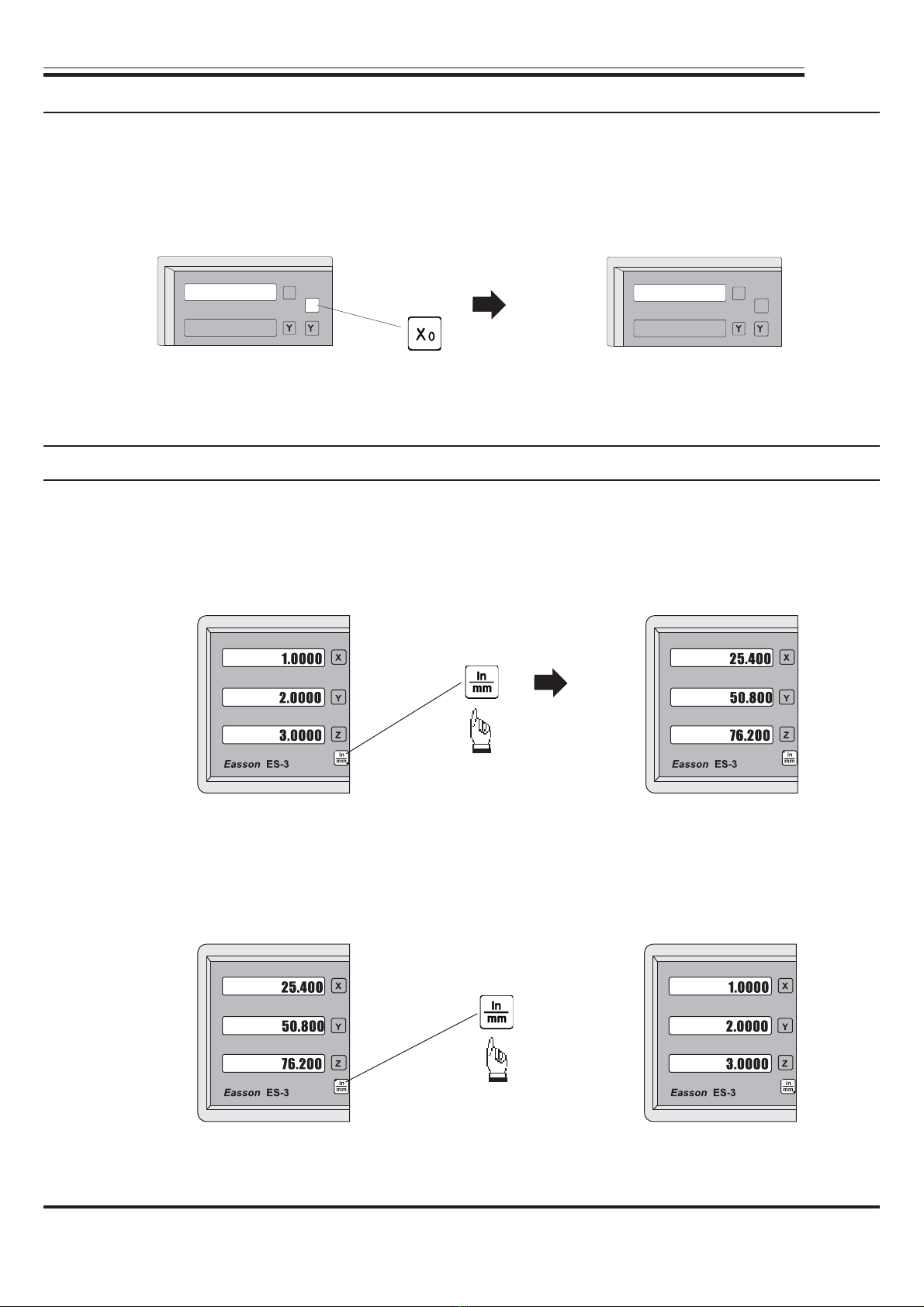

ABS / INC Coordinates display switches

ES-3 ABS

INC

provides two sets of basic coordinate display, they are (absolute)

and (incremental) displays.

