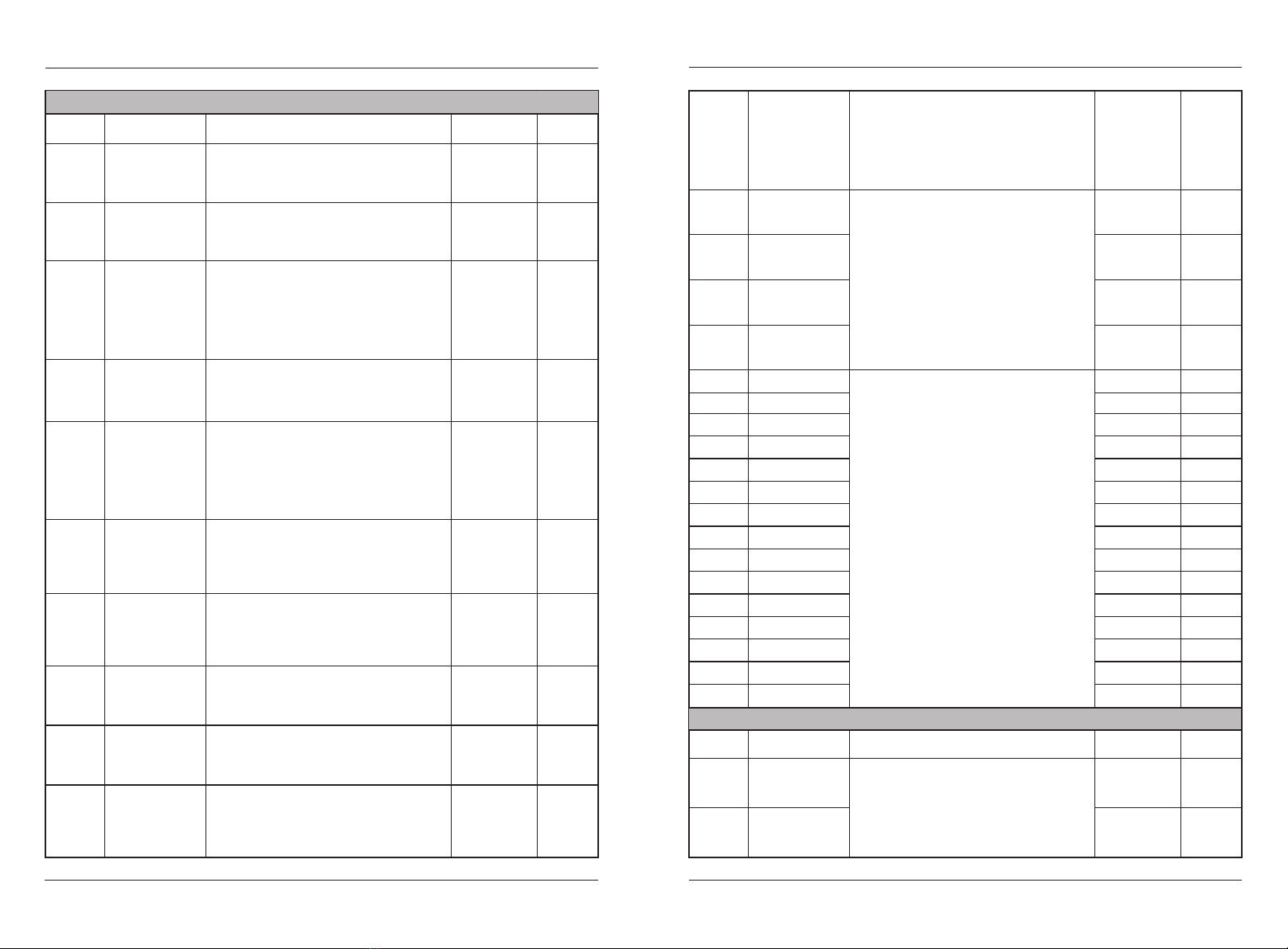

Err04

Overcurrent

at constant

speed

Err05

1: The output circuit is grounded

or short circuited.

2: Motor auto-tuning is not

performed.

3: The input voltage is too low.

4: A sudden load is added during

operation.

5: The AC drive model is of too

small power class.

1: The input voltage is too high.

2: An external force drives the

motor during acceleration.

3: The acceleration time is too

short.

4: The braking unit and braking

resistor are not installed.

1: Eliminate external faults.

2: Perform the motor autotuning.

3: Adjust the voltage to the normal range.

4: Remove the added load.

