EcoFasten Clickfit User manual

RAPID

INSTALLATION,

HIGH-QUALITY SOLAR

MOUNTING SYSTEM

FOR SHINGLE AND

TILE ROOFS

2

REV DATE: 07/16/2020VERSION: 2.0

Subject Page #

Introduction 3

Product Description 4

Ratings 5

System Components 6

Required Tools 7

Array Layout 8

Installing ClickFit 9

Flashing and L feet 10

Installing Tile Hooks 11

Tile Hook Sub-Flashing 12

Installing the Rail 13

Module Installation 14 - 17

Bonding and Grounding 18 - 19

MLPE Clip Intallation 20

UL2703 Certied Modules 21-29

Clamp Tables 30

TABLE OF CONTENTS

3

REV DATE: 07/16/2020VERSION: 2.0

1.0 Introduction

This manual describes the installation of the ClickFit mounting system for photovoltaic modules on steep-

slope roofs. Described within are details for composition shingle and tile, attachments for ClickFit for other

roof types are available at www.EcoFastenSolar.com.

All installation manuals are available for download at www.EcoFastenSolar.com.

2.0 General Installation Conditions

2.1 General

Failure to observe the requirements in this document can lead to the exclusion of all guarantees and

product liability. EcoFasten Solar reserves the right to amend this document without prior notice.

2.2 Stability and Condition of the Roof

The roof must be in good condition and strong enough to support the weight of the modules, including the

additional equipment, wind and snow loads. When in doubt, consult with the engineer of record, and/or the

local building inspector.

2.3 Application Range of ClickFit

• Refer to Compatibility module list on page 21.

• Please refer to the Ecofasten ClickFit span tables for system structural certication

and allowable spans.

2.4 Warranty

Guarantee according to the warranty conditions and general terms and conditions of EcoFasten Solar. These

conditions can be found on the website at www.EcoFastenSolar.com.

2.5 Liability

EcoFasten Solar cannot accept any liability whatsoever for damage or injury caused by not taking adequate

safety precautions or (accurately) following the instructions given, or resulting from negligence during the

installation of the product and any corresponding accessories specied in this document.

*Printing errors reserved

INTRODUCTION

4

REV DATE: 07/16/2020VERSION: 2.0

The ClickFit mounting system consists of patented adjustable tile hooks and L feet, rails,

and the installation materials required for the mounting of photovoltaic modules on

composition shingle or tile roofs. For simplicity, tile hooks and L feet will be referred to as

“attachments”.

3.1 Attaching to the Roof

The attachments are fastened to the rafters. Attachments are height-adjustable to level

the system on uneven roof surfaces.

3.2 Attaching the Rail

The rail assembles to the attachments with a click-connector, or Clicker. The rail simply

clicks into place without the use of any tools.

3.3 Attaching the modules

The modules are attached to the rails by means of mid clamps and end clamps.

Installer must review the module manufacturer’s installation manual to conrm

compliance to the warranty terms and conditions.

PRODUCT DESCRIPTION

5

REV DATE: 07/16/2020VERSION: 2.0

Torque Specications

UL 2703 Marking Example:

Fire Rating** Class A System Fire Rating

Max System Voltage 1500 VDC

Max Fuse Rating 30A

Certication Conforms to UL STD 2703

Warranty 20 Year Material and Workmanship

UL 2703 Markings Product listing label is located on the rail end-caps

Roof Pitch 2:12 – 12:12

UL 2703 Allowable Design Load Rating 10 psf downward, 5 psf upward, and 5 psf lateral

Max Module Size 24 sqft

Module Orientation: Portrait or Landscape

Component Torque (in-lb) Notes

Lag Screw N/A Fully Seat. Use visual indicator of the black EPDM ring around the bonded

washer for torquing.

Mid-Clamp 144

End-Clamp 96

Rail Clicker Leveling Bolt 142 Pre-torqued upon delivery. Applies to Tile Hook and L-Foot/Clicker

Hook Height Bolt N/A Lightly clamp hook to ush with top of next tile row

Ground Lug N/A Refer to specic ground lug manufacturer’s installation manual

MLPE Clip 144

MLPE Mount 144

CLICKFIT

SYSTEM

MFG ID CODE: XXX-MM-YYYY

Conforms to UL STD 2703

1234567

TM

**Class A System re rating with Type 1 & 2 PV modules. Any module-to-roof gap is permitted, with no skirt required. This

rating is applicable with any roof attachment.

NOTE: Mid Clamp, MLPE Clip, and MLPE Bracket have been evaluated for multiple use, position independent.

