Contents:

Safety .............................................................................................................................7

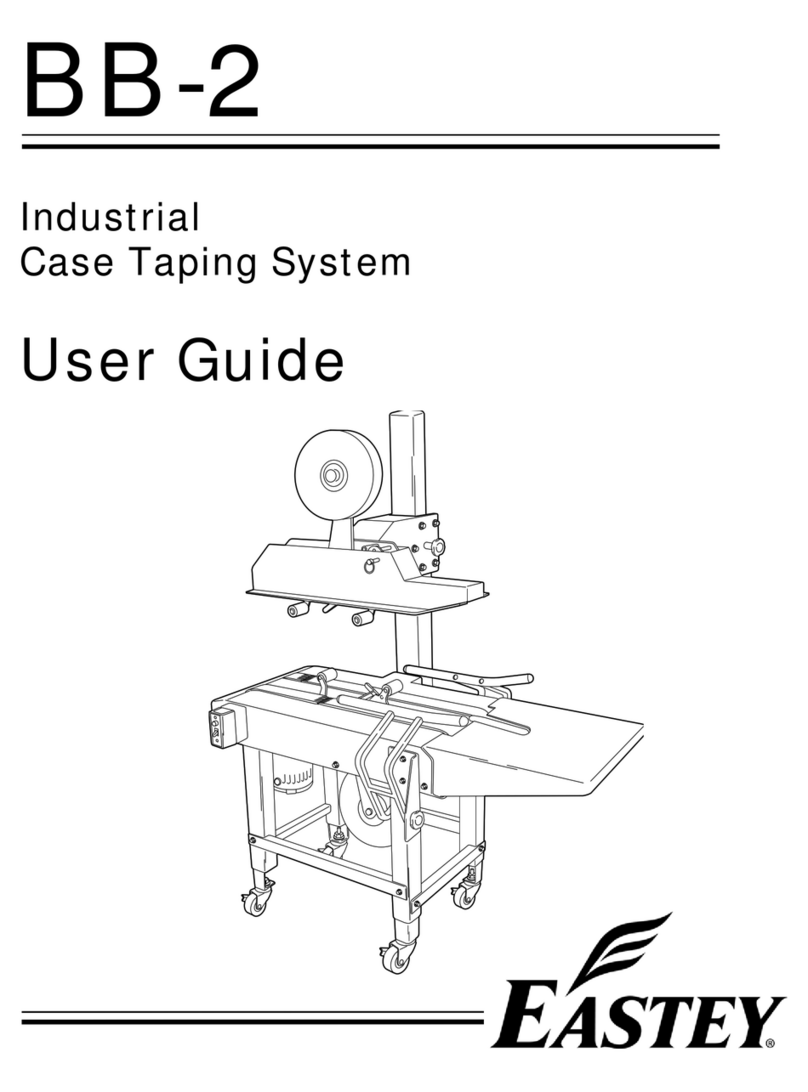

