Instruction Bulletin

Instructions for Installation,

Page 4 Effective: July 2016 Operation and Maintenance of t e

SL800 Classic 7.2 Kilovolt, 720 Amp. Vacuum Contactor

For more information visit: www.eaton.com

IB48082

T e moving contacts are driven by a molded plastic

crossbar rotating wit a square steel s aft supported

by two s ielded, pre-lubricated ball bearings t at are

clamped in true alignment for long life and free

motion. Only t e end edges of t e square s aft are

rounded to fit t e bearings, so t at portions of t e

four s aft flats go t roug t e bearings for positive

indexing of t e mec anical safety interlocks.

T e contacts in an un-mounted vacuum bottle are

normally-closed, because t e outside air pressure

pus es against t e flexible bellows. For contactor

duty, t e contacts must be open w en t e operating

magnet is not energized. T erefore, t e contacts of

t e vacuum bottles must be eld apart mec anically

against t e air pressure w en used in a contactor.

In t e SL contactor, all of t e bottles are eld open

by two kickout springs on t e front of t e contactor.

T e kickout springs press against t e moving

armature and crossbar and t ereby force t e bottles

into t e open contact position. Note t at in t e open

position, t e crossbar is pulling t e moving contacts

to old t em open.

Up to an altitude of 3300 feet, t e contactor is

designed to tolerate normal variations in barometric

pressure. Special factory modifications are required if

t e contactor is to be applied at ig altitude.

Contact t e factory if t e contactor will be applied at

elevations above 3300 feet.

T e contactor is closed by energizing t e contactor

control board wit t e appropriate control voltage at

terminals 1 and 2. T e control board rectifies t e

input voltage and applies a pulse widt modulated

DC output voltage to t e coil. T e output voltage is

approximately full voltage for t e first 200

milliseconds after energization, during w ic time t e

contactor closes and seals. T e output voltage is

t en automatically reduced to approximately 15 VDC

to maintain t e contactor in t e closed position.

