a 6mm Allen wrench, remove the flat head screw from the threaded point that

will be used for locking the angle.

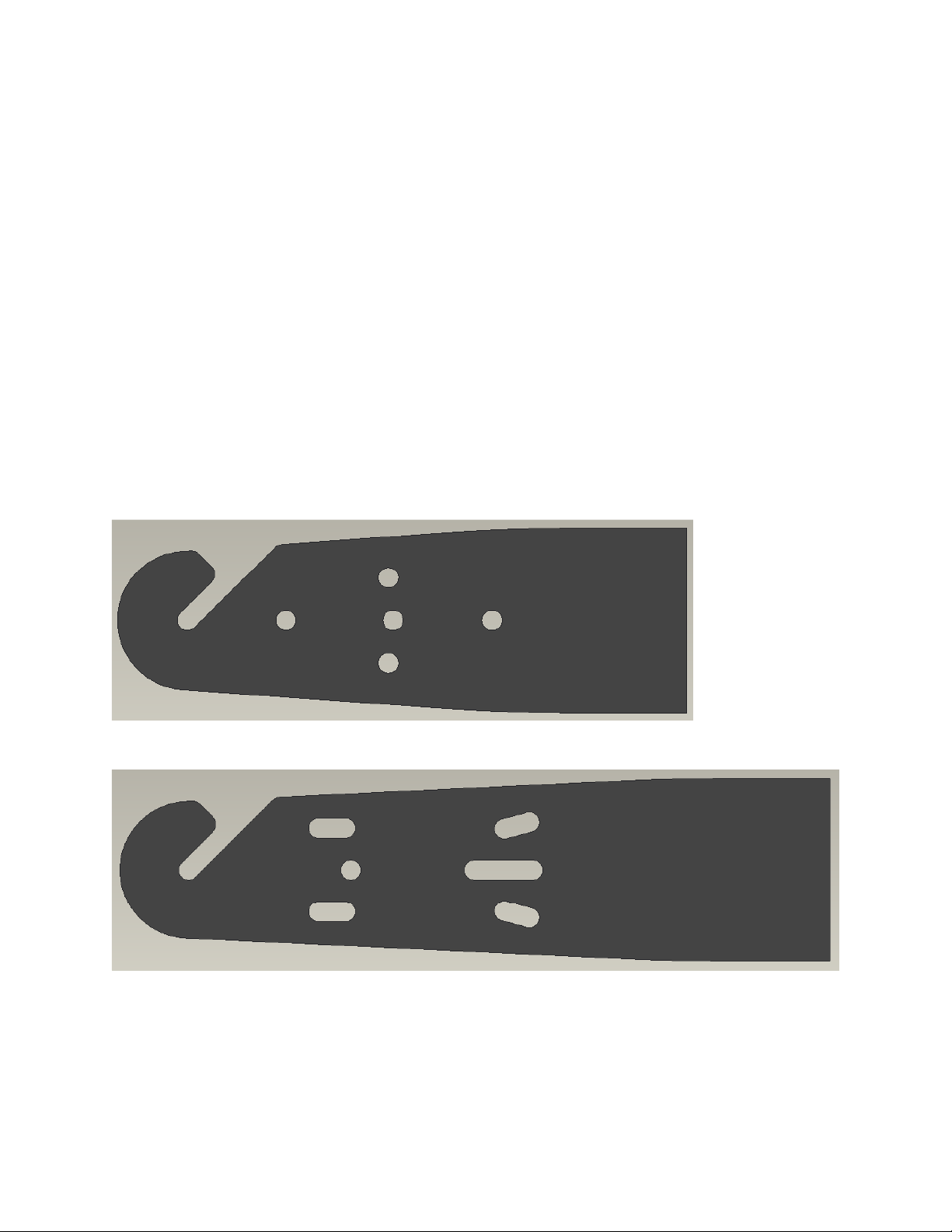

c. The MKD Series Loudspeaker may have weather-protected fiberglass shell which

increases the size of the loudspeaker. There are multiple sized rubber washers (E and F)

included with the MKD Series U-Bracket to accommodate the larger loudspeaker size.

Select the rubber washer to best fill the gap between the loudspeaker and u-bracket for

use equally on both sides of the loudspeaker.

d. Installing the MKD Series Loudspeaker onto a mounted MKD Series U-Bracket.

i. WARNING: Take care when handling and wear PPE gloves to protect from

crushing and impacts with digits, limbs, and/or product.

ii. Note, for weather protected applications (using MKD-WP Series Loudspeakers),

apply user-supplied, waterproof, non-hardening, non-locking thread sealant to

the threads of two button head screws (B) per the thread sealant’s instructions.