RATINGS

6

REV DATE: 07/16/2020VERSION: 2.0

1) ClickFit Rail

1500033 (2130mm)

1500034 (3166mm)

1500035 (4202mm)

8) MLPE Clip (RockIt Clip 2.0)

9) Module Jumper

1500028

7) MLPE Mount

1510057

2) Rail Splice

1008061

4) CF End Clamp

See Section 10

5) CF End Cap

1510041 (Black)

1510042 (Grey)

3) CF Tile Hook and L foot

1500005 - Tile Hook

1500004 - L foot

6) CF Mid Clamp

See Section 10

SYSTEM COMPONENTS

7

REV DATE: 07/16/2020VERSION: 2.0

Checklist of tools and accessories

Note: *Proper PPE shall be worn at all times*

Tape measure

Roof crayon or chalk (a chalk line can be helpful as well)

Cordless drill with torque adjustment and the following bits:

• 1/2” Hex socket

• 1/4” diameter drill bit. (Drilling length no less than lag bolt depth)

Brush for clearing debris from roof surface. Hint: Leaf blowers

work well to remove any leftover moisture prior to installation.

Torque wrench capable of 0-150 in-lbs

REQUIRED TOOLS

8

REV DATE: 07/16/2020VERSION: 2.0

• Refer to span tables, local jurisdiction, or engineer of record specications when determining setbacks

from roof edges, attachment spans, etc.

• Mark the perimeter and corners of the array on the roof surface.

*Add 3/4” to account for the gap between modules in each direction*

• Draw or snap chalk lines where the rails will be installed,(refer to module manufacturer specs to

determine allowable mounting locations).

• Locate rafters within the area of the array. It may be necessary to shift the array East or West on the roof

in order to fall within the rail cantilever specs (l/3) of span).

• Stagger rafters every row if required by the local jurisdiction, engineer of record, or company policy.

