2INSTALLATION AND OPERATION INSTRUCTIONS MN280095EN November 2020

Form 7 Microprocessor-Based Pole-Mount Recloser Control

IMPORTANT

Connect the control battery before AC power is

connected to the control’s AC supply Input Terminal

Block.The battery must be disconnected and removed

prior to shipping. The battery must be disconnected

prior to storing the control. See Figure 13.

ote:N When shipped from the factory, the battery will be in

the same carton as the control. The battery leads will

be taped to the battery casing. Connect the battery

plugs into the mating connectors to complete the

battery circuit.

Dispose expired batteries in an environmentally responsible

manner. Consult local regulations for proper battery disposal.

FORM 7 CONTROL DESCRIPTION

Description

The Form 7 control is designed for use with NOVA NX-T

reclosers to provide protection, metering, and automation

of distribution feeders in substation and line applications.

The control operates the individual reclosers representing

phases A, B, and C.

ote:N The phase sequence positions (phase A, B, and C)

are independent of each other.

The Form 7 recloser control includes extensive system

protection functionality including:

Phase, ground, and negative sequence overcurrent

protection

Over/under frequency and voltage protection

Directionality

Sync check

Analysis tools are provided to empower the user’s ability to

respond to events occurring on their system. These tools

include fault locating, event recording, WorkBench NXG, and

oscillography.

Metering functions include demand and instantaneous

current on a per-phase basis, instantaneous voltage and

power factor on a per-phase basis, and power (real, reactive,

apparent) on a per phase or total basis. Symmetrical

components for both voltage and current are displayed

along with kilowatt-hours for energy metering. Harmonics

from the 2nd to the 15th harmonic are also included.

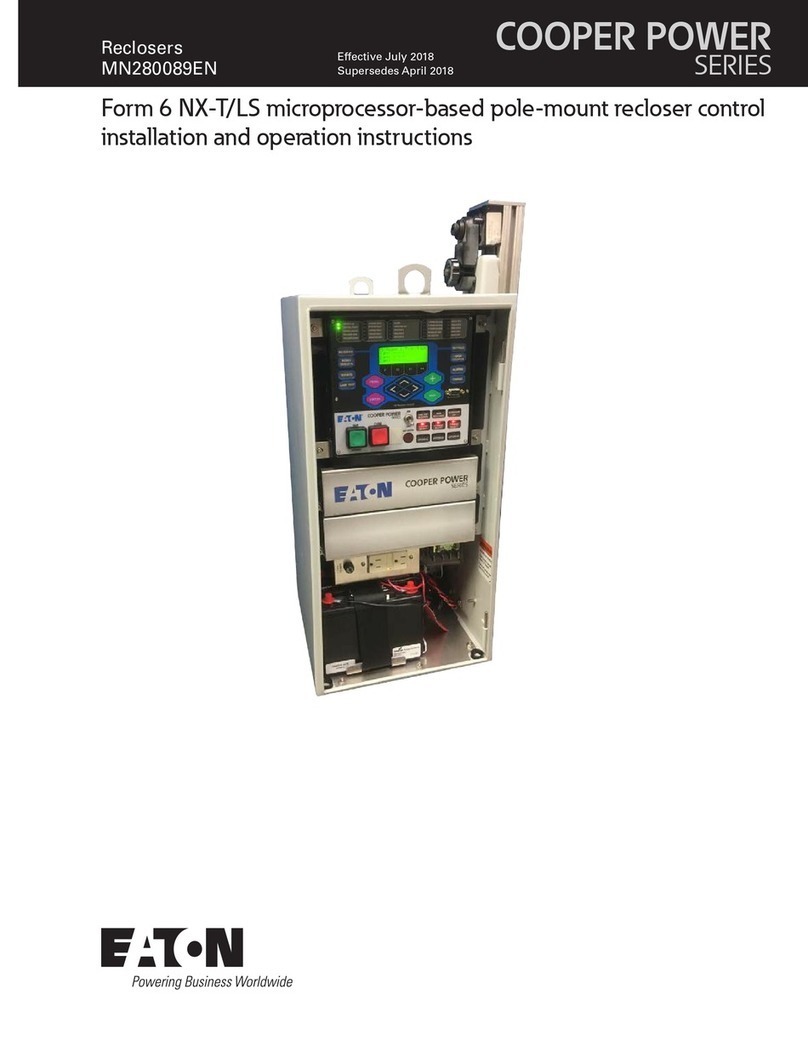

Use the front panel LCD display to:

Configure the operating settings for the control

Display metering, counter information, control

parameters, and alarms

Provide diagnostic information

With Form 7 NXG interface software, you can perform

control programming, interrogation, and operations. Install

the software on a personal computer and connect it to the

control’s front panel through the USB or Ethernet port.

The NXG interface program software includes additional

functions used to create and graphically display Time

Current Curves, and provides the WorkBench NXG for

configuring user-selected inputs and outputs, configurable

event and alarm data, and selectable communication points

for serial and Ethernet communication.

The control operates on 50 and 60 Hz systems.

The control can be configured, by the factory or by the

user, for a wide variety of applications. If user requirements

change, the control functions can be modified to meet the

new requirements.

Theory of operation

A functional block diagram of the Form 7 control is shown

in Figure 1. Current sensing is provided by three current

transformers located in the recloser and interfaced to the

Form 7 control through the control cable. The control cable

also supplies the Form 7 with the trip and close signals, the

recloser status, and provides a connection to the Recloser

Interface (RIF) module that provides isolation and reliable

operation. Voltages for metering are connected to the

voltage data acquisition (DAQ) module through connectors

P251 and P252. If PT (potential transformer) sensing is

being used, the signals are first routed through the PT

sensing board and connected at TB8.

Line current flowing through the recloser is measured by the

integrated current transformers and then converted by the

DAQ module to a digital signal suitable for metering and fault

current calculations. Data sampling occurs at a rate of 128

samples/cycle. The CPU contains a data acquisition section

that uses the acquired samples to compute the fundamental

currents and voltage for use in overcurrent, under/

overvoltage, and under/overfrequency protection, as well as

currents and voltages for metering functions. The current for

overcurrent protection is calculated on a sub-cycle basis; it

includes only the fundamental and DC component.

When the phase or ground current exceeds its programmed

minimum-trip value and associated time-current-curve (TCC)

timing, the control initiates the programmed sequence of

recloser tripping and reclosing operations via the CPU and

RIF modules. If the fault is temporary, the control ceases

to command recloser operations after a successful reclose,

and the control resets to the start of its operating sequence

after a preset time delay. If the fault is permanent, the

control performs its complete programmed sequence of

reclose commands and locks out with the recloser open.

Once locked out, the control must be closed via the

operator panel or SCADA communications. This resets the

control to the start of the operating sequence.