Failure to do so could result in water ingress and damage to the loudspeaker.

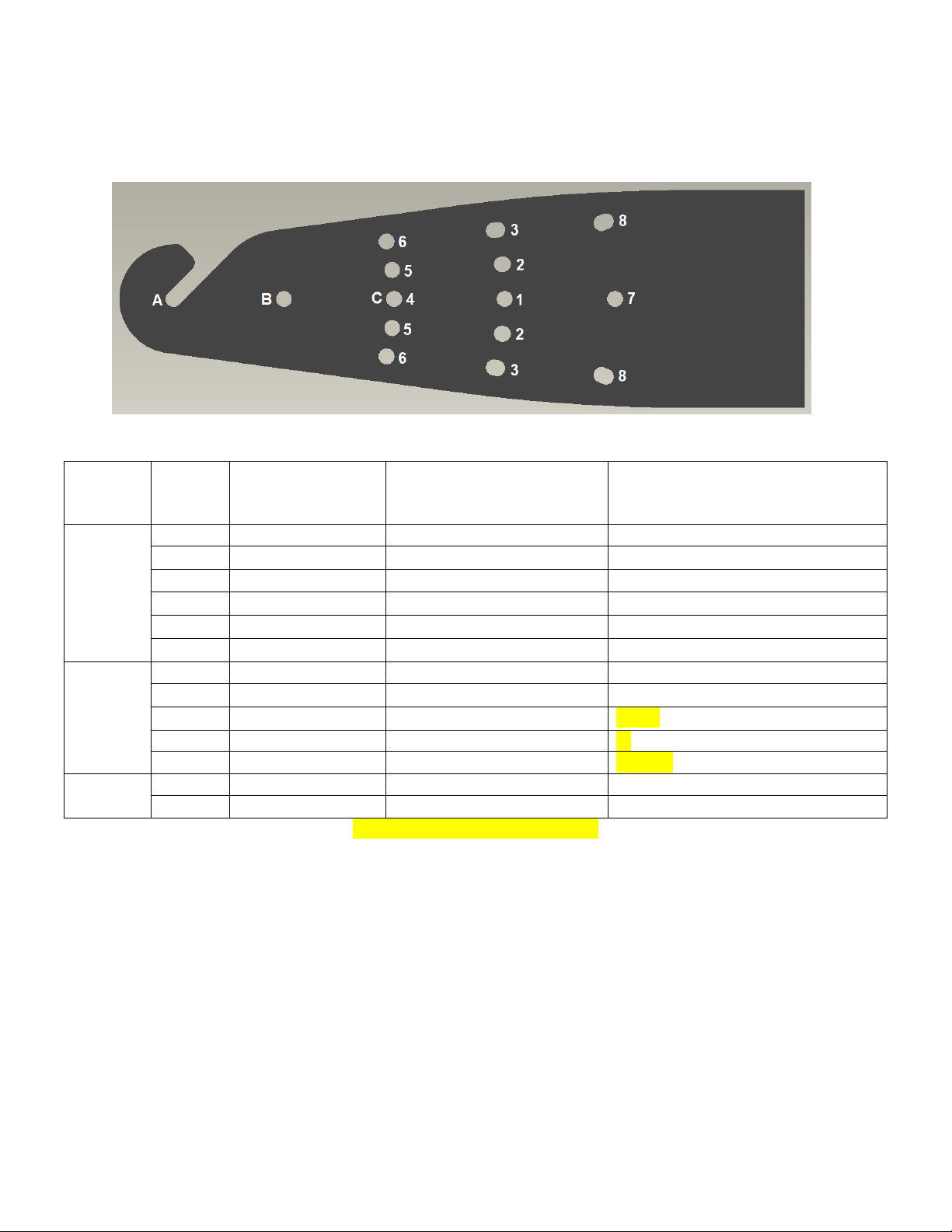

iii. Onto each of two button head screws (B), place a lock washer (C) and a flat

washer (D).

