ECO Sensors A-22 User manual

11-07

ECO SENSORS, INC.

OZONE SENSOR AND MONITOR

Model A-22

INSTRUCTIONS FOR USE

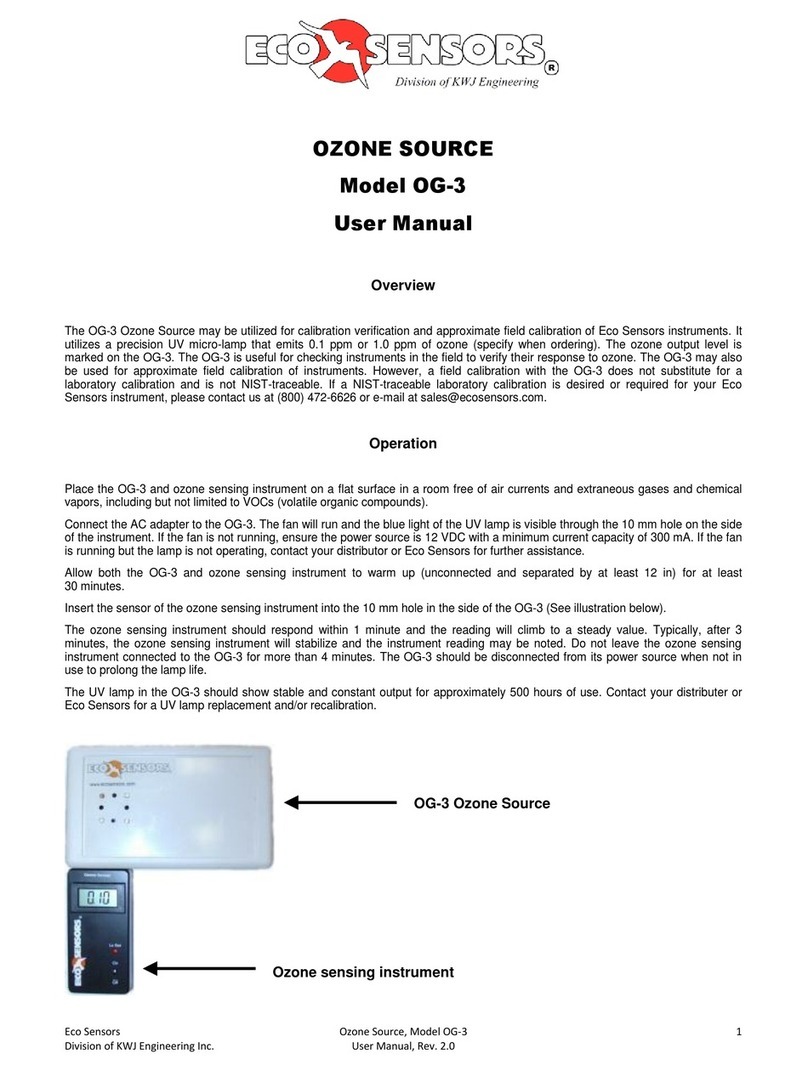

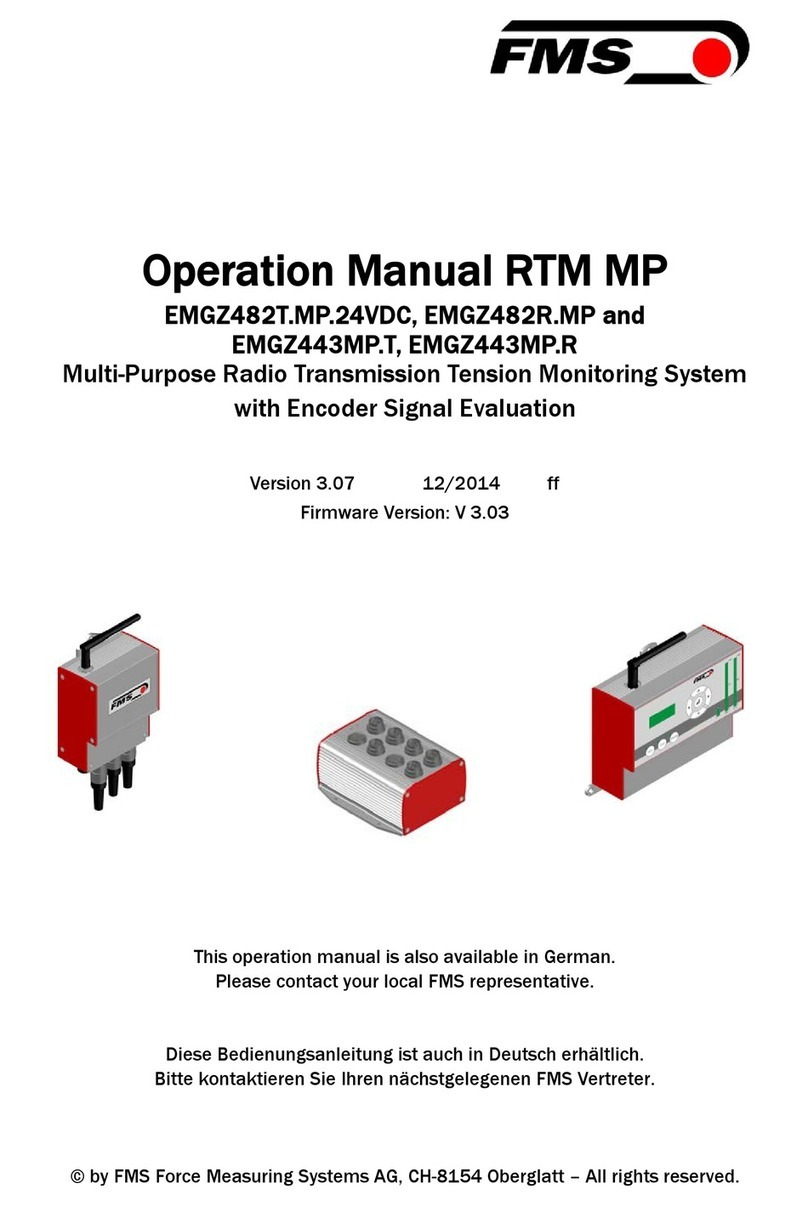

Sensor

A-22

SM-X precalibrated

sensor module.

Replacement easily

sent by mail.

Data and

power jacks

on the side.

Rubber “boot” to

protect against

mechanical damage.

