto the baseplate.

Removing the cover:

The cover is secured in place by means of four screws. One of which is secured beneath the manual override lever.

Using a Philips ® screwdriver remove the

four cover screws.

Unlock and li the manual override. Li the main cover to remove it.

Mounng the gearbox: (You will need a 13mm socket or spanner)

The gearbox is fastened onto the baseplate by means of the 2 x 25mm x M8 machine bolts and custom mounng plates. The gearbox distance from

the gate can be adjusted backwards and forwards by up to 30mm. Remember to ensure that there is enough space allowed between the fascia of the

pinion and the proudest part of the gate that passes the pinion. This is to prevent any part of the gate snagging on the pinion as the gate runs.

At this stage of the installaon it is recomended that you place 2 x 2mm thick at bars in between the baseplate and motor to facilitate the correct

rack height later. See page 12 and 13 overleaf.

2mm at bar spacer

8 to 10mm tolerance

Pinion

Side view

1

2

3

Diagram

number Descripon

1M8 Machine bolt.

2M8 Flat washer.

3Mounng plate.

12

Installing the rack.

Correct Too loose Too tight

Rack to pinion spacing.

Correct.

The driving surfaces of each tooth are 1 to 2mm

apart. Allowing for slight variance in the height

of the rack when the wheels shrink in colder

condions or where the gate exes and the rack

is no longer square to the pinion.

Incorrect!

This will cause skipping of teeth at the slightest

resistance to the gate travel, resulng in the

motor control going out of synchronizaon to

the gate posion. The long term damage here

will be stripped teeth.

Incorrect!

This will cause unwanted rolling resistance

especially in colder condions. Where the wheel

shrinkage will cause the gate to sit heavier on

the pinion or when the rack is no longer square

to the pinion due to gate ex. (False safety

sensing acvaon)

The following shows a simple method of installing a rack that ensures you achieve the correct t between the rack and pinion.

Rack resting on

pinion

Rack clamped

to end of gate

Spirit level

2mm at bar spacers

• Clamp the end of the rst length of rack’s end to the closing edge of the gate.

• Rest the other end of the length on the pinion as shown here.

• Use a spirit level to ensure the rack remains true.

• If sased with the rack level fasten the rst “TEK” screw (supplied) in

the middle of the slot nearest the closing edge of the gate.

13

Remove the 2mm spacers

“TEK” screw installed through

the rack and into the gate to

lock the rack in position.

• Move the gate towards the open posion. Far enough that you can access the last mounng slot at the opposite end of the length of rack to

the end already fastened. Fasten the next “TEK” screw here while the rack sll rests atop the pinion.

• To install addional lengths of rack, move gate closed unl the next length of rack meets the rst length and the opposite end once again rests

on the pinion.

• To ensure the 2 lengths of rack marry correctly use an o cut of rack clamped upside down across the join of the 2 lengths.

• Connue to fasten the “TEK” screws as before

• When nished installing sucient rack to allow for the full travel of the gate plus enough to allow for the limit actuator (as shown in the next

secon) lower the gearbox by removing the two 2mm spacer bars.

• Test the meshing of the rack and pinion. (See pictures of rack to pinion spacing on previous page).

• If sased fasten a “TEK” screw directly through both the rack angle and the gate so that you have 5 “TEK” screws per length of rack evenly

spaced.

14

Electrical and electronic installaon and setup.

As a gate motor vibrates when in use, it is strongly recommended that only mulple strand exible cables be used.

Before closing the unit, always remember to double check that all connecons are securely made, that there are no stray strands aring out that can

short circuit against other adjacent connecons or bared wires and that no cables will be pulled loose when the cover is replaced on the unit.

Double check the baery connecons as loose connecons can cause arcing and corrosion of the baery terminals.

Terminang the AC voltages:

If you have chosen to install the standard kit which requires 220Vac at the gate motor then the 220Vac must be circuited through a weatherproof all pole

isolator switch. This isolator switch must be installed within 1,5m of the unit, must not be installed within the workings of the system (the gate may not

pass in front of it) and must be posioned so that it cannot be tampered with for the outside of the property. This circuit must be cered by way of a

C.O.C. (cercate of compliance) by a registered electrician.

