4

For safe use of your product

Vibration and cold

It is believed that a condition called Raynaud's Phenomenon which affects the fingers of certain individuals may be

brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning,

followed by loss of colour and numbness in the fingers. The following precautions are strongly recommended be-

cause the minimum exposure which might trigger the ailment is unknown.

Keep your body warm, especially the head and neck, feet and ankles, and hands and wrists.

Maintain good blood circulation by performing vigorous arm exercises during frequent work breaks, and also by

not smoking.

Limit the number of hours of operation. Try to fill each day with jobs where operating the duster/mist blower or

other hand-held power equipment is not required.

If you experience discomfort redness and swelling of the fingers, followed by whitening and loss of feeling, con-

sult your physician before exposing yourself further to cold and vibration.

Failure to observe these instructions could result in damage to your health.

Repetitive stress injuries

It is believed that over-using the muscles and tendons of the fingers, hands, arms and shoulders may cause sore-

ness, swelling, numbness, weakness and extreme pain to the areas just mentioned. Certain repetitive hand activities

may put you at a high risk for developing a repetitive stress injury (RSI). To reduce the risk of RSI, do the following:

Avoid using your wrist in a bent, extended or twisted position.

Take periodic breaks to minimize repetition and rest your hands. Reduce the speed and force in which you do the

repetitive movement.

Do exercises to strengthen hand and arm muscles.

See a doctor if you feel tingling, numbness or pain in your fingers, hands, wrists or arms. The sooner RSI is diag-

nosed, the more likely permanent nerve and muscle damage can be prevented.

Failure to observe these instructions could result in damage to your health.

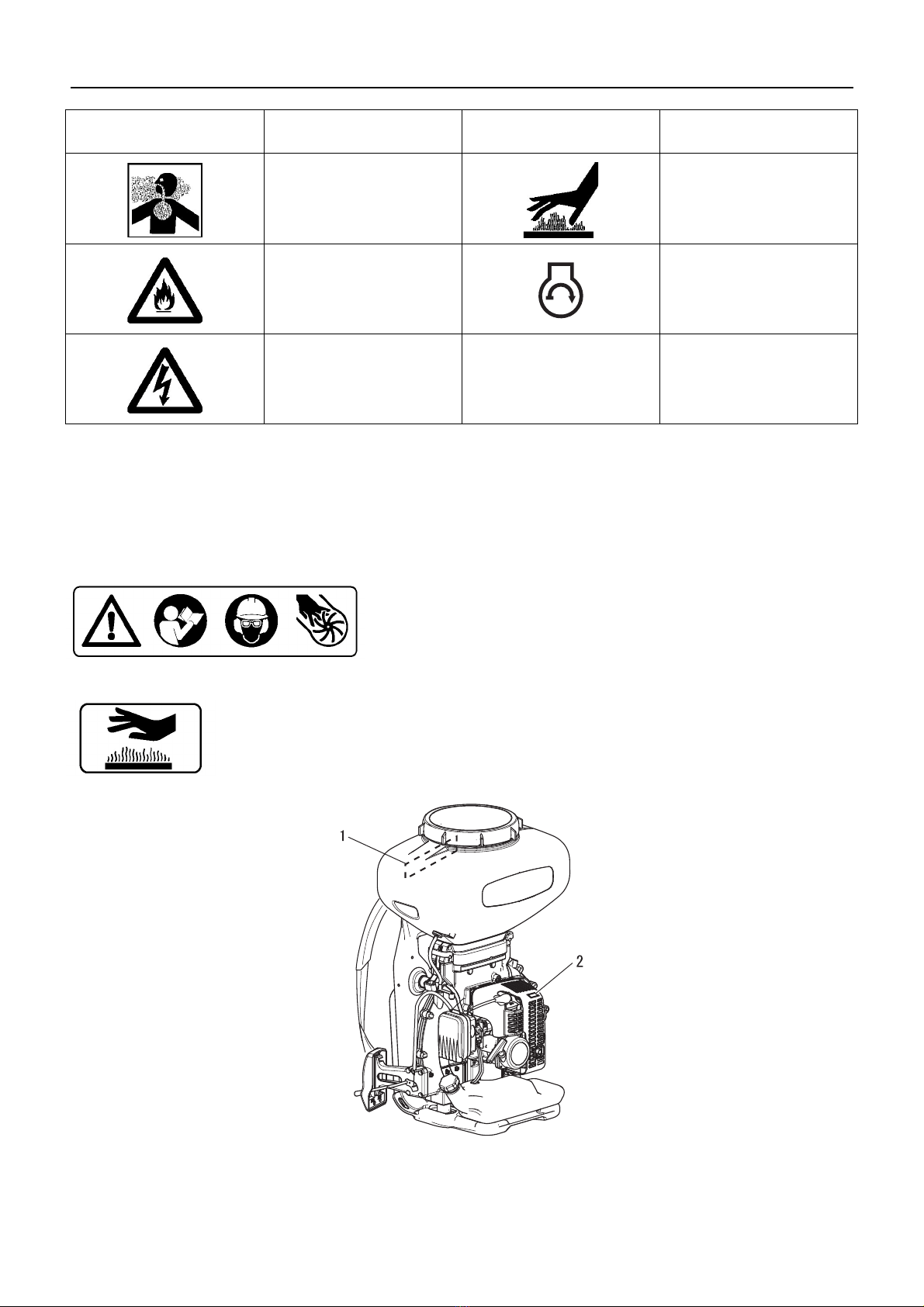

Proper training

Do not permit operation without proper training and protective equipment.

