Page 1

SECTION 1: INTRODUCTION

1.1 PRELIMINARY COMMENTS AND SAFETY

PRECAUTIONS

This technical document is intended to cover most

aspects associated with the installation, application,

operation and maintenance of the Residential Automatic

Transfer Switch. It is provided as a guide for authorized

and qualified personnel only. Please refer to the specific

WARNING and CAUTION in Section 1.1.2 before pro-

ceeding. If further information is required by the pur-

chaser regarding a particular installation, application or

maintenance activity, a Cutler-Hammer representative

should be contacted.

1.1.1 WARRANTY AND LIABILITY INFORMATION

No warranties, expressed or implied, including war-

ranties of fitness for a particular purpose of merchant-

ability, or warranties arising from course of dealing or

usage of trade, are made regarding the information, rec-

ommendations and descriptions contained herein. In no

event will Cutler-Hammer be responsible to the purchas-

er or user in contract, in tort (including negligence), strict

liability or otherwise for any special, indirect, incidental

or consequential damage or loss whatsoever, including

but not limited to damage or loss of use of equipment,

plant or power system, cost of capital, loss of power,

additional expenses in the use of existing power facili-

ties, or claims against the purchaser or user by its cus-

tomers resulting from the use of the information and

descriptions contained herein.

1.1.2 SAFETY PRECAUTIONS

All safety codes, safety standards and/or regulations

must be strictly observed in the installation, operation

and maintenance of this device.

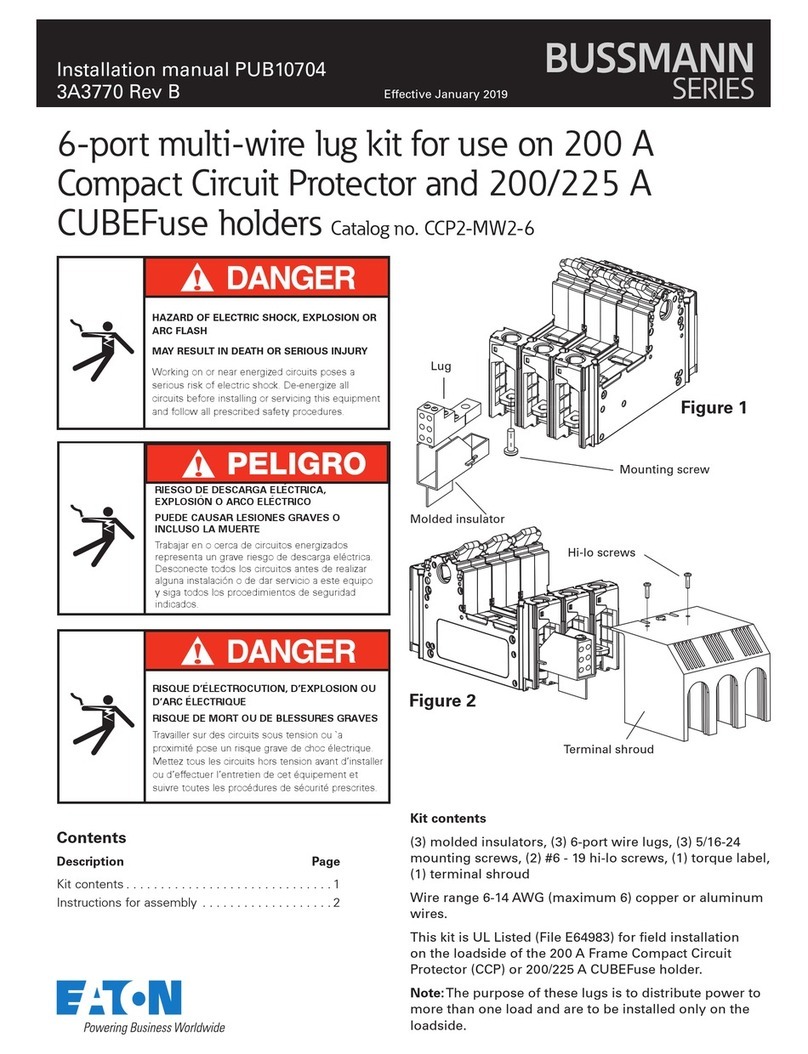

THE WARNINGS AND CAUTIONS INCLUDED AS

PART OF THE PROCEDURAL STEPS IN THIS DOCU-

MENT ARE FOR PERSONNEL SAFETY AND PRO-

TECTION OF EQUIPMENT FROM DAMAGE. AN

EXAMPLE OF A TYPICAL WARNING LABEL HEAD-

ING IS SHOWN ABOVE TO FAMILIARIZE PERSON-

NEL WITH THE STYLE OF PRESENTATION. THIS

WILL HELP TO INSURE THAT PERSONNEL ARE

ALERT TO WARNINGS, WHICH APPEAR THROUGH-

OUT THE DOCUMENT. IN ADDITION, CAUTIONS

ARE ALL UPPER CASE AND BOLDFACE.

