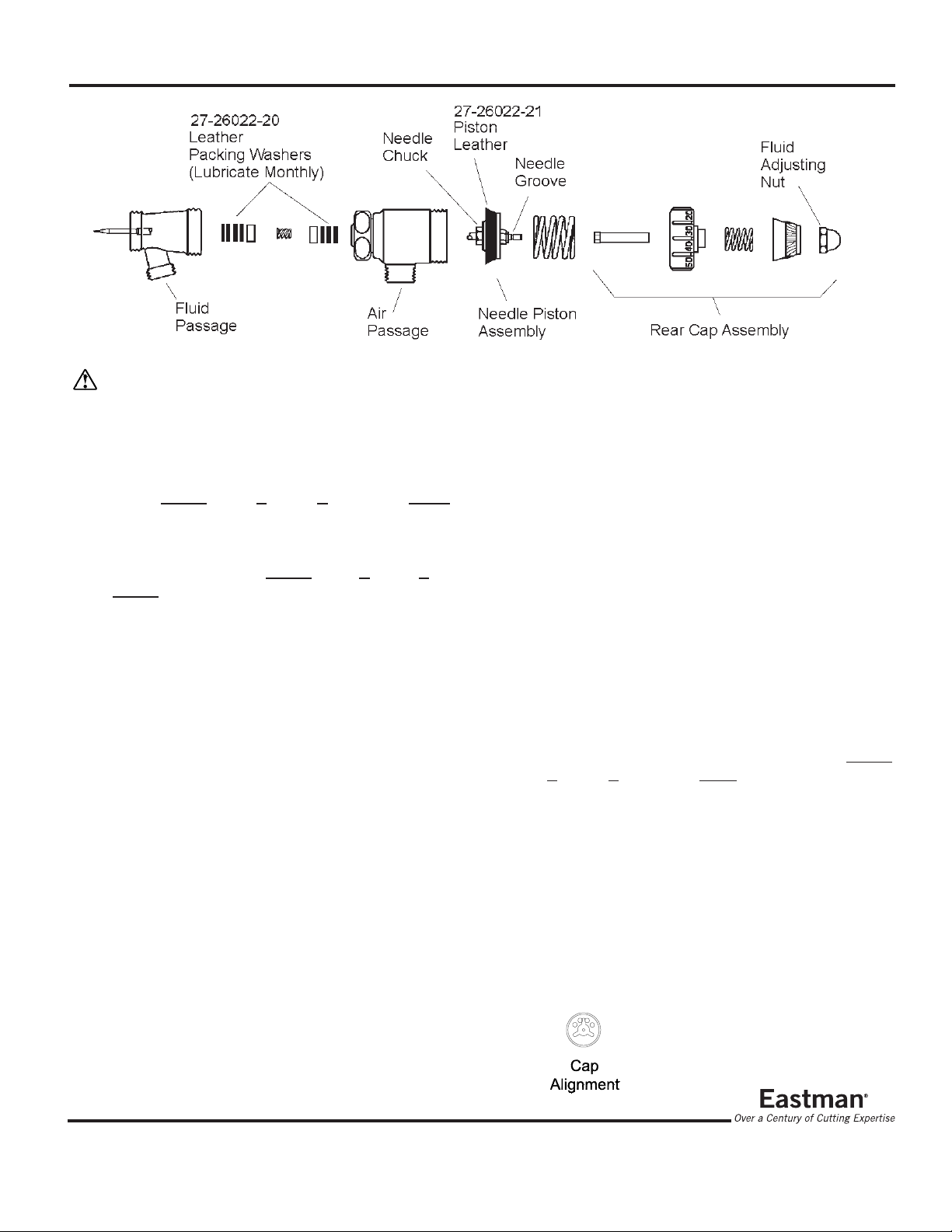

2FormE-522

TheAir Brush Marking System is designed to easily mark

parts during the cutting process to eliminate the time con-

suming step of marking parts before or after cutting. The

markingofpartscanbe usedforparts identification,sewing

lines,mating parts,companylogo's, instructions,etc.Mark-

ing inks are available in a wide variety of colors as perma-

nentandwashableinks.Ifthecoloryourequireisnotshown,

please consult factory.

