ENC EDS800 Series User manual

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO., LTD

Service manual

mini type

0.2-1.5KW

EDS800 series

Ver. 2.2

ISO9001:2008 Quality Management SystemAuthentication

CE Authentication

Print version:V2.2-A11

Foreword

Encom products are designed and produced according to

EN61800-5-1: 2007,EN 61010-1:2010, EN61800-3: 2004+A1:2012 standards

under ISO9001:2008 quality management system.

Thank you for purchasing EDS800 series mini universal inverter from

Shenzhen Encom Electric Technologies CO., LTD.

EDS800 series can fulfill all kinds of demand for general-purpose inverter

by advanced control manner which make high torque, high precision and

wide-range speed regulation drive be available. EDS800 is organic combine of

customer’s general need and industrial requirement to provide practical PID

adjuster, simple PLC, programmable input output terminal control, long-distance

synchronous control, impulse frequency provision and other special inverter

control with powerful function for customer and to provide highly-integrated

incorporative solution of high value for reducing system cost and improving

system reliability for device manufacturing and automatization engineering

customers.

EDS800’s big torque low noise and low electromagnetic disturbance during

operation can fulfill customer’s environmental protection requirement by space

voltage vector PWM control technique and electromagnetic

compatibility unitary design.

Assembling wiring, parameter setting, troubleshooting and daily

maintenance notice are available in this manual. To make sure that you can

correctly assemble and operate EDS800 series inverters to exert their excellent

performance, please read this user manual detailedly before you assemble the

device and conserve the manual appropriately before the end-user get them.

Please contact our office or dealer in all places at any moment if you have

any doubts or special demands when using these inverters, and you can also

contact our after service center in our headquarters directly. We will serve you

with all our heart.

We reserve our right to notice you if we change contents of this manual.

Welcome to choose other inverters of our company:

