Table of Contents

Copyright © 2008 Eaton Corporation. All Rights Reserved.

IPN 997-00012-56C September 2008 iii

Table of Contents

About This Guide

Scope ........................................................................................................................................... i

Audience..................................................................................................................................... i

Related Information .................................................................................................................. i

Reporting Problems with this Guide...................................................................................... i

For Further Information and Technical Assistance .............................................................. i

Chapter 1 General Description

Overview ................................................................................................................................... 1

Enterprise Power Solutions DC Power Systems .................................................................. 2

Model Numbers...............................................................................................................................2

System Sizing ...................................................................................................................................2

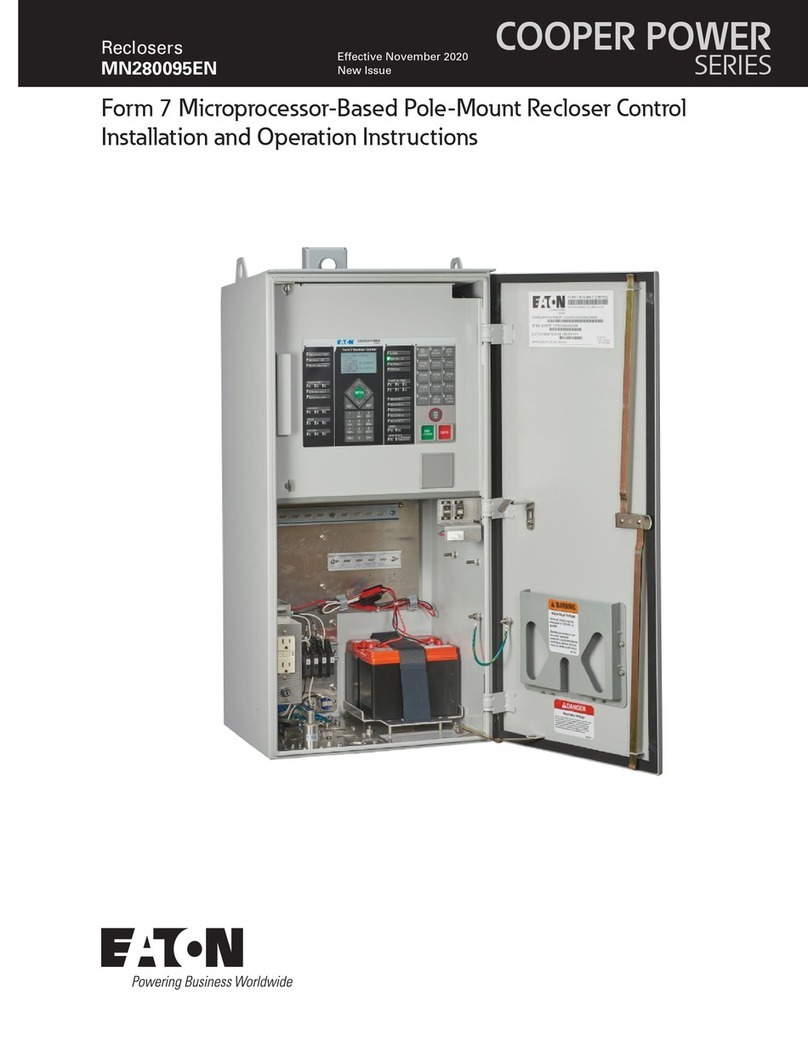

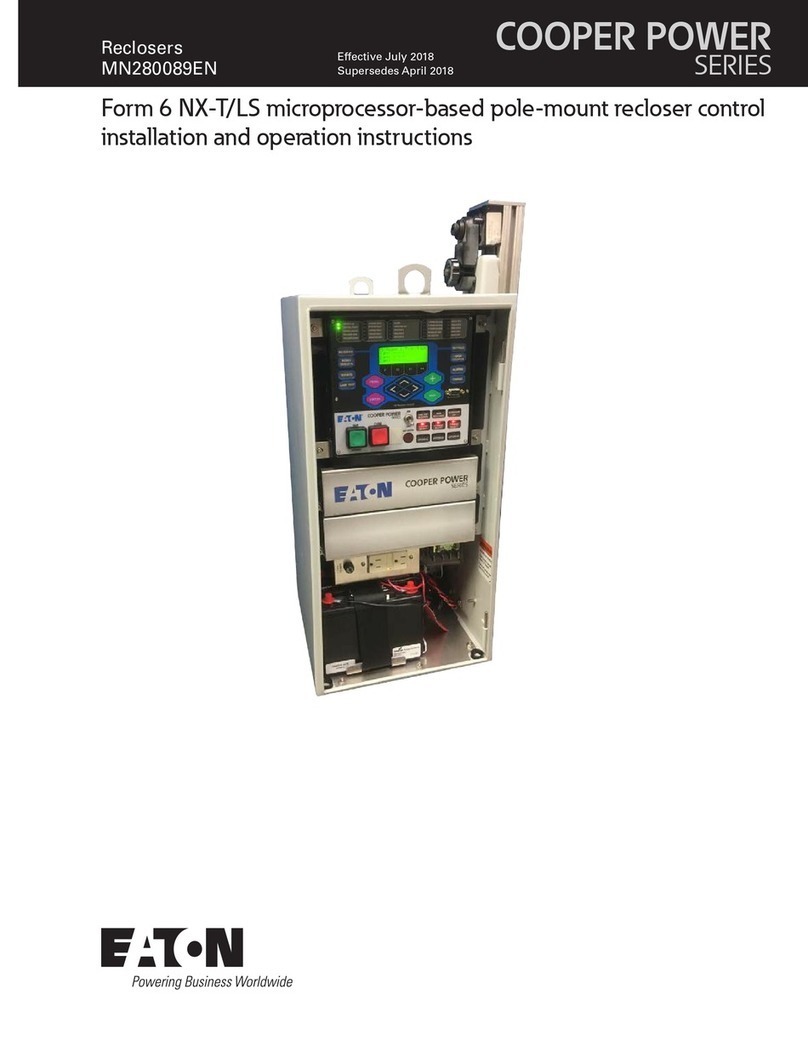

Front Views ...................................................................................................................................... 3

Rear Views........................................................................................................................................4

Rectifier Modules (APR48-3G/EPR48-3G) ........................................................................... 5

System Controller..................................................................................................................... 5

SC200 System Controller ................................................................................................................5

SC100 System Controller ................................................................................................................6

External communications ...............................................................................................................7

Compatible Software.......................................................................................................................7

Optional Battery Modules....................................................................................................... 7

Low Voltage Disconnect (option).................................................................................................. 8