IMPORTANT

Thepurchasermustinstructalloperatorsontheproperuse

of the equipment. All standard industrial safety measures

andequipment should be provided to protect the operator.

Operatorsmustbecautionedthatimproperorcarelessuse

of this equipment may cause personal injury. If you do not

have qualified operators to instruct new persons, contact

your Eastman sales representative or Eastman factory

direct.

Disconnectelectricalpowersourcebeforeproceedingwith

anyinstallation, adjustment or repair of the Eastman Auto-

mated Cutting System.

Installation

TheAirbrush MarkingSystemisdesign for quick and easy

installationwith optimal performance. Before you begin in-

stallation,please readtheinstructions carefully.Familiarize

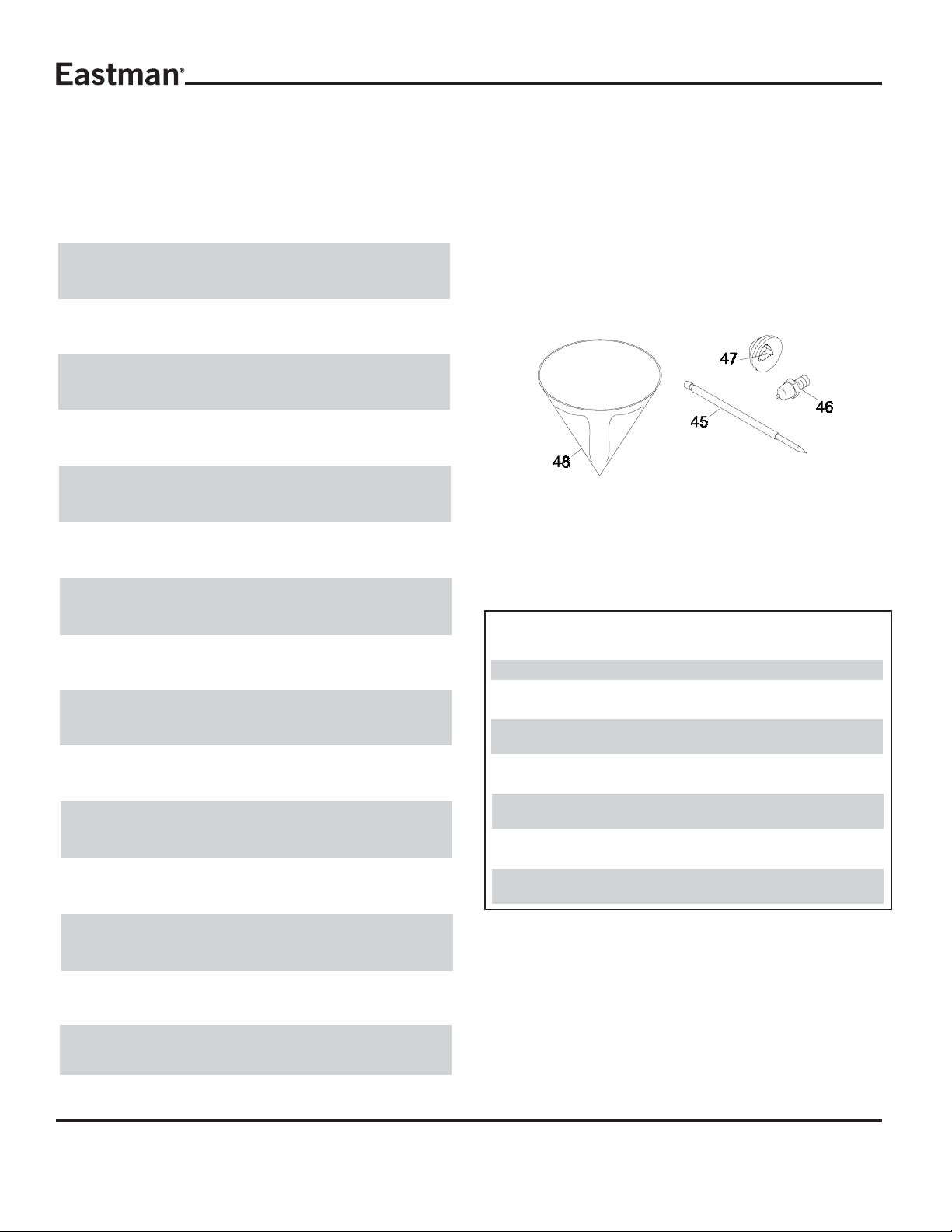

yourselfwithall the components required.

