4

RVAC Fluid-insulated Vacuum Switchgear

InstallatIon, operatIon, and MaIntenance InstructIons MN285005EN March 2018

Installation procedure

WARNING

This equipment is not intended to protect human

life. Follow all locally approved procedures and safety

practices when installing or operating this equipment.

Failure to comply can result in death, severe personal

injury, and equipment damage. G102.1

1. Check the fluid level. Make sure the fluid in the

switchgear tank is at the proper level by checking the

fluid level indicator on the front plate. Two-sided units

have fluid level indicators on both source-side and

tap-side front plates. Make sure both are at the proper

level.

2. Test the fluid dielectric strength and moisture content.

If the switchgear has been stored for some time or

is being relocated, perform these tests on the fluid in

accordance with ASTM-approved testing procedures.

WARNING

This equipment relies on dielectric fluid to provide

electrical insulation between components.The dielectric

strength and moisture content of the fluid must be

checked on a regular basis, as part of the routine

maintenance inspection, to ensure that it is at or

above minimum dielectric requirements and below the

maximum moisture content. Use of this equipment

with dielectric fluid that does not meet requirements

can result in internal flashovers that will damage the

equipment and can result in death or serious injury. G107.3

NOTICE

The use of Envirotemp™ FR3™ dielectric fluid is limited to

a minimum operating temperature of 32 °F (0 °C). Failure

to comply can result in equipment misoperation. T374.0

a. On new equipment, the fluid must have a minimum

dielectric strength of 26 kV.

b. If the dielectric strength of the fluid is less than

26 kV, process or replace the fluid to restore its

dielectric strength to an acceptable minimum level.

c. Refer to the Fluid testing section of this manual for

service recommendations based on the moisture

content of the fluid.

d. For additional information on fluid specifications and

tests, refer to Reference Data TD280022EN and to

the Fluid testing section of this manual.

3. Check the nameplate ratings. Make sure the ratings on

the switchgear nameplate are correct for the planned

installation.

NOTICE

Equipment damage. Never place jacks, tackle or

other attachments under the unit for the purpose of

lifting. Failure to comply will result in damage to the

equipment. T240.0

NOTICE

Follow all locally approved safety practices when lifting

and mounting the equipment. Use the lifting lugs provided.

Lift the unit smoothly and do not allow the unit to shift.

Improper lifting can result in equipment damage. G106.2

4. Mount the switchgear on the concrete pad.

a. The switchgear must be installed on a level concrete

pad or structure that has been designed to support

the size and weight of the unit.

b. The switchgear must be hoisted only by the

recessed lifting provisions provided at the four

corners of the tank. Suitable lifting straps must be

used to prevent damage to the switchgear housing.

c. The switchgear must be anchored to the concrete

pad. Anchor the pad using the mounting cleats

provided or using other suitable mounting hardware.

WARNING

Hazardous voltage. Solidly ground all equipment. Failure

to comply can result in death, severe personal injury,

and equipment damage. T223.2

5. Ground the switchgear. Switchgear must be adequately

grounded. Install a permanent, low resistance

ground connection to the switchgear tank. Grounding

provisions are provided near the bottom of the tank.

CAUTION

Equipment misoperation. Always use compatible

fuses. Follow all locally approved operating practices

whenever changing fuses. Wet-well fuse assemblies

must be re-fused and operated in accordance with the

instructions provided by the fuse manufacturer. Failure

to install the proper fuse can result in switchgear

misoperation, equipment damage, and personal injury.

G260.0

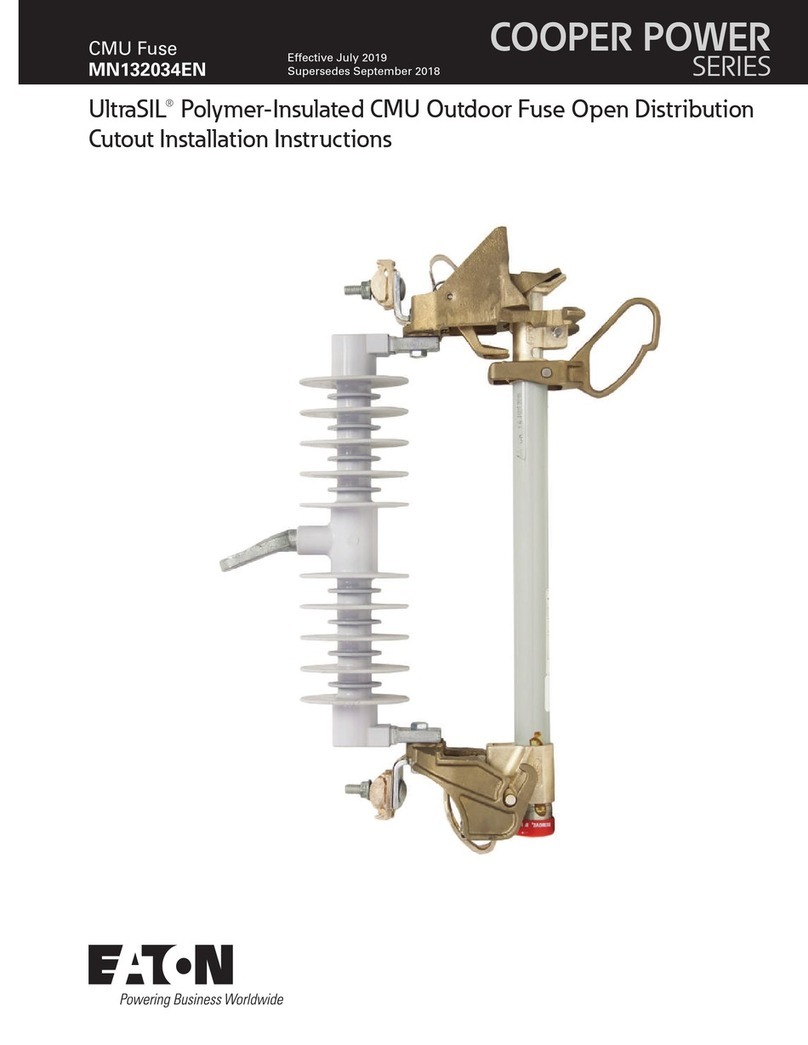

6. Assemble and install fuses. If the switchgear is

equipped with fuses, be sure that the fuses are rated

correctly for the installation and that they are properly

installed. Further verify that the fuses are compatible

with the wetwell fuse holder(s) supplied with the

switchgear. Refer to Figure 5 to ascertain fuse/wetwell

fuse holder compatibility.

ote:N Fuses should be applied on solidly grounded wye

systems only. Consult factory for fuse application

on delta systems.

7. Make the high-voltage line connections.

a. Prior to making connections, make sure that the

source-side and tap-side cable elbows are correctly

identified and that the switchgear unit is oriented

correctly for the installation. The source leads must

connect to the source bushings of the unit, and the

tap leads must connect to tap bushings of the unit.