2

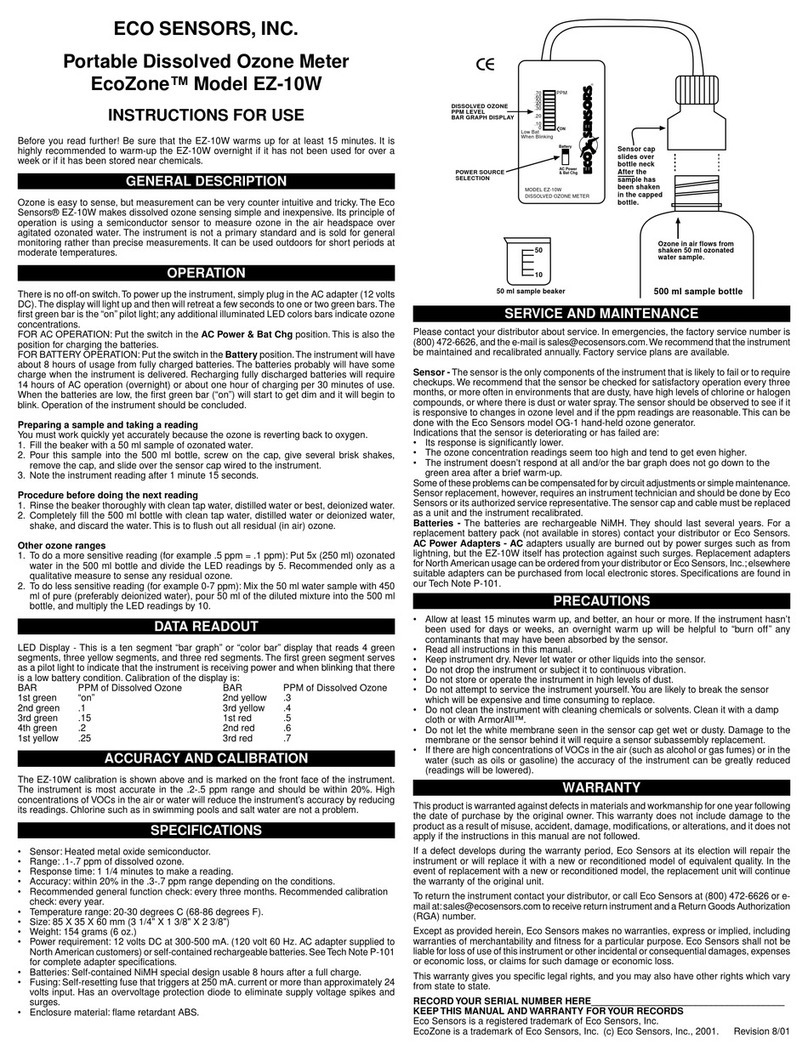

GENERAL

The Eco Sensors A-22 is a general purpose ozone sensor and monitor. It is designed for rugged

indoor use, factories, pilot plants, process facilities and general sensor and monitoring uses. It

uses the same precalibrated sensor modules as our OS-4 permanent monitor and controller. The

internal signal processing is done by digital microprocessors. The A-22 automatically selects the

.030-1.999 or 2.00-20.00 ppm range as required. Its outputs are USB, 4-20 mA, 0-2 VDC and a

digital display that can be back lighted. The plug-in replaceable sensors are precalibrated. The

user can select continuous reading, or the maximum, average or minimum over a period of time.

The hard rubber outer case helps protect the instrument from mechanical shocks. It has a tilt

stand which can also be reconfigured to a hanging hook.

The instrument can be powered by its internal rechargeable batteries or by its AC

charger/adapter.

Do not open or service the instrument or replace the sensor module when the instrument

is turned on. This will damage the sensor calibration memory and possibly other circuits

in the instrument.

The instrument is conditionally warranted for one year. Save a copy of your purchase document

as a proof of purchase and date, and read the warranty statement at the end of this manual.

OPERATION

First, verify that the instrument is working as received. Turn the function switch to on. Digits

should appear on the display and assuming no ozone is present, should stabilize at 0.000. If the

display does not activate, the batteries may have discharged during shipping and storage.

Charge the batteries by rotating the control to the off position. Plug in an AC adapter/charger to

the jack located on the right side of the instrument, and charge overnight.

In order to burn off any chemicals that the sensor may have absorbed during shipping and

storage, you should let the A-22 run with power on and the sensor module connected for 1 hour

before response testing or overnight before the first use on site.

After the instrument has warmed up, you can read the

output with the range of .030-1.999 or 2.00-20.00

automatically selected by the A-22. The output will

also appear as RS-232 at the USB port, 0-2 V for

data logging and 4-20 mA for PLCs.

To read maximum, minimum or average of a data

stream, first turn the control to Reset for a few

seconds until the display reads 0.000. Then, turning

the control switch to Max,Avg or Min will give

corresponding readouts of the data stream maximum value, average value or minimum value

since the instrument was reset. Turning the control to Reset again destroys all previous data.

Maximum, average and minimum data are not stored in memory or outputted from the instrument.

3

The display light button is near the rotary switch control. Pushing that button will activate a

backlight on the LCD display which will remain on for 6 seconds. It will only be visible when the

instrument is in a dark area and should not be used excessively because it creates a large drain

on the batteries.

Note: For best results in moving air, turn the instrument sideways (at 90 deg angle) to the air

flow. Air flow into the sensor will cool it, lowering its temperature, and changing the reading.

CHARGING THE BATTERIES

For the quickest charge (4-5 hours) use a 12-24 VDC adapter, 1 A. A 300 mA adapter, which is

more commonly available, will charge the batteries in about 8 hours (over night). The batteries

should last for 16-24 hours of continuous use (2-3 work days).