ARRAY LAYOUT

9

REV DATE: 07/16/2020VERSION: 2.0

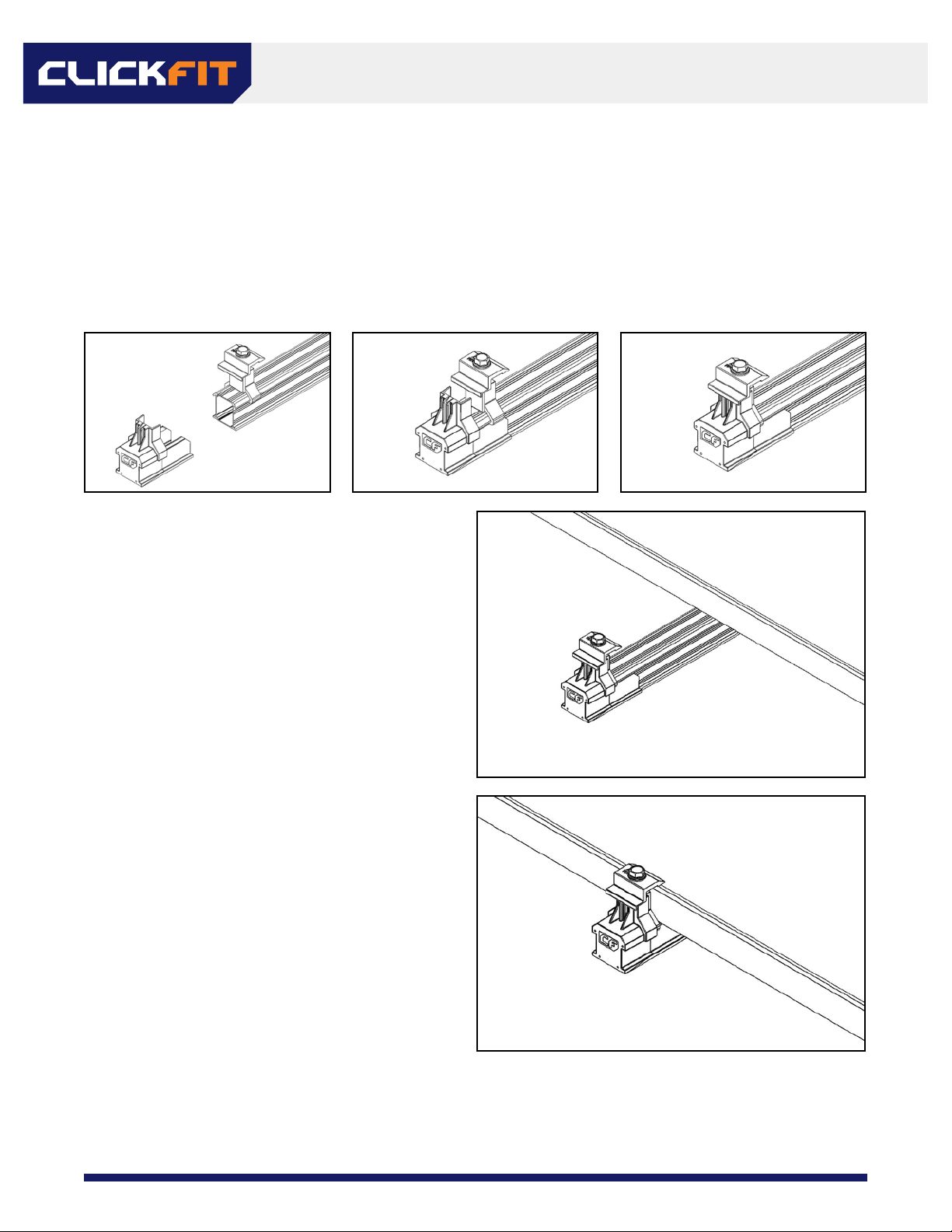

Pre-installing rail splices

1. Determine the number of rails required per row of modules.

2. Insert a rail splice into one rail. *Do not push it past the center bump.*

3. Slide the next rail onto the rail splice until the two rail ends meet.

4. Repeat steps 2 and 3 until the desired length is achieved. *This is usually easiest to do from the

ground.*

INSTALLING CLICKFIT

10

REV DATE: 07/16/2020VERSION: 2.0

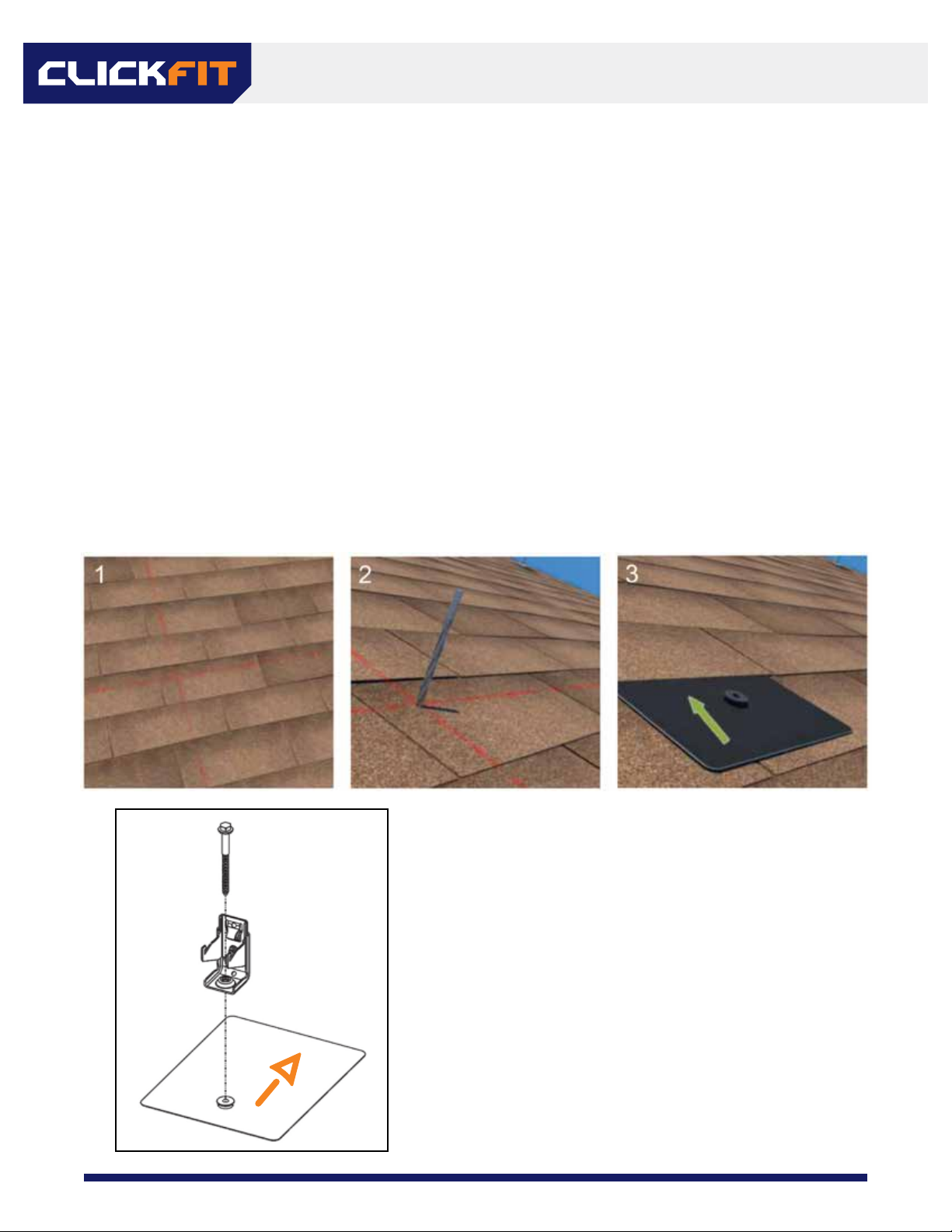

Installation of flashing and L feet

• ClickFit for comp shingle roofs uses EcoFasten Solar’s GFl watertight ashing system

• Other roof types may use dierent EcoFasten Solar attachments, see www.EcoFastenSolar.com for more

information.

Installation Steps:

1. Locate rafter lines from section 5.2.

2. Drill l/4” pilot holes at all attachment points and back ll using roof-compatible sealant.

3. Separate shingles where ashing is to be installed. Insert the ashing so the top portion is under the

next row of shingles North. Ensure the ashing is pushed to the third-course of shingle to prevent water

inltration through the vertical joints between shingles.