In the case of the plug-in transformer opon being used, where the low voltage 29Vac is run to the gate, there is no need for the all pole isolator at the

gate and the circuit does not need to be cered by a registered electrician*. The cable however must sll be installed in its own dedicated conduit

pipe and the basic principles of electrical safety standards should sll be followed when selecng, working with and installing the cable for this circuit.

* Some municipalies may require cercaon of all domesc electrical circuits including those below 50V.

Terminang the 220Vac supply at the motor.

O On

220VAC Live

Earth

220VAC Neutral

O On

Ensure the 220Vac has been isolated. Terminate the 220Vac and earth as shown here. Switch the 220Vac back on.

O On

220V 0.5A Fuse

O On

Ensure the 220Vac has been isolated. Replace the 0.5A 220V fast blow fuse here. Switch the 220Vac back on.

Accessing the 220VAC 0.5A fuse in the case of a burnt out fuse.

15

RED

Motor

BLK

29Vac

@ 1A

230Vac

Earth

Com

N/CN/O

100Ω

N/O

-

+

24V 3.5Ah

Baery

Auxiliary

relay for use

in a courtesy

light, electric

lock or alarm

circuit. This

can also be

used as a 1ch

receiver. See

the next page

for examples

of circuits.

Manual release

AUX Rly LED

Limit LED

Safety beam

RX with

End of line

resistor

installed

N/O

Buon trigger

Pedestrian

N/O

Limit switch

Manual release monitoring switch.

VAC Supply Motor Limit Aux Relay Ancilliary connecons

Not

used

2A Aux Relay Fuse

10A Motor Fuse Gate closing

Gate opening

Wiring and terminaon of the control card.

Label Descripon Label Descripon

AC 29VAC input. COM Auxiliary relay common input.

BAT Baery power input. NC Auxiliary relay normally closed output.

M+ Motor red output. 12V Ancillaries 12VDC power output.

M- Motor black output. 0V 0V Common output.

0V 0V Common output. ST Status LED output. (-)

LC Closed limit input. BM Safety beam (detecon device) input.

LO Not used IN1 Buon trigger input. Full opening.

5V Not used IN2 Pedestrian trigger input. Paral opening.

NO Auxiliary relay normally open output. IN3 Not used

16

Installing the limit actuator.

1/2 1/2

Magnet

Magnet

Reed switch

This diagram depicts how to install the limit actuator.

1. Push the gate up against the closed stopper.

2. Remove the rack screw (Holding the nylon teeth to the steel angle) closest to being

in line with the limit switch. Or in the case of steel rack, weld a M4 x 20 machine bolt

upside down on top of the spine of the rack in line with the limit switch.

3. Fasten the actuator down onto the rack using either the M4 x 20 self-tapping screw

supplied with the kit or with a nut in the case of steel rack.

4. Adjust the actuator so that it is approximately halfway across the limit switch.

5. Move the gate open and then closed again. Ensure the limit LED comes on before the

gate impacts with the closed stopper. (Posive closed mode will always close the gate

the last 50mm if selected in programming)

Wiring and terminaon of the control card - Auxiliary relay examples.

AUX Relay

Baery back-up

power-supply rated

to match the lock

load.

+

0V

+0V

IN4007 back

EMF diode.

Strike lock.

AUX Relay

Baery back-up

power-supply rated

to match the lock

load.

+

0V

+

0V

IN4007 back

EMF diode.

Magnec lock.

AUX Relay

220V non-inducve

light bulb/s.

3A connuous.

5A peak.

Live

Neutral

Minimum 1,5mm

cross secon wire.

