BOSS Products limited consumer warranty and BOSS

Products commercial warranty policies are located at

www .bossplow .com .

Patent www .ttcopats.com .

Introduction

This spreader is intended to be used by professional,

hired operators. It is designed to dispense ice-control

solutions on residential or commercial properties.

Using this product for purposes other than its intended

use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate

and maintain your product properly and to avoid

injury and product damage. Y ou are responsible for

operating the product properly and safely .

V isit www .bossplow .com for product safety and

operation training materials, accessory information,

help nding a dealer , or to register your product.

Whenever you need service, genuine BOSS parts, or

additional information, contact an Authorized BOSS

Dealer or BOSS T echnical Service ( 1-800-286-4155 )

and have the model and serial numbers of your

product ready . Figure 1 identies the location of the

model and serial numbers on the product. W rite the

numbers in the space provided.

g382865

Figure 1

1. Serial number location

Model No.

Serial No.

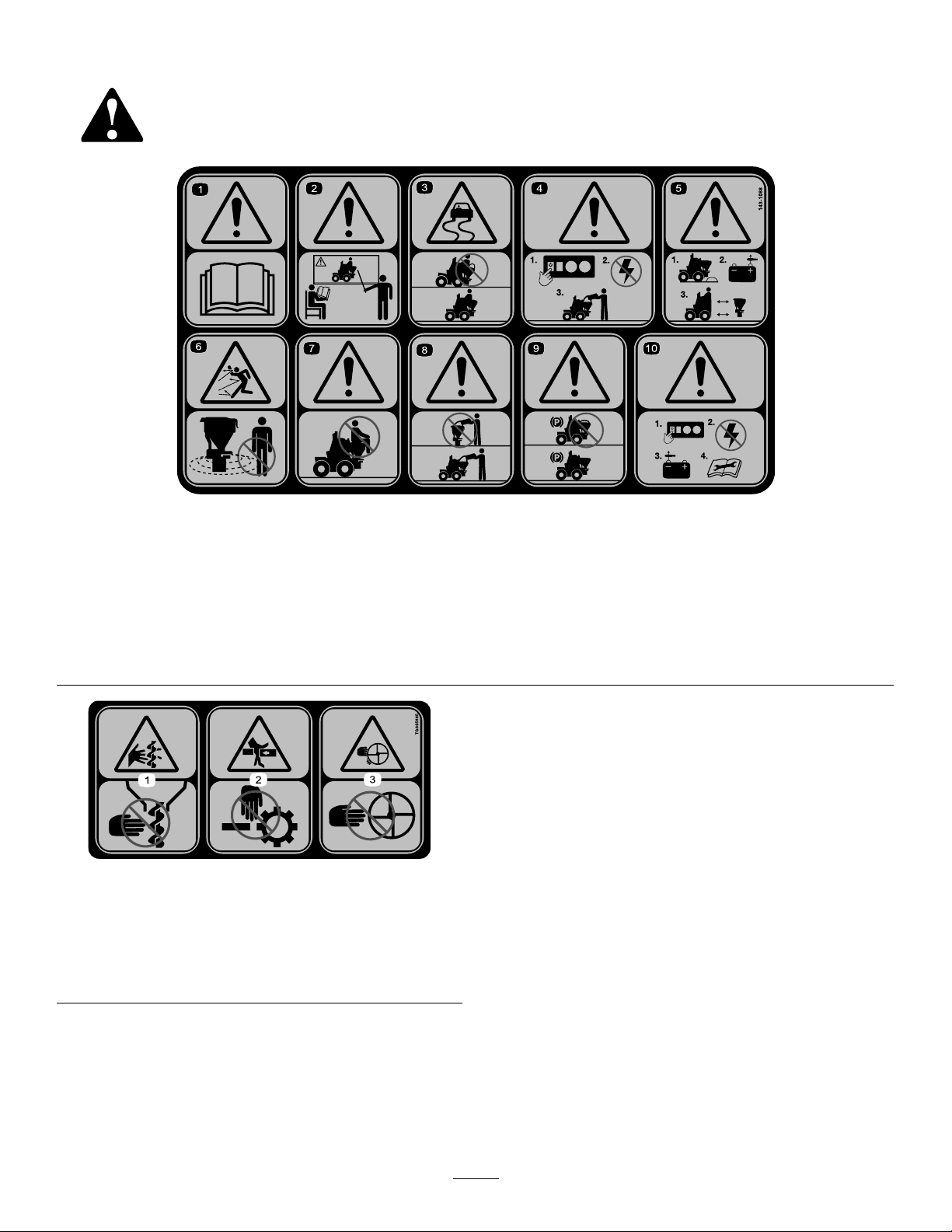

The safety-alert symbol shown in this manual and on

the machine identies important safety messages that

you must follow to prevent accidents.

g000502

Figure 2

Safety-alert symbol

The safety-alert symbol appears above information

that alerts you to unsafe actions or situations and

is followed by the word DANGER ,W ARNING , or

CAUTION .

