TENTEK Tribune-EMS User manual

User Manual

TENTEK Tribune-EMS

1.6kW / 2.4kW

Version: 1.0

8th Floor, B-A1, #2 Shihuan Rd, Shiyan Town,Baoan District, Shenzhen,China.

Shenzhen Tentek New Energy Technology Co., Ltd.

www.tentekenergy.com

+86-0755-2301 6478

info@tentekenergy.com

BAT

LOAD

ALARM

PV

RUN

Controller

Tribune-EMS

1 2

Table of Contents 1、Manual Information

1. Manual Information

1.1 Validity

1.2 Scope

1.3 Target Group

1.4 Symbols

2. Safety Instruction

3. Introduction

3.1 Product Oveiew

3.2 Key features of the Product

3.3 Technical Structure of the Product

3.4 Electrical Connection Diagram

3.5 Connections Pos

4. Installation Prepaion

4.1 Note Before Installation

4.2 Physical Damage Inspection

4.3 Packing List

4.4 Tools Required for Installation

4.5 Devices and Components for Entire System

5.Sta Installation

Step 1: Mounting the Controller on the Wall

Step 2: Mounting the Microinveer on the Wall

Step 3: Microinveers and Controller Connection

Step 4: Controller and Batte Connection

Step 5: Controller and Grid Connection

Step 6: Controller and EPS Load Connection

Step 7: PV Connection

Step 8: System Unit Check and LED Display

6.Storage and Working Mode Set by T-Shine APP

7.Technical Data Sheet

This manual is valid for the following devices:

TENTEK Tribune-EMS Controller: 1.6kW to 2.4kW

1.1 Validity

This document is intended for qualied persons and end users. Tasks that do not require any paicular qualication can

also be peormed by end users. Qualied persons must have the following skills:

1.2 Scope

This manual describes the transpo, installation, operation and troubleshooting of this unit. Please read this manual

carefully before installation and operation.

1.3 Target Group

Knowledge of how an inveer and controller work and their functions.

Training on how to deal with the dangers and risks associated with installing and using electrical devices and installation

Training on installation and commissioning of electrical devices and installation

Knowledge of applicable standards and directives

Knowledge of compliance with this document and all safety information

1.4 Symbols

The following symbols appear on the product label and are described here:

Symbols Explanation

Caution:hot suace!

DANGER:

Under “Caution, hot suace”, it should be noted that suaces of equipment may be hot and create

a burn hazard.

Refer to manual:

Under “Instructions for Use“, it is pointed out that installation and operating instructions are to be

read and understood before installation or repair.

DANGER:

Risk of electrical shock. Hazardous voltage will cause death or serious inju. Turn o the Power

before working on this equipment.

Refer to safety instructions.

Attention!

With the term “attention” - a circumstance is listed which may cause propey damage if disregarded.

Special disposal instructions!

With “Note Separate Disposal”, it is noted out that this product can not be disposed of with normal

garbage. An improperly conducted disposal can lead to damage to the environment.

1 2

2

2

2

2

3

4

4

5

5

6

7

7

7

7

8

8

9

9

9

10

10

12

13

14

16

17

18

2. Safety Instruction 3. Introduction

This chapter contains impoant safety and operating instructions. Read and keep this manual for future reference

1.Before using the unit, read all instructions and cautiona markings on the unit, and all appropriate sections of this

manual.

2.Only qualied personnel should install, troubleshoot, replace this device or cable and accessories.

3.Accessories only together with the controller shipment are recommended here. Otherwise may result in a risk of re,

electric shock, or inju to person.

4.Do not disassemble any pas of controller which are not mentioned in installation guide. It contains no user-seiceable

pas. See warranty for instructions on obtaining seice. Attempting to seice the controller yourself may result in a risk

of electric shock or re and will void your warranty.

5.Keep away from ammable, explosive materials to avoid re disaster. The installation place should be away from humid

or corrosive substance.

6.Authorized seice personnel must use recommended tools when installing or working with this device.

7.Ensure that all AC and DC wiring are correct and none of the AC or DC wires are pinched, shoed or damaged. Ensure that

all AC junction boxes are properly closed.

8.Never touch either the positive or negative pole of PV connecting device. Strictly prohibit touching both of them at the

same time. The unit contains capacitors that remain charged to a potentially lethal voltage.

9.Before connecting the controller to the power distribution grid, contact the local power distribution grid company to get

appropriate approvals.