Be thoroughly familiar with the controls and proper use of unit.

Know how to stop the unit and shut off the engine.

Know how to unhook a harnessed unit quickly.

Never allow anyone to use the unit without proper instruction.

Failure to observe these instructions could result in damage to your health.

Wear proper clothing.

Do not wear ties, jewellery, or loose, dangling clothing which could be caught in the

unit.

Do not wear open toed footwear, or go bare-foot or barelegged.

Secure hair so it is above shoulder length.

Failure to observe these precautions could result in damage to your sight or hearing, or lead

to a serious injury.

Wear protective gear

Always wear the following protective gear when working with the unit.

Head protection (cap): Protects the head

Ear muffs or ear plugs: Protect the hearing

Safety goggles: Protect the eyes

Officially approved toxic mist respirator: Protects the breathing

Non-slip, heavy rubber work gloves: Protect the hands from chemicals

Chemical resisting work clothes: Protect the body

Non-skid sole shoes (with toecaps) : Protect the feet

Failure to observe these precautions could result in damage to your sight or hearing, or lead to a serious injury.

Environment of use and operation

Do not use the product:

a windy day or rainy day to avoid chemical drift.

on steep slopes or in places which give no secure foothold and are thus slippery.

at night or in dark places with poor visibility.

A serious injury could result if you fall or slip, or fail to operate the product correctly.

Heavy protective clothing can increase operator fatigue which may lead to heat stroke. Delay heavy work until the

temperature drops.

Failure to observe these instructions could result in damage to your health.

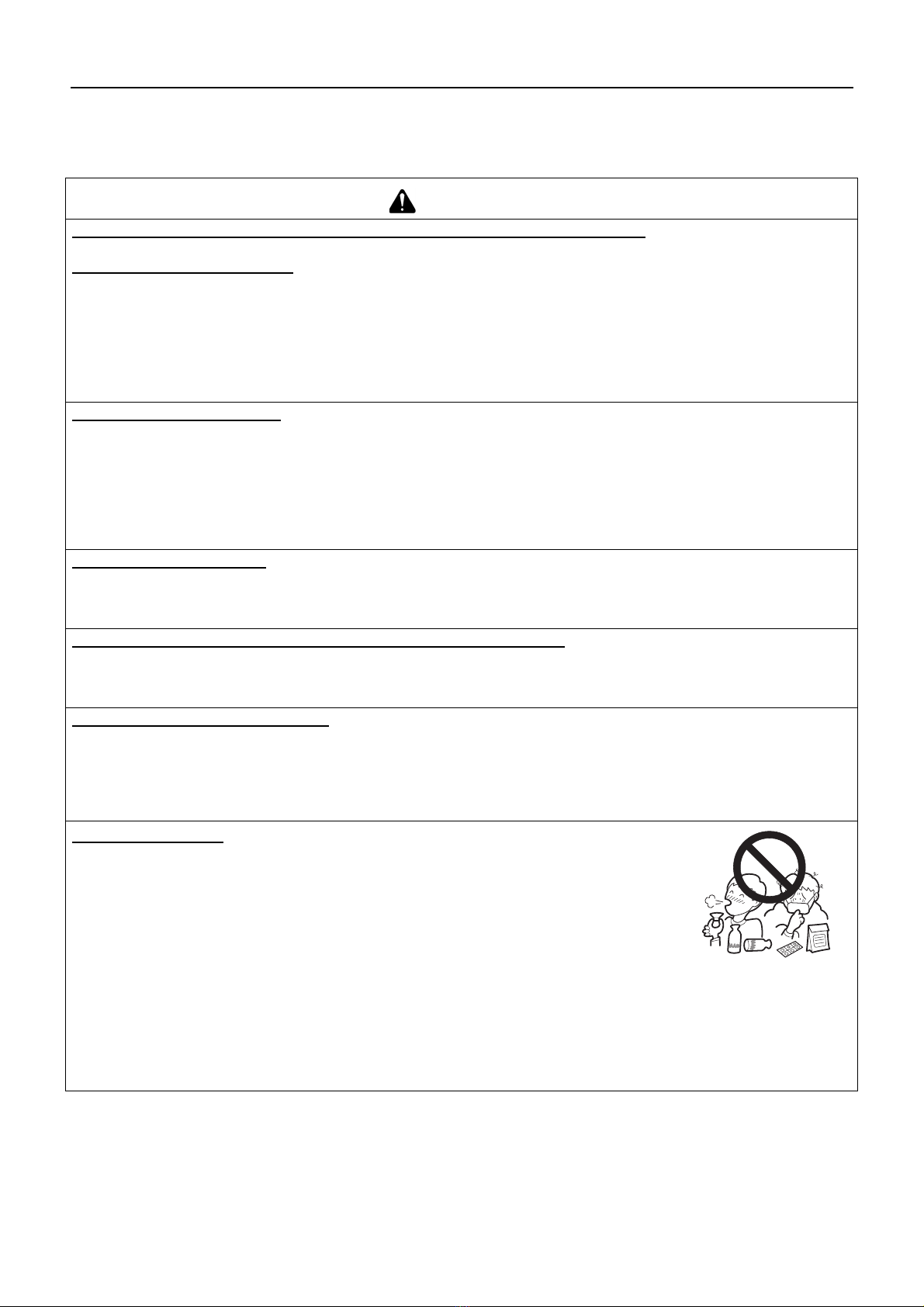

WARNING