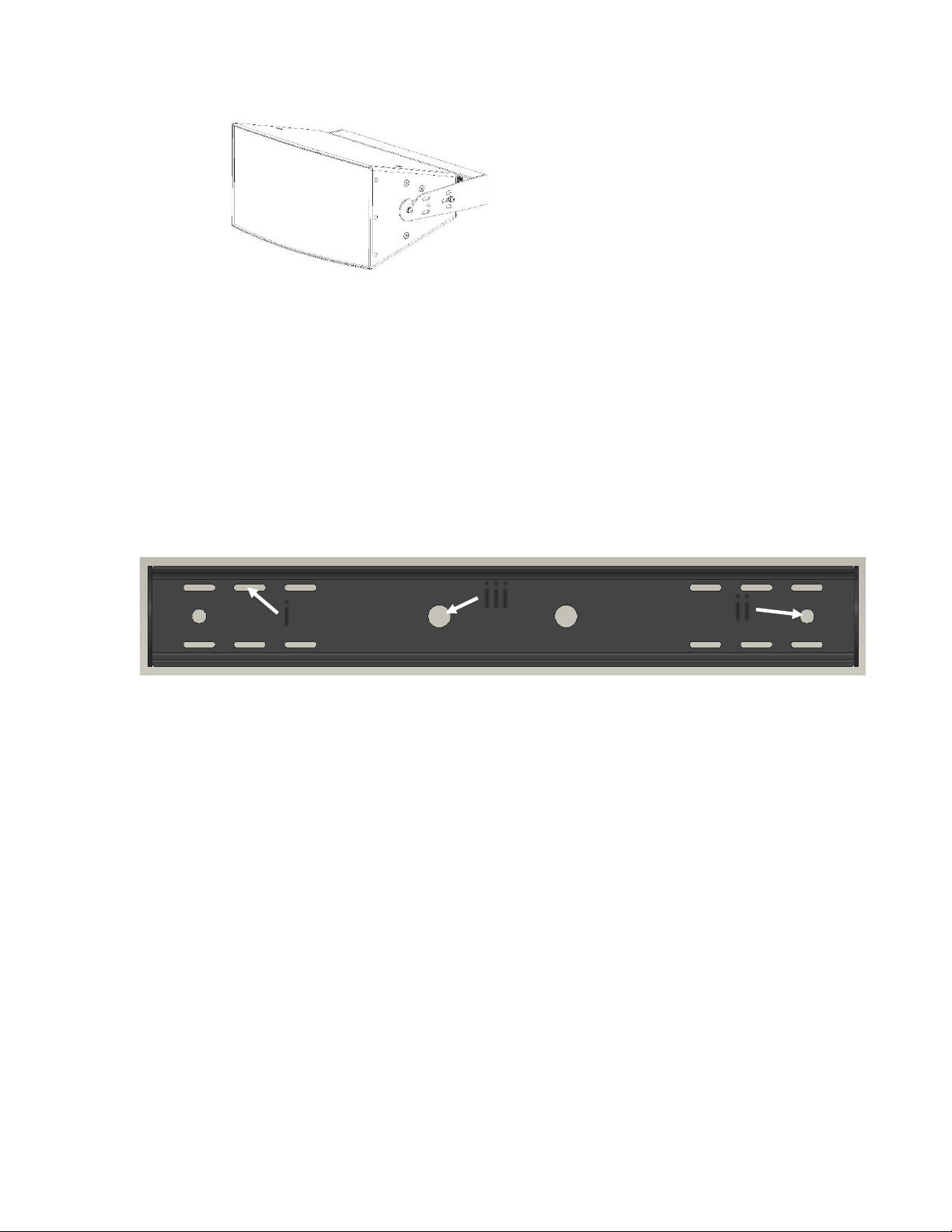

iv. WARNING HEAVY LIFTING, MULTIPLE PERSON LIFT –Lift the MKD Series

Loudspeaker to align the loudspeaker’s center threaded mounting hole with the

MKD Series U-Bracket preferred mounting point.

v. Using a 6mm Allen wrench, loosely thread the screws and washers (B, C & D)

through the MKD Series U-Bracket mounting point, through the selected rubber

washer (E or F) and into the loudspeaker’s center threaded mounting hole.

Repeat for the opposite side.

vi. If using the MKD Series U-bracket’s slotted mounting point “A”, the hardware

may be preassembled to the MKD Series Loudspeaker.

1. Note, if using the slotted mounting point, the MKD Series U-Bracket must

be installed oriented with the slot angled upward, opposing the ground.

2. Note, for weather protected applications (using MKD-WP Series

Loudspeakers), apply user-supplied, waterproof, non-hardening, non-

locking thread sealant to the threads of two button head screws (B) per

the thread sealant’s instructions. Failure to do so could result in water

ingress and damage to the loudspeaker.

3. Onto each of two button head screws (B), place a lock washer (C), a flat

washer (D) and the selected rubber washer (E or F). Thread these screws

and related hardware three complete turns into the loudspeaker’s two

center threaded mounting holes.

4. Leave as large a space as possible between the rubber washer (E or F) and

the flat washer (D).

5. WARNING HEAVY LIFTING, MULTIPLE PERSON LIFT –Lift the MKD Series

Loudspeaker into the MKD Series U-bracket slots with the large rubber

washers (E) inside the u-bracket and the flat and lock washers (C & D)

outside the u-bracket.

vii. Position the MKD Series Loudspeaker to the desired angle.