EasyPro PA34 Owner's manual

Other EasyPro Pond Pump manuals

EasyPro

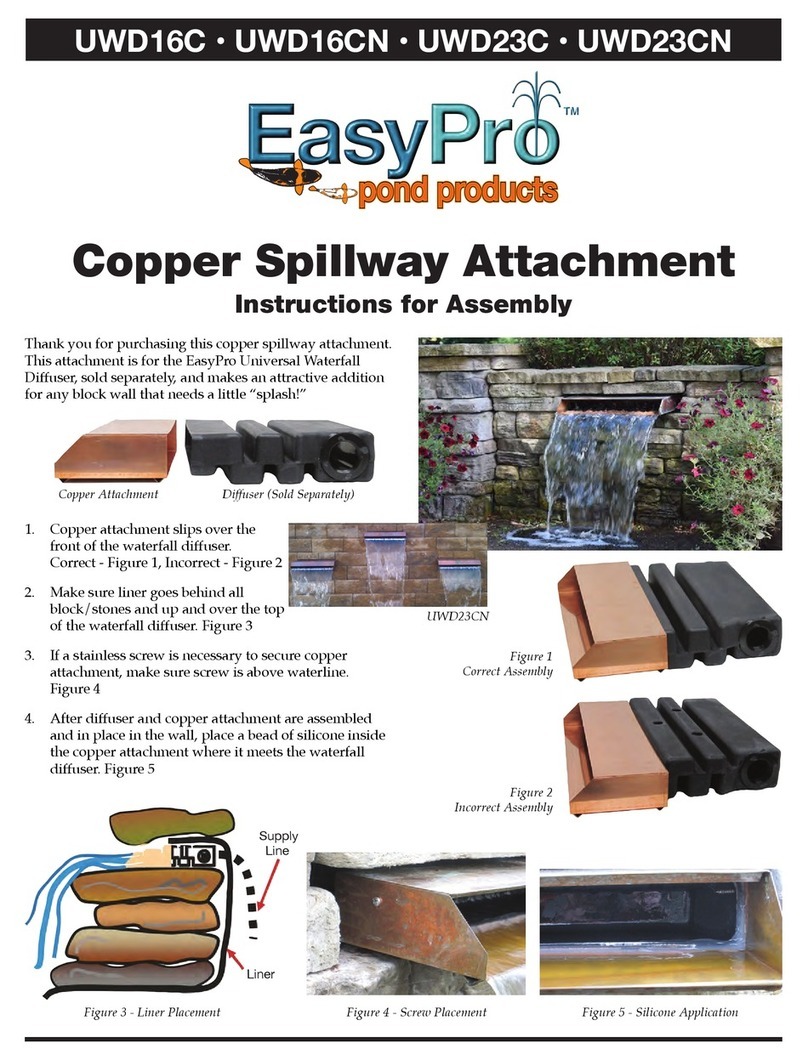

EasyPro UWD16C Assembly instructions

EasyPro

EasyPro Mag Drive Use and care manual

EasyPro

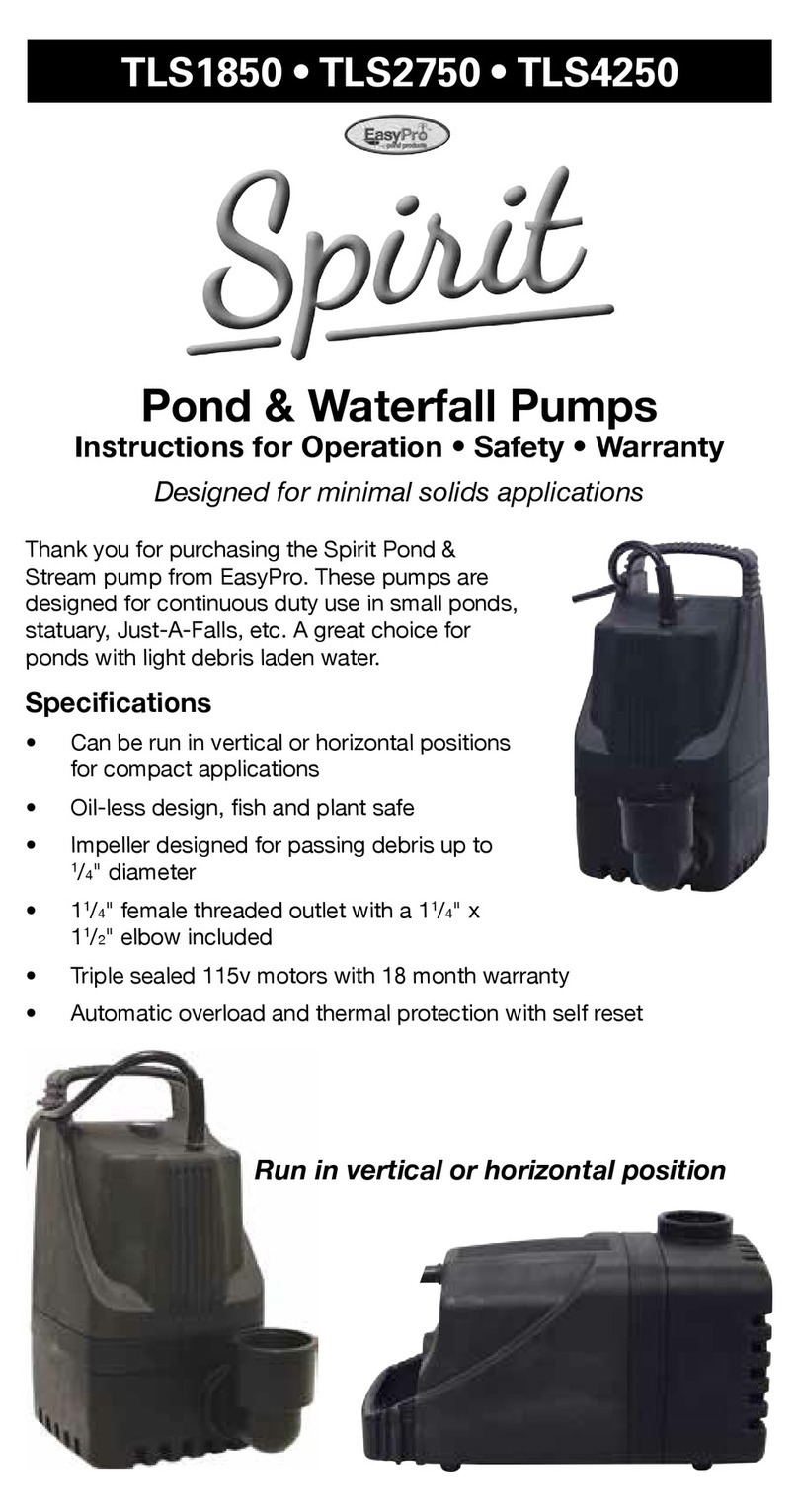