EDS-V300 series sensorless current vector control inverter

EDS1000 series multi-function universal inverter

EDS2000 series high performance universal inverter

EDS2860 series special integrative inverter for injection

molding machine

EDS3000 series high performance closed loop vector control

inverter

Contents

1 Safety information and use notice points

1.1 safety precautions

1.2 use range

1.3 use notice points

1.4 scrap notice points

2 Type and specification of the inverter

2.1 incominginverterinspect

2.2 typeexplanation

2.3 nameplateexplanation

2.4 seriestypeexplanation

2.5 appearance and parts name explanation

2.6 outersizeandgrossweight

2.7 outer size of keypad and its fixing box

2.8 product technic index and spec

3 Installation and wiring

3.1 installationambient

3.1.1 demandforinstallationambient

3.1.2 installationdirectionandspace

3.2 partsdisassemblyandinstallation

3.2.1 key board disassembly and installation

3.2.2 plasticcoverdisassembly

3.3 wiringnoticepoints

3.4 main loop terminal wiring

3.4.1 connection between inverter and fitting parts

3.4.2 mainloopterminalwiring

3.5 basicrunningwiringdiagram

3.6 controlloopcollocationandwiring

3.6.1 location&function of terminal and jump-wire

3.6.2 explanation for control panel terminal

3.6.3 analog input output terminal wiring

3.6.4 communicationterminalwiring

1

1

2

2

4

5

5

5

5

6

6

19

6

7

7

10

10

10

10

10

11

11

12

12

14

14

13

14

16

10

18

3.7 installationguideforanti-jamming

3.7.1 restraining to noise disturbance

3.7.2 localewiringandearthing

3.7.3 relation of long-distance wiring and current leak

and the countermeasure

3.7.4 installation demand for electromagnetic on-off

electronic device

4 Run and operation explanation for inverter

4.1 runofinverter

4.1.1 runningorderchannels

4.1.2 frequency-provision channel

4.1.3 workstate

4.1.4 runmode

4.2 operation and use of key board

4.2.1 keypadlayout

4.2.2 keypadfunctiondescription

4.2.3 LEDandindicatorlight

4.2.4 keyboarddisplaystatus

4.2.5 method for operating keypad

4.3 inverterelectrification

4.3.1 checkbeforeelectrification

4.3.2 first electrification

5 Functionparameterschedulegraph

5.1 symboldescription

5.2 function parameter schedule graph

6 Detailedfunctiondescription

6.1 basic run function parameter group: F0

6.2 start-up, stop, braking function parameter group:F1

6.3 auxiliary run function parameter group:F2

6.4 closed-loop run control parameter: F3

6.5 simple PLC run function parameter group:F4

6.6 terminal correlative function parameter group: F5

20

20

22

23

23

24

24

24

24

24

25

26

26

26

28

30

33

33

33

27

67

35

35

35

58

76

81

51

51

56

6.7 traverse special function

p

arametergroup:F6

6.8 frequency provision function parameter group: F7

6.9 motor and vector control function parameter group: F8

6.10 protection function parameter:F9

6.11 failurerecordfunctionparameter:Fd

6.12 code and manufacturer function parameter: FF

7 Troubleshooting

7.1 failureandcountermeasure

7.2 failurerecordlookup

7.3 failure reset

8 Maintenance

8.1 routinemaintenance

8.2 inspection and replacement of damageable parts

8.3 repairguarantee

8.4 storage

9 Examples

9.1 common speed regulation running

9.2 terminalcontrolrunning

9.3 multi-step speed control running

9.4 closed-loopcontrolsystem

9.5 consecutiveactionrunning

10 Modbus communication protocol

Appendix 1 Serial port 485 communication protocol

Appendix 2 Braking resistance

109

93

95

110

111

112

112

114

115

116

123

111

134

97

98

101

102

108

108

109

103

103

106

106

EDS800 series Service Manual

1

1 Safety information and use notice points

In order to ensure the safety of your personal and equipment, before using the

inverter, please read this chapter of contents conscientiously.

1.1 Safety precautions

There are three kinds of safe relevant warnings in this service manual, they

are as follows:

This symbol explains items that need to be paid attention to when being

operated.

This symbol is briefed on some useful information.

This symbol briefs on: If does not operate on request, may cause death,

severely injured or serious property loss.

.

(1) Forbid to connect U, V, W output end to AC power supply, otherwise cause the

complete damage of the inverter.

(2) Don't make P- and P + short-circuited, otherwise cause the inverter to be

damaged.

(3) The inverter is forbidden to install on the flammables, otherwise have danger of

fire.

(4) Don't install it in the environment with explosive gas, otherwise have danger of

causing explosion.

(5)After connecting main loop, should carry on insulating treatment to bare wiring

end, otherwise have danger of getting an electric shock.

(6) If being connected to the power supply, don't operate the inverter with moist

hands, otherwise have danger of getting an electric shock.

(7) The ground terminal of the inverter must be grounded well.

(8) Inverter being connected to power supply, please don't open cover and carry on

wiring, can connect the wire or check only after closing power for 10 minutes.

(9) Only qualified personnel may carry on wiring and forbid leaving over any

conductive thing in machine, otherwise have danger of getting an electric shock

or causing damage of the inverter.

(10) Inverter stored for over 2 years, should be stepped up gradually with voltage

regulator first while having the electricity, otherwise have danger of getting

electric shock and explosion.

!

!

note

!

EDS800 series Service Manual

2

1.2 Use range

(1) This inverter is only suitable for three phases AC asynchronous motor in general

industrial field.

(2) While applying inverter to such equipments that relate much to the life, great

property, safety devices etc., must handle cautiously, and consult with producer,

please.

(3) This inverter belongs to the control device of general industrial motor, if used in

dangerous equipment, must consider the security safeguard procedures when the

inverter breaks down.

1.3 Use notice points

(1) EDS800 series inverter is voltage-type inverter, so temperature, noise and

vibration slightly increasing compared to power source running when using,

belongs to normal phenomenon.

(2) If need to run for a long time with constant torque of low-speed, must select

motor of frequency conversion for use. Use general asynchronous AC motor

when running at a low speed, should control temperature of the motor or carry

on heat dissipation measure forcedly, so as not to burn the generator.

(3) Such mechanical device needing lubricating as the gearbox and gear wheel, etc.,

after running at a low speed for a long time, may be damaged as lubrication

result become poor, please take necessary measure in advance.

(4) When the motor running with frequency above specified, besides considering the

vibration, noise increase of the motor, must also confirm speed range of the

motor bearing and the mechanical device.

(5) For hoist and great inertia load, etc., the inverter would shut off frequently due to

over-current or over-voltage failure, in order to guarantee normal work, should

consider choosing proper brake package.

(1) It is prohibited that connect AC220V signal to control ends except TA, TB, TC,

otherwise have danger of damaging property.

(2) If the inverter is damaged or without all parts, please don't install and operate it,

otherwise have danger of fire or cause personnel to be injured.

(3) When installing, should choose a place where can endure the inverter, otherwise

have danger of injuring personnel or damaging property while falling down.

!

EDS800 series Service Manual

3

(6) Should switch on/off the inverter through terminal or other normal order

channels. It is prohibited that switch on/off the inverter frequently by using

strong electric switch such as magnetic control conductor, otherwise will cause

the equipment to be damaged.

(7) If need to install such switch as the magnetic control conductor, etc. between

inverter output and the motor, please guarantee the inverter is switched on/off

without output, otherwise may damage the inverter.

(8) The inverter may meet with mechanical resonance of the load within certain

range of frequency output, can set up jumping frequency to evade.

(9) Before using, should confirm the voltage of the power is within the working

voltage range allowed, otherwise should vary voltage or order special inverter.

(10) In the condition of altitude above 1000 meters, should use the inverter in lower

volume, reduce output current by 10% of specified current after each 1500

meters height increasing.