4. Align GFl ashing hole with pilot hole. Insert the lag bolt with pre-installed bonded washer through the L

foot and EPDM grommet. Tighten the lag bolt until a ring of EPDM is visible around the circumference of

the bonded washer.

Tighten the lag until fully seated. The EPDM Ring visual indicator is the most eective way to ensure a watertight seal.

*Note the orientation of the L foot and Clicker. The two

Clicker “arms” should be facing downslope*

FLASHING AND L FEET

11

REV DATE: 07/16/2020VERSION: 2.0

1. Locate rafters on the roof, mark the tiles to be removed. Hint: In some cases rafter tails are visible at the

eaves of the roof, making it easy to nd the rough location of the rafters. In other cases, the fascia board

may have nail heads visible where it was attached to the rafters. In the worst-case a row of tiles may

need to be moved to determine the rafter locations.

2. Slide the tile at the desired location upward to expose the roof sub surface. If the tile is to be notched,

or if using a replacement ashing, remove it entirely. Clean the sub surface with a brush to remove any

debris that could aect the sealing.

3. Locate the rafter center and mark it.

4. Place the tile hook with the hook itself in the valley of the next tile below. Drill one l/4” pilot hole in the

rafter center, taking care to keep the hook in the valley of the tile below. Backll this hole with a roof-

compatible sealant. For at tiles, try to avoid having the hook land directly under a joint between tiles,

this will create a larger gap or more notching than necessary.

5. Install one 5/16” x 4” lag screw on the row of holes closest to the tile hook arm. If possible, install the

screw in one of the three holes directly next to the arm. If the lag screw must be installed in one of the

seven holes furthest from the arm (denoted by the red rectangle below), install three deck screws in the

pattern shown by the green circles below.

6. Adjust the height of the tile hook as necessary using the bolt shown in the fourth image.

7. Flash the surrounding area and lag screw head with roof-compatible sealant as necessary. Refer to Tile

Hook Subashing Installation guide on the next page.

8. Replace the tile that was moved and/or removed, or install the tile replacement ashing. If it is to be

notched, mark the tile for notching. Notching can be done with a grinding wheel or by using a chisel.

5.

6.

INSTALLING TILE HOOKS

12

REV DATE: 07/16/2020VERSION: 2.0

CLICKFIT TILE HOOK SUB-FLASHING INSTALLATION STEPS:

Tools Required: Caulking gun, roong mastic applicator

Materials Required: Roong mastic, reinforcing fabric, roof sealant

Lower the sub-ashing over the tile hook base. It may

be necessary to move adjacent tiles to easily lower the

sub-ashing onto the roof deck.

Apply a continuous line of the roong

manufacturer’s approved sealant on the

underside of the ClickFit tile hook sub-ashing

to form a U-shape around the raised edges.

EcoFasten recommends following the TRI guidelines

three-course sealing method. Start the three-course

sealing method by applying a layer of roong mastic

over the edges of the tile hook sub-ashing.

Place the sub-ashing over the base of the tile hook so

the ashing covers the entire base.

Apply a nal layer of mastic to completely cover

the reinforcing fabric. The ashing is now installed

and sealed.

Place strips of reinforcing fabric over mastic to

cover approximately 2” from the edge of the

sub-ashing in both directions. Place strips on

the side rst, then the top edge.