EasyPro Spirit TLS1850 Operation and maintenance manual

EasyPro

EasyPro ETP05 Use and care manual

EasyPro

EasyPro Rocking Piston PA86A Owner's manual

EasyPro

EasyPro LA5N Use and care manual

EasyPro

EasyPro TH Series Use and care manual

EasyPro

EasyPro Eco-Clear EPS1300 Use and care manual

EasyPro

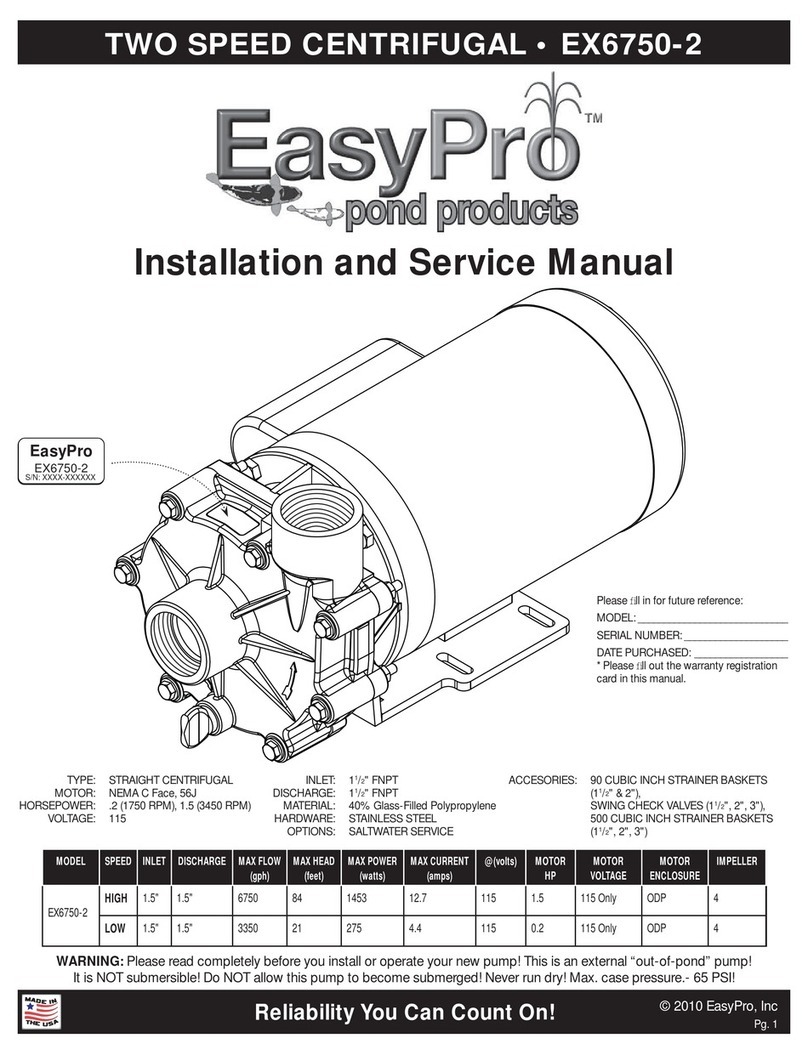

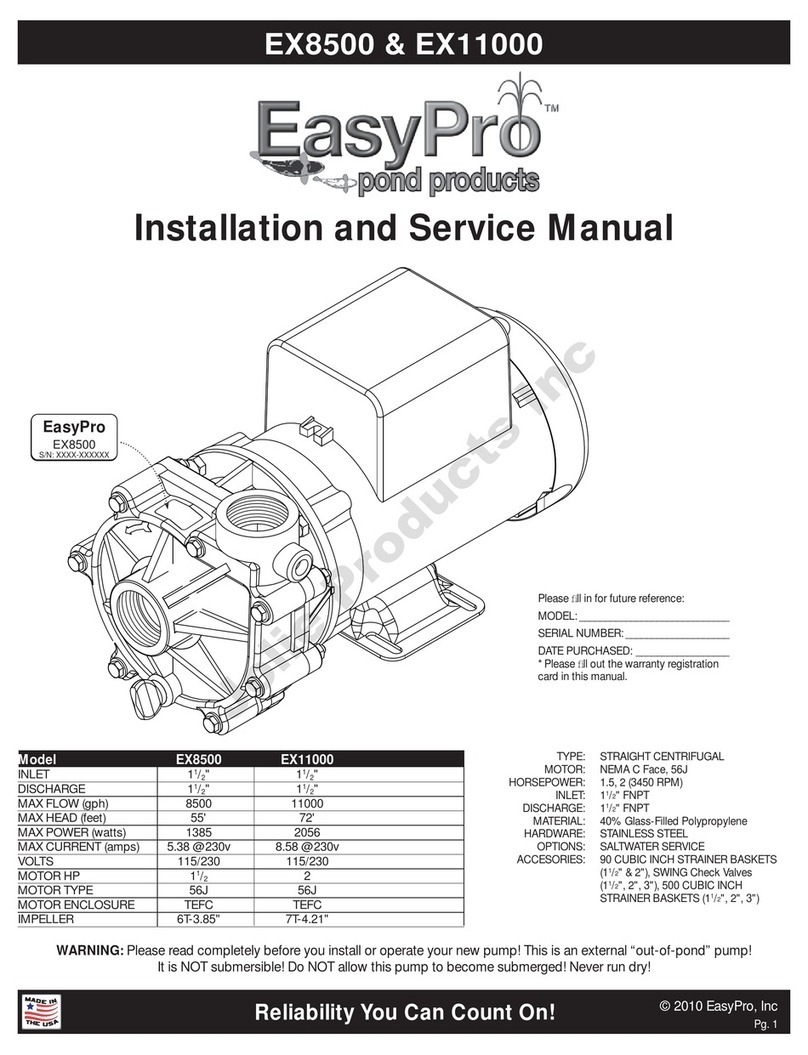

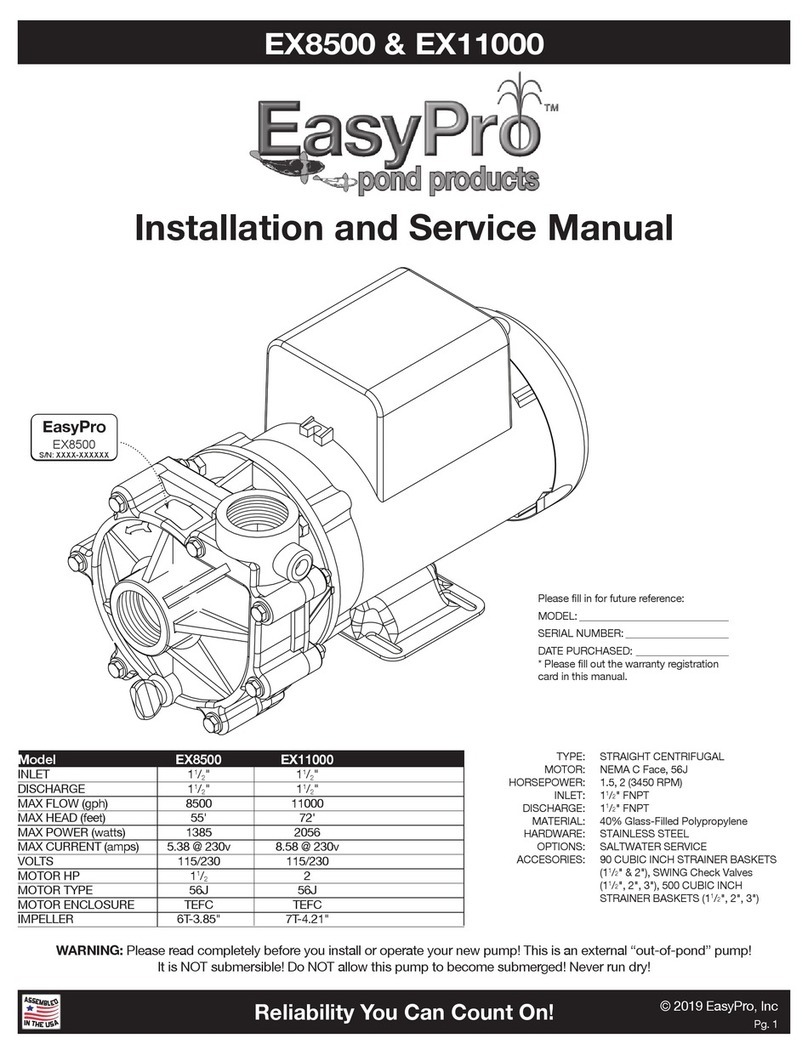

EasyPro EX8500 Manual

EasyPro

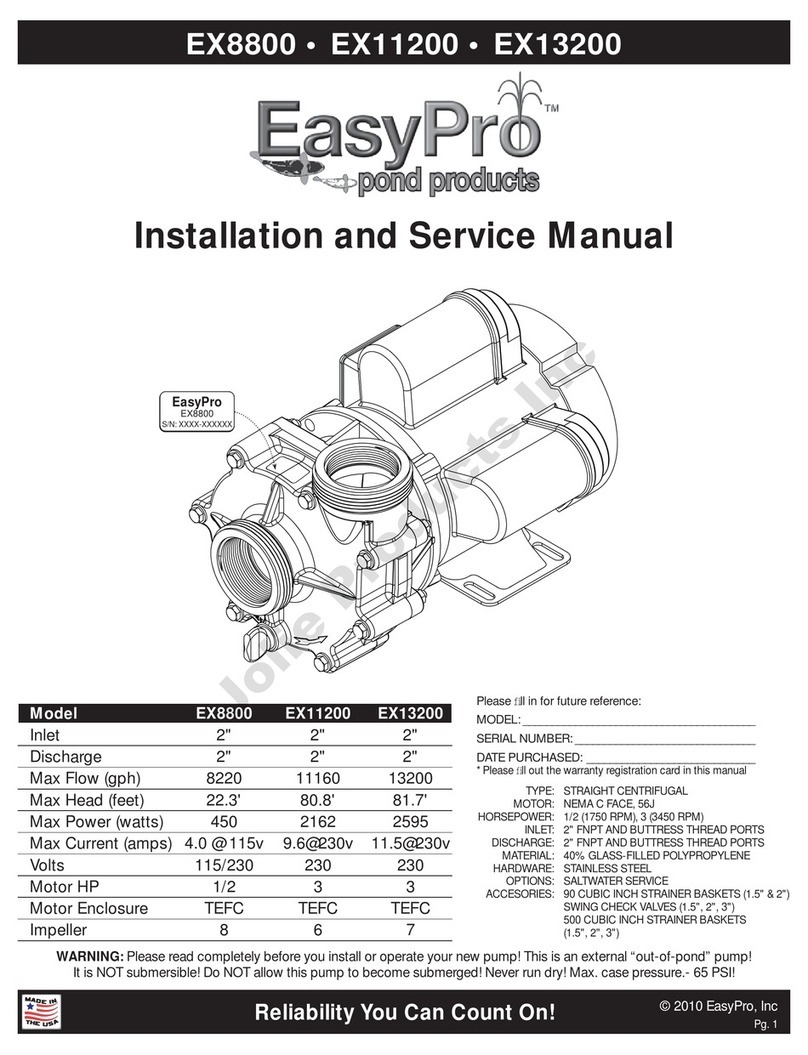

EasyPro EX8800 Manual

Popular Pond Pump manuals by other brands