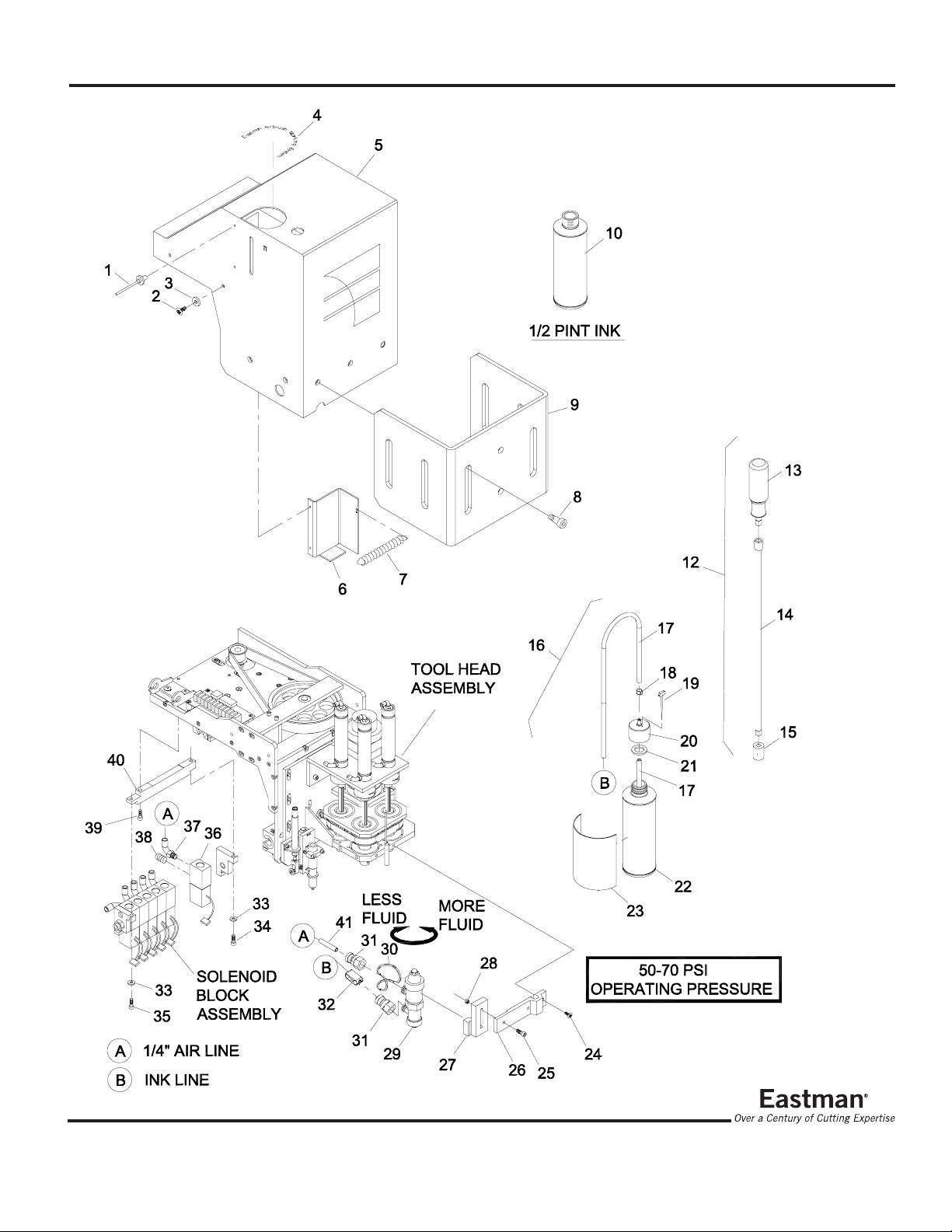

1)Disconnectthemainpowerandrelieve airpressure tothe

gantry.

