Difficulty actuating the pump lever and/or Upper valve plate sticks Clean or replace valve plate

pump handle moves itself back up. Piston cylinder outlet passage clogged Clean piston cylinder outlet passage

Little or no resistance during Damaged/worn/dirty/upper and or lower valve plate Clean or Replace Valve Plate

repeated pumping – no pressure. Damaged /worn upper o-ring on piston Replace O-ring

Piston Collar or piston cylinder assembly is worn Replace Collar or Piston cylinder assembly

Too much resistance after just a few Not enough air cushion in the pressure Release pressure in pressure chamber

pumping strokes but pressure only lasts chamber Remove the hose & drain pressure

briefly. chamber. Reconnect the hose.

Upper valve plate damaged/worn/dirty Clean or replace upper valve plate

Upward pumping action is more difficult Vent hole is clogged Clear the vent hole in cap

and/or pump handle moves itself Lower valve plate sticks Clean or replace the valve plate

backdown. Clogged filter Clean in tank filter

Piston cylinder intake clogged Clean piston cylinder intake

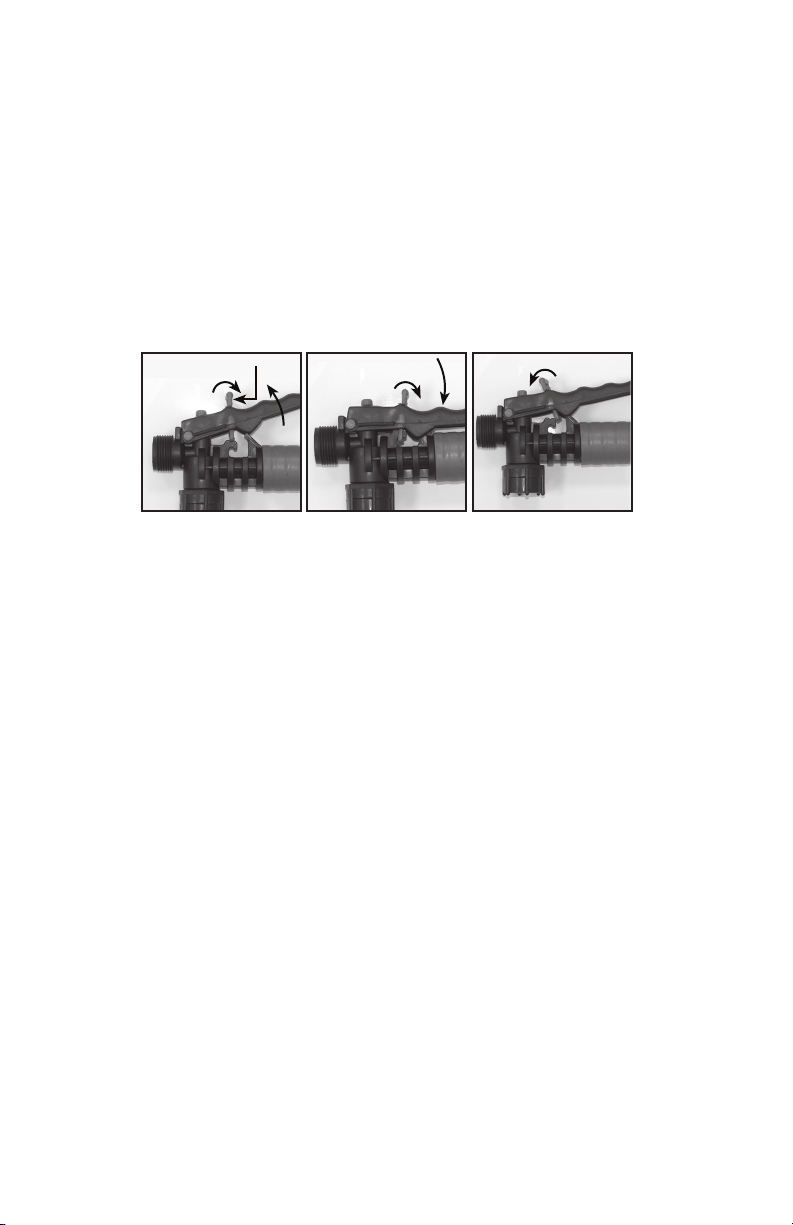

When the handle is pulled up it moves Valve Plate sticking Clean or replace valve plate