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury .

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury .

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury .

This manual uses 2 words to highlight information.

Important calls attention to special mechanical

information and Note emphasizes general information

worthy of special attention.

Contents

Safety ....................................................................... 3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety and Instructional Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setup ........................................................................ 5

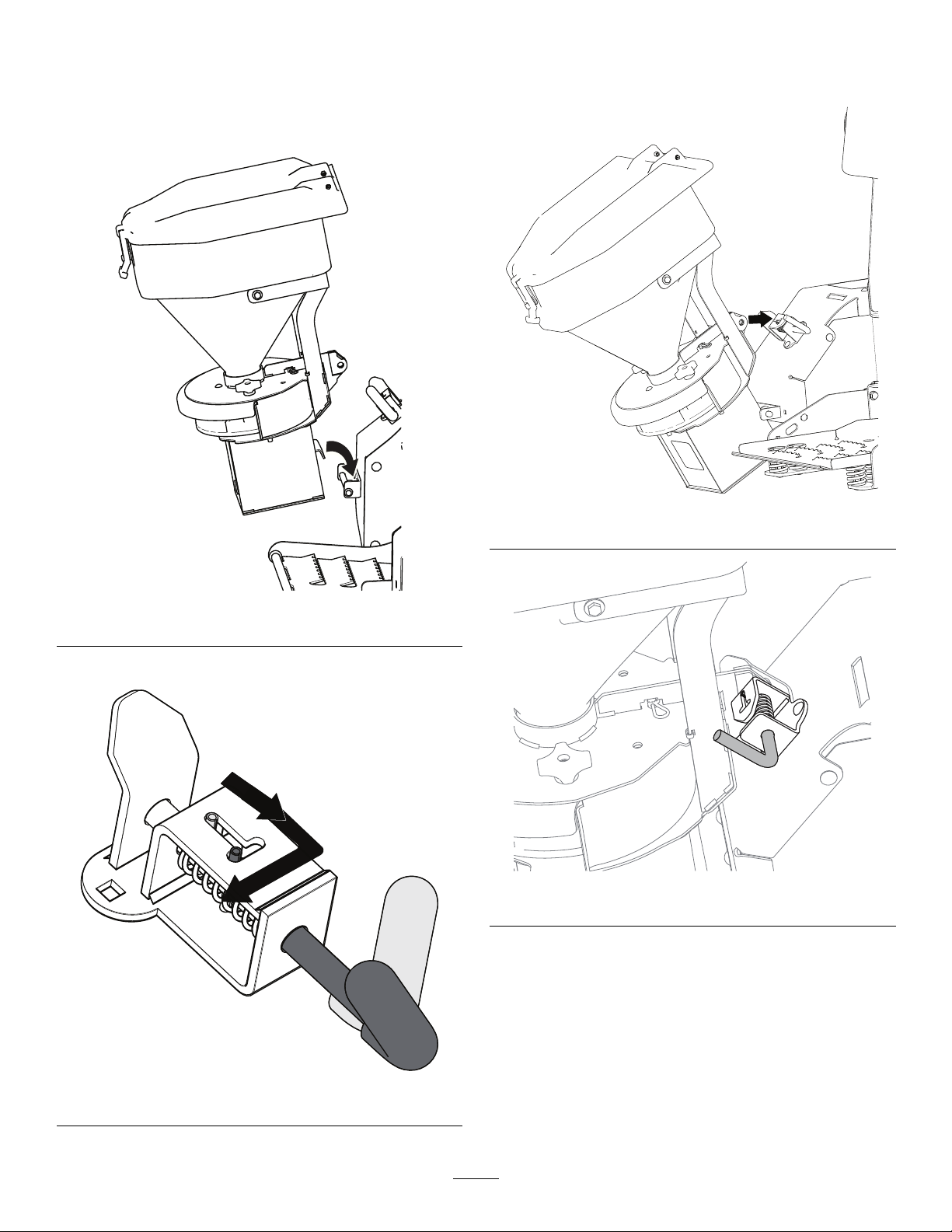

Installing the Mounting Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Drilling Mounting Holes on the Fender . . . . . . . . . . . . . . . . 6

