Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton.com

© 2020 Eaton

All Rights Reserved

Printed in USA

Publication No. IL053007EN / Z24464

October 2020

Eaton is a registered trademark.

All other trademarks are property

of their respective owners.

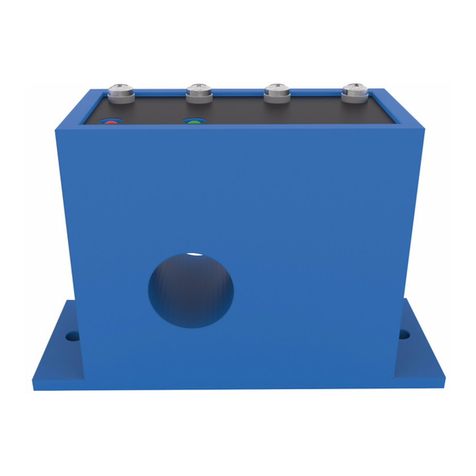

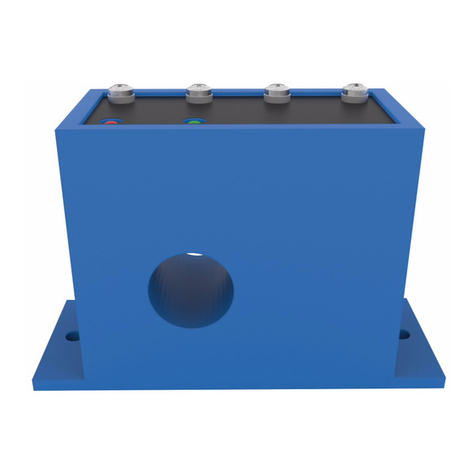

E56 High Noise Immunity

inductive proximity sensor

Instruction Leaet IL053007EN

Effective October 2020

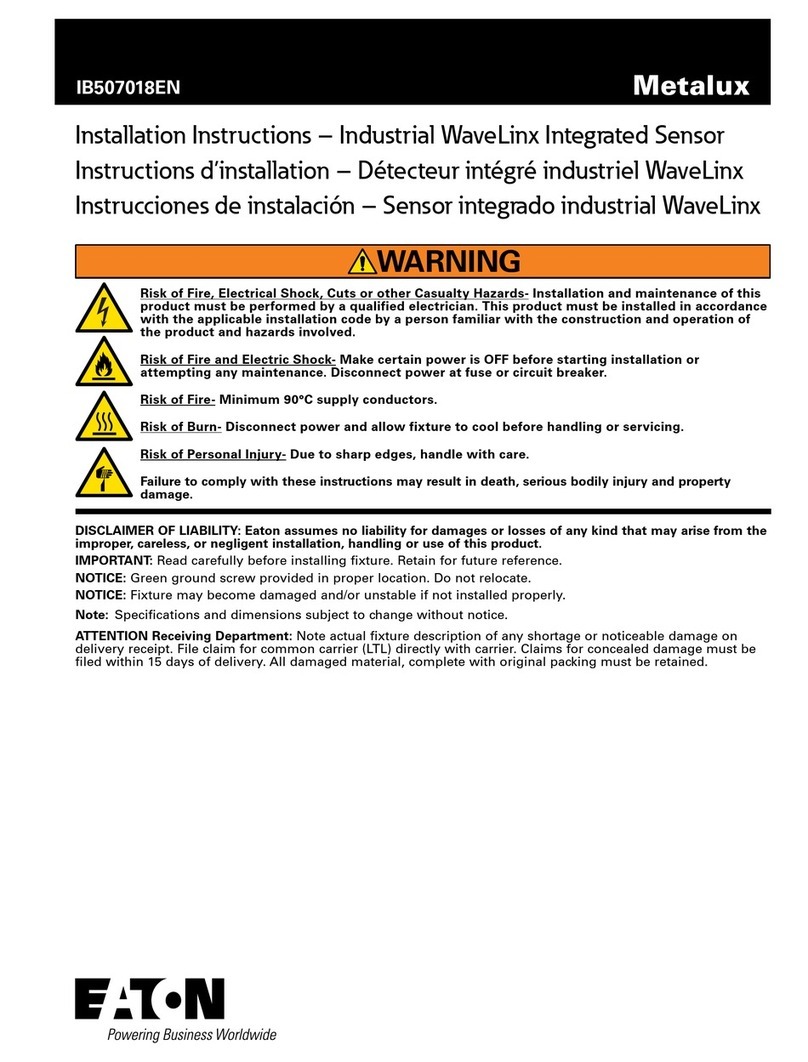

Periodic maintenance requirement

Periodic maintenance is required to ensure sensors perform to expectation, given the range of possible

