EC5000

Catalogue

- 1 -

TABLE OF CONTENTS

Chapter 1 Read Below Information Before Use

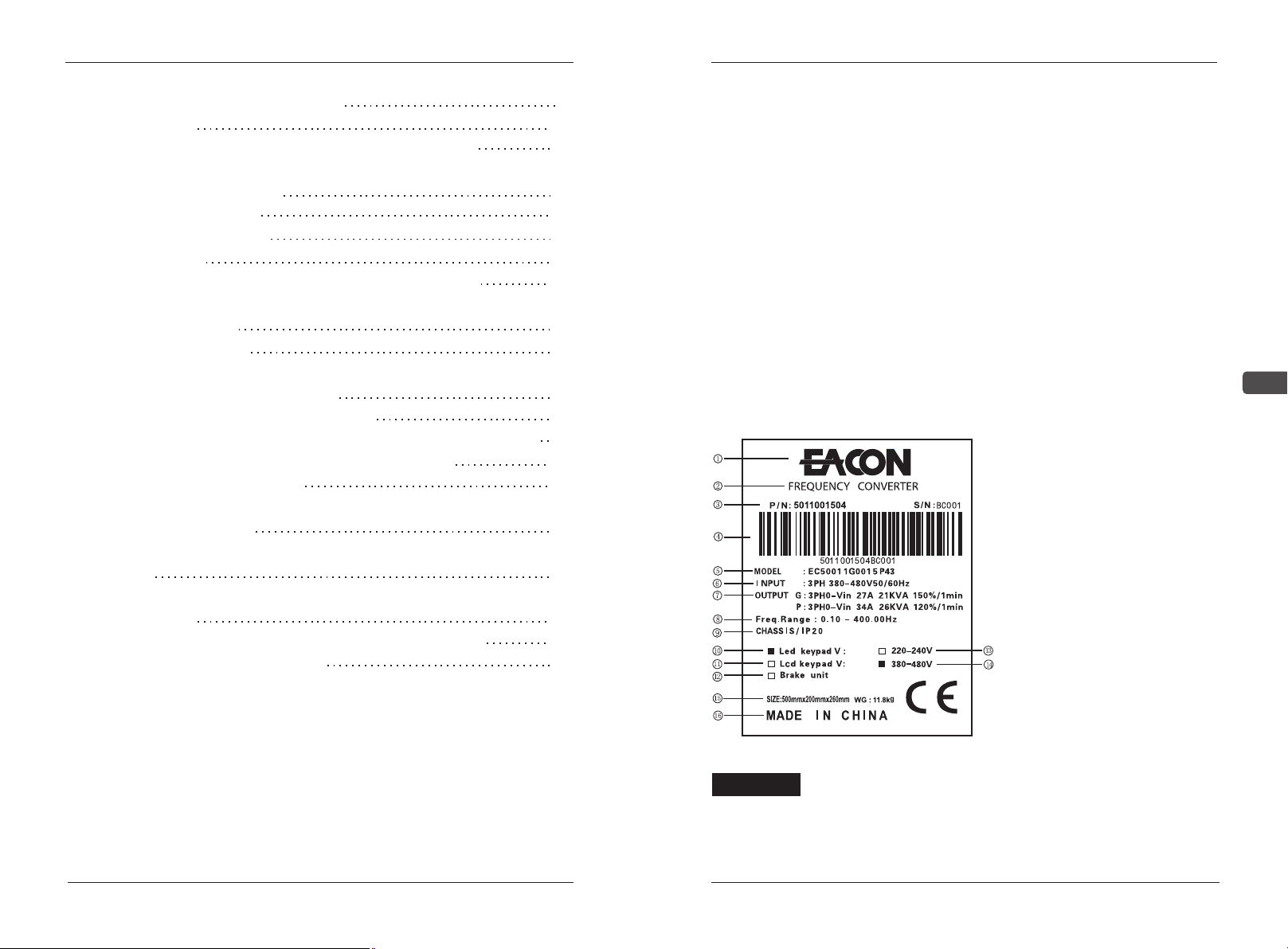

1.1 Delivery Inspection

1.2 Transport

1.3 Storage

1.4 Considerations for Choices of AC Drives

Chapter 2 Installation and Wire Layout

2.1 Installation Environment

2.2 Installation Conditions

2.3 Installation Dimension of AC Drive

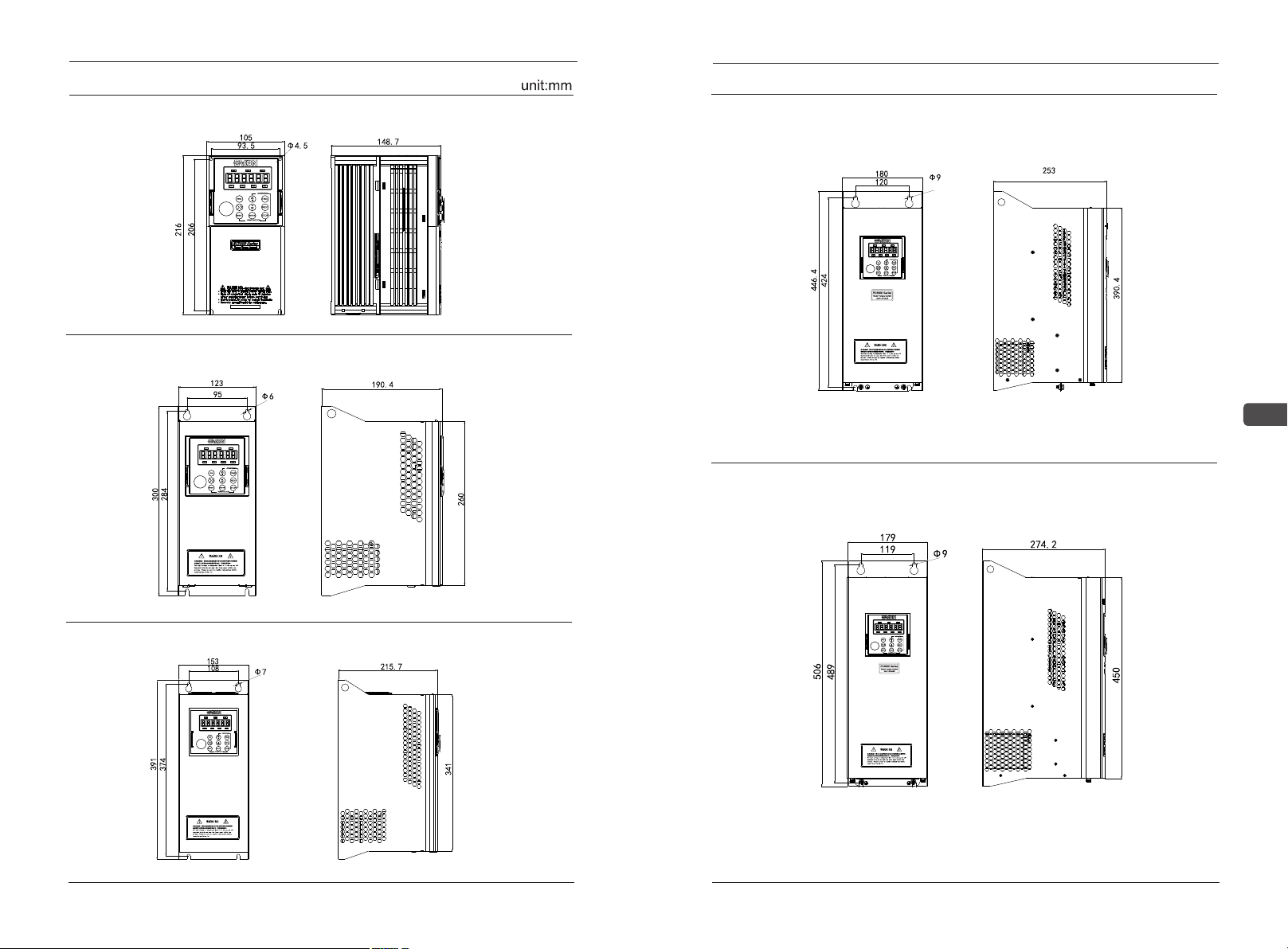

2.3.1 200V Installation Dimension of AC Drive

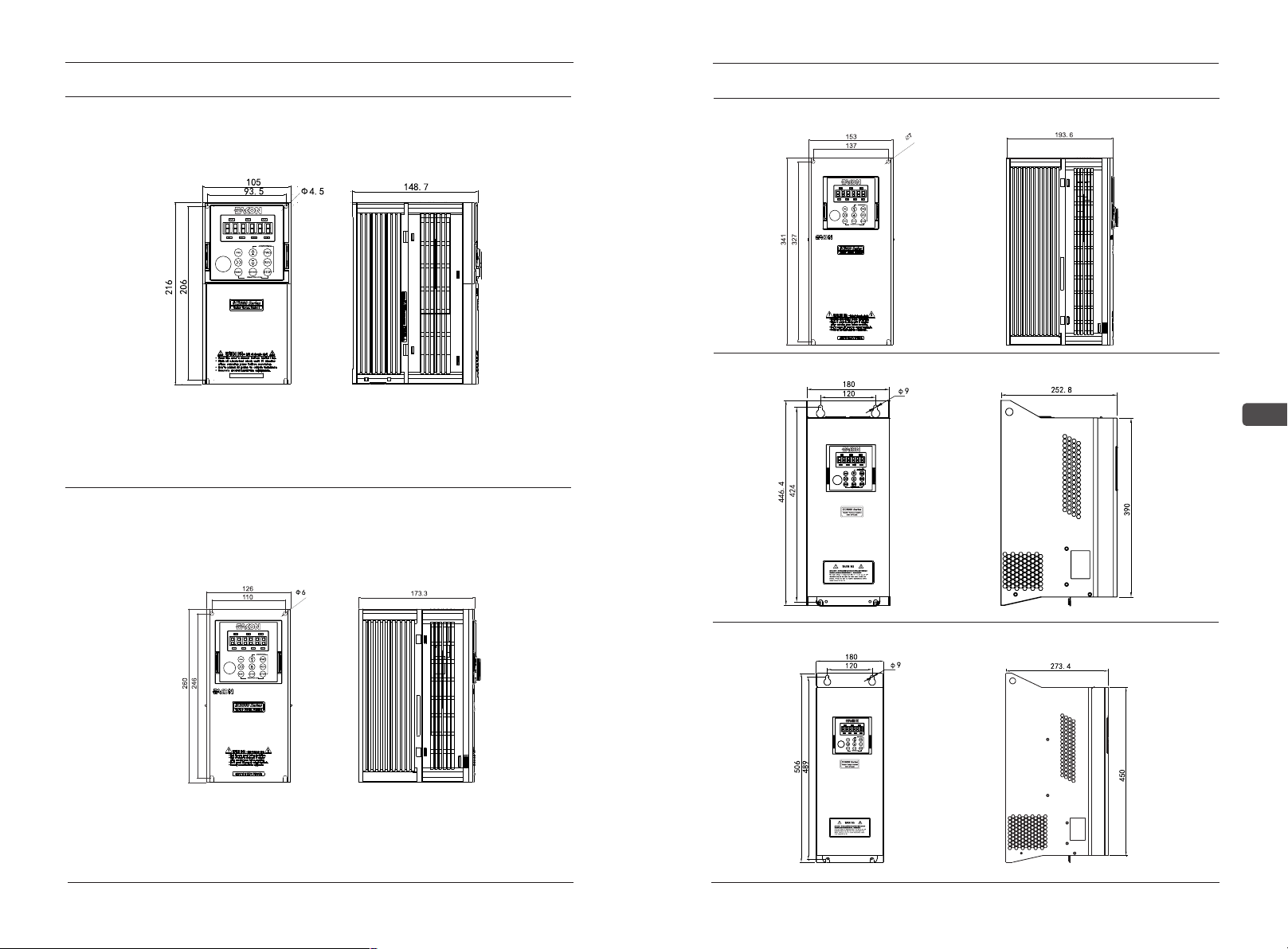

2.3.2 400V Installation Dimension of AC Drive

2.4 Instruction for Wire Layout

2.4.1 Basic Wire Layout

2.4.2 System Wiring Diagram

2.4.3 Main Circuit Terminal Connection

2.4.4 Control Terminal Connection

Chapter 3 Operation and Inspection

3.1 Check and Test before Operation

3.2 Running Way

3.3 Test Run

Chapter 4 Operation Keypad Panel

4.1Appearance & Operation Procedure of LED Keypad Panel

4.1.1 Appearance of LED Keypad Panel

4.1.2Operation Procedure of LED Keypad Panel

4.2 Appearance & Operation Procedure of LCD Keypad Panel