5: Select an AC drive of higher power

class.

1: Adjust the voltage to normal range.

2: Remove the external force or install a

braking resistor.

3: Increase the acceleration time.

4: Install the braking unit and braking

resistor.

Err10

Err11

Err06

Err07

Err08

Err09

Overvoltage

during

acceleration

AC drive

overload

Motor

overload

Overvoltage

during

deceleration

Overvoltage

at constant

speed

Control

power supply

fault

Undervoltage

1: The load is too heavy or

locked rotor occurs on the motor.

2: The AC drive model is of too

small power class.

1: P9-23 is set improperly.

2: The load is too heavy or

locked rotor occurs on the motor.

3: The AC drive model is of too

small power class.

1: The input voltage is too high.

2: An external force drives the

motor during deceleration.

3: The deceleration time is too

short.

4: The braking unit and braking

resistor are not installed.

1: The input voltage is too high.

2: An external force drives the

motor during running.

1: The input voltage is not

within the allowable range.

1: Instantaneous power failure

occurs on the input power supply.

2: The AC drive's input voltage

is not within the allowable range.

3: The DC-Bus voltage is abnormal.

4: The rectifier bridge and

buffer resistor are faulty.

5: The drive board is faulty.

6: The main control board is

faulty.

1: Reduce the load and check the motor and

mechanical condition.

2: Select an AC drive of higher power

class.

1: Set it correctly.

2: Reduce the load and check the motor and

the mechanical condition.

3: Select an AC drive of higher power

class.

1: Adjust the voltage to normal range.

2: Remove the external force or install a

braking resistor.

3: Increase the deceleration time.

4: Install the braking unit and braking

resistor.

1: Adjust the voltage to the normal range.

2: Remove the external force or install

the braking resistor.

1: Adjust the input voltage to the

allowable range.

1: Reset the fault.

2: Adjust the voltage to the normal range.

3: Contact technical support.

4: Contact technical support.

5: Contact technical support.

6: Contact technical support.