itself back down

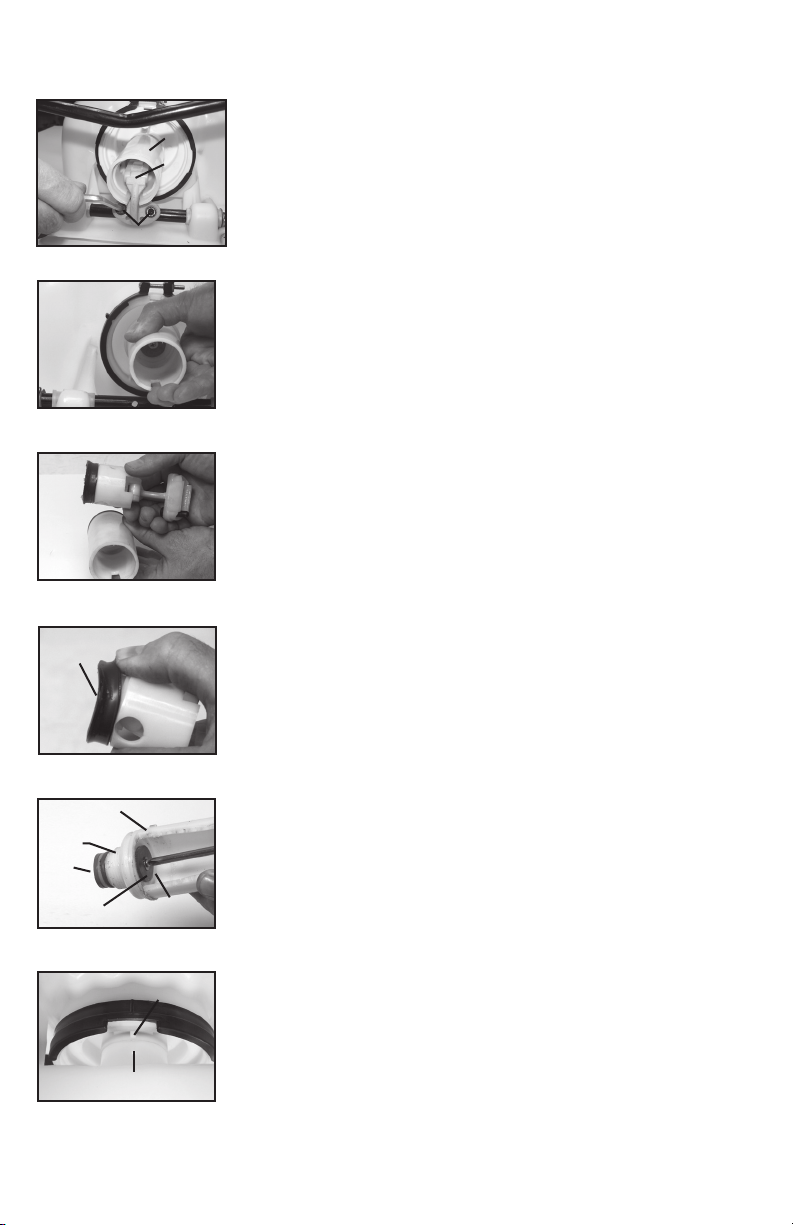

Leaks at Piston Cylinder Damaged/worn/Dirty Collar Clean or Replace Piston Collar

