3

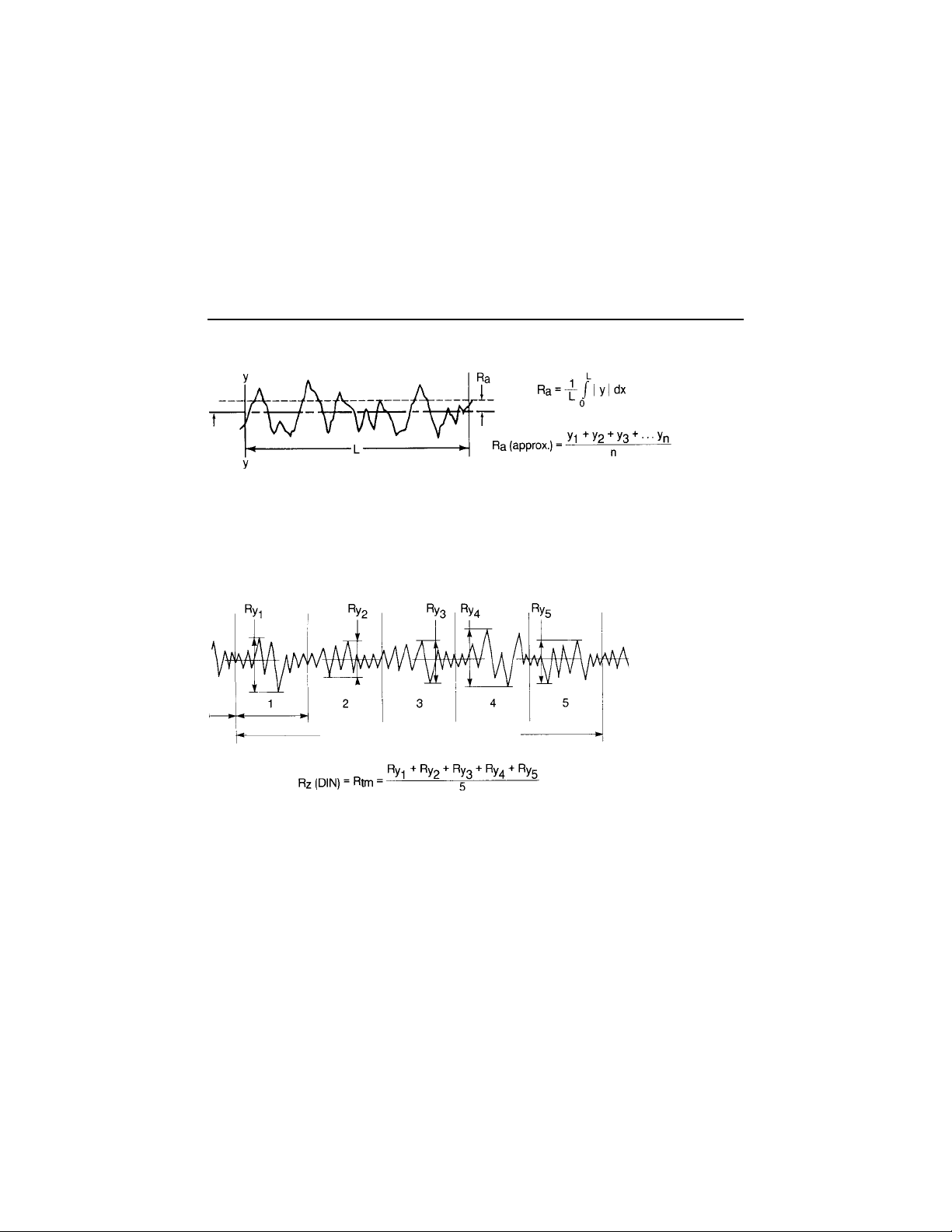

Measuring Ranges . . . . . . . . . . . . . . Ra— 1µ" to 250µ"/0,03µm to 6,35µm

Ry— 8µ" to 999µ"/0,2µm to 25,3µm

Rmax — 8µ" to 999µ"/0,2µm to 25,3µm

Rz— 8µ" to 999µ"/0,2µm to 25,3µm

Display Resolution . . . . . . . . . . . . . . 1µ"/0,01µm

Measurement Accuracy . . . . . . . . . Meets ASME B46.1, ISO and DIN

standards and MIL specifications

Digital Readout . . . . . . . . . . . . . . . . . 3-digit LCD display, with “Battery” icon

Traverse Length (Selectable). . . . . . See table on page 9.

Evaluation Length (Selectable) . . . . See table on page 9.

Traverse Speed . . . . . . . . . . . . . . . . . .2"/5,08mm per second

Cutoff . . . . . . . . . . . . . . . . . . . . . . . . . .030"/0,8mm; 2 RC filter

Probe Type . . . . . . . . . . . . . . . . . . . . . Piezoelectric

Maximum Stylus Force

(within displacement range) . . . . . . . 1500mgf/15.0mN

Power . . . . . . . . . . . . . . . . . . . . . . . . . 9-volt consumer-type alkaline battery

Battery Capacity . . . . . . . . . . . . . . . . Approx. 2500 measurements, depending

on frequency/degree of usage

Operating Temperature . . . . . . . . . . 50° to 113°F/10° to 45°C

Storage Temperature . . . . . . . . . . . . –

4° to 149°F/-20° to 65°C

Note: Rmax and Rzper DIN 4768

Specifications

ModelsModels

ModelsModels

Models

Pocket Surf

Kit Model No.

EGH-1019 Probe and PMD-90101 EMD-1500-311

Certified Reference Specimen

EGH-1019 Probe and EMD-90010 EMD-1500-312

Precision Reference Specimen

EGH-1026 Probe and PMD-90101 EMD-1 500-321

Certified Reference Specimen

EGH-1026 Probe and EMD-90010 EMD-1500-322

Precision Reference Specimen