operating conditions they can face. Semiannually, a standard 4130 steel target in the size shown in

the table below should be used to verify the “Maximum Sensing Distance” for every sensor. See the

table below for standard target sizes and rated maximum sensing distances. This measurement must

also consider the temperature in the sensing environment and account for the possibility of up to 10%

temperature drift as shown in the table below. Any sensor that fails this periodic Maximum Sensing

Distance test should be immediately replaced.

Specications

AC 2-wire DC 4-wire

Small (0.5 inch) Large (1.0 inch) Large (1.5 inch) Small (0.5 inch) Large (1.0 inch) Large (1.5 inch)

Operating voltage 65–130 Vac 60 Hz 10–30 Vdc

Load current (resistive) 1.25 A rms 250 mA

Load current (inductive) Make: 10 A rms for 3 cycles

Break: 1.25 A rms

250 mA

0.10 A lamp load

Burden current/burden resistor Burden resistor may be required for some 2-wire input applications

(example: PLC use)

<50 mA

Minimum load 15 mA rms N/A

Off-state leakage <4 mA <300 uA at 35 Vdc

Voltage drop <4 Vac <1.5 Vdc

Cable MIL-C-24643/43, type LS2SJ-16 2 conductor w/shield

20-foot length

MIL-C-24643/43, type LS4SJ-20 4 conductor w/shield

20-foot length

Circuit protection Overload protection to 6 A rms Overload, short circuit, reverse polarity

Dielectric withstand 1000 Vac between case and each conductor

>60 seconds, <1.5 mA

250 Vdc between case and each conductor

>60 seconds, <0.75 mA

Outputs Normally open or normally closed (by model) 1 x normally open, 1 x normally closed

Standard target size (4130 steel) 3 inch square,

0.062 thick

4 inch square,

0.062 thick

4 inch square,

0.062 thick

3 inch square,

0.062 thick

4 inch square,

0.062 thick

4 inch square,

0.062 thick

Head-on sensing range 0.5 ± 0.05 inch 1.0 + 0.22 inch

– 0.08 inch

1.5 + 0.50 inch

– 0.12 inch

0.5 ± 0.05 inch 1.0 + 0.22 inch

– 0.08 inch

1.5 + 0.50 inch

– 0.12 inch

Hysteresis 5–20% 5–30% 5–40% 5–20% 5–30% 5–40%

Weight <5 lb <6 lb <6 lb <5 lb <6 lb <6 lb

Response time <50 msec

Switch stabilization <500 msec

Operating temperature –20 to 70 °C (–4 to 158 °F)

EMC MIL-STD-461G (RS103 at 200 V/m) above deck usage (see Note)

Enclosure rating NEMA 4, 4X, 6, 6P IP67, IP68

Approvals MIL-PRF-24711B

Indicator LED (selected models) Target present - LED on, target absent - LED off, internal fault - slow blink, external fault - fast blink

Vibration MIL-STD-167-1, Type 1

Shock MIL-S-901, Grade A, Type A, Class I lightweight equipment

Humidity MIL-STD-202, Method 103B, test condition B

Materials of construction 316 stainless steel base, PA66 cover

Patents Covered by US patent 7,296,485 and EU patent 1728058 B1. Other patents pending.

ote:N All units referenced in this document meet the requirements of MIL-STD-461G CS114 with the exception of DC

models under certain specific conditions. DC models meet the requirements of the bulk cable injection test under all

conditions, above and below deck, but do not meet the requirements when the power conductor is tested individually

above deck, outside of a shielded junction box, over the 2 MHz–30 MHz frequency range.