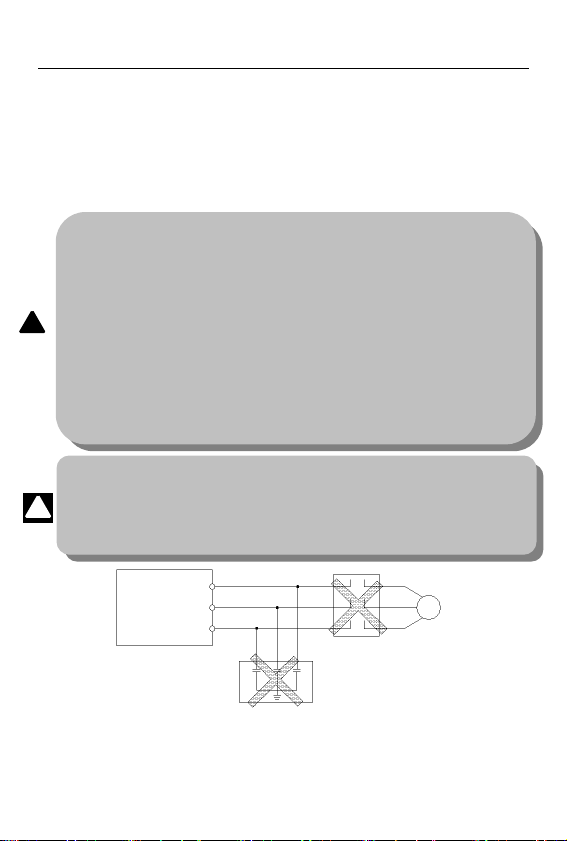

(11) Should make insulation check to the motor before using it for the first time or

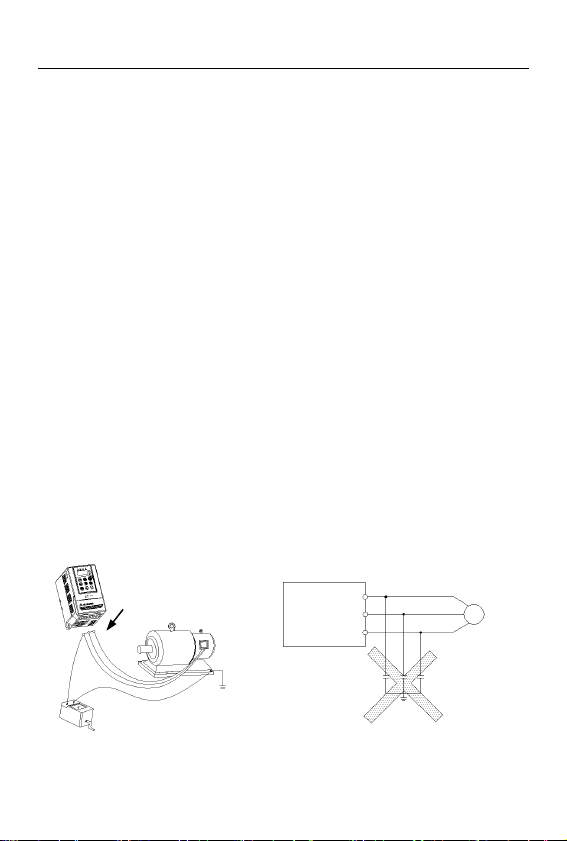

after a long time placement. Please inspect with 500V voltage-type megohm

meter according to method shown as graph1-1 and insulation resistance should

not be smaller than 5 MΩ, otherwise inverter may be damaged.

(12) To forbid assembling capacitor for improving power factor or lightningproof

voltage-sensible resistance etc., otherwise will cause malfunction trip of the

inverter or damage of the parts, shown as graph 1-2.

Fig.1-1 motor insulation measure Fig.1-2 capacitor at output side forbidden

U

V

W

M

EDS800

EDS800

motor

Grounding part

Megohm meter

U VW

After wiring, short-circuit U, V, W

to measure insulation resistance.

EDS800 series Service Manual

4

1.4 Scrap notice points

When disposing scrap inverter and its parts, please note:

(1) The unit: please discard as industrial useless.

(2) Electrolytic capacitor: when burning the inverter electrolytic capacitor in it

may explode.

(3) Plastic: when plastic, rubber parts etc. in the inverter are burning, they may

bring bad, poisonous gas, so please be ready to safeguards.

EDS800 series Service Manual

5

2 Type and specification of the inverter

2.1 Incoming inverter inspect

(1) Check if there is damage during transportation and inverter itself has damage or fall-off

parts.

(2) Check if parts presented in packing list are all ready.

(3) Please confirm rated data of the inverter is in line with your order requirement.

Our product is guaranteed by strict quality system during manufacturing,

packing, transportation etc., please contact our company or local agent rapidly if

some careless omission or mistake arise, we’ll deal with it as soon as possible.