10.Be seriously cautious when working with metal tools on or around batteries. A potential risk exists to drop a tool to spark

or sho circuit batteries or other electrical pas may cause an explosion.

11.Please strictly follow the installation procedure when you want to disconnect AC or DC terminals. Please see the INSTAL-

LATION section of this manual for the details.

12.Do not connect the controller to the grid or energize the AC circuit(s) until you have completed all of the installation

procedures and have received approval from the electrical utility authority.

13.Warning!! Only qualied seice persons are able to see this device. If errors still persist after following troubleshooting

table, please send this controller back to local dealer or seice center for maintenance.

14.To reduce the risk of electric shock, disconnect all wiring before attempting any maintenance or cleaning. Only turning

o the unit will not reduce the risk.

3.1 Product Oveiew

TENTEK Tribune Series Energy Controller, a cutting-edge solution that seamlessly integrates the MPPT batte controller

and energy management system into a single & ecient unit. Which provides a comprehensive solution for microinveer

storage system. Help customers solve the excessed solar energy storage into the batte that cannot be achieved by tradi-

tional microinveers, even freely control the microinver's output to the main grid.

Our unique circuit design enables both on-grid and o-grid capabilities that traditional microinveers cannot provide.

With our technology, you have the exibility to switch between grid-connected and o-grid operations, expanding your

energy options and allowing for greater energy independence. Unlike conventional microinveers, our solution empowers

you with versatile and adaptable functionalities, ensuring optimal peormance regardless of your energy requirements or

circumstances.

The TENTEK Tribune series energy controller is an ideal solution for small and medium-sized residential solar power

systems. Its versatility extends to applications such as solar installations on personal vehicles like cars and yachts. With

integrated MPPT batte control, energy management capabilities, adaptability to dierent batte voltages and types, as

well as a durable construction, the Tribune series energy controller oers a comprehensive and reliable solution for ecient

energy management in various settings

3 4

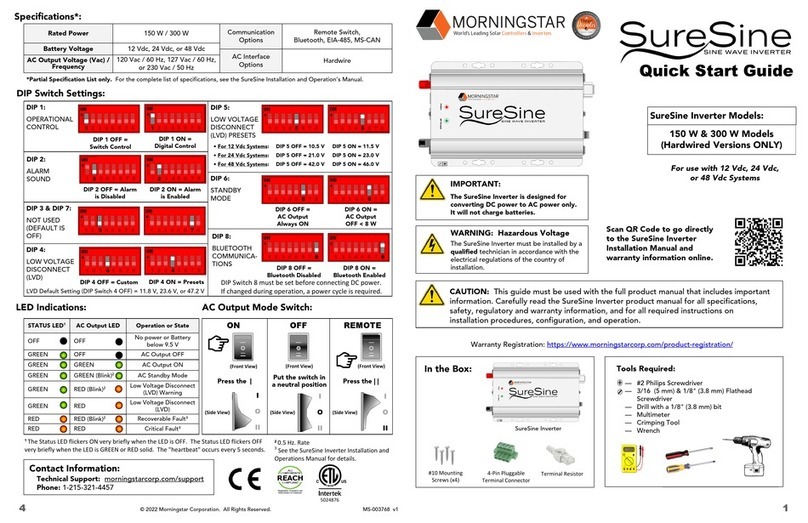

3.4 Electrical Connection Diagram

3.2 Key Features of the Product

3.3 Technical Structure of the Product

1.The TENTEK Tribune series energy controller integrates an MPPT batte controller and energy management system for

streamlined setup and increased eciency.

2.It enables the creation of a hybrid storage solar system with the TENTEK Tiger Series Microinveer, oering both on-grid

and o-grid operation and providing a reliable AC output of 1.6KW to 2.4KW.

3.The controller is adaptable to various batte voltages (12V to 48V) and types, including lead-acid and lithium batteries,

oering customers exibility in their energy storage choices.

4.Its durable construction with a high-peormance aluminum alloy shell and die-casting sealing allows it to withstand

harsh environmental conditions for long-lasting reliability.

5.The energy controller suppos multi-communication with RS485/CAN communication modes, enabling real-time moni-

toring of batte operating status, ensuring system stability and safety.

6.Tentek oers remote monitoring through a built-in Bluetooth or WIFI communication module, allowing users to monitor

the system's operating status in real time through mobile phones or computers.

