Echo SHRED-N-VAC ES-1000 User manual

Other Echo Lawn And Garden Equipment manuals

Echo

Echo HC-155 User manual

Echo

Echo EA-410 User manual

Echo

Echo EA-400 User manual

Echo

Echo 05999999 User manual

Echo

Echo Bear Cat SC5540B User manual

Echo

Echo POWER PRUNER DPPT-2600H User manual

Echo

Echo 2410 - Type 1E User manual

Echo

Echo Power Pruner PPT-266LA User manual

Echo

Echo HC-1500 Instruction Manual

Echo

Echo 99944200590 SRM-2100SB/2400SB User manual

Echo

Echo Pro Attachment Series User manual

Echo

Echo PAS-260 PRO - 03-03 User manual

Echo

Echo SHC-266 User manual

Echo

Echo HC-180 User manual

Echo

Echo HC-150 - 04-06 1 User manual

Echo

Echo EA-410 User manual

Echo

Echo Pro Attachment Series User manual

Echo

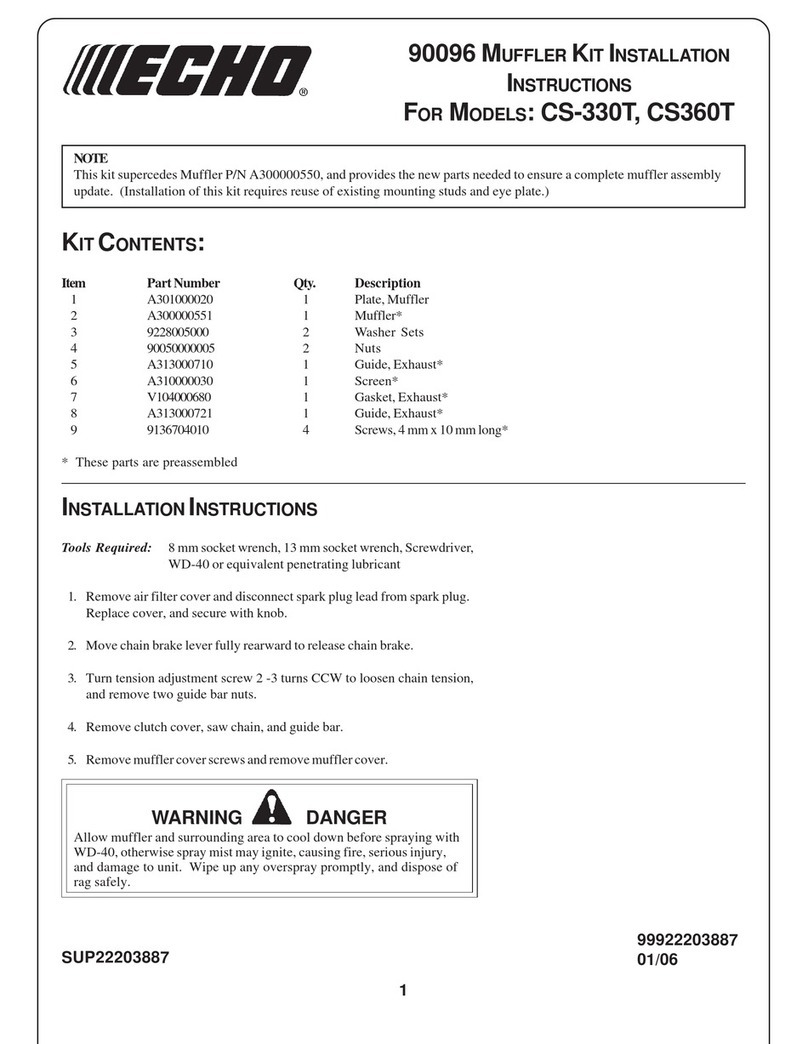

Echo 90096 MUFFLER KIT CS-330T User manual

Echo

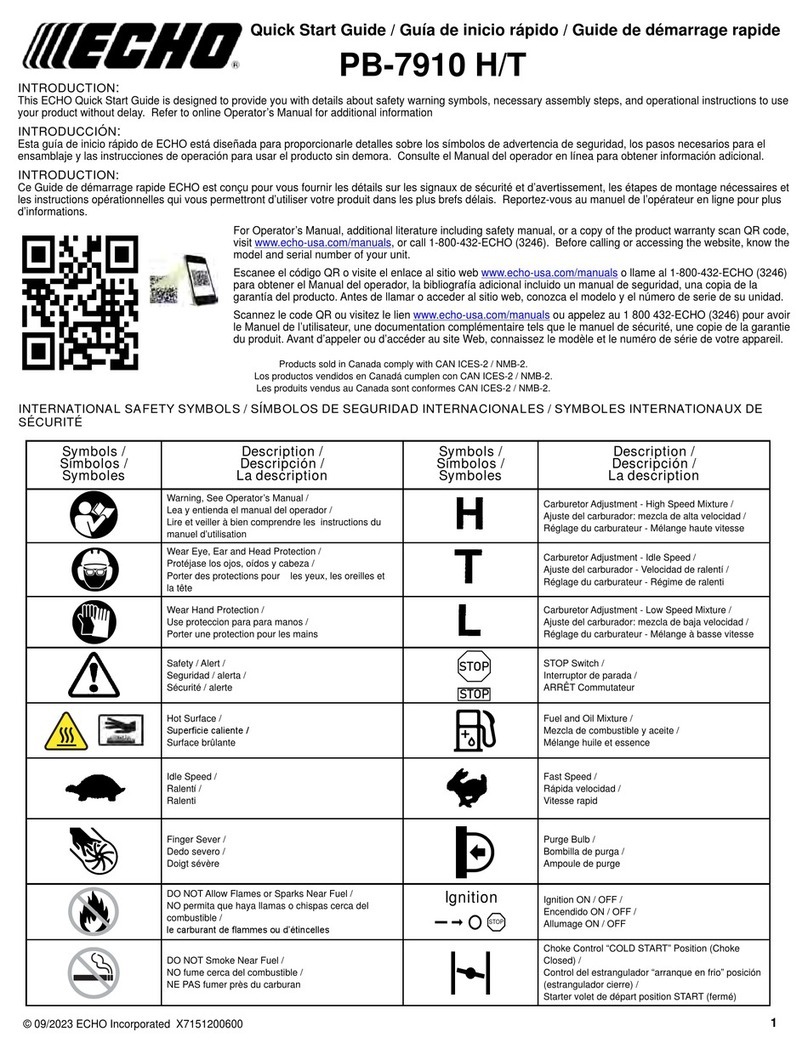

Echo PB-7910 H/T User manual

Echo

Echo HC-150 HEDGE CLIPPER - PARTS CATALOG SERIAL NUMBER 08001001 -... Instruction Manual

Popular Lawn And Garden Equipment manuals by other brands

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Millcreek

Millcreek 406 Operator's manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

AQUA FLOW

AQUA FLOW PNRAD instructions

Tru-Turf

Tru-Turf RB48-11A Golf Green Roller Original instruction manual

BIOGROD

BIOGROD 730710 user manual

Land Pride

Land Pride RCF2784 Operator's manual

Makita

Makita UM110D instruction manual

BOERBOEL

BOERBOEL Standard Floating Bar Gravity Latch installation instructions