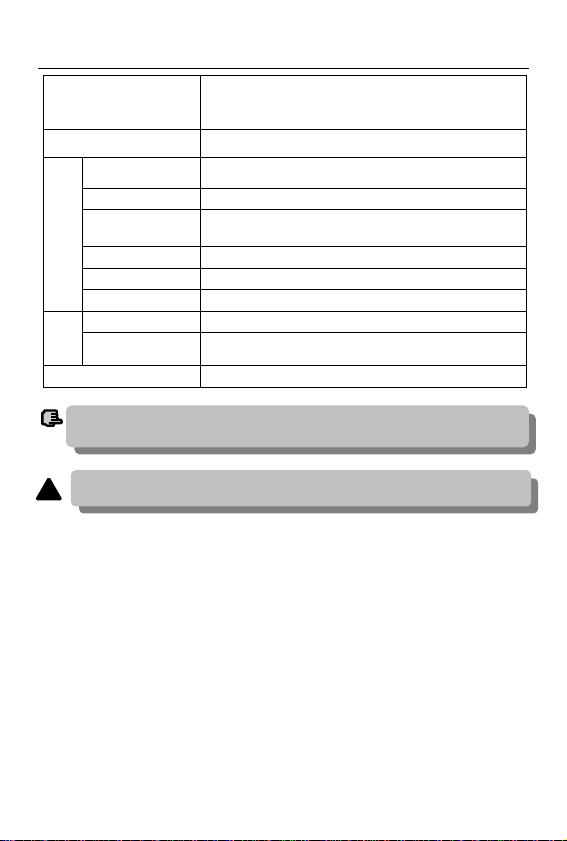

2.2 Type explanation

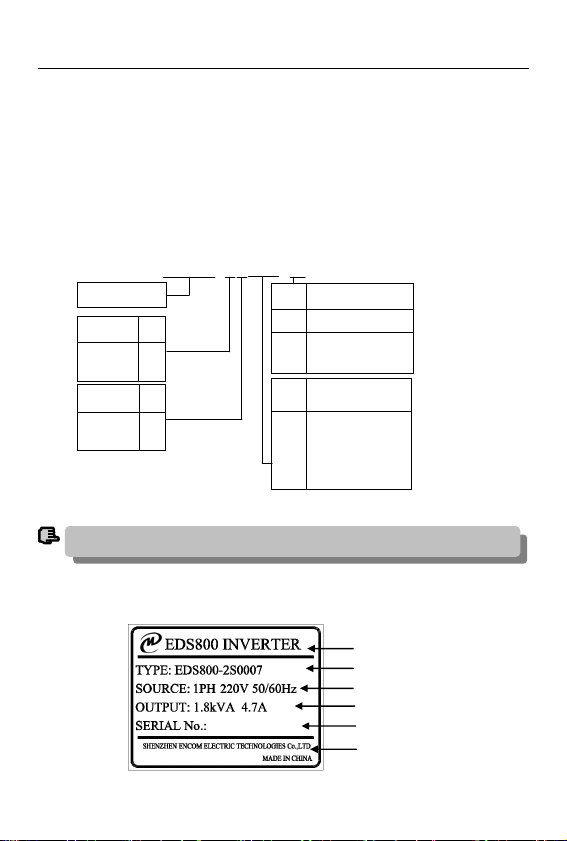

EDS800– 4 T 0015 B

Fig. 2-1 type description

2.3 Nameplate explanation

Nameplate presented as figure 2-2 with type and rating data at the bottom of

inverter right side.

If the inverter hasn’t relevant content or can be defaulted, code after “/” will be ignored.

note

Fig.2-2 Nameplate

Type

Serial No.

Rated input volt. and frequency

Output apparent power

Series No.

Manufacturer

code Fitting part

Bbuilt-in brake unit

Cbuilt-in brake unit

&brake resistance

code Motor power

(KW)

0002

0004

0007

0015

0.2

0.4

0.75

1.5

Input volt. Code

Single phase

3 phase

S

T

Volt. grade code

220V

380V

2

4

Inverter serial no

EDS800 series Service Manual

6

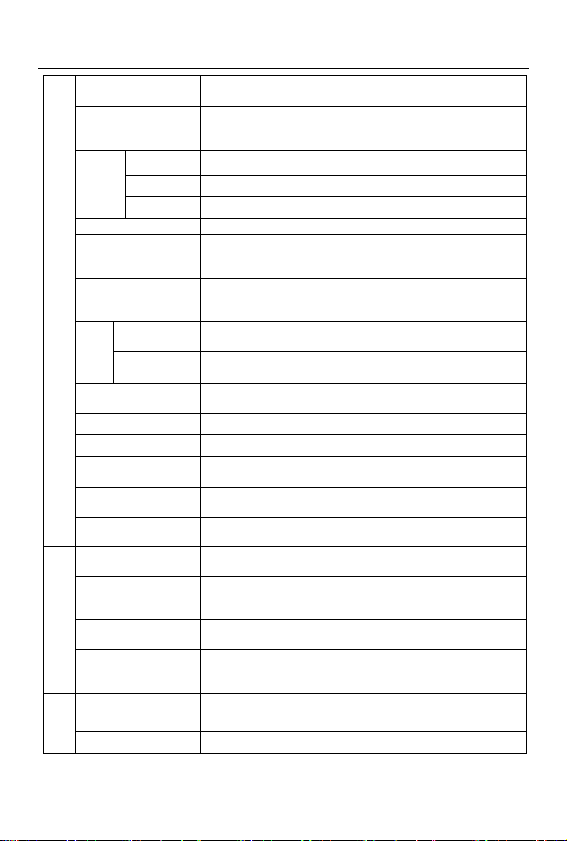

2.4 Series type explanation

Table 2-1 series type explanation

Inverter type

Rated power

(KVA)Rated output

current(A)Adapted motor

(KW)

