3

Contents

Decals and symbols...............................................................................................4

Rules for safe operation.........................................................................................5

Operator safety.................................................................................................. 5

Reduce noise ....................................................................................................5

Reduce chances of damage..............................................................................6

Physical condition..............................................................................................6

Hot humid weather ............................................................................................ 6

Operation...........................................................................................................6

Eye, breathing and hearing protection ..............................................................6

Wear proper clothing.........................................................................................6

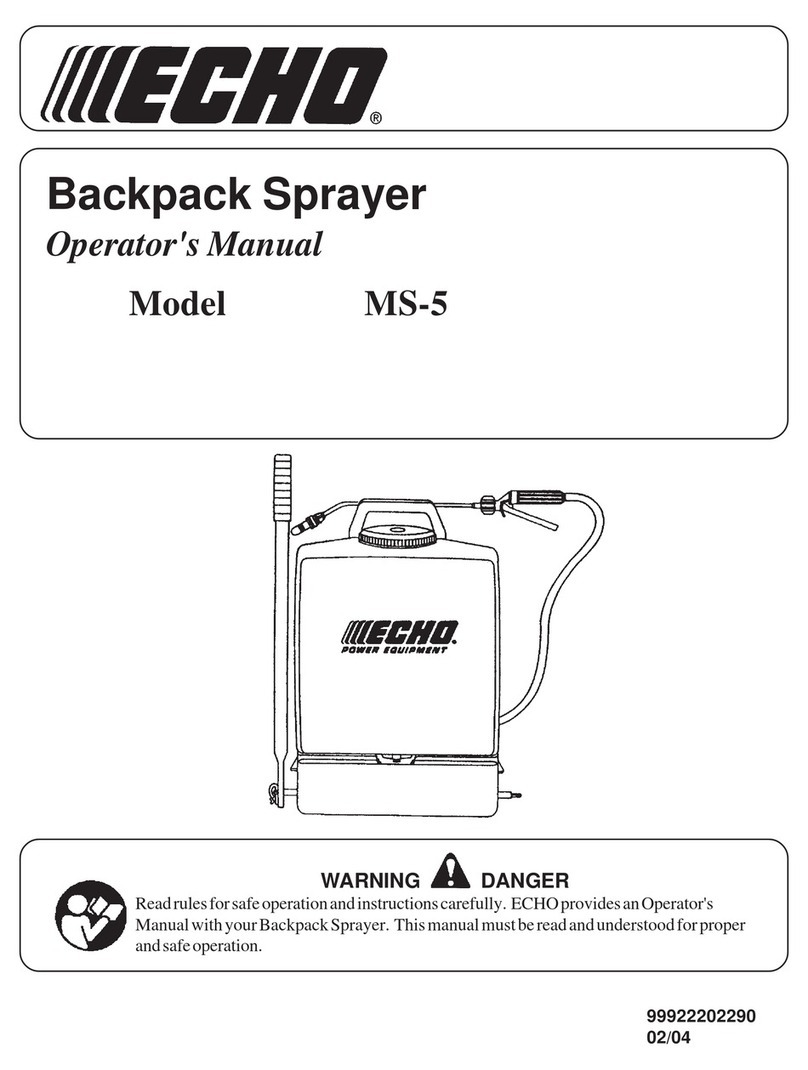

Description ............................................................................................................. 7

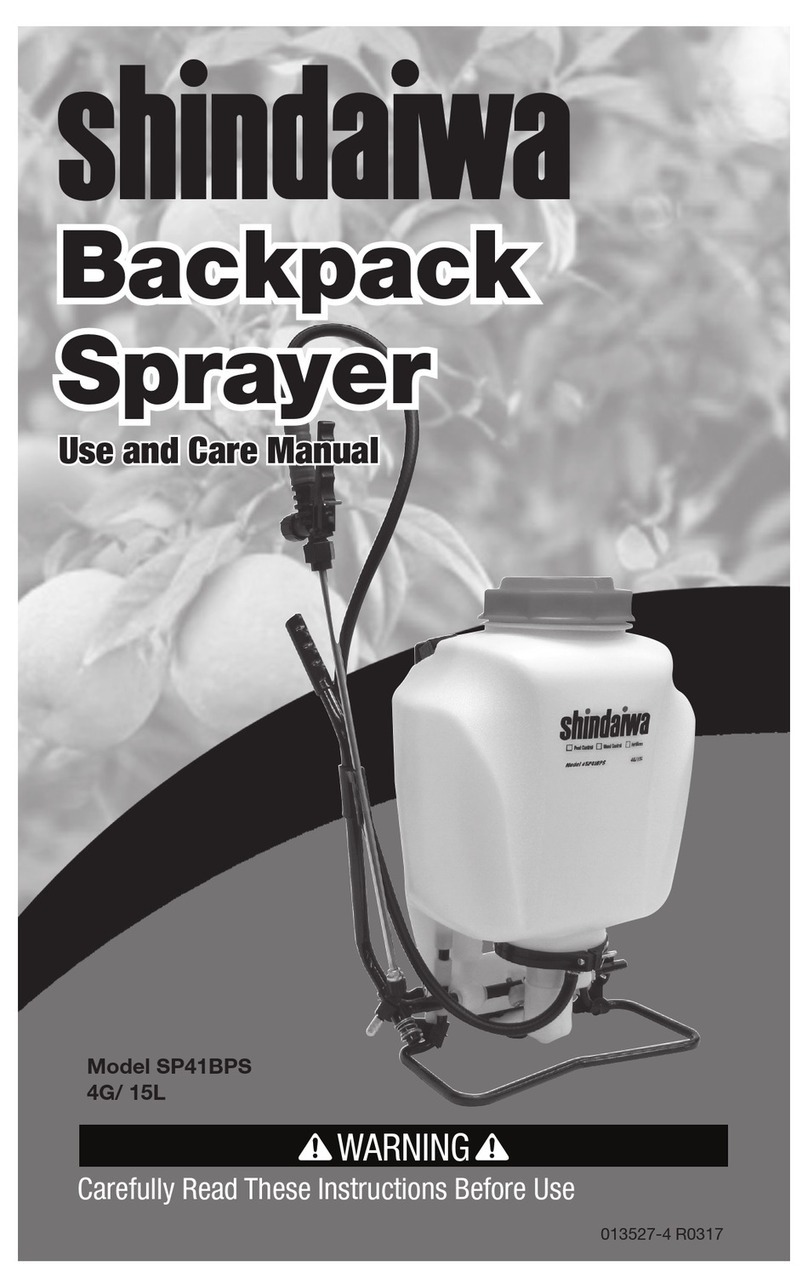

Assembling ............................................................................................................8

Spray hose and nozzle......................................................................................8

Operation ............................................................................................................... 9

Fuel ...................................................................................................................9

Handling fuel .....................................................................................................9

Chemicals..........................................................................................................9

Starting the cold engine...................................................................................10

Starting the warm engine ................................................................................10

Stopping the engine ........................................................................................11

For safe operation ...........................................................................................11

Spraying ..........................................................................................................11

Service maintenance guide..................................................................................12

Troubleshooting ...................................................................................................13

Maintenance and care .........................................................................................14

Cleaning air filter .............................................................................................14

Check fuel system ........................................................................................... 14

Replacing fuel filter.......................................................................................... 14

Check spark plug.............................................................................................14

Cylinder fins (Cooling system).........................................................................15

Carburettor adjustment....................................................................................15

Cleaning silencer.............................................................................................15

Pump greese supply........................................................................................15

Storage ................................................................................................................16

Disposal procedure ..............................................................................................17

Specifications.......................................................................................................18