AUX Relay

Alarm panel zone

24hr zone

0V

E.O.L

Strike Lock Example Magnec Lock Example

Courtesy light Example Alarm zone Example

17

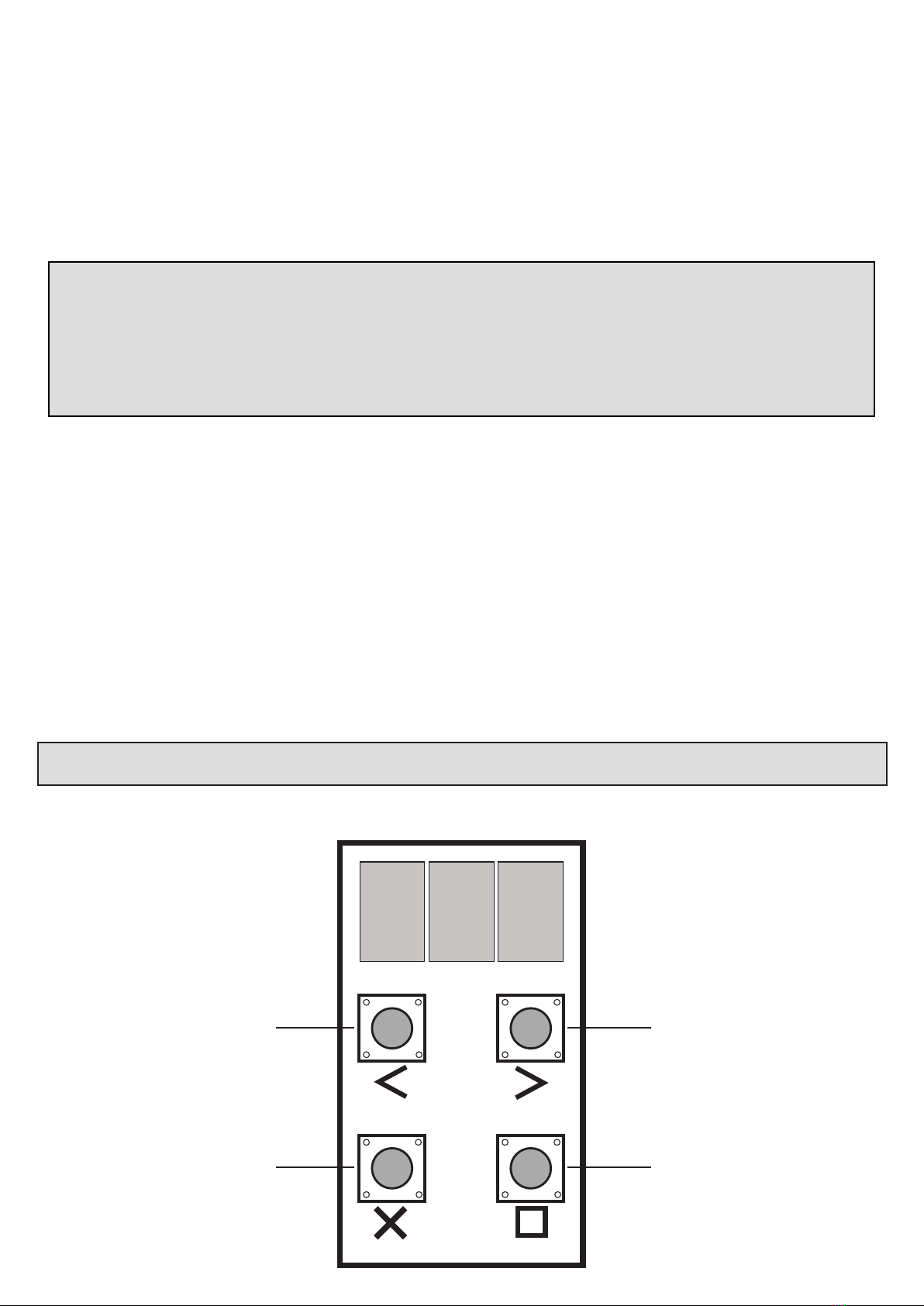

Using the control card display and dashboard.

The Drive 300 is equipped with an LED display and interacve keys for simplied programming and diagnoscs. All setup of the various features requires

that the control card dashboard be used. Below are the funcons of each key on the dashboard.

rdy

Enter programming, advance to next

level of opon on display or save value

on display.

Exit menu levels without saving.

Navigate backward in menus, decrease

values or indicate lehand closing gate

in runme setup funcon.

