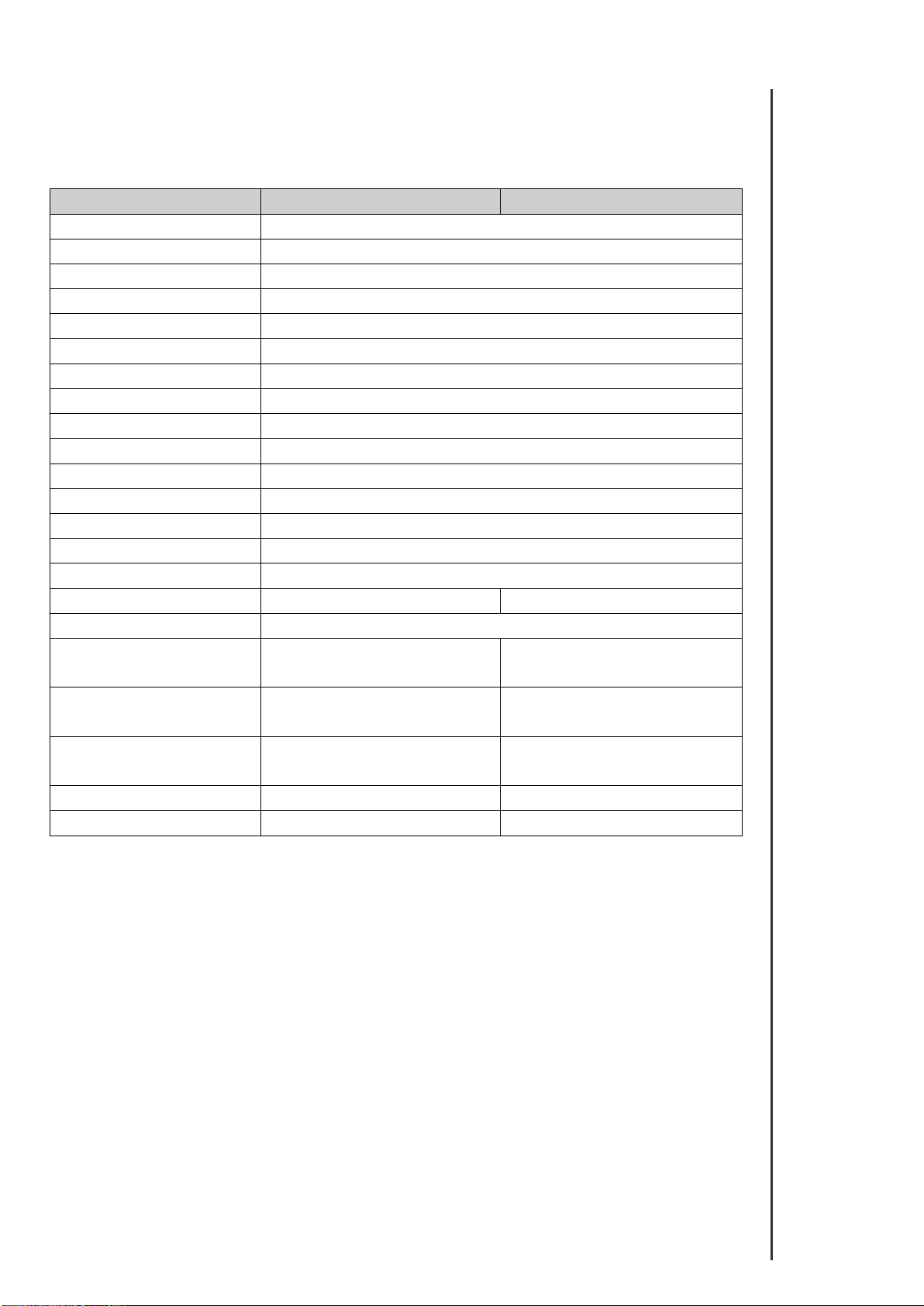

Content

1. Information..............................................................................................................................................1

2. Safety Instruction.....................................................................................................................................2

2.1 Safety parts...............................................................................................................................................2

2.2 Warning Sign ............................................................................................................................................2

2.3 Safety Tips ................................................................................................................................................3

3. Specifications...........................................................................................................................................5

3.1 Specifications of the Machine..................................................................................................................5