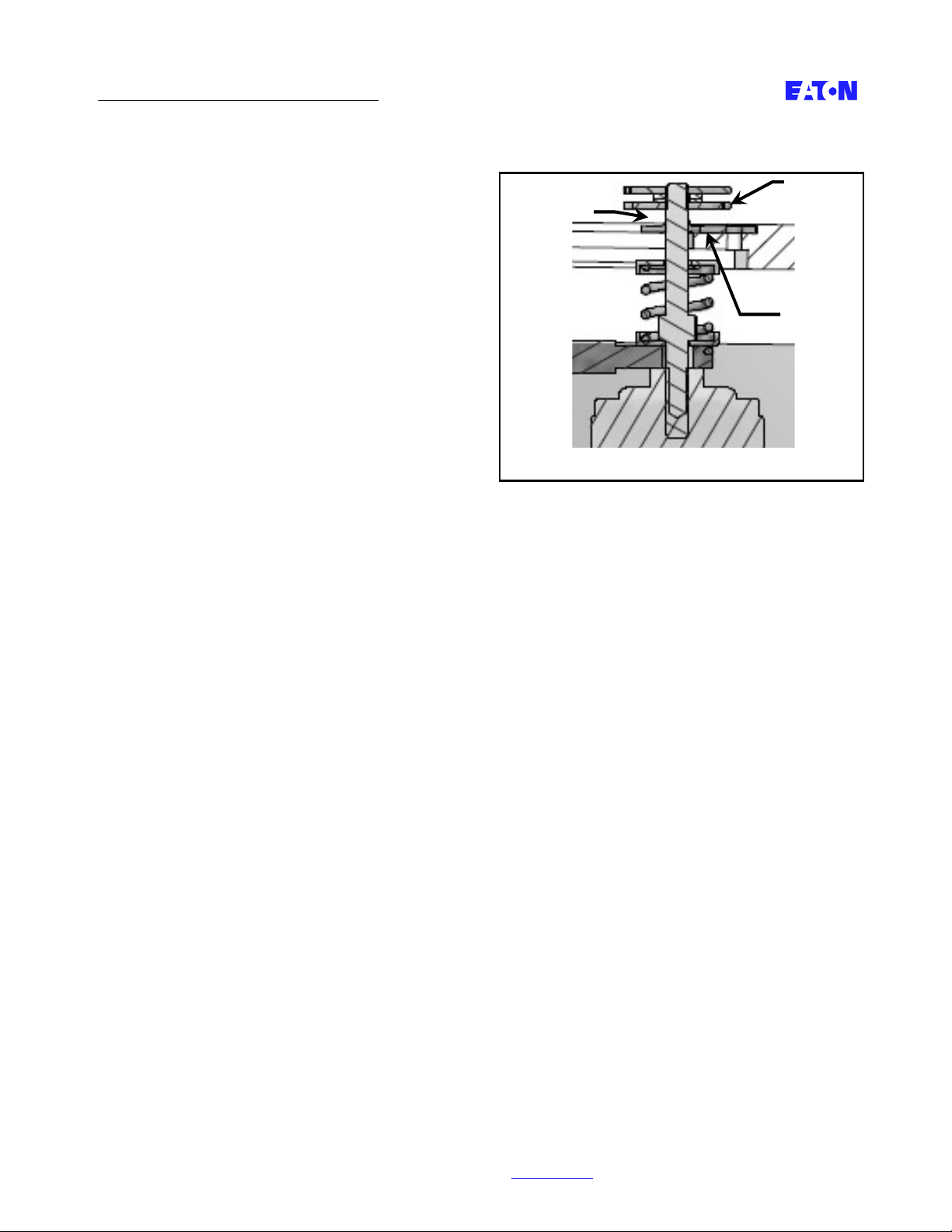

T e coil core is magnetized w ic rotates t e

armature s aft, armature, and crossbar. As t e

armature moves toward t e coil core, t e main

contacts close. T e crossbar continues to move an

additional distance (known as overtravel), w ic

allows for contact preload and wear. T e overtravel

distance is t e gap between t e lower bottle nut and

t e pivot plate as s own in Figure 2.

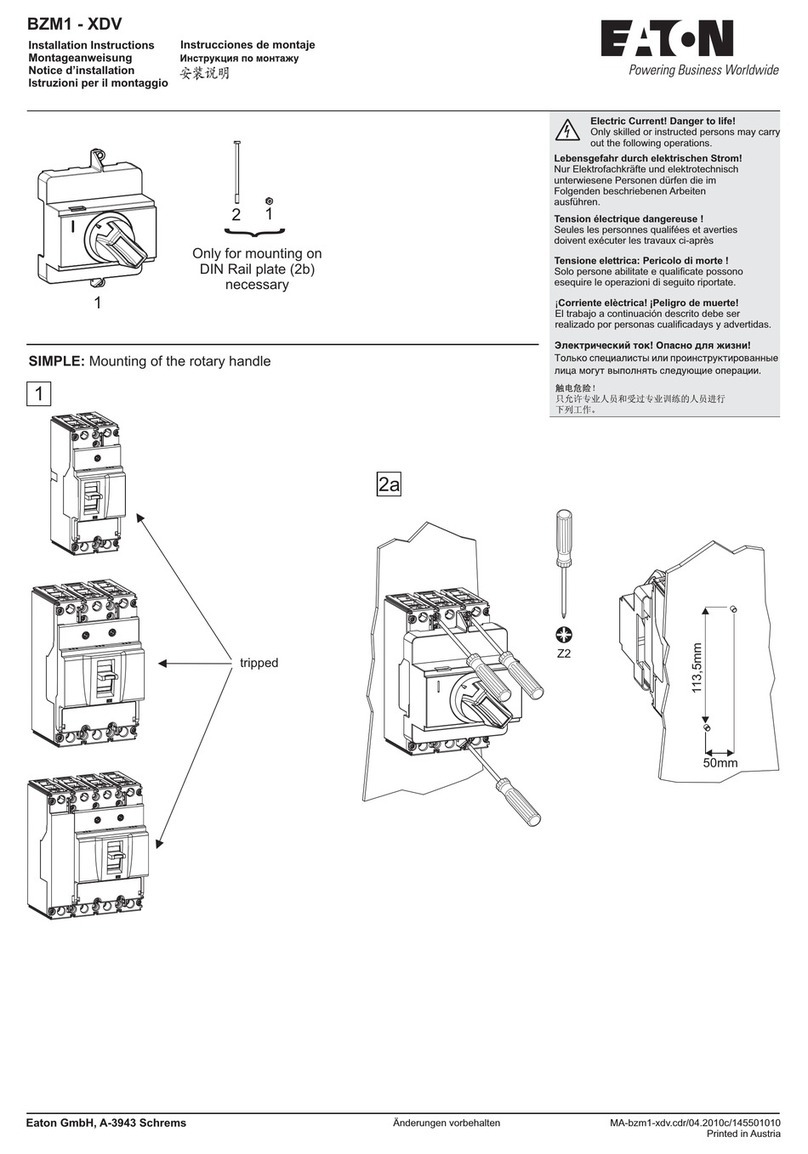

Fig. 2 Closed Contactor

W en control power is removed from t e control

board, t e magnetically eld contactor remains

closed for a preset time and t en opens. T e range

of time between t e removal of control power and

contact opening is from 50 to 330 milliseconds

depending on t e setting selected on t e control

board. T e time can be adjusted for suc factors as

fuse coordination and voltage loss ride-t roug .

Unless ot erwise specified, t e factory default

dropout setting is 130 milliseconds, or approximately

8 line cycles (60Hz). To maintain proper

coordination wit t e starter power fuses, do not use

t e 50ms setting.

A selectable dip switc is located on t e control

board for setting t e control voltage level and t e

contactor dropout time. See Figure 3. T e control

board must be removed from t e cavity in t e

contactor ousing to gain access to t e dip switc .

Table IIIa lists t e available voltage settings and

Table IIIb lists t e available dropout settings. T ese

tables are also printed on t e back of t e control

board. T e control voltage setting s ould matc t e

starter control circuit voltage.

Bottle

Nuts

Pivot

Plate