Contents

Safety ............................................................................................................................. 7

General Safety Precautions .......................................................................................... 7

Explanation of Symbols................................................................................................. 9

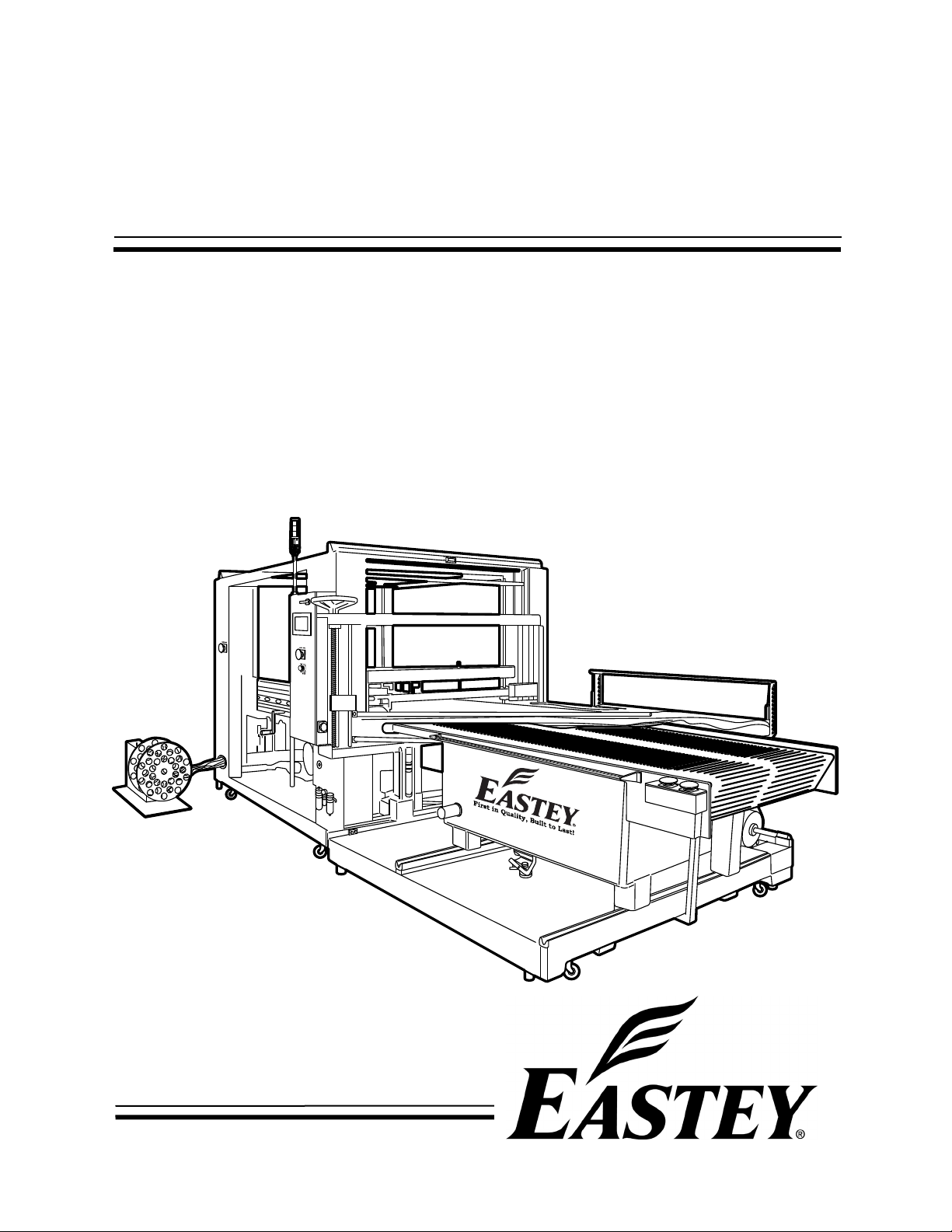

Introduction ................................................................................................................. 10