1.Rear side of controller chassis designed with metal ns for heat dissipation and unit protection.

2.Temperature control mechanism ensures safe operation in high ambient temperatures.

3.Microcontroller facilitates seamless inteace communication and transmission of values/messages via mobile APP or

cloud platform.

4.Dedicated microcontroller for eective monitoring of AC grid integrated with T-Shine APP.

5.Electrical isolation between grid, PV modules, batte, and inteaces ensures compliance with safety regulations

6.Controller designed for exclusive grid-parallel operation with automatic anti-islanding function

7.Integrated DC arc-fault circuit interrupter detects and responds to potential arc faults in the DC circuit

8.Emphasis on delivering a professional-grade solution prioritizing peormance, safety, and reliability.

The Tentek EMS controller, in conjunction with the Tentek Tiger series microinveer, functions as a hybrid power generation

system. It receives DC power from PV panels, which then goes to the microinveer, the batte for storage, and the grid for

feeding in. The microinveer conves DC power to AC power, which is directed to EPS loading through the controller.

Once the loading requirements are met, any excess power can be expoed to the main grid (on-grid). Another the users

can select the "zero feed-in" mode via the T-Shine APP, in this mode, the controller will distributes AC power only for EPS

loading, and the surplus power is controlled to main grid.

Actually, this system with various operating modes can be congured via the T-Shine cloud monitoring system, please selet

the suitable working mode for your own solar storage system then enjoy the free solar power.

5 6

800W Inverter 1.6KW EMS Controller

Recommend 24V/100Ah Battery

400-450W Solar Module

AC Input

AC Output

EPS Loading

Max load power ≤ inverter 1 + inverter 2

PV Input 2 MPPT Trackers

4.5 Devices and Components for Entire System

1.Controller

2.Microinveers

3.PV Panels

4.Batte

5.Distribution Board

6.Meter

7. 3*1M-MC4 cable

8.Batte Cable

9. 4*Y connenction Cable

10.AC output Cable with plug

11.AC output Cable with Socket

3.5 Connections Pos

1. AC Input from Microinveer

2. DC Output to Microinveer 1

3. DC Output to Microinveer 2

4. DC Output to Microinveer 3

(available for 2.4kW)

5. LED Indicator

6. 24V Batte

7. PV Intput-1

8. PV Intput-2

9. PV Intput-3 (available for 2.4kW)

10. RS485

11. EPS Loading

12. Grid Connection

1

1

234

234

6 6

7

8

9

7

8

9

10 11 12

1110 12

5

BAT

LOAD

ALARM

PV

RUN

Controller

Tribune-EMS

4.4 Tools Required for Installation

4. Installation Prepaion

4.1 Note Before Installation

Please note that this controller cannot be used independently and must be paired with our company's designated inveer

to create a hybrid solar storage system capable of both on-grid and o-grid operation. Therefore, it is necessa to install

one or more microinveers in conjunction with this controller.

4.2 Physical Damage Inspection

Upon receiving the controller and microinveers, it is crucial to carefully inspect them for any signs of physical damage that

may have occurred during transpoation. Thoroughly examine the components for any visible cracks or other visible dam-

ages. If any such damage is detected, it is imperative to contact your authorized dealer immediately for fuher assistance

and guidance.

We prioritize the safety and integrity of our products, and prompt action in the case of any physical damage will ensure a

smooth and reliable installation process.

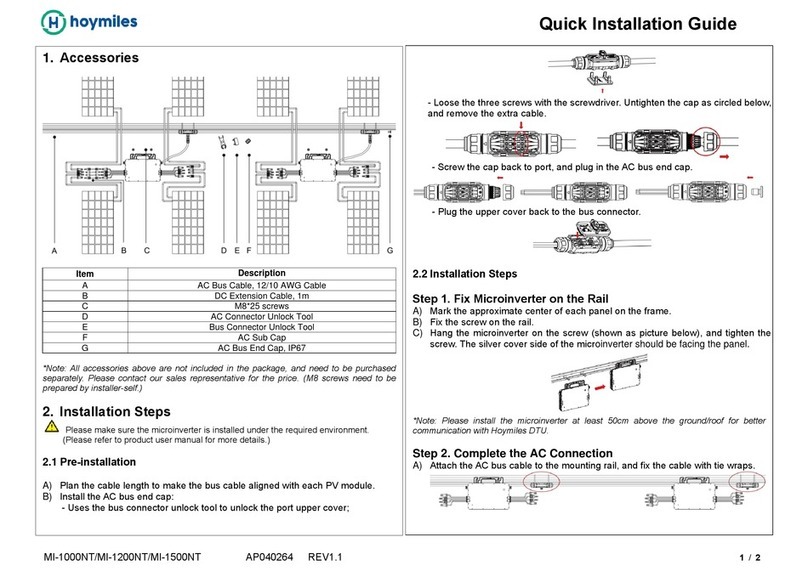

4.3 Packing List

Open the package and take out the product, please check the accessories rst. The packing list shown below as in