Jan-2020, Rev 1

TILE HOOK SUB-FLASHING

13

REV DATE: 07/16/2020VERSION: 2.0

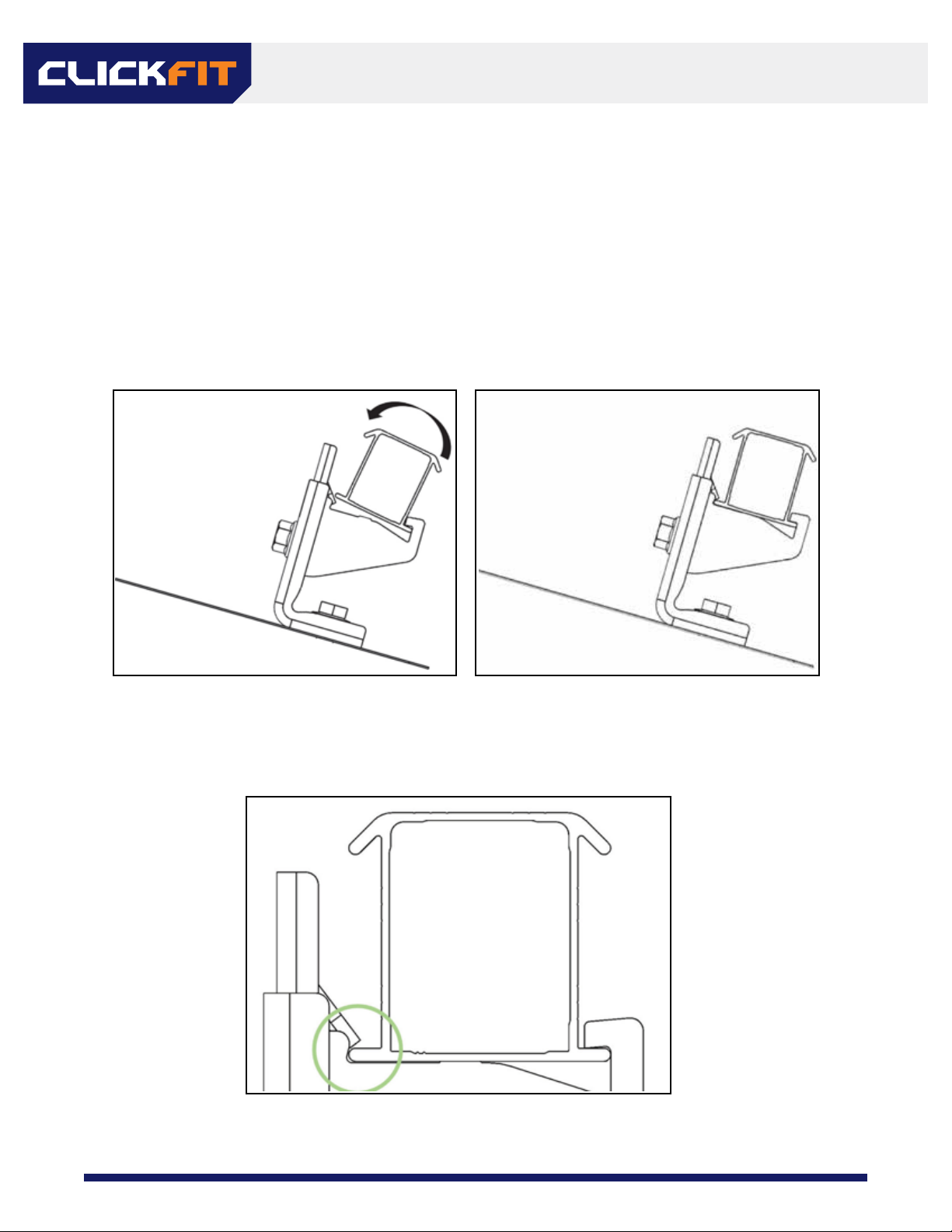

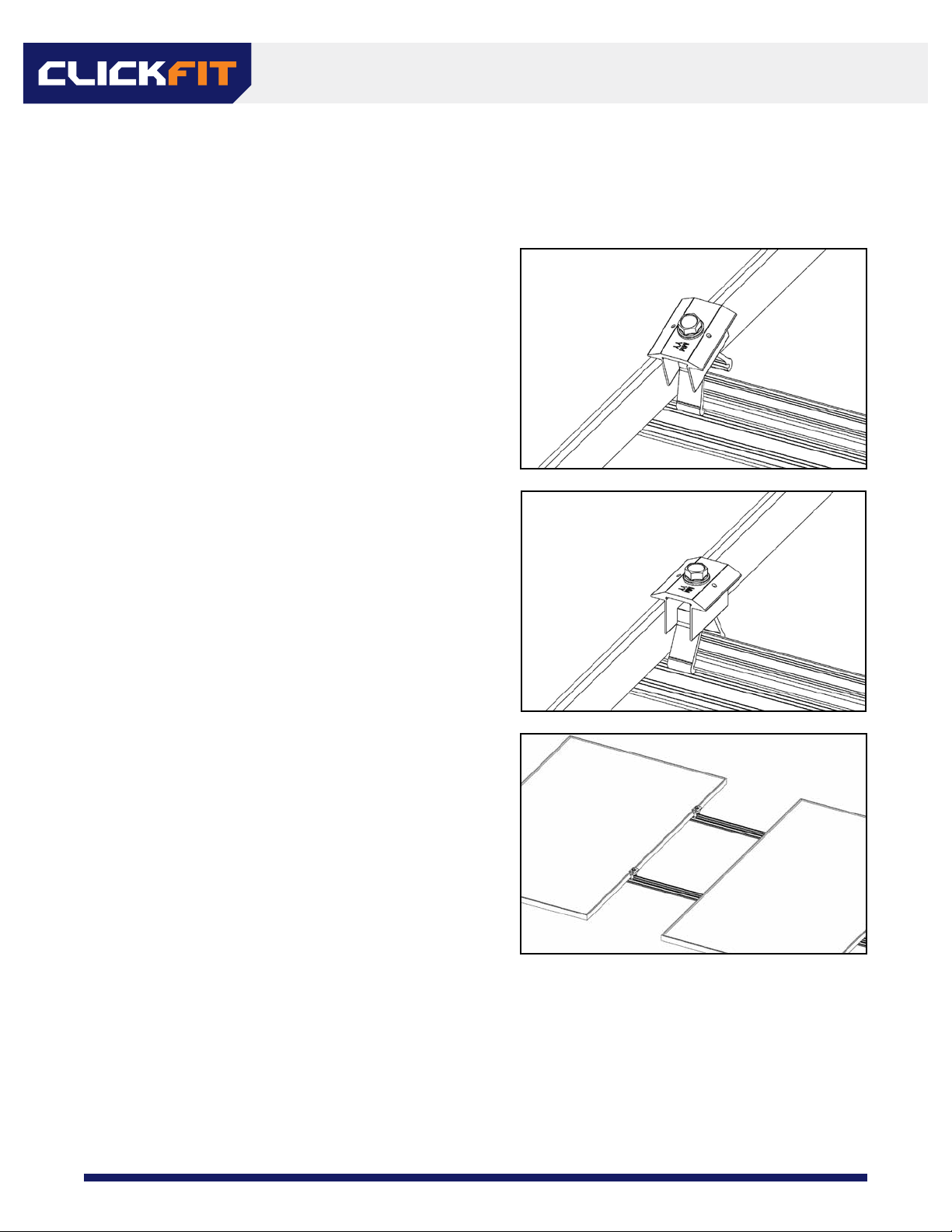

1. Place the rail in the Clickers.

2. Ensure the rails extend a minimum of 2” past the last attachments in each row and that each rail is

aligned with the next row North and/or South.

3. Roll the rail into each Clicker, an audible “click” should be heard. If attachments are extremely misaligned

it may be necessary to loosen the leveling bolt, snap the Clicker onto the rail, then re-tighten the leveling

bolt to 142 in-lbs.

4. Level the rail if necessary by loosening the bolt attaching the Clicker to the L foot or tile hook.

*Ensure the tab on the Clicker is aligned with the rail edge as shown below*

INSTALLING THE RAIL

14

REV DATE: 07/16/2020VERSION: 2.0

1. Install the end clamps on each rail on whatever end you are starting with.

• Snap the end clamp onto the rail.

• Slide the end cap onto the rail.

• Turn the leg of the end clamp around the cap.

2. Place the module on the rail.

*Ensure module junction box is up-slope.*

3. Slide the module to the end clamp and align

it with the array corners. Tighten the end

clamp to 96 in-lb.

MODULE INSTALLATION

15

REV DATE: 07/16/2020VERSION: 2.0

6.6 Installing additional modules on the rail

1. Click a mid clamp onto each rail.

2. Slide the mid clamps until they are ush with the

side of the existing module.

3. Place and slide the next module rmly against

the mid clamps. Align the bottom edges of the

modules. Tighten mid clamps to 144 in-lb.

MODULE INSTALLATION

16

REV DATE: 07/16/2020VERSION: 2.0

6.7 INSTALLING END CLAMPS AT THE END OF A ROW

1. Install the last mid clamps in the row.

2. Measure the rails from the last mid clamp to the module width plus l”.

3. Cut the rails at this mark. There is some adjustment in the end cap/clamp so it does not need to be a

perfect cut.

4. Install end clamps and end caps, tighten to 96 in-lb

Alternative method:

1. Install the last module in the row, tighten the mid clamps.

2. Using a circular saw with a metal blade, or carefully with a reciprocating saw, cut the rail approximately

l” past the edge of the last module.