Chapter 2 Preparation

Overview ................................................................................................................................... 9

Warnings ................................................................................................................................. 10

Inspecting the Equipment and Reporting Damage ........................................................... 12

Chapter 3 Installation

Overview ................................................................................................................................. 13

Installation Tasks.................................................................................................................... 14

Task 1 - Check the AC Supply.............................................................................................. 14

Task 2 - Customize EPS2/EPS5............................................................................................ 15

Task 3 - Mount the EPS2/EPS5 in the Rack........................................................................ 18

Task 4 - Connect the Output Cables .................................................................................... 21

Task 5 - Install the Batteries Modules (if required)............................................................ 23

Task 6 - Mount the Battery Temperature Sensor (if required) ......................................... 26

Task 7 - Connect communications cable (if required) ....................................................... 26

Task 8 - Connect to the AC Supply Point............................................................................ 28

Installation Completed ..........................................................................................................28

Chapter 4 Start-Up

Overview ................................................................................................................................. 29

Start-Up Tasks......................................................................................................................... 30

Task 1 - Inserting the Rectifiers ............................................................................................ 30

Task 2 - Pre-Power-Up Checklist ......................................................................................... 31

Task 3 - Applying AC Power................................................................................................ 31

Task 4 - Configuring the DC Power System ....................................................................... 32

Task 5 - Applying DC Power to Battery and Load ............................................................ 34

Start-Up Completed ............................................................................................................... 34