Navigate forward in menus, increase

values or indicate righthand closing

gate in runme setup funcon. Test

BT mode seng from “ready” status.

Before connuing with the commisioning.

If you are unfamiliar with the funconality of this product’s modes, it is suggested that you

familiarise yourself with the basic and advanced operang features detailed from page 32

of this instrucon manual.

18

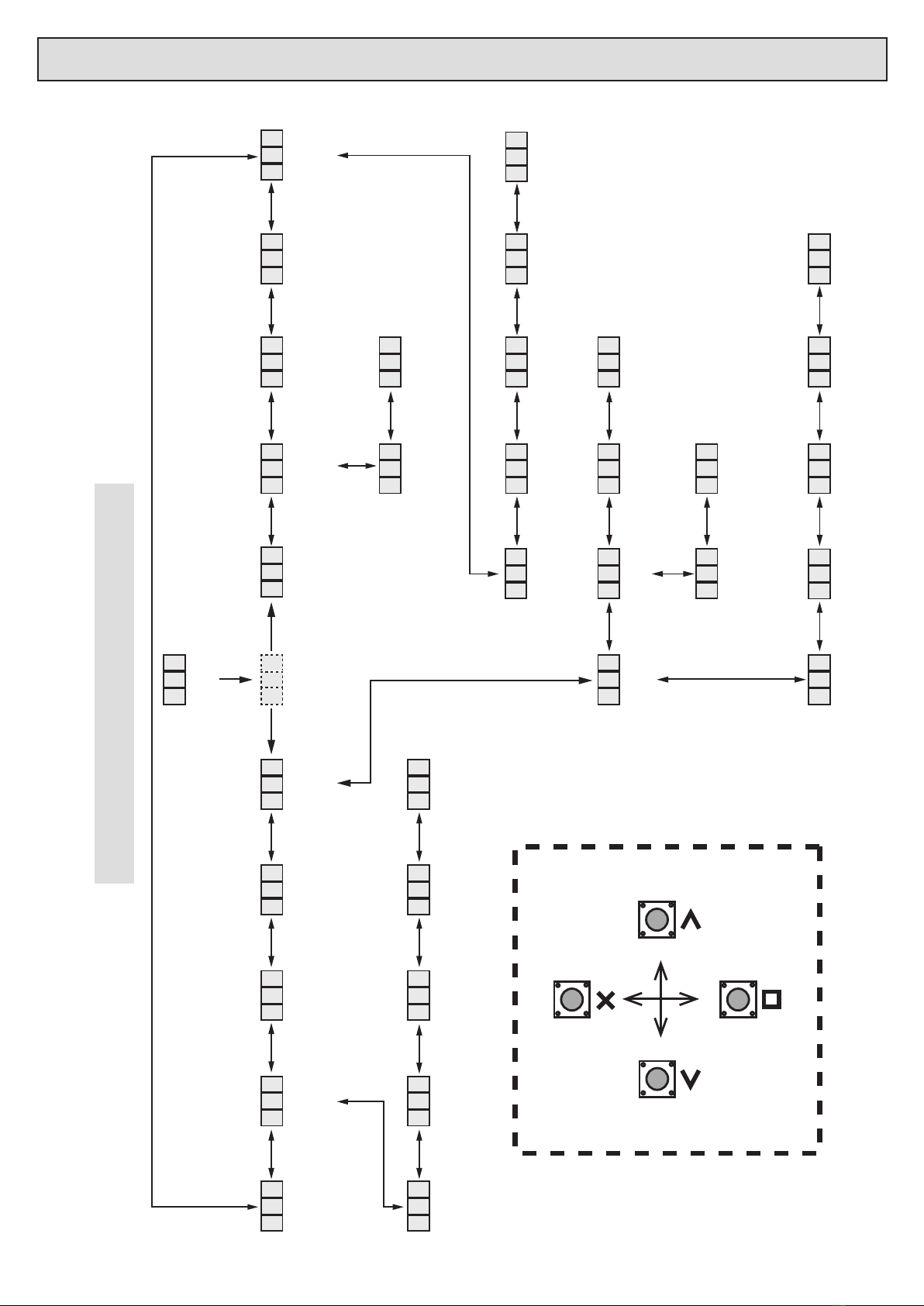

Control card programming and setup.

