2 February 1996 – 1C7836

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting from any use of

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

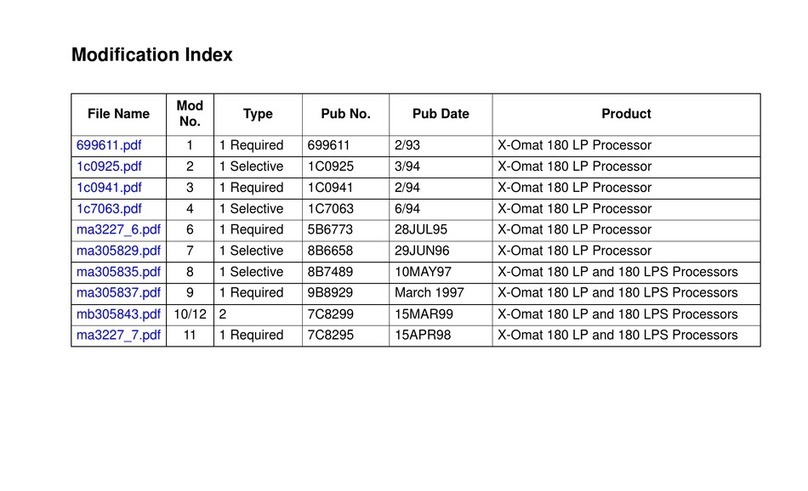

Description Page

Table of Contents

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preparing the PROCESSOR for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Special Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

