Compliance

Properly installed, the system is compliant with The National Electric Code (NEC)

Section 480.9 (A) for ventilation of battery rooms. This is also the specified requirement

for solar or wind generated power Battery Rooms. It is also compliant with The National

Fire Protection Association, NFPA 2 Hydrogen Technology Code, which is more

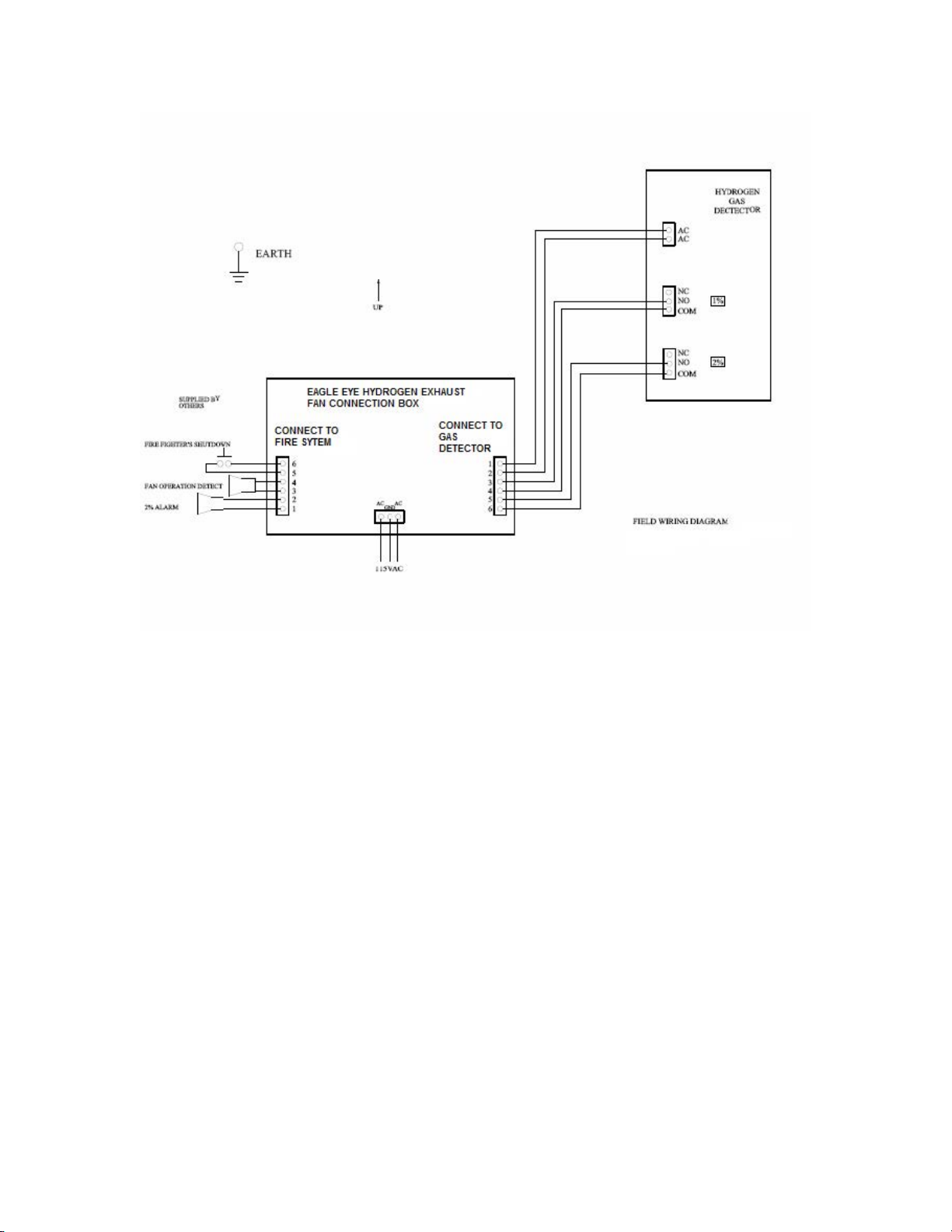

stringent. The minimum system consists of an Hydrogen Gas Detector, and a Battery

Room Forced Ventilator with Positive Airflow Shut Off, a remote firefighter’s shutdown

capability, a backflow damper, and a 2% monitored alarm. This unit complies with NEC

501.125. (B), 501.105 (1)-3 and is designed for use in Class 1 Div. 2 hydrogen

containing classified areas.

.The fan unit is compliant with the NFPA Standard on Clean Agent Fire Extinguishing

Systems (2001) Section C2.8.2.7.7 and may be used as per Sections 5.3.4, 5.3.6,

7.7.2.4.8, A5.3.6, A8.7.2 and C2.4.3.4

The fan unit is compliant with the NFPA Standard 90A Section 4.2.3, 4.2.3.1, 4.2.3.1.2,

4.2.3.2.2, and 4.2.3.3

All the active component parts on the Eagle Eye Fan Battery Room Exhaust Fan With Positive

Airflow Shut Off System that are subject to testing are certified by the Underwriters’ Laboratory as

follows.

Part Number Description and Manufacturers Part # - UL number

191200 FAN DC 254X89 48V 690CFM -Orion# OD254AP-48MB - UL E17049

311011 Wire, UL1430 #24 Brown

311019 Wire, UL1430 #24 White

311060 Wire, UL1430#18 Black

311066 Wire, UL1430 #18 Blue

311072 Wire, UL1430 #16 Red

311057 Wire, UL1430 #20 Violet

151259 Receptacle, Mplex, 9 pin – Molex # 538-19-09-1099 - UL E29179

150110 Pin & Socket Connectors 9 CIRCUIT HOUSING- Molex# 15-31-1096 - UL E29179

131005 CALRAD Magnetic Switch #40-660 - UL 634

131004 DELTROL TUBULAR FRAME Solenoid, 24V MED 16 X 2.000 – UL E57982 &

E74443

130003 Power Relay, Compact PC Board, NAIS# JW1FSN-DC48V – UL E43028

Additional parts found only on the Eagle Eye Hydrogen Gas Detector

130007 Power Relay, Compact PC Board, NAIS# JW1FSN-DC12V– UL E43028

140014 Flyback Transformer, Premier Magnetics # PNY-24004 – UL E162344

150058 Phoenix Contact # 1715734

www.eepowersolutions.com

|

Tel:

1-877-805-3377

|

Fax:

1-414-962-3660

|

[email protected] |

V1.0