4.2.1 LCD Keyboard Panel Appearance

4.2.2 Operation Procedure of LCD Keypad Panel

Chapter 5 Description of Functional Parameter

5.1 Function Parameter List

5.2 Detailed Description of Functional Parameters

Chapter 6 MODBUS Communication Protocol

6.1 Communication Data Structure

6.2 Data Format Frame

6.2.1 Communication Address

Warning!

Notice!

1.Please do not test the voltage resistance of the interior components

of the driver, as the semiconductor of the driver is easy to be punctured

and damaged by high voltage.

2. The circuit board of the driver has CMOS IC which is extremely

easy to be damaged by static electricity, thus please do not touch the

circuit board with your hand before taking anti-static electricity measures.

3.Even if the motor is inactive, the main loop terminal of the driver

may still have dangerous high voltage.

4.Only the qualified motor professionals can install the driver, lay the

wire, repair and maintain the driver.

1.When certain functions of the driver are set, the motor may

immediately start after the power input.

2.Please choose a safe place to install the AC drive to avoid the high

temperature, direct sunlight, humidity and splash of water drops.

3.Please prevent the children or irrelevant people against being

close to the AC drive.

4.The AC drive can only be used in the places recognized by our

company, and the usage in an environment not recognized by our

company may lead to fire, gas explosion or electrification.

5.When the wire between the AC drive and the motor is too long, the

inter-layer insulation of the motor may be damaged, please use the

special AC motor for AC drive, or add a reactor between the driver and the

motor to prevent the AC drive from being burned due to the damage of

insulation.

6.he rated voltage of the power system for the driver can't be higher

than ±15% of the rated voltage of product, and the current can't be over

5000A RMS (The current of 40HP (30kW) type or above can't be over

10000A RMS).

1

2

3

4

6

6

7

7

11

16

16

21

26

27

31

31

32

33

33

34

35

36

36

40

53

97

98

96