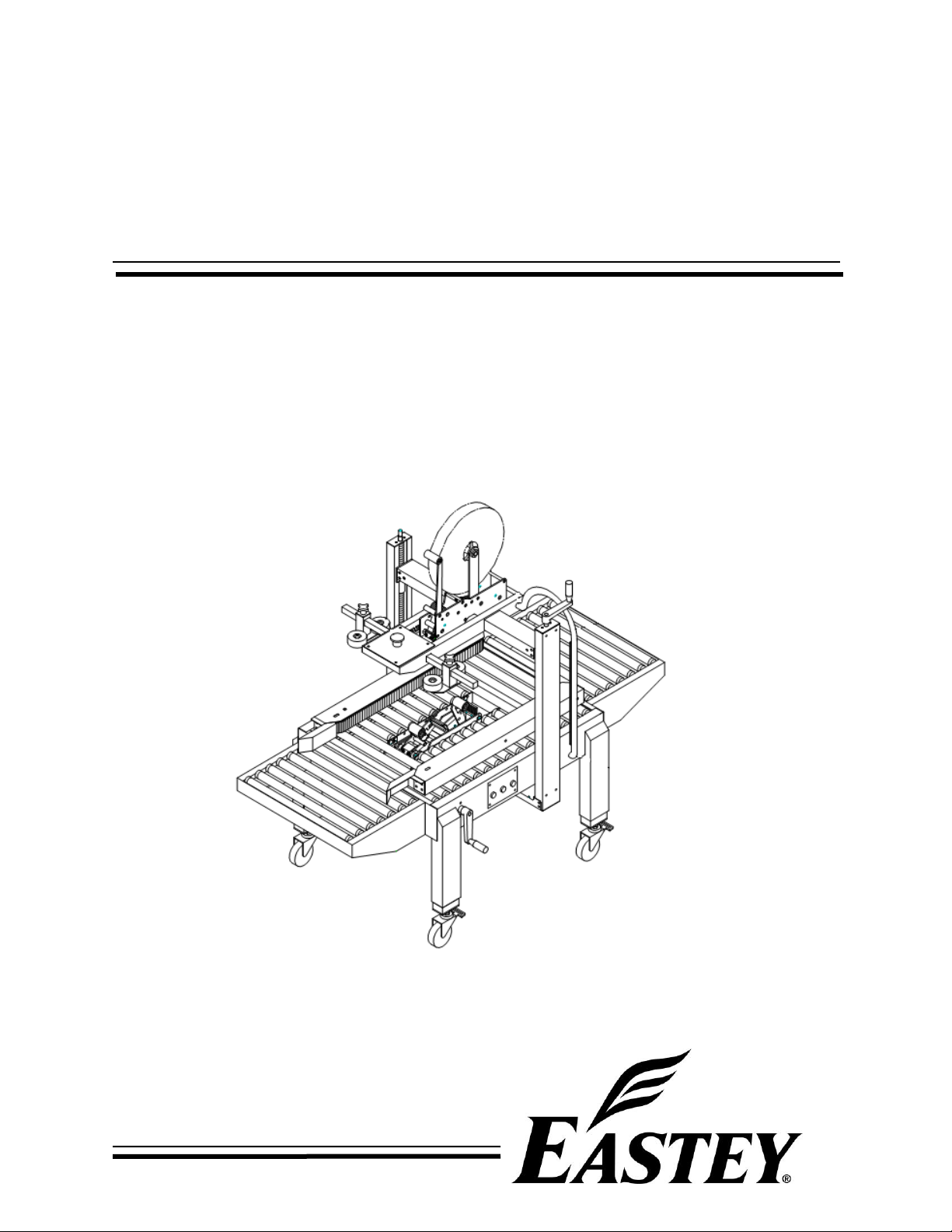

Introduction ...................................................................................................................8