Oase

Oase PondJet Eco operating instructions

Profi-pumpe

Profi-pumpe Rügen operating instructions

HEISSNER

HEISSNER F540-00 Instructions for use

1A Profi Handels

1A Profi Handels OASIS 501R-1 operating instructions

Biotop Garden

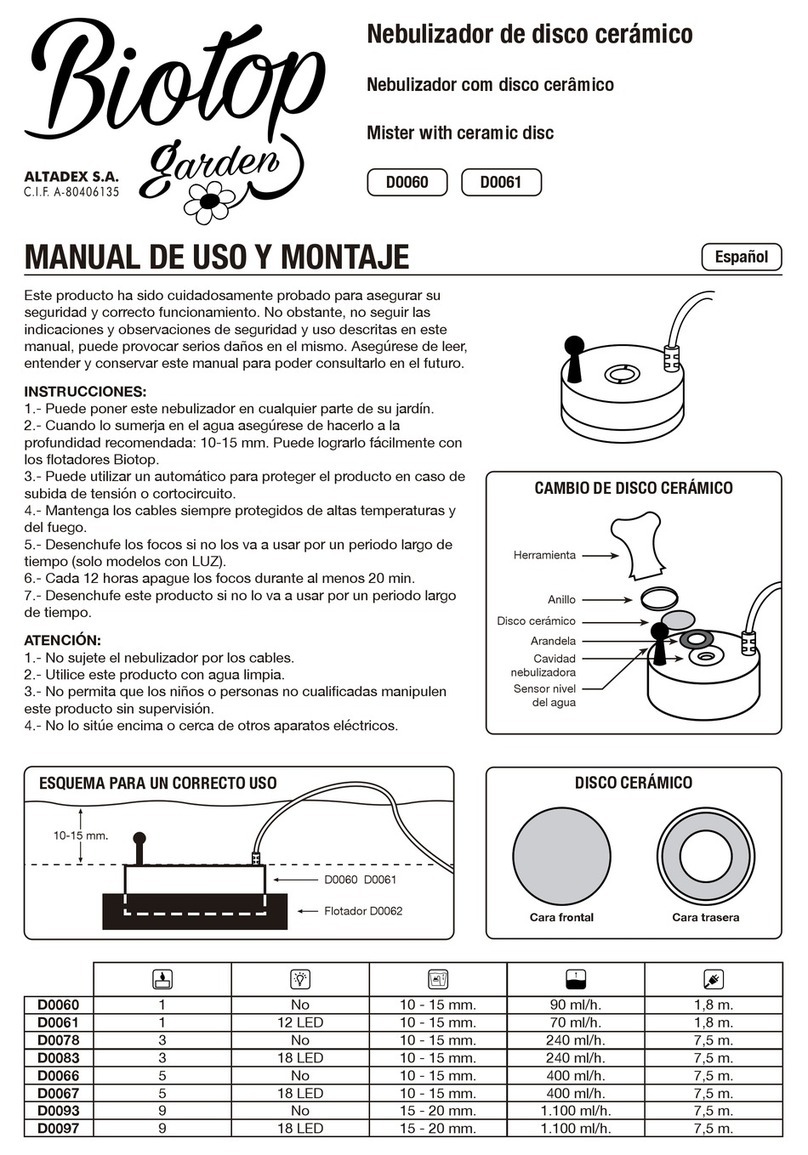

