Maintenance information

RVAC switchgear is a deadfront design. All live parts are

contained within the sealed tank enclosure. A routine

maintenance inspection program is required to ensure

proper operation.

Routine inspection

It is necessary to establish and maintain a regular schedule

for checking the pressure of the insulating SF6to ensure

proper dielectric strength within the switchgear. Inspect

the unit on 6 month intervals, whether in storage or in

service, for the first year and annually thereafter. Check the

gas pressure gauge and update the unit’s inspection and

maintenance log each time the switchgear is inspected.

Maintenance inspection procedure

RVAC switchgear must be de-energized, grounded, and

removed from service before conducting any maintenance,

or SF6sampling or filling procedures.

1. De-energize and ground switchgear.

2. Check SF6pressure. Make sure SF6within the

switchgear tank is at the proper pressure by checking

the pressure gauge(s) on the front plate(s) of the unit.

3. Inspect for damage. Check for any unusual wear to

the paint finish. Check bushings and elbows make

sure connections are secure. Check for SF6leaks

or other unusual or abnormal indications of wear or

abuse. Make sure cabinet doors lock securely. Record

any unusual conditions and make arrangements for

immediate repair if required.

Internal inspection and repair

If internal damage is suspected, or if the switchgear

must be returned to the factory for service, contact your

Eaton representative for shipping instructions and a return

authorization number.

Adding SF6gas

The SF6pressure in the unit will normally fluctuate due to

changes in ambient temperature. SF6gas should be added

when the pressure gauge reads 2 psig lower than the

recommended gas pressure. Refer to Table 2 for a listing of

the recommended gas at various ambient temperatures.

If SF6must be added, contact your Eaton representative

for SF6Gas Top-Off Kit Catalog numbers KPA-1043-1/KPA-

1043-2 ordering information. Be prepared to provide a copy

of the switchgear inspection and maintenance log, the

serial number of the unit and a status report of its condition.

Refer to Service Information S285-10-3, SF6 Gas Top-Off

Kit Operating Instructions for recommended SF6top-off

procedures when using the KPA-1043-1/KPA-1043-2 Gas

Top-Off Kit.

The recommended procedure for adding SF6gas is as

follows.

1. Verify the quality of SF6gas in the cylinder to be used

during the transfer process.

2. Open the fill port of the pad-mounted switchgear tank.

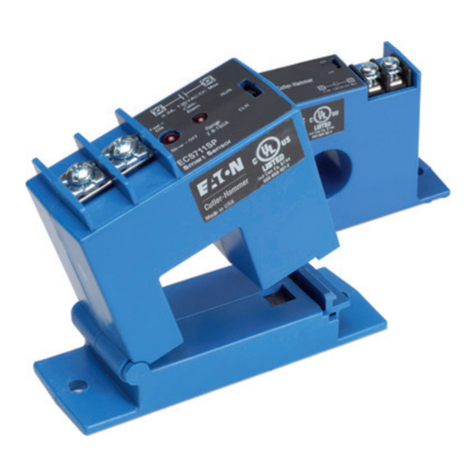

3. Connect the coupling valve of the SF6gas filling

apparatus to the fill port of the pad-mounted switchgear

tank (Figure 8).

4. Slowly open the outlet valve of the regulated SF6

source gas cylinder.

5. Refer to the chart on the switchgear tank to determine

CAUTION

This equipment requires routine inspection and

maintenance to ensure proper operation. If it is not

maintained, it can fail to operate properly. Improper

operation can cause equipment damage and possible

personal injury. G105.1

CAUTION

This equipment relies on SF6to provide electrical

insulation between components.The pressure of the

SF6within the unit must be checked on a regular

basis, as part of the routine maintenance inspection,

to ensure that it is at or above minimum requirements.

Use of this equipment with low SF6pressure, can

result in internal flashovers that will damage the

equipment and can cause personal injury. G125.2

CAUTION

Toxic materials, skin irritant. Arcing in sulphur hexafluoride

gas (SF6) creates toxic by-products. Avoid breathing

SF6that has been exposed to electrical arcing. Suitable

protective clothing must be worn to avoid contact with

the powder residues that remain after electrical arcing in

SF6. Failure to use a suitable mask and protective clothing

can result in skin irritation and illness. G121.1

WARNING

Hazardous voltage.This equipment must be

de-energized and grounded prior to conducting any

maintenance, SF6sampling or SF6filling procedures.

Failure to comply can result in death or severe personal

injury. T242.0

IMPORTANT

Care should be exercised to avoid any introduction of

moisture or air into the SF6gas chamber of the RVAC unit

during filling operations. Introduction of air or moisture can

result in reduced dielectric performance of the SF6gas.

IMPORTANT

Filling apparatus used to introduce and transfer SF6gas

into the pressurized SF6gas chamber of the RVAC unit

must contain an adjustable regulator for control of SF6flow

during filling operations.

6RVAC, SF6 insulated, vacuum break switch; installation, operation, and maintenance instructions MN285003EN September 2015