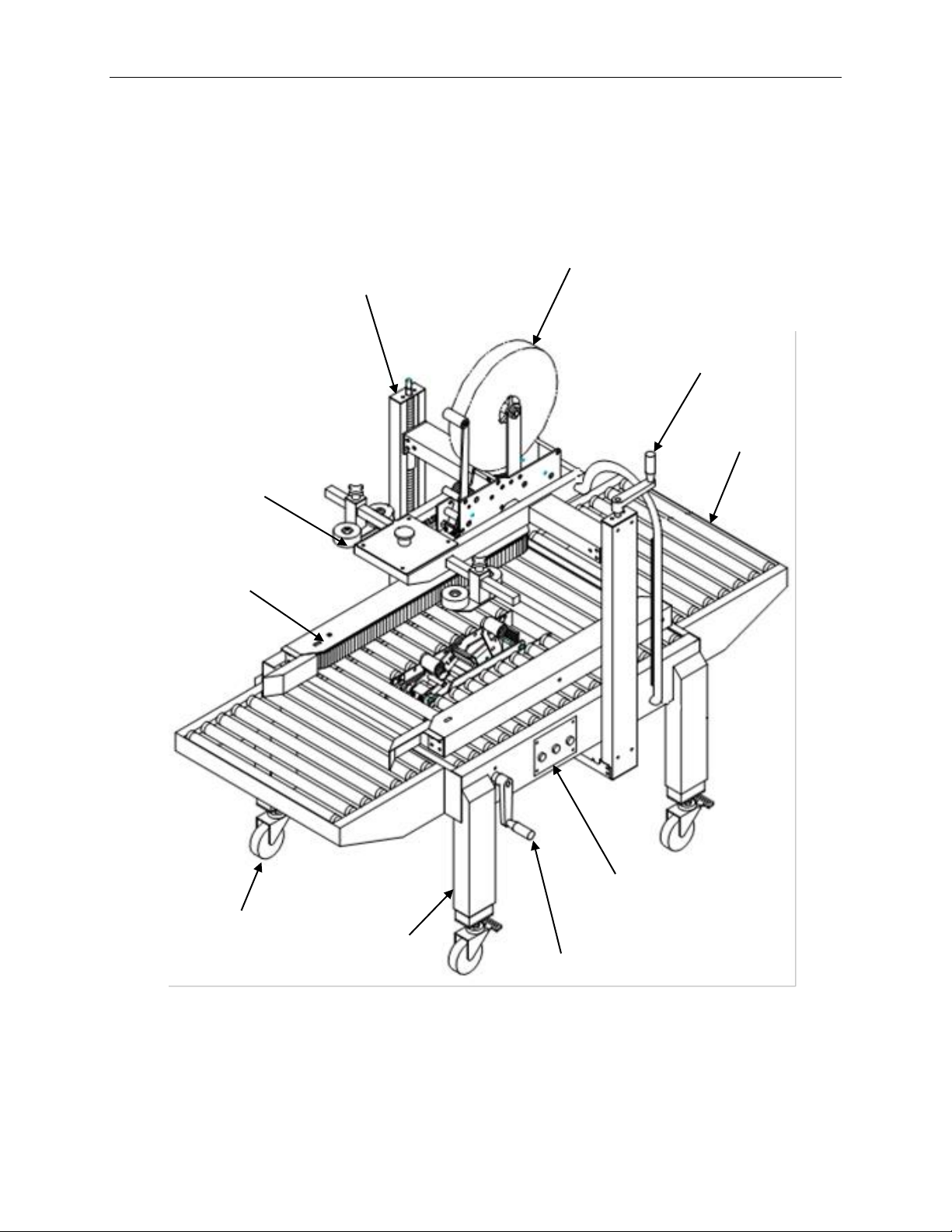

General System Description..........................................................................................8

Specifications................................................................................................................9

Options..........................................................................................................................9