Installing the Spreader on the Mounting

Plates .............................................................. 7

Installing the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Routing the Wire Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

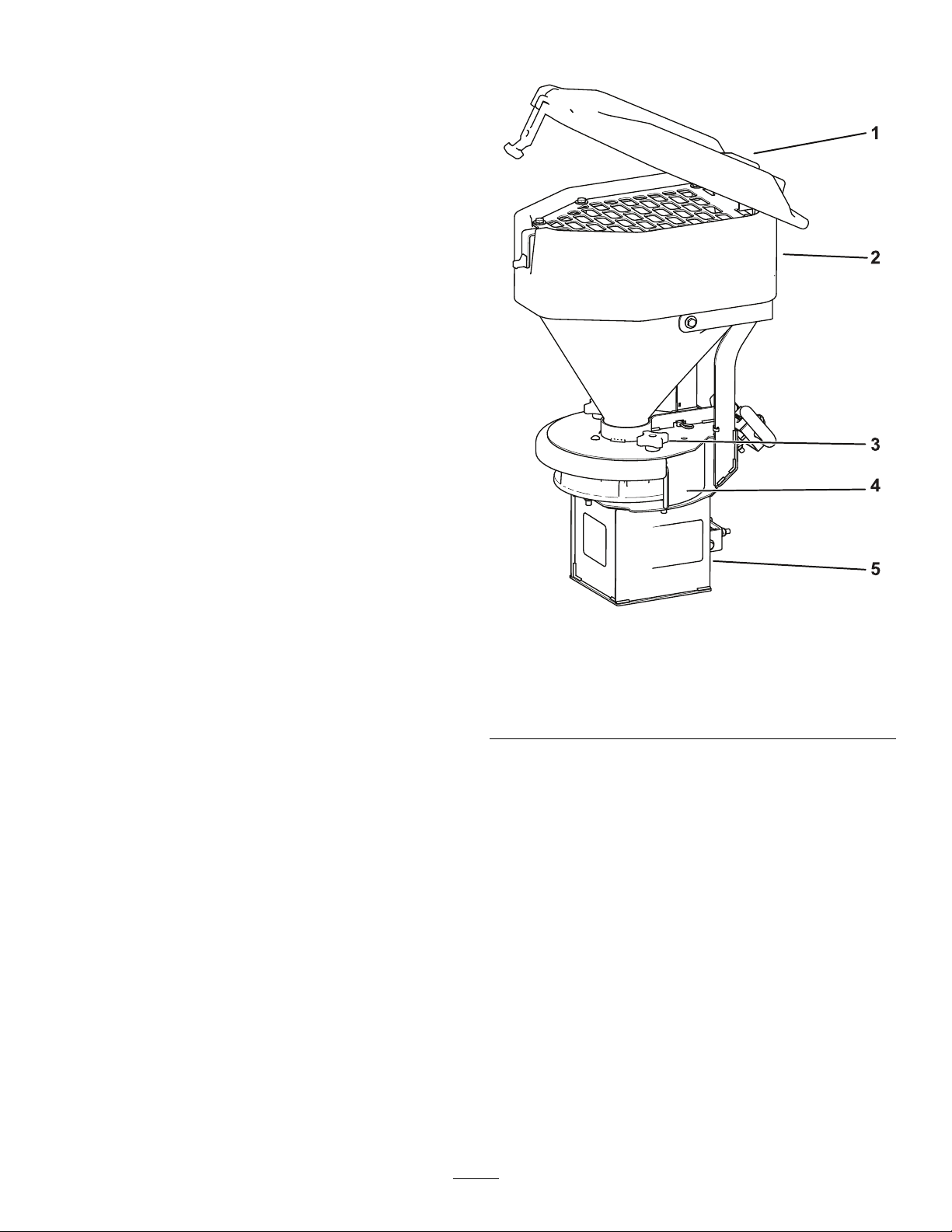

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Removing the Spreader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Loading the Spreader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating the Spreader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Freeing a Clog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Adjusting the Material Deectors . . . . . . . . . . . . . . . . . . . . . . 12

Unloading the Spreader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning the Spreader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

T roubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

© 2023—BOSS Products

2010 The BOSS W ay

Iron Mountain, MI 49801

2

Contact us at www .bossplow .com.

Printed in the USA

All Rights Reserved