EDS800-2S0002 0.6 1.6 0.2

EDS800-2S0004 1.1 3 0.4

EDS800-2S0007 1.8 4.7 0.75

EDS800-2S0015 2.8 7.5 1.5

EDS800-4T0007 1.5 2.3 0.75

EDS800-4T0015 2.4 3.7 1.5

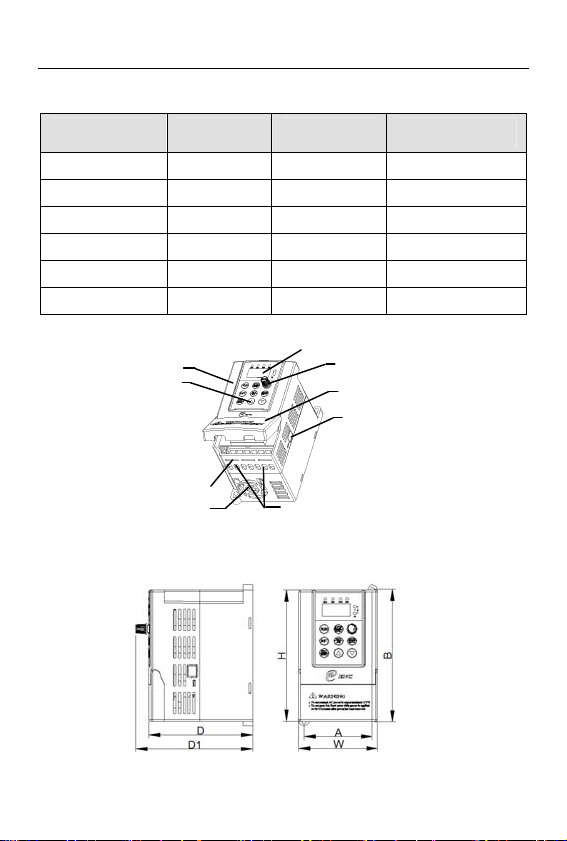

2.5 Appearance and parts name explanation

Fig. 2-3 Parts name sketch for EDS800

2.6 Outer size and gross weight

Fig.2-4 Outline Image

analog potentiometer

power input and inverter output terminal

take this part off to connect

brake resistance(options)

terminal cover

LED

control cable inlet

top cover

keypad

vent

EDS800 series Service Manual

7

Table 2-2 EDS800-2S0002~EDS800-4T0015 mounting size

Inverter type W

(mm)

H

(mm)

D

(mm)

D1

(mm)

A

(mm)

B

(mm)

Fixing

aperture

(mm)

Gross

weight

(kg)

EDS800-2S0002

85 141.5 112.5 126 74 136 5

1

EDS800-2S0004 1

EDS800-2S0007 1.1

EDS800-2S0015 1.2

EDS800-4T0007 1.1

EDS800-4T0015 1.1

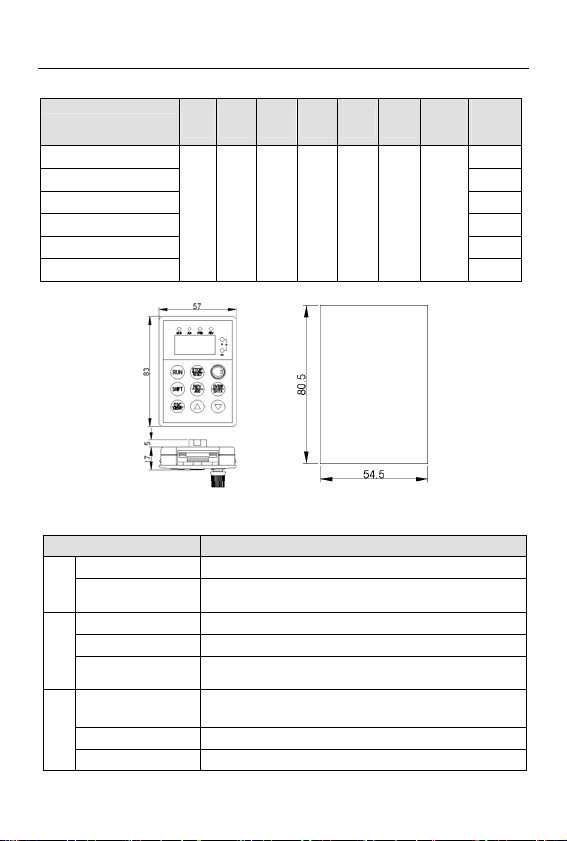

2.7 Outer size of keypad and its fixing box (unit: mm)

Fig.2-5 outer size of keypad and outline of its fixing box

2.8 Product technic index and spec.

item Item description

Input

Rating volt.,frequency 3 phase 380V, 50Hz/60Hz; single phase 220V, 50Hz/60Hz

Allowed work volt. range 3 phase voltage: 320V~460V;

single phase voltage: 200V~260V

output

Voltage 380V grade: 0~380V; 220V grade: 0~220V

Frequency 0Hz-400Hz

Over loading capacity 150% of rating current for1 minute,200% of rating current for 0.5 second;