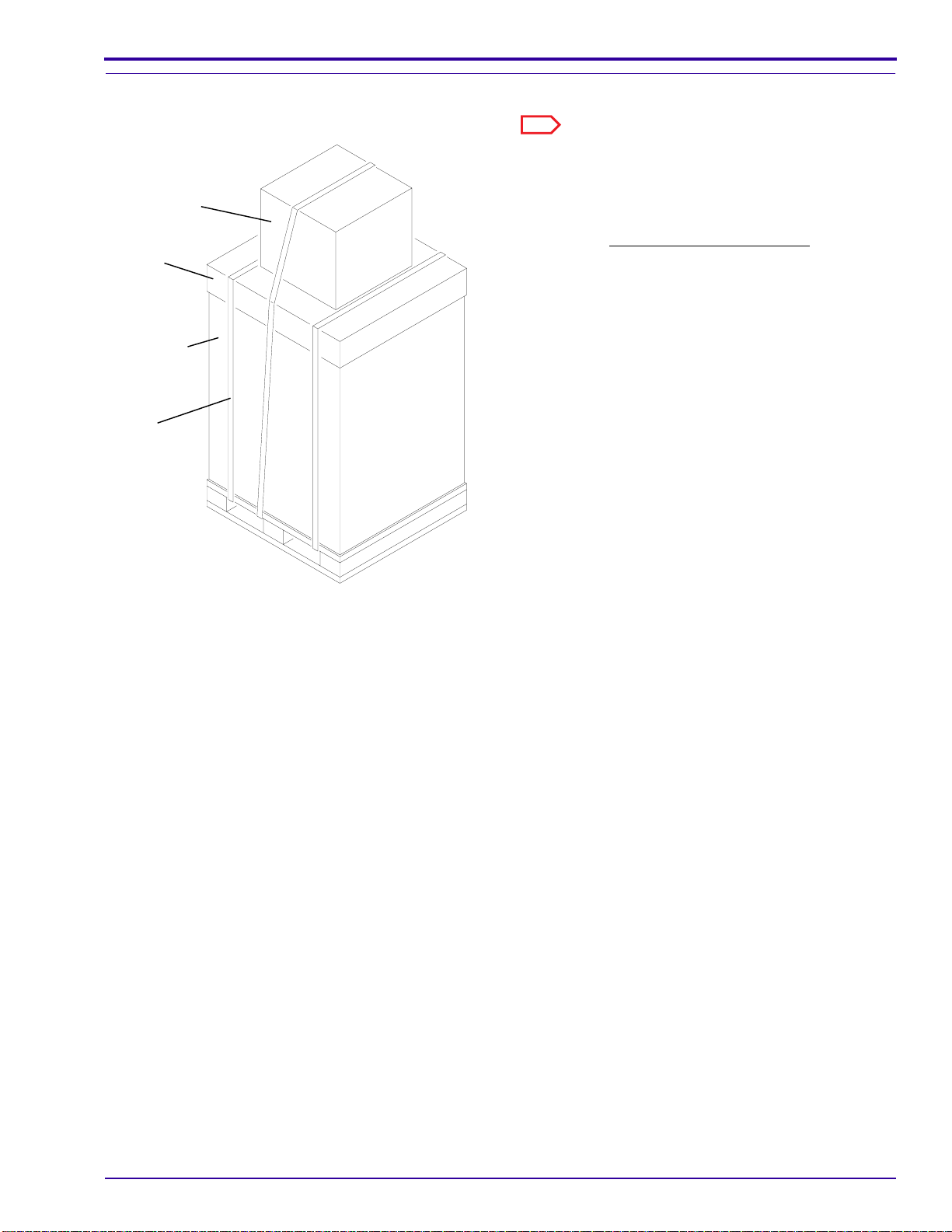

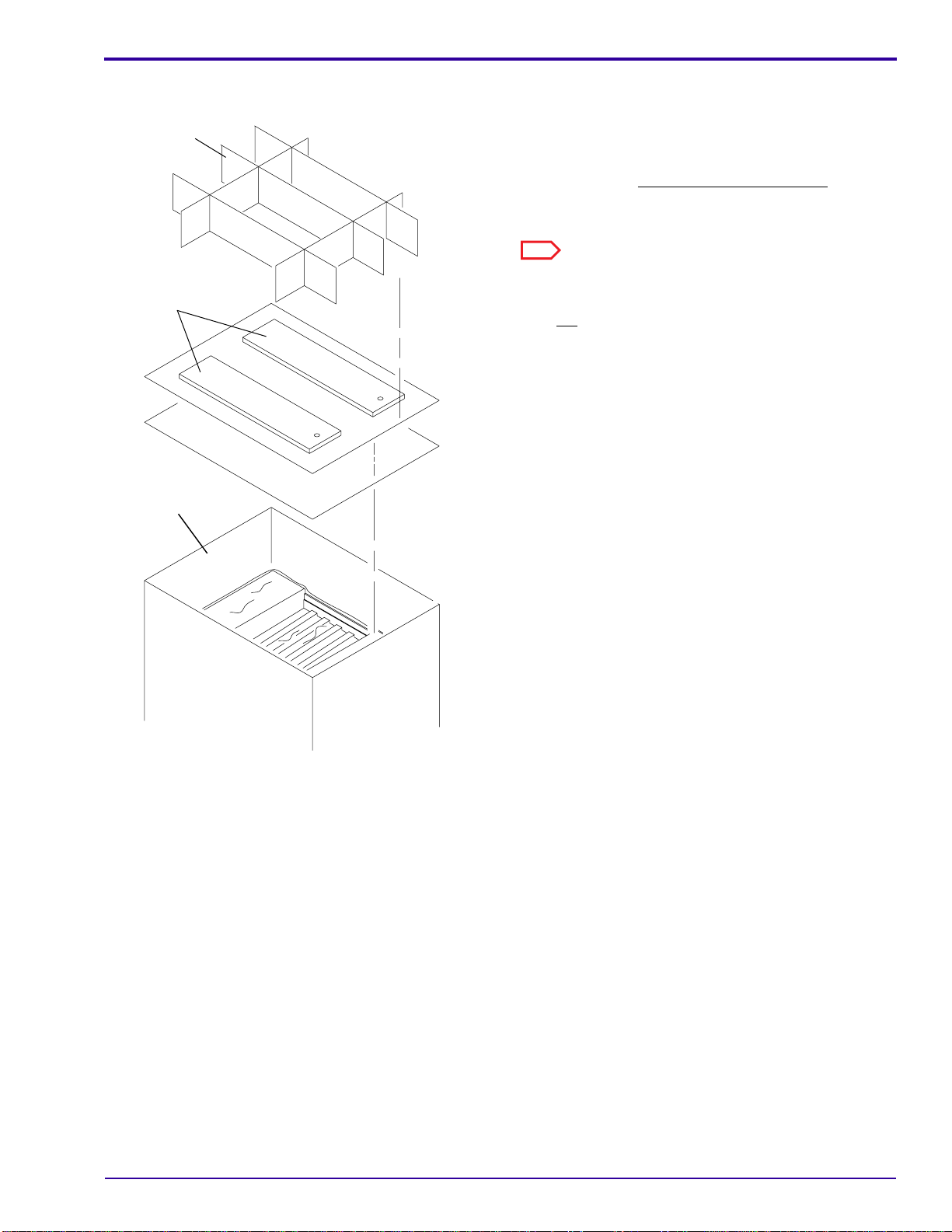

Unpacking the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

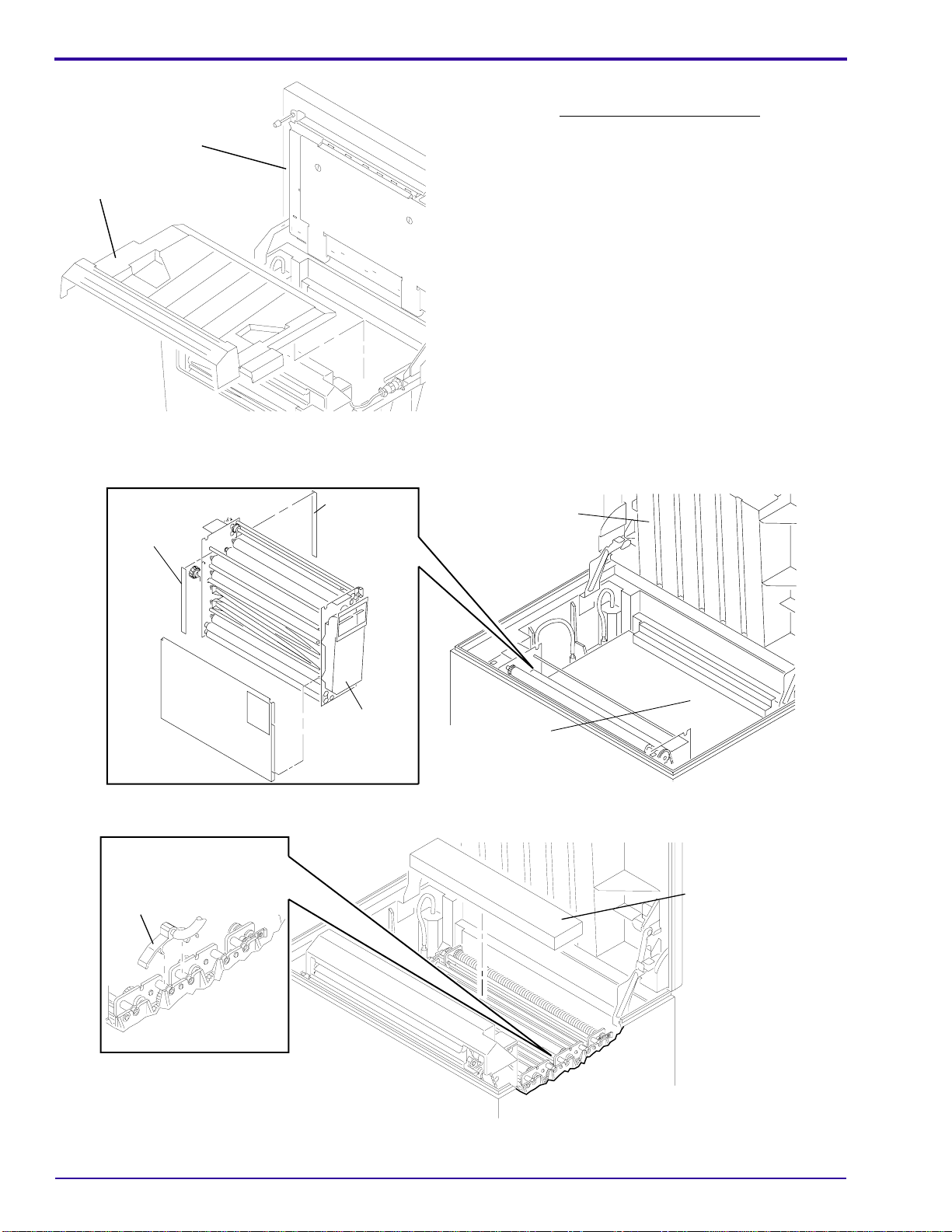

Checking the DRIVE SHAFT SPROCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the RACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Moving the PROCESSOR into Position and Leveling the PROCESSOR . . . . . 15

Measuring the Distance between the SORTER and the Processing TANK . . . 17

Connecting the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing the SEISMIC KIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Tightening the CLAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Making the Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting the Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting the Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting the REPLENISHER TANKS and STRAINERS . . . . . . . . . . . . . . . 30

Connecting the EXHAUST DUCT from the DRYER . . . . . . . . . . . . . . . . . . . . . 31

Installing the DEVELOPER FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Checking for Correct Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Checking the Components and SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Checking the SORTER, 180 LPS PROCESSOR Only . . . . . . . . . . . . . . . . . . . 35

Checking the Adjustment of the ACCESS DOOR LATCH on the SORTER . . . 38

Continuing to Check the Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Calibrating the Replenishment System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41