CALIBRATION

The A-22 uses a calibration concept that is somewhat novel: The ozone sensor is mounted on a

sensing board, called the SM-X, includes a microprocessor and EEPROM memory. The exact

calibration curve for that particular ozone sensor is burned into the EEPROM. The A-22 host

instrument adjusts the sensor readings for temperature and relative humidity based on data sent

from the sensor module.

In most cases, it is probably cheaper and faster to replace the SM-X sensor board with a freshly

calibrated one than to send the current old one back for recalibration. Also the SM-X board can

NOT be recalibrated in the field. It can only be done by a special computer at Eco Sensors, Inc. It

is more expensive to recalibrate the SM-X than to by a new precalibrated one because the

original SM-Xs are calibrated with semiautomatic equipment.

The SM-X calibration can be checked by the Eco Sensors OG-3 calibration checker. The

calibration is within 15% over the sensor's range. For the OG-3 to mate with the A-22 sensor, it

will be necessary to remove the orange protective “boot” that surrounds and protects the

instrument.

OUTPUTS TO EXTERNAL EQUIPMENT

The A-22 has a variety of outputs to external equipment. Referring to the jacks on the right side

of the instrument, these are:

AC Adaptor USB 2 Circuit output jack:

Tip: 0-2 VDC

Ring: 4-20 mA

4

Connecting the USB output to your computer is shown in Appendix B. This is designed for

Microsoft 2000and XP. It may work on some other Microsoft operating systems. Some computers

will find a deriver in their system that works with our USB. Otherwise, drivers can be emailed to

you by our tech support department reached at tech@ecosensors.com.

MOUNTING STAND

The A-22 outer case includes a removable stand which can be used two ways:

As tilt stand Hung from wall hook

SERVICE AND MAINTENANCE

Do not attempt to do board level repairs or microprocessor programming yourself. This will void

the warranty. We recommend checking the calibration monthly and replacing the sensor module

annually. General repairs should be done at the factory or by an Eco Sensors authorized service

representative.

Calibration of the sensor on its board (SM-X) is done by computer in a special laboratory at the

factory. Therefore in most cases it is lowest cost to replace the SM-X board than to request that it

be recalibrated.

Instruments with problems during the warranty period should be returned as system (OS-4 and

SM-4) to the factory or authorized service representative for diagnosis and repair.

AC ADAPTER

For use in 120 V 60 HZ areas, the Eco Sensors P-20 adapter should be used. For other areas

adapters should be purchased local that fit local wall sockets and conform to local codes. The

output should be 12 volts DC unregulated, 300-500 mA. For fast charge, the adapter output

should be 1 amp. The plug to our instrument should fit a 5.5/2.5 mm socket with the center pin +.

For further details see our Tech Note P-101.

SPECIFICATIONS

Sensor: Heated metal oxide semiconductor.

Ranges. 0-1.999 ppm and 2.00-20.00 ppm autoselected.

Sensitivity: First responds at .01 ppm

5

Response time: Within one minute of when gas reaches the sensor.

Temperature and humidity range: 0-40 deg C and 0-80% relative humidity.

Supply voltage required: 8-24 volts DC, 300-500 mA. Ground -.

Adapter plug: 5.5 mm/2.5 mm female, center +.

Size of instrument: 219 (H) X 111 (W) X 61 mm (D) (8.63" X 4.38" X 2.38").

Weight of instrument: 745 grams (1.64 lbs.).

SAFETY FEATURES

Sensor: Heated element is flame arrestor protected.

Electrical: (a) Circuits operate at 12-24 volts (b) Self-resetting fuse to protect against excess input

current flow. (d) Overvoltage protection diode barrier to protect against supply voltage surges,

spikes, overvoltage, and reverse polarities.