Control

performance

Control mode Optimum space voltage vector SVPWM constant volt. Frequency ratio V/F

control

Speed regulation range 1:100

Start-up torque 100% of rating torque at low frequency

EDS800 series Service Manual

8

Running speed stable state

precision ≤±0.5% of rating synchronous speed

Frequency precision Digital setting: max. frequency×±0.01%; analog setting:

max.frequency×±0.5%

Frequency

resolution

Analog setting 0.1% of max. frequency-+96

Digital setting 0.01Hz

Exterior pulse 0.5% of max. frequency

Torque boost Automatic torque boost,manual torque boost 0.1%~20.0%

V/F curve (volt. frequency

characteristic)

Set rating frequency randomly at range of 5~400Hz,can choose constant

torque, degressive torque 1, degressive torque 2, degressive torque 3 in total

4 kinds of curve

Accelerating decelerating

curve

2 modes: straight line accelerating decelerating and S curve accelerating

decelerating; 7 kinds of accelerating decelerating time (unit

minute/second can be optioned), max. time 6000 minutes.

brake

Powerconsumption

b

rake exterior brake resistance

DC brake Optional start-up and stop,action frequency 0~15Hz,action volt. 0~15%,

action time 0~20.0 s

Jog Jog frequency range: 0.50Hz~50.00Hz; jog accelerating decelerating time

0.1~60.0s can be set

Multisection speed running Realized by interior PLC or control terminal

Interior PID controller Be convenient to make closed-loop system

Automatic energy save

running Optimize V/F curve automatically based on the load to realize power save

running

Automatic volt. regulation

(AVR) Can keep constant output volt. When power source voltage varies.

Automatic current limiting Limit running current automatically to avoid frequent over-current which

will cause trip

Running function

Running order specified

channel Key pad specified, control terminal specified, serial port specified

Running frequency

specified channel Digital provision, analog provision, impulse provision, serial port provision,

combined provision,can be switched at any time by kinds of method

pulse output channel Impulse square wave signal output of 0~20KHz,can realize output of

physical parameter such as setting frequency, output frequency etc.

Analog output channel 1 channel of analog signal output,AO channel can be 4~20mA or 0~10V;

through it the inverter can realize output of physical parameter such as

setting frequency, output frequency etc.

keypad

LED display Can display setting frequency, output frequency, output voltage, output

current etc. in total 14 kinds of parameter

Lock the button Lock all or part of the buttons(analog potentiometer can’t be locked)

EDS800 series Service Manual

9

Protection function Over-current protection, over-voltage protection, lack-voltage

protection, over-heat protection, over-load protection, missing phase

protection (in option)etc.

Fitting parts brake subassembly, remote-control keypad, connecting cable for

remote-control keypad etc.

ambient

Use ambient indoor,not bare to sunlight,no dust, no corrosive gas, no flammable

gas, no oil fog, no vapor, no water drop or salt etc.

altitude Lower than 1000m

Ambient temperature -10ºC~+40ºC(under ambient temperature 40ºC ~50ºC, please reduce the

volume or strengthen heat sink)

Ambient humidity Smaller than 95%RH, no condensation water

vibration Smaller than 5.9m/s²(0.6g)

Storage temperature -40ºC~+70ºC

Config-

uration

Defending grade IP20

Cooling mode By fan with automatic temperature control

Mounting mode Wall hanging

To exert excellent performance of this inverter, please choose correct type and check

relevant content according to this chapter before wiring for use.

note

Must choose correct type, otherwise may cause abnormal running of the motor or

damage

!

EDS800 series Service Manual

10

3 Installation and wiring

3.1 Installation ambient

3.1.1 Demand for installation ambient

(1) Installed in drafty indoor place,ambient temperature within -10ºC~40ºC,need

external compulsory heat sink or reduce the volume if temperature exceeds40ºC.

(2) Avoid installing in place with direct sunlight, much dust, floating fibre and metal

powder.

(3) Forbid to install in place with corrosive, explosible gas.

(4) Humidity should be smaller than 95%RH,without condensation water.

(5) Installed in place of plane fixing vibration smaller than 5.9m/s²(0.6g).

(6) Keep away from electromagnetic disturbance source and other electronic

apparatus sensible to electromagnetic disturbance.

3.1.2 Installation direction and space

(1) Normally the inverter should be mounted vertically, horizontal mounting will

seriously affect heat dissipation and the inverter must be used in lower volume.

(2) Demand for minimum mounting space and distance,please see Fig.3-1.

(3) When install multiple inverters up and down, must apply leading divider between

them, see fig. 3-2.