3. Install end clamps and end caps, tighten to 96 in-lb

MODULE INSTALLATION

17

REV DATE: 07/16/2020VERSION: 2.0

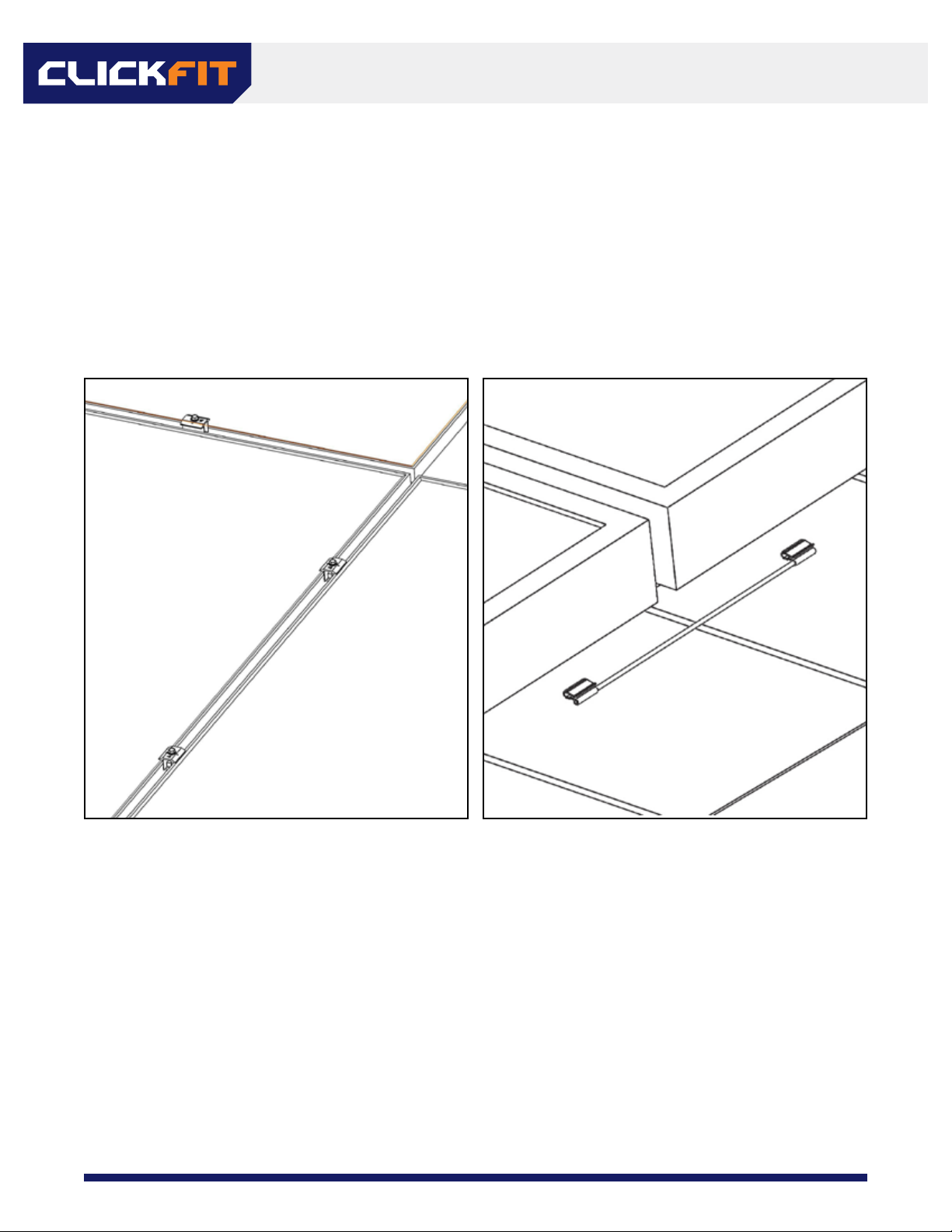

6.8 Installing additional rows of modules

1. Place the rst module of the next row against the end clamps.

2. Temporarily place a mid clamp in the N-S gap between rows of modules, slide the modules up to the

mid clamp as shown below.

3. Once the modules are aligned tighten the end clamps.

4. Install Dynobond clip on the bottom lip of the module frames to bond rows together.

5. Repeat steps 6.5-6.7 until the array is complete.

MODULE INSTALLATION

18

REV DATE: 07/16/2020VERSION: 2.0

Bonding Paths

All bond paths are carried either module-to-module through the mid clamp, or module-to- module through

the module jumper shown below (bond paths shown in green):

1 ground lug per

continuous array

BONDING AND GROUNDING

19

REV DATE: 07/16/2020VERSION: 2.0

Install ground lug on the module per ground lug and module manufacturer’s instructions

NECESSARY COMPONENTS:

On of the following ground lugs (or any UL 2703 compliant ground lug):

• BurndyCL50-1TN Ground Lug (UL 2703 - E3514343 / UL 467-E9999)

• ILSCO SGB-4 Ground Lug (UL 2703 - E354420 I UL 467 - E34440)

• ILSCOGBL-40BT(UL2703 - E354420 I UL467 - E34440l

• ILSCO GBL-4DBTH (UL 2703 - E354420 / UL 467 - E34440)

• ILSCO GBL-455 (UL 2703 - E354420 I UL 467 - E34440)

This system needs to be grounded in accordance with the National Electrical Code, ANSI/NFPA 70.

*Copper wire should not come in direct contact with aluminum at any point on the array*