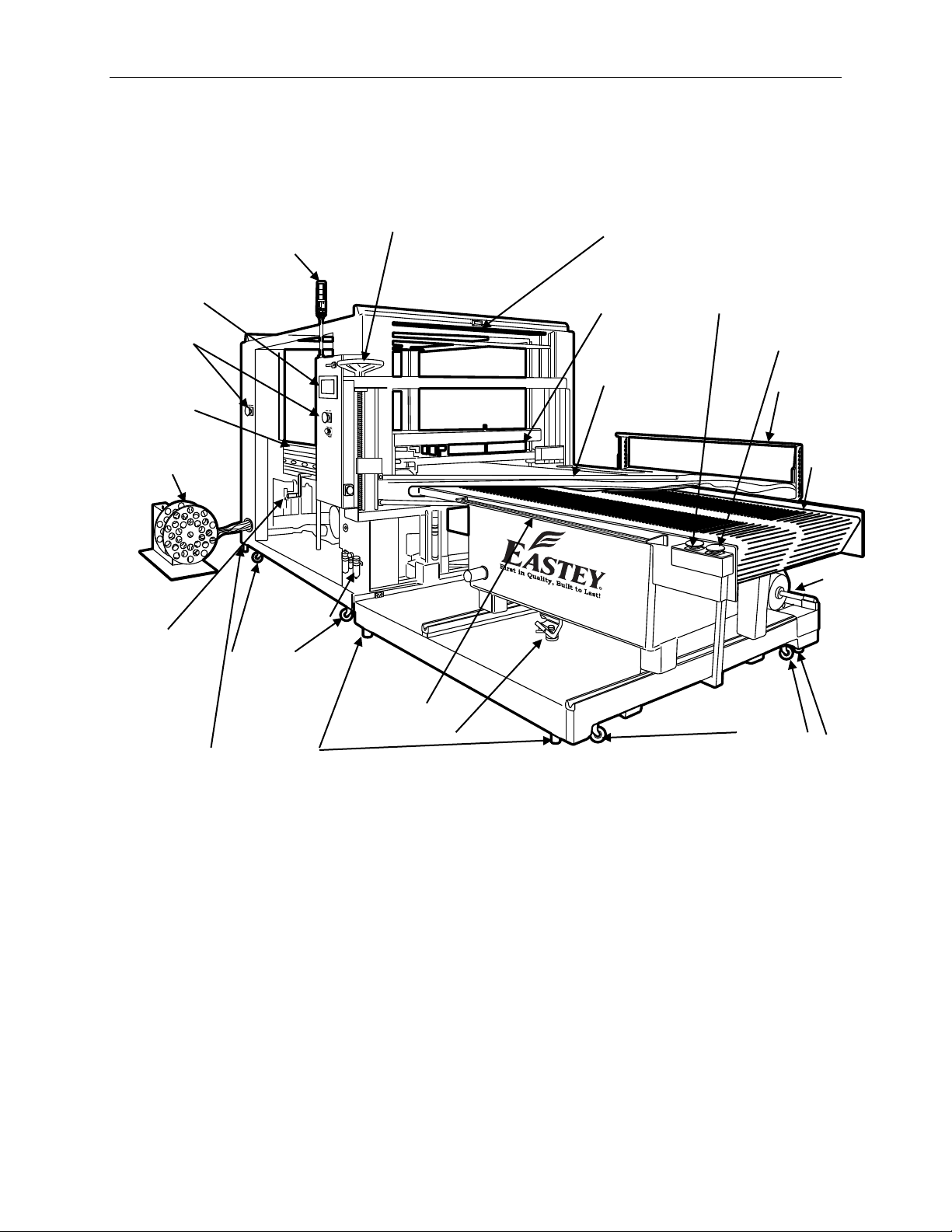

General System Description........................................................................................ 10

Specifications.............................................................................................................. 11

Dimensions ................................................................................................................. 13

Unpacking.................................................................................................................... 14

Loading and Unloading Instructions ............................................................................ 15

Installation ................................................................................................................... 16

Location Requirements ............................................................................................... 16

Moving Units Together and Making Connections........................................................ 18

Connecting Power....................................................................................................... 20

Operation ..................................................................................................................... 21

Machine Controls and Control Panel........................................................................... 21

Other Features............................................................................................................ 23

Setting Temperatures and Timers............................................................................... 25

Setup Screen Settings ................................................................................................ 27

Loading Film................................................................................................................ 29

Setup for Scrap Winding ............................................................................................. 34

Adjusting Package Height ........................................................................................... 35

Running Product ......................................................................................................... 39

Running One Product at a Time.................................................................................. 40

Product Indexing ......................................................................................................... 40

Adjustments ................................................................................................................ 41

Operator’s Panel Screen Adjustment .......................................................................... 41

Fine Tuning the Sealer................................................................................................ 44

Air Regulator Adjustments........................................................................................... 45

Conveyor Tension Adjustment .................................................................................... 46

Seal Head Pressure Adjustment ................................................................................. 47

Scrap Film Take-up Spool Clutch Tension Adjustment............................................... 48

Maintenance ................................................................................................................ 49

Weekly or Monthly Maintenance ................................................................................. 49

Preventative Maintenance for Modular Plastic Conveyor Belts................................... 50

Belt Assembly and Disassembly ................................................................................. 51

Replacing Conveyor Components............................................................................... 53

Replacing Power Film Unwind Components ............................................................... 55

Troubleshooting .......................................................................................................... 57