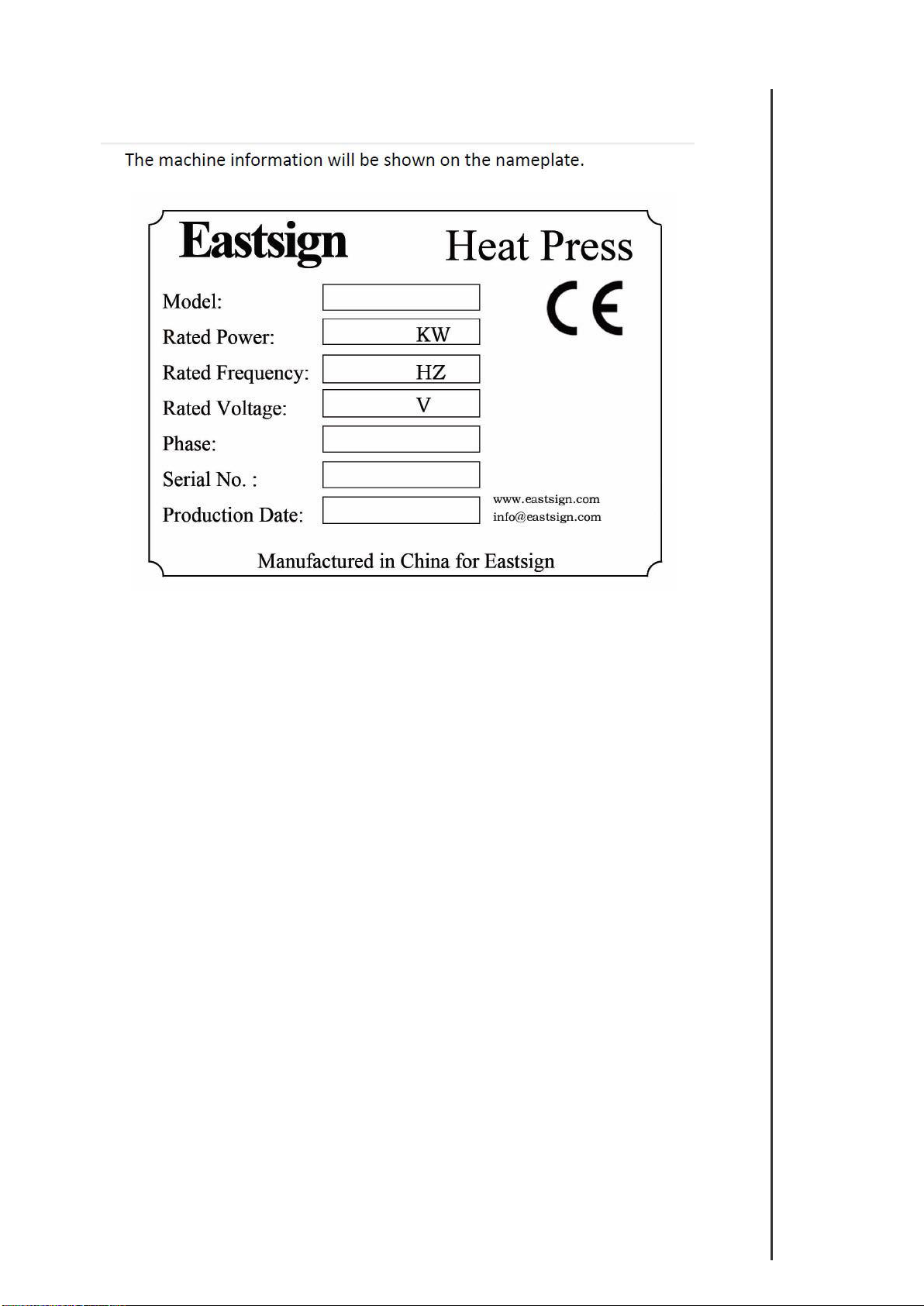

3.2 Nameplate................................................................................................................................................6

4. Structure..................................................................................................................................................7

4.1 Explanation of appearance and all parts..................................................................................................7

4.2 Configuration of left cabinet ....................................................................................................................8

4.3 Configuration of right cabinet ..................................................................................................................8

5. Installation...............................................................................................................................................9

5.1 Unpacking.................................................................................................................................................9

5.2 Installation of worktable ..........................................................................................................................9

5.3 Notice.....................................................................................................................................................10

6. Operation Guide .................................................................................................................................... 11

7. Notice for operation............................................................................................................................... 12

7.1 Pre-shrink on blanket .............................................................................................................................12

7.2 Accomplish the procedure of pre-shrink on blanket based on following data sheet:............................12

7.3 Horizontal adjustment............................................................................................................................13

7.4 Heating system.......................................................................................................................................14

8. Processes Diagram .................................................................................................................................15

9. Trouble Shooting....................................................................................................................................16

Warranty ...................................................................................................................................................17

Limitation of liability.................................................................................................................................. 18

Contact us.................................................................................................................................................. 19