Programming menu quick reference guide:

Buon trigger

setup

Page 21

b t

Posive close

setup

Page 30

p c l

Auxiliary relay

setup

Page 31

r l y

Infra-red beam

setup

Page 20

i r b

Collision force

setup

Page 20

f o r

Power supply

setup

Page 29

p 5 u

Slow down

distance

Page 30

5 l o

Pedestrian

setup

Page 22

p e d

Ready status

Page 17

r d y

Programming

menu

p r 9

Runme

setup

Page 19

r u n

AC

monitoring

a c

Charger

On/Off

c h r

P.I.R.A.C

mode

p i r

Simple auto-close

mode

a u t

Standard

mode

5 t d

Condominium

mode

c o n

Courtesy light

mode

l i t

Receiver relay

mode

r c

Mag-lock

mode

l c 2

Strike lock

mode

l c 1

Tamper alarm

mode

a l a

Corresponding

buon learn

c o r

Version

informaon

i n f

Holiday lock out

channel

h o l

Diagnosc

tool

d i a

Erase all

a l l

Auxiliary relay

channel

r l y

Erase

menu

e r a

Erase

address

a d r

Pedestrian

channel

p e d

Receiver

setup

Page 23

r c

Learn

menu

l r n

Buon trigger

channel

b t

P.I.R.A.C + Condo

mode

p - c

Exit

Set

Le Right

19

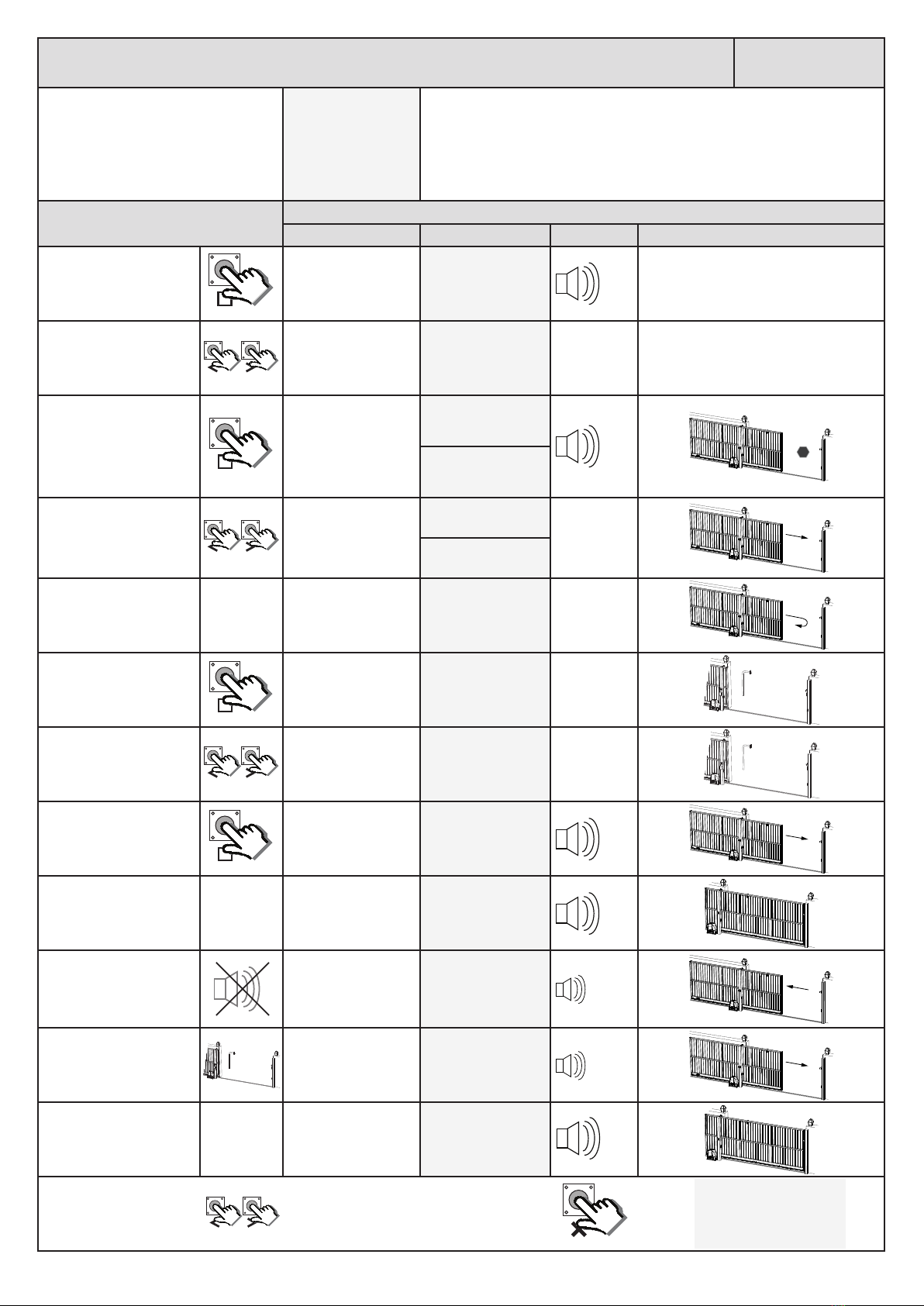

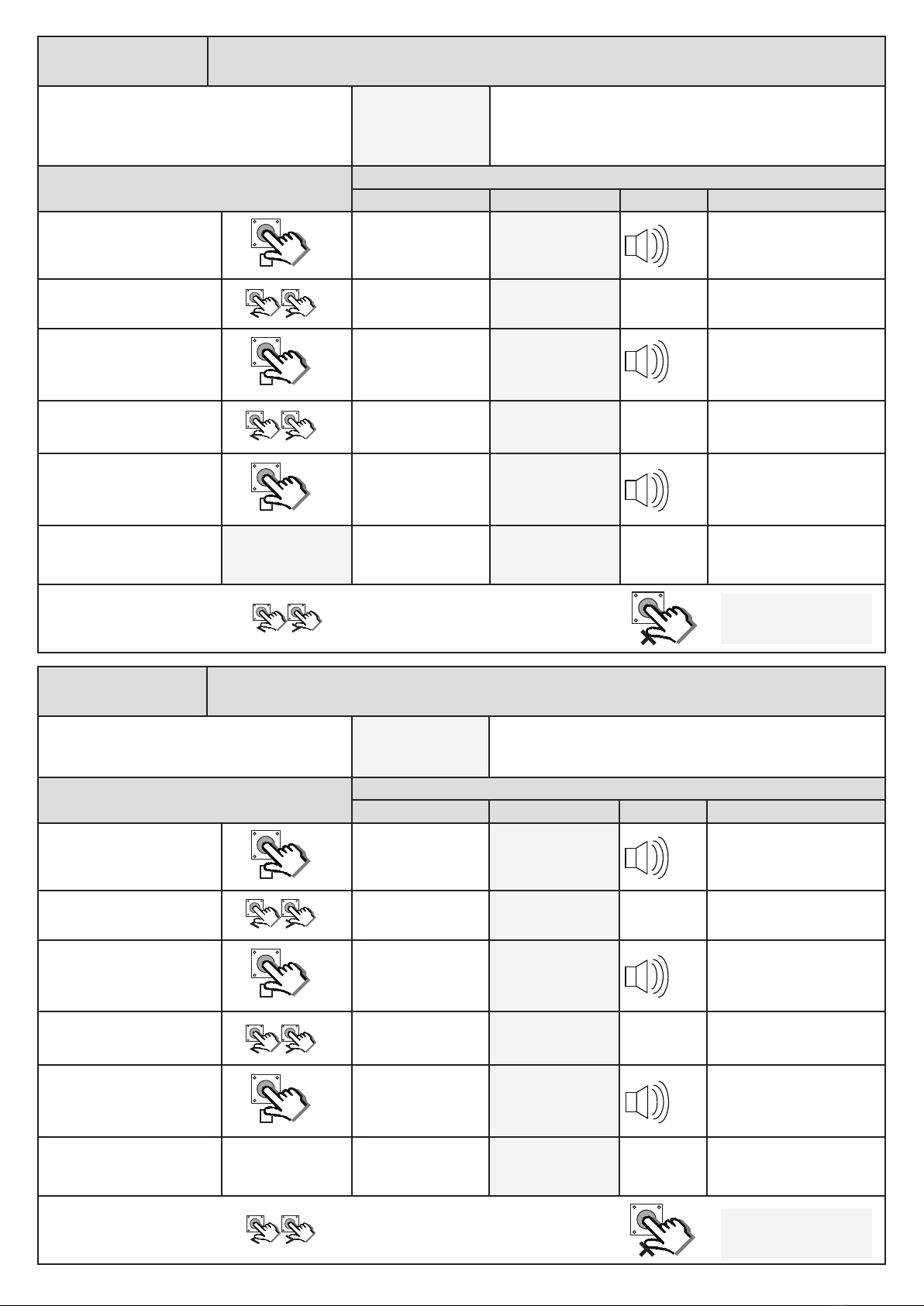

Seng up the gate runme. (Mandatory) run

From Ready status rdy

Before connuing with the runme setup ensure the limit actuator has

been installed correctly as per page 16 in this manual. Begin with the

gate midway in its travel.

NB. To speed up the gate while running during this procedure, press and hold

either the < or > buons.

Acon Response

Descripon Display Buzzer Gate/s

To enter the program

menu. Press and hold the

buon unl buzzer

beeps.

Display and buzzer

conrms. pr9

Scroll < or > to select the

runme setup opon.

Display scrolls

through opons. run

Ensure gate is engaged

midway and then press

buon.

Display prompts

you to conrm gate

closing direcon.

cl

dir

Conrm gate closing

direcon by pressing and

releasing either the < or >

buon.

Gate closes slowly.

Display conrms.

Lft

r9t

When the closed posion

is reached and the closed

limit is triggered. LED on.

Gate stops and starts

opening. lrn

Press and release the

buon to stop the gate

at the required open

posion.

Gate stops opening.

Display asks you to

ne adjust the open

posion if required. adj

Fine adjust the open

posion using the < or >

buons, if necessary.

Gate moves with

each buon press in

either direcon. adj

When sased with the

open posion, press and

release the buon to

save that posion.

Gate closes slowly.

Display and buzzer

conrms. lrn

When the closed posion

is reached and the closed

limit is triggered. LED on.

Gate stops. Display

and buzzer warn the

proling is about to

begin. pro

Once warning tone has

stopped.

Gate begins running

open at full speed.

Display conrms. pro

When the previously

programmed open

posion is reached.

Gate stops and

begins closing again

at full speed. Display

conrms. pro

When the closed posion

is reached and the closed

limit is triggered. LED on.

Gate stops. Display

and buzzer conrms. dne

x2

x1 STOP

x1

x1

On/o...

On/o...