READ AND UNDERSTAND THE MATERIAL PRE-

SENTED IN THIS DOCUMENT BEFORE ATTEMPTING

INSTALLATION, OPERATION OR APPLICATION OF

THE EQUIPMENT. IN ADDITION, ONLY QUALIFIED

PERSONS SHOULD BE PERMITTED TO PERFORM

ANY WORK ASSOCIATED WITH THE EQUIPMENT.

ANY WIRING INSTRUCTIONS PRESENTED IN THIS

DOCUMENT MUST BE FOLLOWED PRECISELY.

FAILURE TO DO SO COULD CAUSE PERMANENT

EQUIPMENT DAMAGE.

1.2 GENERAL INFORMATION

Transfer switches are used to protect critical electrical

loads against loss of power. The load’s normal power

source is backed up by a secondary (emergency) power

source. A transfer switch is connected to both the nor-

mal and emergency power sources and supplies the

load with power from one of these two sources. In the

event that power is lost from the normal power source,

the transfer switch transfers the load to the secondary

(emergency) power source. Transfer can be automatic

or manual, depending upon the type of transfer switch

equipment being used. Once normal power is restored,

the load is automatically or manually transferred back to

I.B. ATS-RM05

Effective 6/01

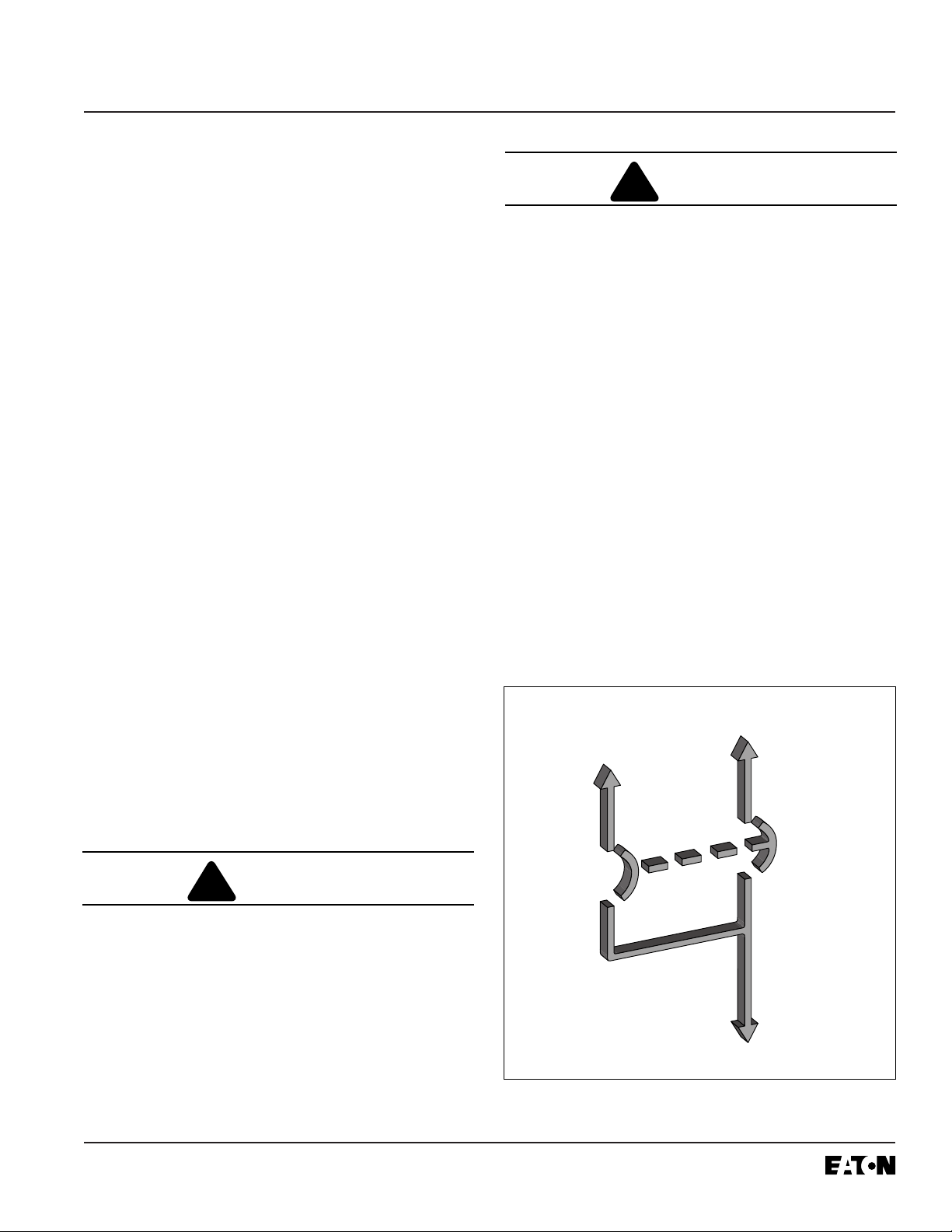

Figure 1-1 Typical Load Transfer Switch (circuit break-

er type) Schematic