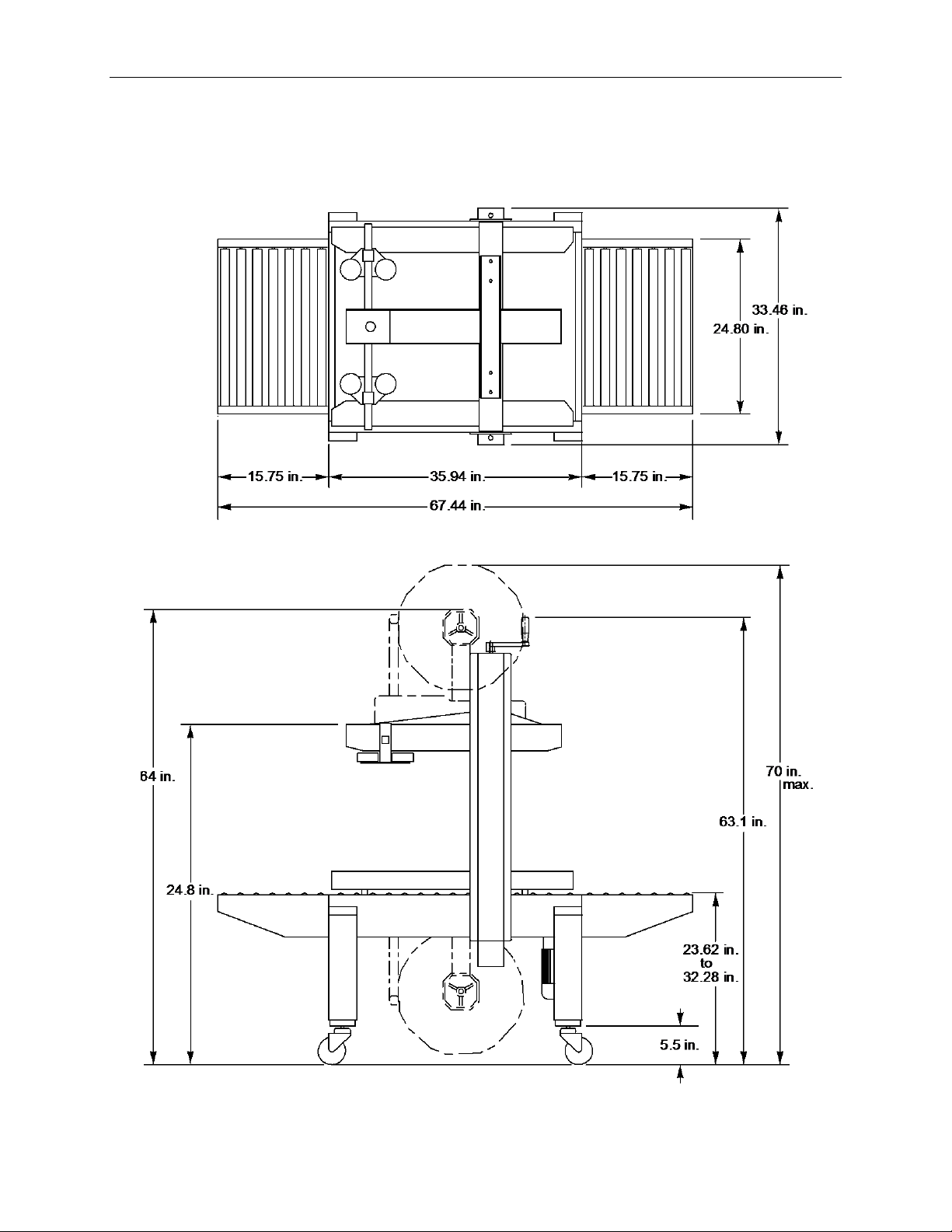

Dimensions .................................................................................................................10

Installation ...................................................................................................................11

Location Requirements ...............................................................................................12

Install Front and Rear Tables......................................................................................13

Next Steps...................................................................................................................13

Operation.....................................................................................................................15

Loading the Tape Cartridges.......................................................................................15

Check Tension............................................................................................................16

Thread Tape................................................................................................................16

Center Tape —Eastey-EX Tape Head only........................................................................18

Main Spring.................................................................................................................18

Power..........................................................................................................................19

Control Panel ..............................................................................................................19

Emergency Stop..........................................................................................................20

Adjustments ................................................................................................................21

Carton Height and Width Adjustments.........................................................................21

Belt Adjustment...........................................................................................................23

Machine Body Height Adjustment...............................................................................23

Maintenance ................................................................................................................25

Rollers.........................................................................................................................25

Cutting Knives.............................................................................................................25

Troubleshooting..........................................................................................................27

Parts List......................................................................................................................29

Electrical......................................................................................................................29

Side Belt Assembly.....................................................................................................33

Side Belt Assembly (Stainless) ...................................................................................36

Vertical Column...........................................................................................................38

Vertical Column (Stainless).........................................................................................41

Machine Body .............................................................................................................43

Machine Body (Stainless)............................................................................................45

Warranty Statement ....................................................................................................47

Customer Support.......................................................................................................49