x2

Scroll le or right to next

program opon. OR rdy

EXIT back to ready

status

20

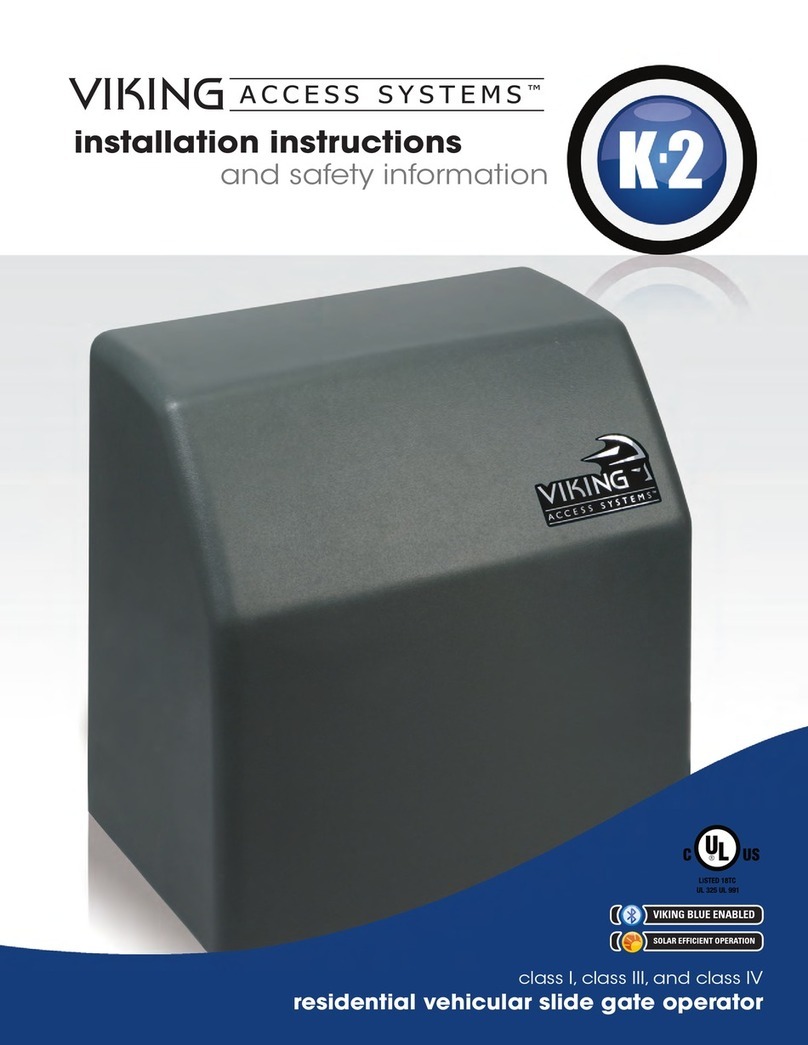

for Selecng a safety level.

From Ready status rdy

This adjusts the force level, over and above the nominal gate

resistance, needed to trigger the safety overload rounes.

Level 1 being the most sensive and 8 being the least sensi-

ve. The factory default is level 3.

Acon Response

Descripon Display Buzzer Gate

To enter the program menu.

Press and hold the buon

unl buzzer beeps.

Display and buzzer

conrms. pr9

Scroll < or > to select the

collision force setup opon.

Display scrolls

through opons. for

With “For” on the display,

press and release .

Display shows current

opon status. 003

Scroll < or > to the required

seng.

Display changes

respecvely. 006

With required seng

displayed, press and release

.

Display briey shows

the new seng is

saved. 006

Aer display conrms new

seng. 006 Display returns to

programming menu

opons list. for

x2

x1

x2

Scroll le or right to next

program opon. OR EXIT back to Ready

status rdy

irb Safety infra-red beams setup.

From Ready status rdy Use this opon to enable the safety beam circuit. The safety

beams circuit must be congured as per page 15 with the

end of line resistor installed.

Acon Response

Descripon Display Buzzer Gate

To enter the program menu.

Press and hold the buon

unl buzzer beeps.

Display and buzzer

conrms. pr9

Scroll < or > to select the

beam setup opon.

Display scrolls

through opons. irb

With “irb” on the display,

press and release .

Display shows current

opon status. off

Scroll < or > to toggle

between “on” or “o”.

Display changes

respecvely. on

With required seng

displayed, press and release

.

Display briey shows

the new seng is

saved. on

Aer display conrms new

seng.

Beam Setup

Enabled Saved

Display returns to

programming menu

opons list. irb

x2

x1

x2

Scroll le or right to next

program opon. OR pr9

EXIT back to standby

status

Table of contents

Other E.T. Systems Gate Opener manuals

Popular Gate Opener manuals by other brands

Viking Access Systems

Viking Access Systems K-2 installation instructions

Portamatik

Portamatik TOP500 User's and installer's manual

SEA

SEA Libra Mini Tank INSTALLATION MANUALS AND SAFETY INFORMATION

Eagle Access Control Systems

Eagle Access Control Systems X9S Installation & owner's manual

Toona

Toona TO6024HS Instructions for installation and use

Dea

Dea LIVI 403E Operating instructions and warnings