2)Removethe gantrye-chaincoverandthe toolheadcover.

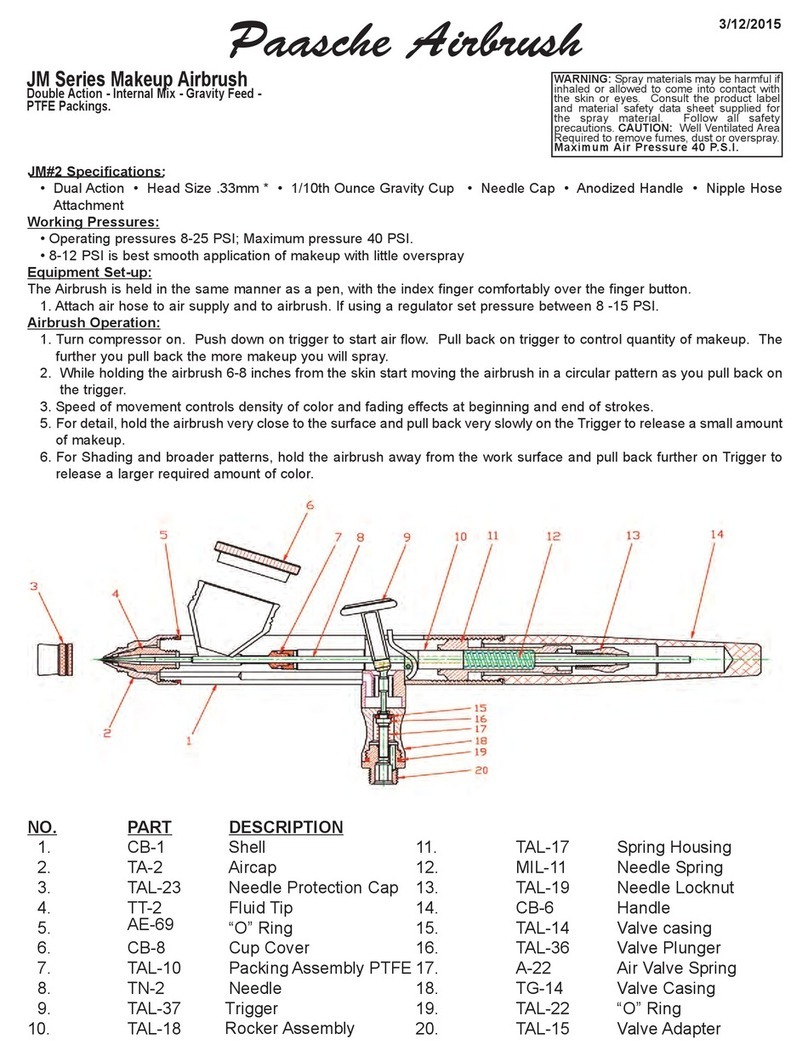

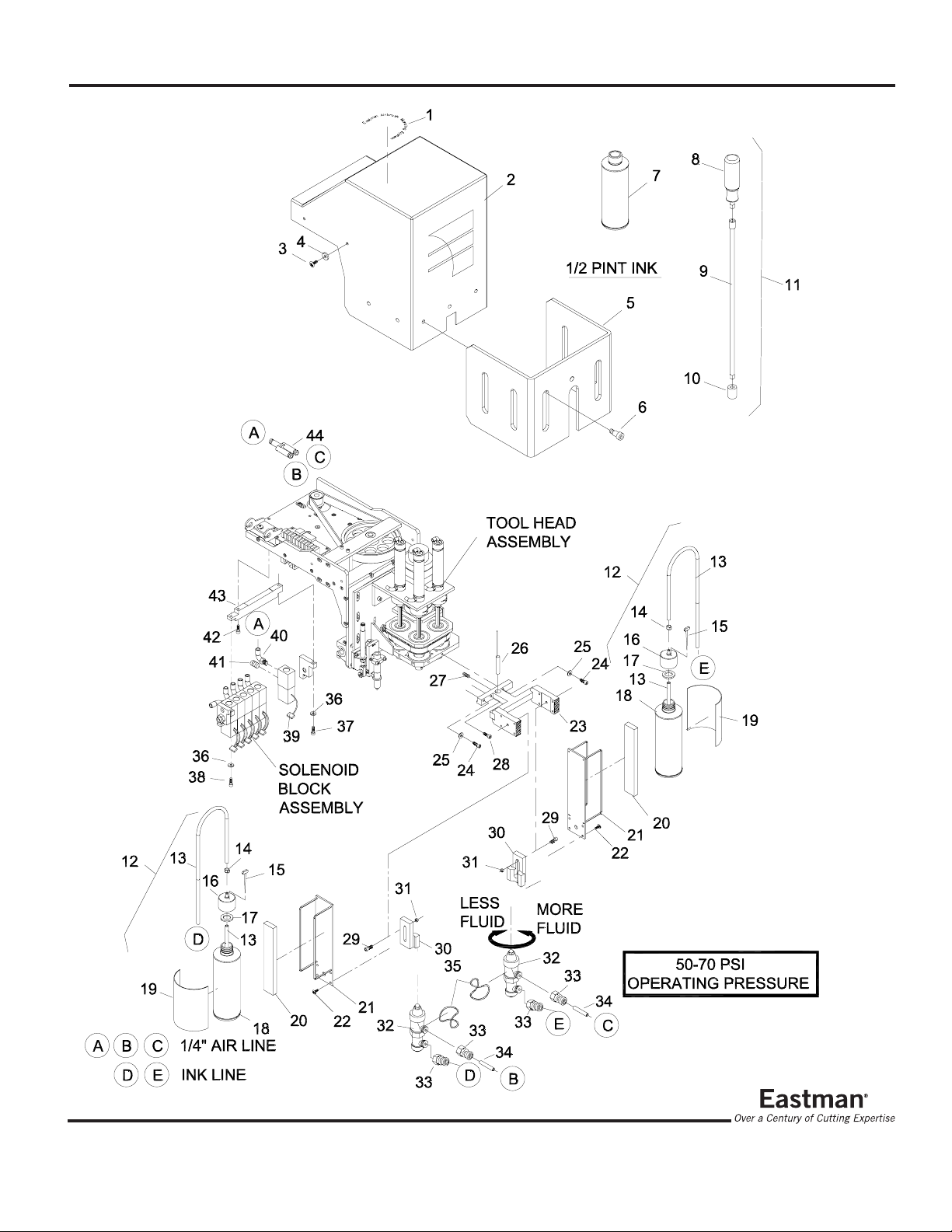

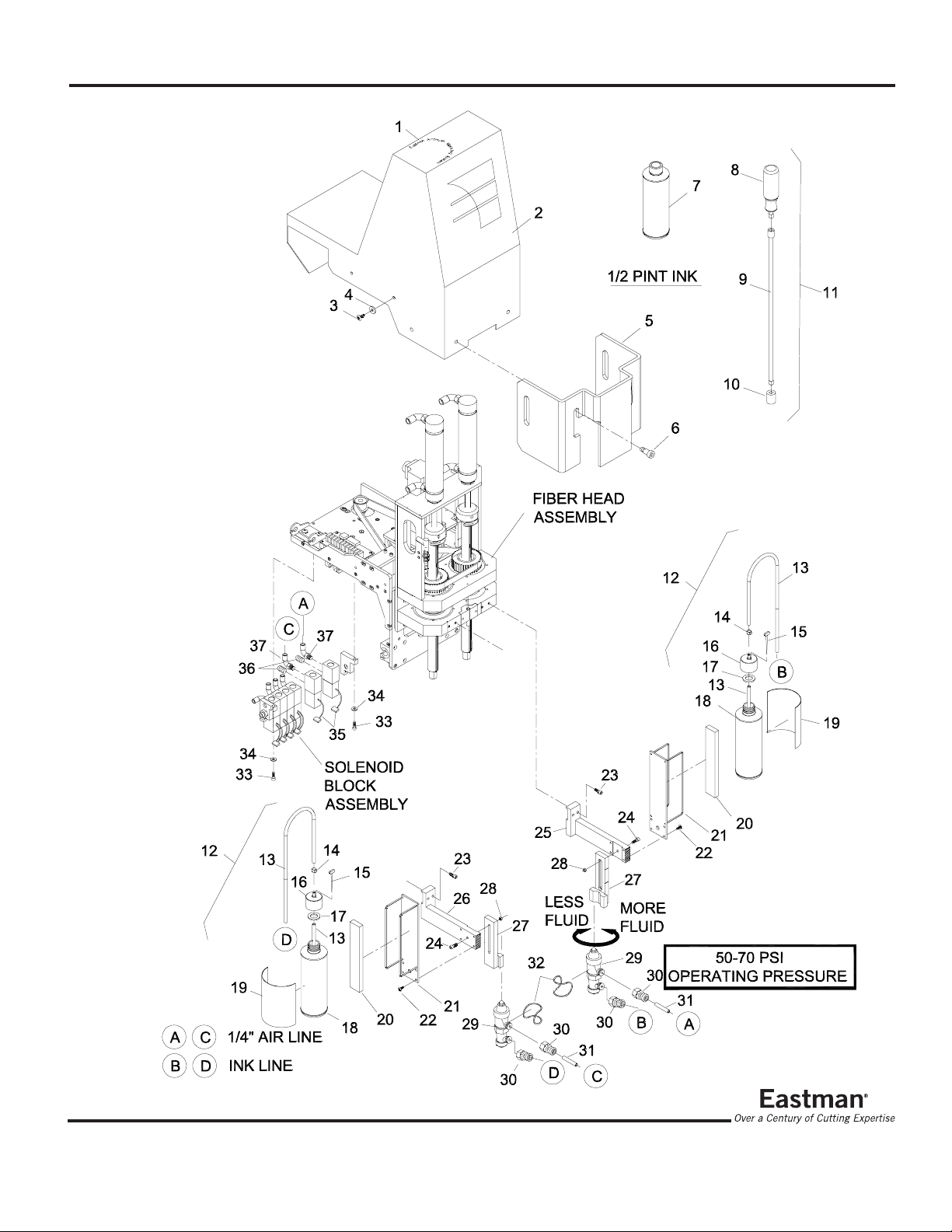

3) Remove and disassembly the solenoid block assembly

asshownonpage 5. Install the additional solenoid (#36)

with fittings. Mount the complete assembly using the

adapterbar.Connectsolenoidelectrical connector to the

matingconnectoronthe y-axis board (SOL4).

4)Removetheexistinglaserpointermountandreplacewith

the new air brush mounting base as shown on page 5.

5) Mount the new air brush stylus using the locking band.

6) Install air line and ink line as shown.

7) Remove the tool guard from the old toll head cover and

installonthenewtoolheadcover.

8) Install new tool head cover. The ink reservoir will slip in

under thetool head cover and intotheholder.

9)Yourairbrushmarkingsystemisnowreadyforoperation.