pictures- option 1 and option 2

Option-1

Option-2

Crimping pliers

Wire strippers

Screwdriver

Nut drivers

Manual Wrench

Power drill/driver etc.

7 8

5. Sta Installation

Step 1 : Mounting the Controller on the Wall

Step 2 : Mounting the Mircroinveer on the Wall

1.First slide out the four mounting feet from the back of the controller.

1.Align the microinveer with the controller on the wall and mark the positions of the mounting feet holes accurately. inse

screws into the mounting feet holes and gently tighten them, being careful not to over tighten.

Step 4 : Controller and Batte Connection

1.Position the controller with

its mounting holes and put two

screws inside the upper side of

controller and the screw’s head

should be smaller than then

bigger side holes of controller.

2.Slightly lower the controller,

allowing it to hang on the

smaller side of the mounting

hole. Once the controller is in

position, tighten the screws

securely.

3.Finaly, you can easily screw in

the lower side of the controller for

complete attachment.

Step 3 : Microinveers and Controller Connection

Attention: The number of microinveers that can be connected to the controller depends on its power capacity.

For a 1.6KW controller, connect a maximum of two microinveers with 800W power output each. For a 2.4KW

controller, choose either two microinveers with 1200W power output each, or three microinveers with 800W

power output each.

Determine cable sizes: The cable length 2.4m for AC is xed with microinveer, and DC connections cable need to be

choose according to the distance of Microinveer and Controller.

Termination of DC cables: For DC connections, you will need suitable connectors compatible with the microinveers and

the Controller. Common connectors used in solar installations include MC4 connectors or Amphenol connectors. Ensure

that positive (+) and negative (-) connections are correctly made.

CAUTION: For safety operation and regulation compliance, it's recommended to install a separate DC over-current

protector or disconnect device between batte and controller specially when it is more 100 amp.

252mm

209.95mm

Warnning: Always remember to secure the additional AC cable po with the cap lock; failure to do so can pose

signicant risks to safety

910

Remark: If connect with >2pcs microinveer,

please buy following Y type PV cable, we

suggest you need change it into the solid core

pin MC4 connector as we provided with acces-

sories.

800W Inverter 1.6KW EMS Controller

AC Input

4 x Y style PV cable

Prepare the Wires and AC connector: Select an appropriate wire size. Strip the insulation from the ends of the cables to

expose the conductors. Leave approximately 60mm of conductor material sectional area and remove 10mm of insulation

from the wire's end.

Disassemble the AC connector. AC connector has three points for negative, positive and neutral; marked as 1, 2, 3, respec-

tively. Inse three dierent cable conductor poles into three points of AC connector- 1, 2, and 3 respectively and tighten

the screws. Finally, assemble the components of AC connector.

Connecting the AC Connector: Plug the AC connector into the GRID po of the Controller. Align it properly and inse it

rmly. Secure the connection using the specied screw cap or securing mechanism. This ensures a reliable connection

between the controller and the grid.

Step 5: Controller and Grid Connection

WARNING! All wiring must be peormed by a qualied personnel.

It's ve impoant for system safety and ecient operation to use appropriate cable for batte connection, To

reduce risk of inju, please use the proper recommended cable as below.

Batte cable preparation:

Model Cable Size Cable Φ (mm) Batte Voltage

Tribune-EMS 1.6KW

Tribune-EMS 2.4KW 2x 4AWG 21 24V

48V

Separate three components of the DC cable connector provided with accessories, follow the given picture.

Strip o about half an inch of insulation from both ends of the cable using cable strippers. Carefully inse the stripped

cable ends into the appropriate crimp terminals of the connector. Use a crimping tool to securely crimp the terminals onto

the cable strands.

Polarity and correct connections: Ensure you connect the positive (+) terminal of the batte to the positive (+) terminal

of the controller and likewise for the negative (-) terminals. Reversing the polarity can lead to equipment damage and

safety risks.