Fig. 3-1 mounting space Fig. 3-2 mounting of multiple inverters

3.2 Parts disassembly and installation

3.2.1 Key board disassembly and installation

(1) disassembly

Let the forefinger press finger inlet on the keypad,depress fixing flexible plate on

the top lightly, draw it outward, then you can disassemble the keypad.

(2) assembly

in

ve

rt

e

rinverter

Leading

divider

50mm

mm or more

100 mm or more

100mm or more

50mm

mm or more

Fan

exhaust

EDS800 series Service Manual

11

First place the fixing hook at the bottom of keypad onto mounting claw on

keypad mounting hole, let forefinger press fixing flexible plate on top of keypad

and then push it inside, release it in proper location(after a crisp sound).

3.2.2 Plastic cover disassembly

Put the finger into handle hole on the bottom of cover, lift it, then you can

disassemble the cover.

3.3 wiring notice points

Fig.3-3 banned magnetic control conductor and absorbing capacitance between

inverter and motor

U

Inverter V

W

M

(1)Before wiring, assure power supply is cut off completely for 10 minutes and all LED indicator ligh

extinguished.

(2)Before internal wiring, confirm that DC volt. Between main loop end P+ and P- fall down to below DC36V.

(3)Wiring can only be done by professional person trained and qualified.

(4)Before electrification, check if voltage grade of the inverter is in line with that of power supply volt.,

otherwise will cause personnel injured and device damaged.

!

(1)Assure power cuf off completely for above 10 minutes before wiring, otherwise have danger of

getting electric shock.

(2)Forbid connecting power wire to output U, V, W of the inverter.

(3)There is current leakage in the inverter and leak current of middle/high power inverter is bigger than 5mA,

for safety reason,inverter and motor must be earthed safely, commonly use 3.5mm² above copper wire as

ground wire and ground resistance smaller than 10Ω.

(4)Before shipment compression resistance test of the inverter is passed,so user should not conduct

compression resistance test again.

(5)Should not assemble electromagnetic contactor and absorbing capacitance or other absorbing device,

see Fig.3-3.

(6)To be convenient to over current protect of input side and power off maintenance inverter should be

connected to power supply through relay.

(7)Connecting wire for relay input and output loop(X1~X8, OC1~OC4, FWD, REV), should use above

0.75mm² glued wire or shielding wire,one shielding layer end hung in the air, the other connected to

grounding end PE or E, connecting wire shorter than 20m.

!

EDS800 series Service Manual

12

3.4 Main loop terminal wiring

Fig.3-4 main loop simple wiring

3.4.1 Connection between inverter and fitting parts

(1) Must assemble disjunction device such as isolation switch etc. between

powersource and the inverter to assure personal safety when repairing the inverter

and needing compulsory power off.

(2) Power supply loop must have breaker or

fuse with over current protection function to

avoid malfunction expanding caused by failure

of after device.

(3) AC input reactor

If high-order harmonics between inverter and

Power supply is biggish which can’t fulfil

system requirement, or need to improve input

side power factor, AC input reactor is needed.

(4) Magnetic control conductor only be applied

to power supply control and don’t apply

magnetic control conductor to controlling on/off

of the inverter.

(5) Input side EMI filter

Can use EMI filter to inhibit high-frequency

conduction disturbance and emission

disturbance from inverter power supply wire.

(6) Output side EMI filter

Can use EMI filter to inhibit emission disturbance

noise and wire leakage current from output side.

(7) AC output reactor

Advise assembling AC outputreactor to avoid

motor insulation damage, too large over current

and inverter frequent protection when connecting wire from inverter to motor

Power

supply

L1

L2

L3

U

W

PE

V M

EDS800

3 phase breaker

AC ouput reactor(in option)

Output EMI filter (in option)

Braking resistor

Brake unit

Input EMI filter(in option)

Magnetic control conductor

AC input reactor(in option)

Breaker or fuse

Isolation switch

EDS800

PE W

V

U

L1 L2 L3

L1

L2

L3

N

(in option)

M

Fig.3-5 connection of inverter and fitting parts

EDS800 series Service Manual

13

exceeds 50m.But voltage drop of AC output reactor must be considered. Improve

input output voltage of the inverter or let the motor in lower volume to avoid

burning off the motor.

(8) Complete ground wire

Inverter and motor must be earthed and grounding resistor smaller than

10Ω.Grounding wire should be shorter enough and wire diameter be bigger

enough(not smaller than 3.5mm²):