PRECAUTIONS

xAlways have the function switch in the off position with the adapter disconnected when

servicing the instrument or changing the sensor module.

xAllow at least 1-4 hours warm-up for functionality testing and 24 hours warm-up for

operational use.

xRead all instructions in this manual.

xKeep instrument dry. Never let water or other liquids into the sensor.

xDo not drop the instrument or subject it to continuous vibration.

xDo not store in high levels of dust.

xDo not clean the instrument with cleaning chemicals or solvents. Clean it with a damp

cloth.

xDo not operate near heavy aerosols (spray) usage or where oxygen is being

administered.

xCall a qualified electrician if you have any doubts about voltages, currents, electrical

practice, etc.

xDo not operate the instrument or rely on its readings where there are high concentrations

of:

- Chlorine or other halogen compounds

- Sulfur compounds

- Strong VOCs such as solvent vapors.

- Silicone compounds such as RTV.

- Urine residues and ammonia compounds

- Acid gases such as sulfuric acid or nitric acid fumes.

xKeep at least a meter above fruit in food storage applications to avoid the negative

influence of ethylene ripening agent emitting from the fruit.

When in doubt, operate the instrument in your worst case conditions for at least 24 hours to see if

it will operate properly.

6

WARRANTY

This product is warranted against defects in materials and workmanship for one year following the

date of purchase by the original owner. This warranty does not include damage to the product as

a result of misuse, accident, damage, modifications or alterations, and it does not apply if the

instructions in this manual are not followed.

If a defect develops during the warranty period, Eco Sensors at its election will repair the

instrument or replace it with a new or reconditioned model of equivalent quality. In the event of

replacement with a new or reconditioned instrument, the replacement unit will continue the

warranty of the original unit.

If the product should become defective during the warranty period, please return it through your

return instructions and a Return Goods Authorization (RGA) number.

Except as provided herein, Eco Sensors makes no warranties, express or implied, including

warranties of merchantibility and fitness for a particular purpose. Eco Sensors shall not be liable

for loss of use of this instrument or other incidental or consequential damages, expenses or

economic loss, or claims for such damage or economic loss.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

RECORD YOUR SERIAL NUMBER HERE__________________________________

KEEP THIS MANUAL AND WARRANTY FOR YOUR RECORDS.

Eco Sensors is a registered trademark of Eco Sensors, Inc.

© Eco Sensors, Inc. 2007. A-22 REV 1, SM-X, Manual rev 2/07

For brochures, application and tech notes, and other useful information, visit our extensive

7

APPENDIX A

REPLACING THE SENSOR MODULE

1 - Always have the function switch in the off position with the adapter disconnected when

servicing the instrument or changing the sensor module.

2 - Remove instrument from the orange boot and then

remove the sensor module access cover.

3 - Locate the sensor module board. Care note its

location on the main board. It can be unplugged

by pulling it up.

4 - Select a replacement sensor module holding it

by the edges as shown to avoid static electricity

being transferred from your fingers to the

delicate semiconductor chips.

5 - Plug it into the main circuit board so that all the pins

on the main board fit into socket holes on the

module board. The replaced sensor module

should appear as in the photo for step 3.

6 – Replace the sensor module access cover.

7 – Replace the orange “boot.”

8

8 – Power the instrument and after 15 minutes check to see if the sensor seems to be responding

to ozone.

9 – Leave the instrument on for at least an hour and preferably overnight to burn-in the new

sensor (to restore it to its original calibration by burning off VOCs which could be absorbed by the

sensor during storage).

9

APPENDIX B

A22 USB Direct Connect Procedure

Items:

xA22

xUSB Cable

xPC Computer with Windows 2000 or XP

xUSB to UART Driver Disk

1. Install USB to UART Driver Disk in the computer’s CD ROM drive.

2. With the A22 off, attach USB cable from A22 to a USB port on the computer.

3. Turn on A22.

4. The computer should recognize the USB connection

.

5. Select the “Install from a specific location” option.

6. Navigate to the CD ROM drive.

10

7. Run the Installation wizard

8. Finish the driver installation.

11

A22 Communication with the Computer

1. Open HyperTerminal in Windows.

2. Title Connection “A22”.

12

3. Set communication parameters as shown. The COM port will be the highest one. i.e,

COM6

4. The A22 will output at 1 second intervals.

A22 Reading 1.296 PPM:

Table of contents

Other ECO Sensors Measuring Instrument manuals