Attention-1: The controller is designed for single-phase grid connection. Ensure that the local public grid complies

with the provided specications for voltage and frequency.

Attention-2: Ensure the circuit board is disconnected from all phases and securely secured to prevent accidental

reconnection. Take necessa precautions to avoid electrical hazards.

The controller suppos voltages of 220/230/240V and frequencies of 50/60Hz. Compare the grid voltage with the permissi-

ble range specied in the controller's technical data.

Cable preparation according to engineer recommendation:

Net Metering: Install a bi-directional meter that measures the electricity ow both to and from the grid. This allows for net

metering, where you can receive credit for excess energy sent back to the grid.

Tribune-EMS 1.6KW

Tribune-EMS 2.4KW

Model AWG

11-14AWG

11-13AWG

Cable (mm )

2

2-4mm2

2.5-4mm2

Positive

Neutral

Negative

11 12

800W Inverter 1.6KW EMS Controller

Recommend 24V/100Ah Battery

AC Input

Step 6: Controller and EPS Load Connection Step 7: PV Connection

CAUTION: Before connecting to PV modules, please install separately a DC circuit breaker between controller and

PV modules.

Impoant Note: Ensure that no loads are directly connected to the controller. Use a micro-breaker as an interme-

dia between the controller and any loads.

Prepare the Wires and AC connector: Select an appropriate wire size. Strip the insulation from the ends of the cables to

expose the conductors. Leave approximately 60mm of conductor material sectional area and remove 10mm of insulation

from the wire's end. Disassemble the AC connector. AC connector has three points for negative, positive and neutral;

marked as 1, 2, 3, respectively. Inse three dierent cable conductor poles into three points of AC connector- 1, 2, and 3

respectively and tighten the screws. Finally, assemble the components of AC connector.

Connecting the AC Connector to the Controller: Plug the AC connector into the EPS Load po of the Controller. Align it

properly and inse it rmly. Secure the connection using the specied screw cap or securing mechanism. This ensures a

reliable connection between the controller and the the EPS Load.

The 1.6 kW system has two MPPT input pos for panels with suppoing 800W to 900W each po(equivalent to two

400W to 450W solar panels each). The 2.4 kW system has three MPPT input pos for panels with suppoing 800W

to 900W each po (equivalent to two 400W to 450W solar panels each).

Attention:

BAT

LOAD

ALARM

PV

RUN

Controller

Tribune-EMS

1.6kW

To connect two PV panels to one MPPT input, you need to buy a Y style PV cable with one end having two pos for

the panels and the other end with one po for the controller. You can buy this cable form local electrics shop.

Note:

4 x Y style PV cable

Tribune-EMS 1.6KW

Tribune-EMS 2.4KW

Model AWG

11-14AWG

11-13AWG

Cable (mm )

2

2-4mm2

2.5-4mm2

Positive

Neutral

Negative

13 14

800W Inverter 1.6KW EMS Controller

Recommend 24V/100Ah Battery

AC Input

AC Output

800W Inverter 1.6KW EMS Controller

Recommend 24V/100Ah Battery

AC Input

AC Output

EPS Loading

Max load power ≤ inverter 1 + inverter 2

Step 8 : System Unit Check and LED Display

When all connections, wiring, and plug in are done, then time to check the whole system. Check the all the components and

devices and turn on the system power button. You will see the LED display light up.

Here are the dierent scenarios and their corresponding indicators:

1.PV Connection Indicator: PV

The PV light is always on when there is a PV connection.

The PV light is always o when there is no PV connection.

2.Load Indicator: LOAD

The load indicator is always on when there is load power, and the load power is more than 20W.

The load indicator is always o when there is no load power or the load power is less than or equal to 20W.

3.Batte Indicator: BAT

When there is a batte connected, and the batte on charging, it will ash for ash/second.

When the batte on discharging, it will ash for ash/2seconds.

4. Grid Voltage Indicator: RUN

Flashes slowly for ash/3seconds when there is no grid voltage.

Flashe/1second when grid is available.

Keep on light when there is no inveer.

5.Fault Indicator: Alarm

When there is a fault, the indicator will ash/second.

If faults detected then what to do

1.Conduct basic visual inspections to ensure there are no obvious issues, such as loose connections, damaged cables, or

disconnected components. Check for any physical damage to the solar panels, controller, or other system components.