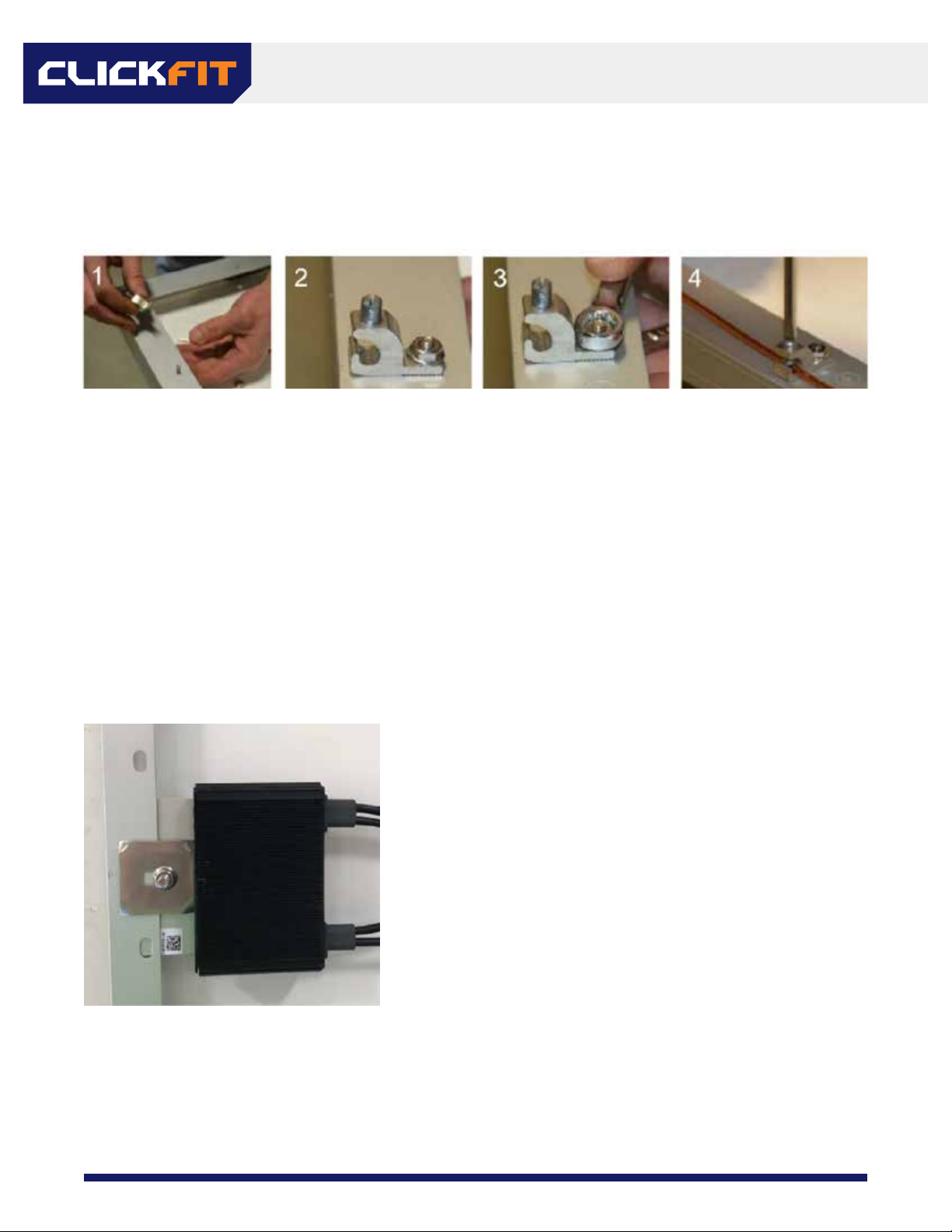

7.3 MLPE Clip Installation (Optional)

7.2 Grounding

GROUNDING LUG INSTALL

INSTALL MLPE CLIP ACCESSORY

• Determine mounting location of the MLPE and MLPE Clip

on the module frame. Take care not to block drainage

holes on the frame.

• Push the nut/bolt of the MLPE Clip so the carriage bolt

head is furthest away from the stainless plate.

• Slide the bolt shaft into the slot on the MLPE mounting

ange.

• Place the assembly onto the module ange, MLPE

mounting ange on the far face (upper side) of the

module frame ange, stainless plate on the closer face

(bottom side) of the module frame ange.

• Hold the carriage bolt into the MLPE mounting ange

slot with your nger, this will keep the carriage bolt from

spinning in the slot. Tighten the nut to 144 in-lbs using a

1/2” hex socket.

MLPE CLIP IS COMPATIBLE WITH:

• Enphase Products: M250-72, 250-60, M215-60, C250-72, S230, S280, IQ

6, IQ 6+, IQ, IQ7, IQ 7A, IQ 7+, IQ 7X, Q Aggregator

• SolarEdge Products: P300, P320, P340, P370, P400, P405, P485, P505,

P600, P700, P730, P800p, P800s, P850, P860

• See page 21 for compatible module list with MLPE Clip

BONDING AND GROUNDING

20

REV DATE: 07/16/2020VERSION: 2.0

MLPE MOUNT INTALLATION

Lower the MLPE Mount to the rail

Set the MLPE Mount ush with the top of the rail

Tighten the bolt to 144 in-lbs

Tilt and hook the mount around

the top “dog ear” of the rail

Slide the microinverter ange between the

MLPE Mount and the serrated bolt ange

Repeat this process for all other microinverter

and/or optimizer installations

MLPE MOUNT IS COMPATIBLE WITH:

Enphase Products: M250-72, 250-60, M215-60, C250-72, S230, S280, IQ 6, IQ 6+, IQ, IQ7, IQ 7A, IQ 7+, IQ 7X, Q Aggregator

SolarEdge Products: P300, P320, P340, P370, P400, P405, P485, P505, P600, P700, P730, P800p, P800s, P850, P860

Other manuals for Clickfit

1

Table of contents

Popular Inverter manuals by other brands

Manitou Systems

Manitou Systems PB-3 SERIES owner's manual

Kaco

Kaco blueplanet 50.0 TL3 Basic operation instruction

Western Co

Western Co W-HPT-3000 Quick installation guide

Huawei

Huawei SUN2000-196KTL-H0 quick guide

TRU Components

TRU Components 1570889 operating instructions

Ingersoll-Rand

Ingersoll-Rand 4TXK2309A1 installation manual