Biotop Garden D0060 User instructions

Profi-pumpe

Profi-pumpe JR-800LV operating instructions

TeichTip

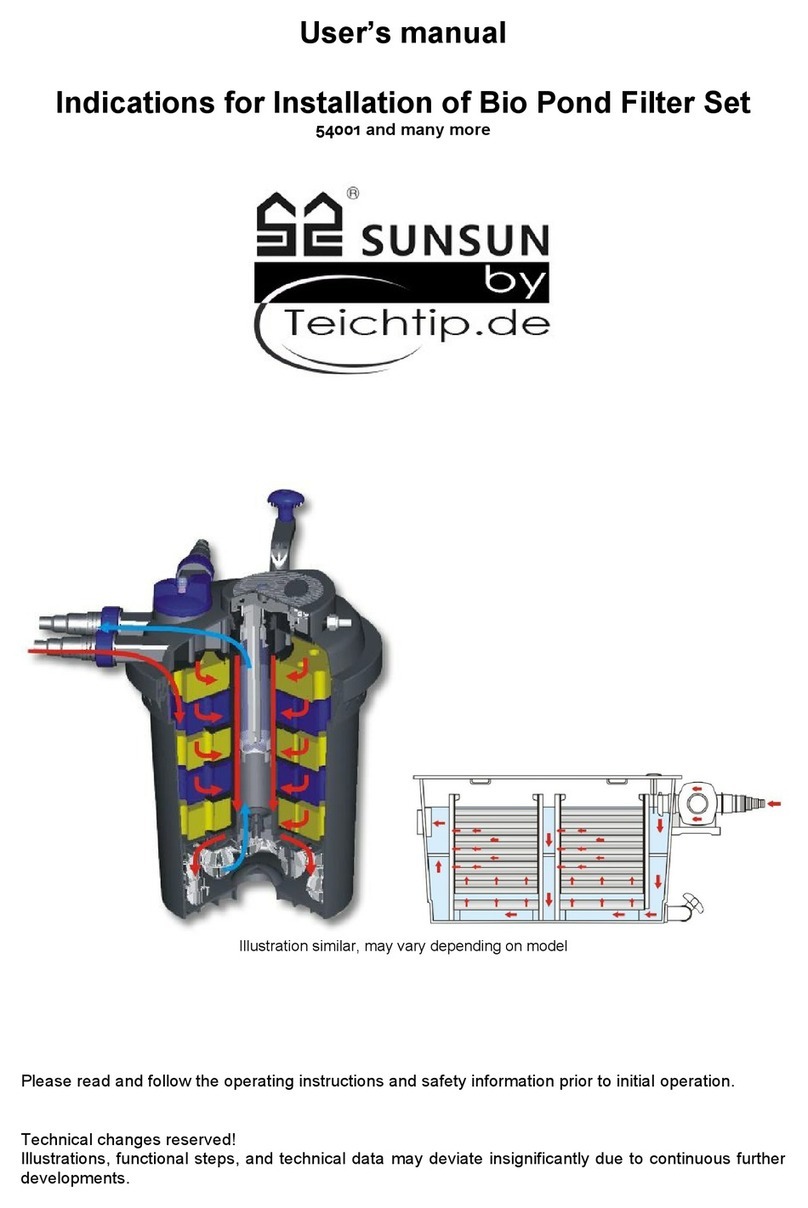

TeichTip Sunsun Bio Pond Filter Set user manual

Hozelock Cyprio

Hozelock Cyprio Cascade 5500 Installation and operating instructions

Hozelock Cyprio

Hozelock Cyprio Aquaforce Series Installation and operating instructions

HEISSNER

HEISSNER SPF 150-00 manual

AquaScape

AquaScape AQUAFORCE 4000-8000 Instructions & maintenance

Messner

Messner system-X 1501 operating instructions