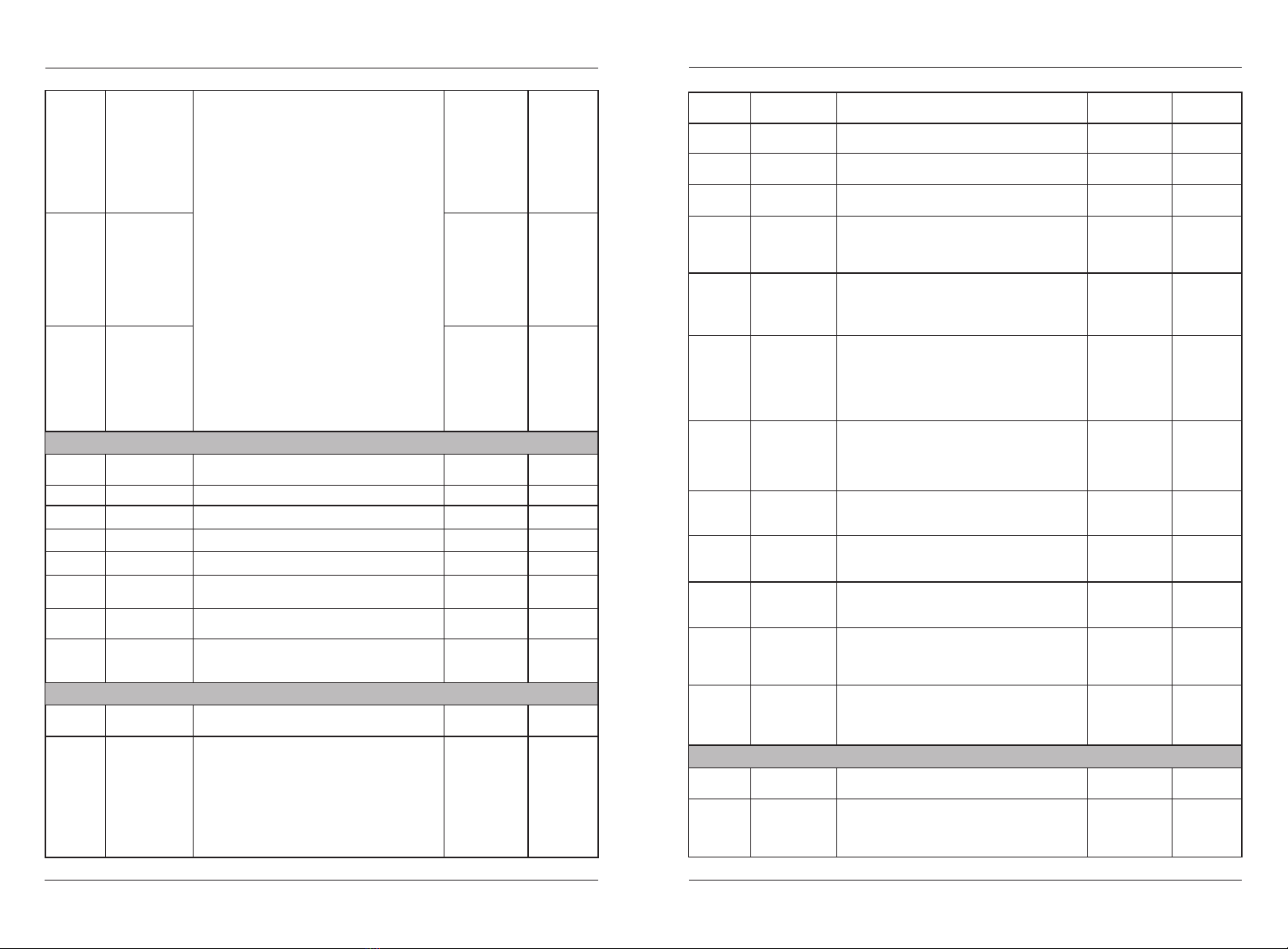

Err12 Power input

phase loss

1: The three-phase power input is

abnormal.

2: The drive board is faulty.

3: The lightening board is faulty.

4: The main control board is

faulty.

1: Eliminate external faults.

2: Seek technical support.

3: Seek technical support.

4: Seek technical support.

Err13 Power output

phase loss

1: The cable connecting the AC

drive and the motor is faulty.

2: The AC drive's three-phase

outputs are unbalanced when the

motor is running.

3: The drive board is faulty.

4: The module is faulty.

1: Eliminate external faults.

2: Check whether the motor three-phase

winding is normal.

3: Seek technical support.

4: Seek technical support.

Err14 Module

overheat

1: The ambient temperature is too

high.

2: The air filter is blocked.

3: The fan is damaged.

4: The thermally sensitive

resistor of the module is damaged.

5: The inverter module is damaged.

1: Lower the ambient temperature.

2: Clean the air filter.

3: Replace the damaged fan.

4: Replace the damaged thermally

sensitive resistor.

5: Replace the inverter module.

Err15

Err16

Err17

Err18

Err19

Err20

Err21

Err22

Err24

External

equipment

fault

Communication

fault

Contactor

faul

Current

detection

fault

Motor

auto-tuning

fault

Encoder

fault

EEPROM

readwrite

fault

AC drive

hardware

fault

Running

time reached

1: The motor parameters are not

set according to the nameplate.

2: The motor auto-tuning times out.

1: The encoder type is incorrect.

2: The cable connection of the

encoder is incorrect.

3: The encoder is damaged.

4: The PG card is faulty.

1: External fault signal is input

via S.

1: The host computer is in

abnormal state.

2: The communication cable is

faulty.

3: The communication parameters in

group PB are set improperly.

1: The drive board and power

supply are faulty.

2: The contactor is faulty.

1: The HALL device is faulty.

2: The drive board is faulty.

1: The EEPROM chip is damaged.

1: Overvoltage exists.

2: Overcurrent exists.

1: Accumulative running time

reaches setting.

1:Reset the operation.

1: Check the cabling of host computer.

2: Check the communication cabling.

3: Set the communication parameters

properly.

1: Replace the faulty drive board or

power supply board.

2: Replace the faulty contactor.

1: Replace the faulty HALL device.

2: Replace the faulty drive board.

1: Set the motor parameters according

to the nameplate properly.

2: Check the cable connecting the AC

drive and the motor.

1: Set the encoder type correctly

based on the actual situation.

2: Eliminate external faults.

3: Replace the damaged encoder.

4: Replace the faulty PG card.

1: Replace the main control panel.

1: Handle based on over-voltage.

2: Handle based on over-current.

1: Clear the record through the

parameter initialization function.

Err23

Short

circuit

to ground

1: The motor is short circuited

to the ground. 1: Replace the cable or motor.

Err25 User-defined

fault 1 1: The user-defined fault 1 signal

is input via DI. 1: Reset the operation.

Err26 User-defined

fault 2

Fa u lt s a nd s o lu t io n s

EC 6 70

Fa u lt s a nd s o lu t io n s

EC 6 70

- 7 - - 8 -