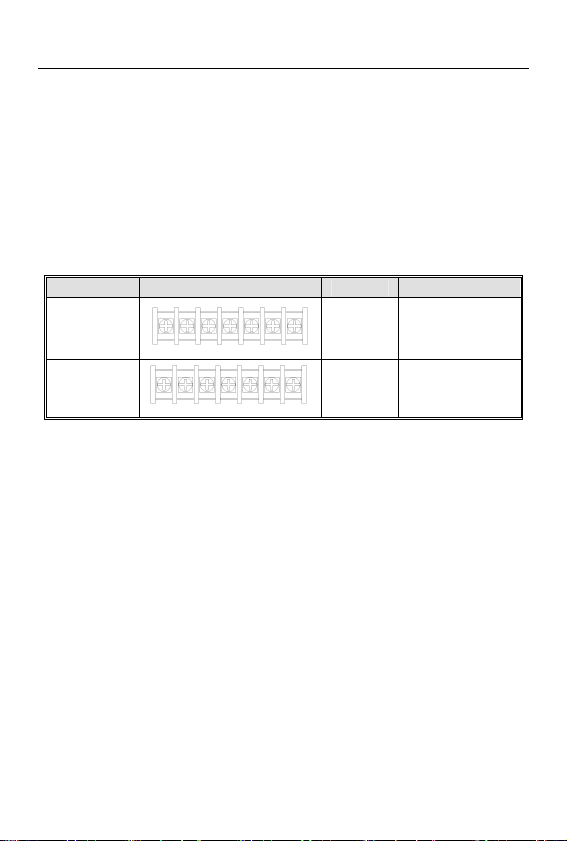

3.4.2 Main loop terminal wiring

For main loop input output terminal, see table 3-1.

Table 3-1 main loop input output terminal description

Adapted type Main loop terminal End name Function description

EDS800-2S0002~

EDS800-2S0015

L1

L2

E

U,V,W

Zero wire

live wire

Grounding terminal

3 phase AC output end

EDS800-4T0007

EDS800-4T0015

L1,L2,L3

E

U,V,W

3 phase AC intput end

Grounding terminal

3 phase AC output end

L1 L2 UV

W

E

L1 L2 UVW

E

L3

EDS800 series Service Manual

14

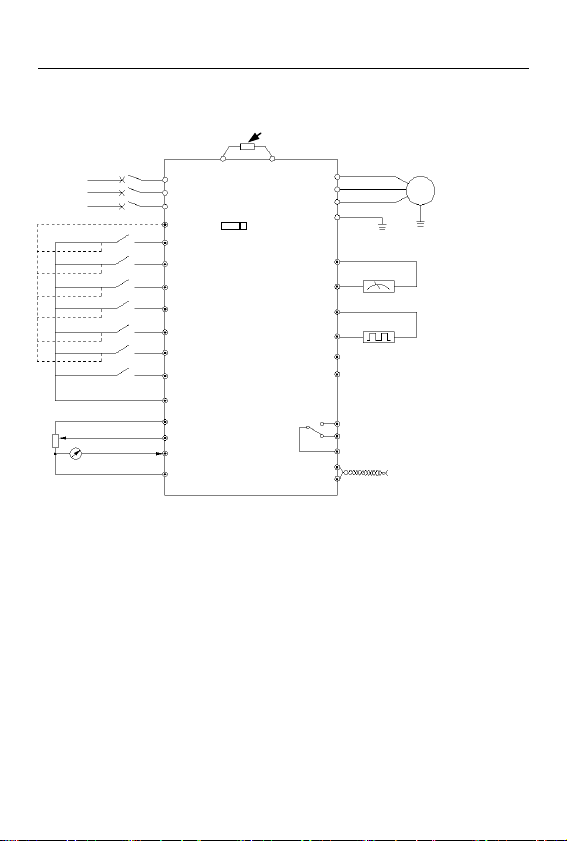

3.5 Basic running wiring diagram

Notice1:When FWD,RWV,X1~X5 terminal imput signal need low level(or pup

joint with COM) is effective. Please put JP3 on “L”.

Notice2:When FWD,REV,X1~X4 terminal imput signal need high level(or pup

joint with +10v) is effective. Please put JP3 on “H”.

3.6 Control loop collocation and wiring

3.6.1 Location&function of terminal and jump-wire:

For location of terminal and switch on the CPU board, please see Fig.3-7.

Function description of terminal provided for the user, please see Table 3-2,

function and setup description of switch, please see Table 3-3,terminal CN1 is for

manufacturer’s use. Should carry on terminal wiring correctly and set switch on the

CPU board before using the inverter,to use at least No.24 conducting wire as

terminal connecting wire is recommended.

Fig. 3-6 basic wiring diagram

Braking unit (external,fitting part, interface at the

right side of inverter )

P+ PB

L1

L2

L3

breaker

forward run/stop

reverse run/stop

multi-function 1

multi-function 2

m

ulti-function 3

m

ulti-function 4

multi-function 5

FWD

REV

X5

X4

X3

X2

X1

U

V

W

E

GND

AO

DO

OC

TA

TB

TC

485A

485B

EDS800

Standard RS485

communication port

Malfunction relay output

open circuit collector output

Cymometer

Output 12V impulse signal

M

0~10V or 4~20mA

0~10V

speed command

+10V

VCI

CCI

GND

COM

power

su

pp

l

y

DC amperometer

4-20mA current signal

or 0~10v voltage signal

COM

OCG Maximum 220VAC, 0.5A

+10V JP3

H L

multi-function5 canbe

used for high spee

d

pulse input

①Notice 1

②

N

otice2

This manual suits for next models

6

Table of contents

Other ENC Inverter manuals