Operation

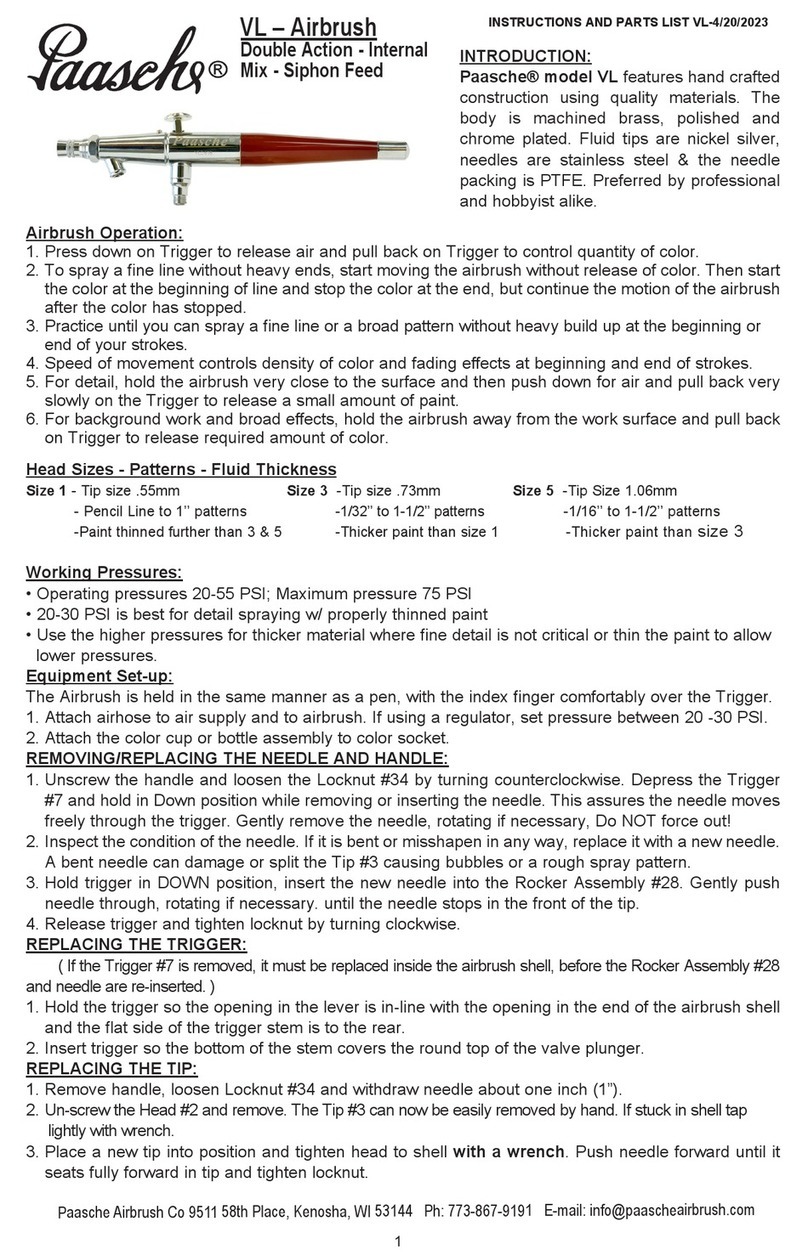

WARNING:Spraymaterialsmaybeharmfulifinhaledor

allowed to come into contact with the skin or eyes.

Consult the product label and Material Safety Data

Sheetsuppliedwiththespraymaterial.Followallsafety

precautions. Use in Well Ventilated Area to remove

fumes,dust orover spray.

M a x i m u m A i r P r e s s u r e 1 0 0 P . S . I .

Initial Setup

Set the tool head mount setting to STD 4 Tool.

REF: Log in to easicut to gain access to machine settings.

(User Name: Eastman Password: Eastman*tech).

Select: Options. Select: Machine... . Select: System.

Select Tool Head Type: STD 4TOOL. Select: OK.

SettheTool Mount 4 to down bit 8 (Mount 4 is the airbrush

mount).

REF: Log in to easicut to gain access to machine settings.

(User Name: Eastman Password: Eastman*tech).

Select: Options. Select: Machine... . Select: Tool

Mounts.SelectToolMount:Mount4. Enter8 forDown

Bit setting. Select: OK.

If required, set the offsets and time settings now.

Set theAir Brush tool pressure setting to 70.

REF: Select: Options. Select: Machine... . Select: Tools.

Select Tool: Airbrush. Select Tool Mount: Mount 4. Select

Tool Type: Draw_Tool. Enter 7 for Velocity and 70 for pres-

sure. Select: OK.

Machine Operation

TheAir BrushMarkingSystem isdesignedto operate inthe

same manner as any other tool on the tool head. Create a

file with the cut pattern and marking pattern on separate

layers. Set the marking layer tool mount by drag & drop to

the airbrush tool mount picture. This will set the tool mount

for the marking layer. Remove the air sealing pin from the

ink bottle top, this will help ink flow. The machine is ready

fornormaloperation.