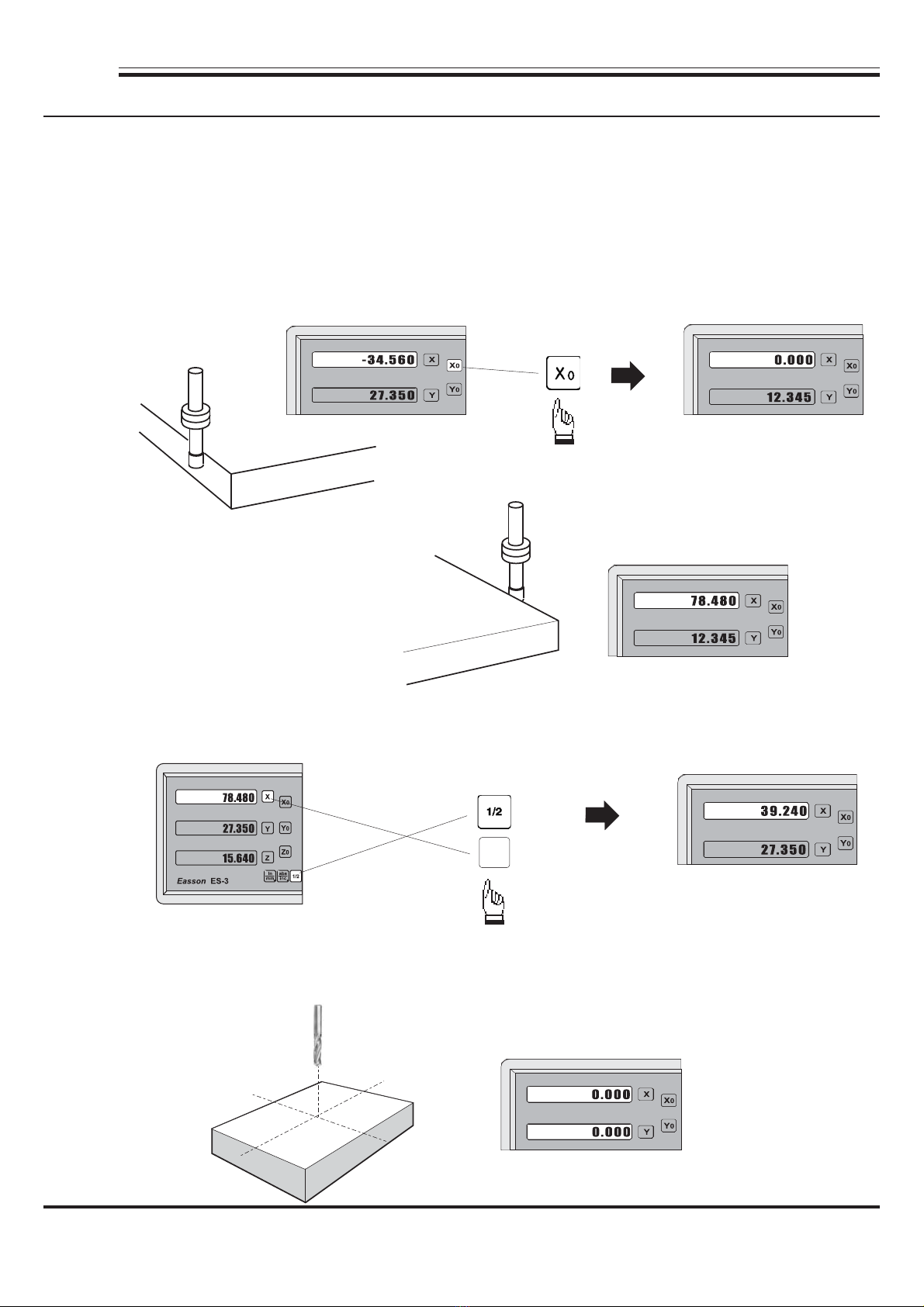

During machining operations, the operator can

The operator is then free to zero the axes or preset any dimensions into any

axis in INC coordinate for relative position machining. The work piece datum

( work piece zero position ) is still retained in ABS coordinate by the ES-3.

Operator can then toggle between ABS (absolute) and INC (incremental)

coordinates without losing the work piece datum ( work piece zero position ).

store the work piece datum ( zero

position ) in ABS coordinate, then switch to INC coordinate to continue machining

operations.

-5-

Purpose :

Example 1 : Currently in display coordinate, to switch to display coordinateABS INC

Example 2 : Currently in display coordinate, to switch to display coordinateINC ABS

Easson Easson