Damaged Piston Cylinder Replace Piston Cylinder

Damaged Piston Replace Piston

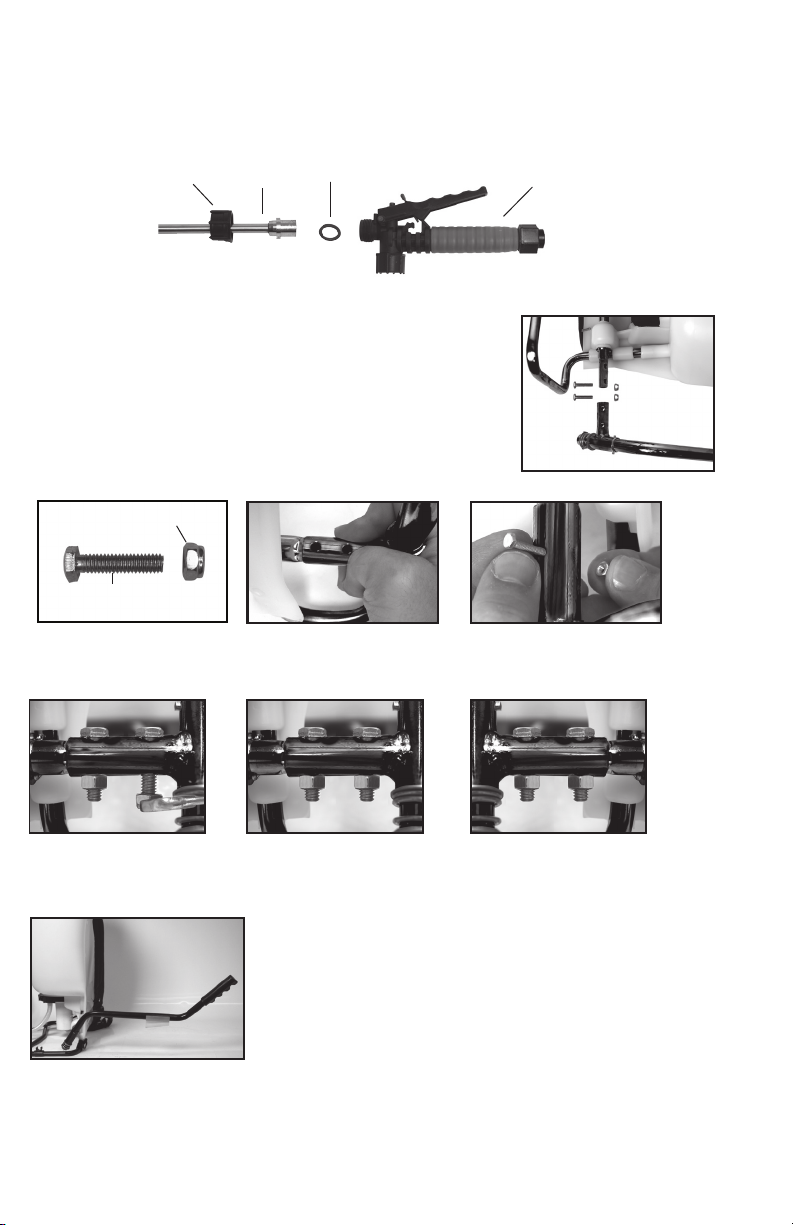

Shut-off leaks Connections loose Tighten connection

Worn or damaged shut-off Rebuild or replace the shut-off valve

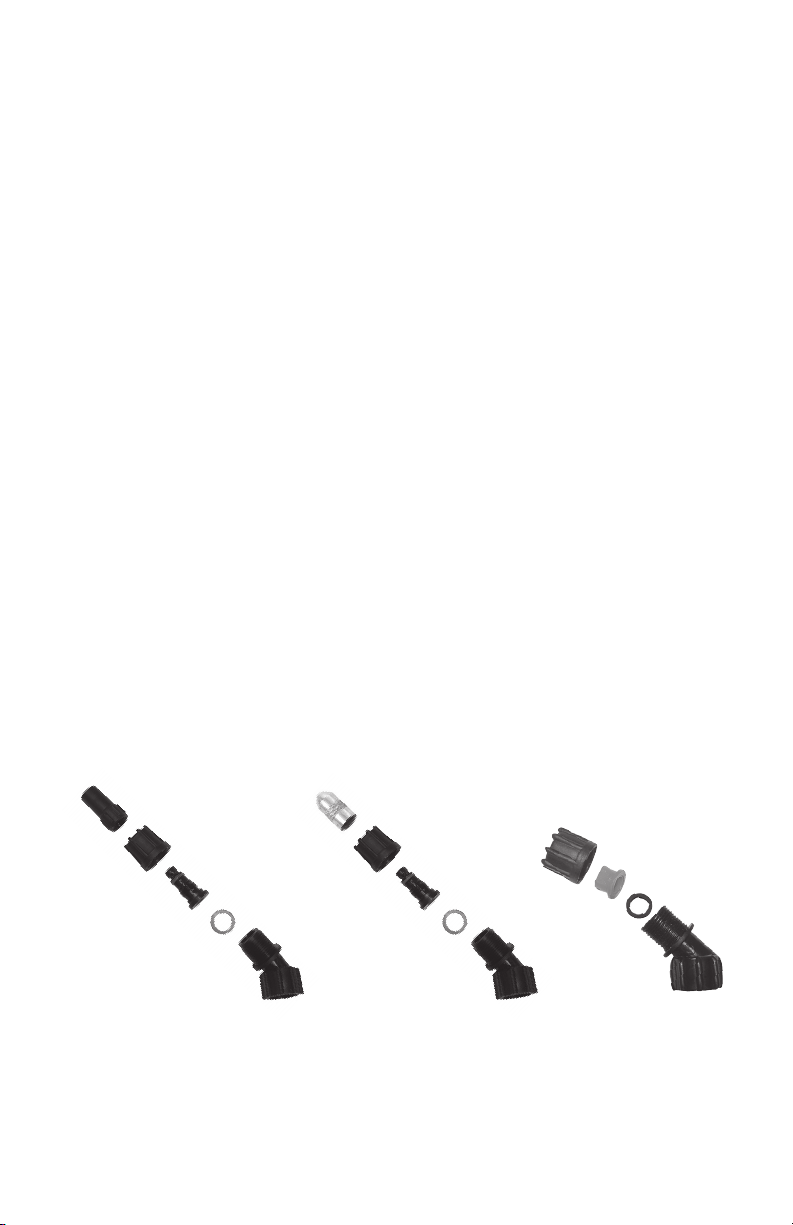

Wand assembly leaks Connections loose Tighten connection

Damaged or worn o-ring/gasket Replace o-ring/gasket

Nozzle assembly leaks Connections loose Tighten connection

Damaged or worn o-ring/gasket Replace o-ring/gasket

Leak between pump assembly Pump clamp loose Tighten clamp

and tank O-ring worn or damaged Replace pressure chamber o-ring

Hose leaking at tank outlet Hose clamp loose Tighten clamp

Hose leaking at shut-off Connection loose Tighten retaining nut

Damaged or worn o-ring/gasket Replace o-ring/gasket

STORING / MAINTAINING YOUR SPRAYER

• The sprayer should be stored out of direct sunlight in a cool dry space.

• Before freezing weather make sure to drain all liquid in the tank, pump, pressure cylinder, hose,

shut-ovalve,wandandnozzle,toavoidliquidexpansionandcrackinginthesprayercomponents

(See“Cleaning”section).Locktheshut-ovalveinthe“open”position.

• When service is required call your nearest dealer and always insist on original manufactured

replacement parts.

•Inspectthehose,wand,pump,tankandshut-ovalveforwear,damageorleaksonaregularbasis

and repair defects promptly.

TROUBLE SHOOTING YOUR SPRAYER

Symptom Possible Reason Correction

7E