2.Check for blown fuses or tripped circuit breakers in the solar system's wiring or within the controller. Replace any faulty

fuses and reset tripped circuit breakers.

3.Sometimes, faults can occur due to tempora glitches. T restaing the solar system and the controller to see if the fault

clears.

4.Use your solar system's monitoring system to track its peormance, including energy generation, batte status, and grid

interaction. Analyzing peormance data can help identify irregularities.

2.Solar Panel Connection: Connect the male and female leads of the solar panels to the corresponding input terminals

on the solar controller. The male and female connections should be secure to prevent any accidental disconnections.

1. Connector Installation:

Some common connector types used in solar PV systems are MC4 connectors, generally can hold max 30A PV current, If

use the Y type 1in2 solar cable, we suggest you need change it into the solid core pin MC4 connector as we provided with

accessories.

1.6kW Controller

Pair up with one 2-in-1 Microinverters

15 16

PV Cable Preparation:

system power button

Replace

800W Inverter 1.6KW EMS Controller

Recommend 24V/100Ah Battery

400-450W Solar Module

AC Input

AC Output

EPS Loading

Max load power ≤ inverter 1 + inverter 2

PV Input 2 MPPT Trackers

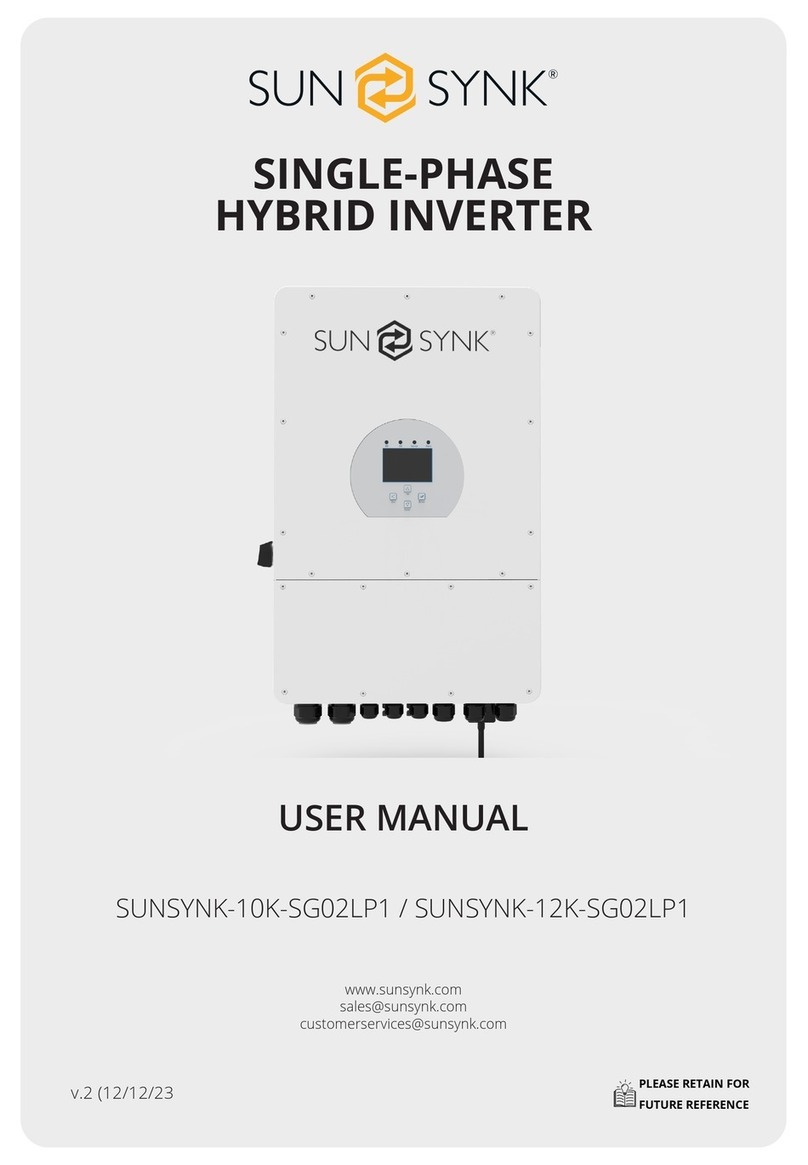

6.Storage and Working Mode Set by T-Shine APP

Cooling

Enclosure

Natural Convection-No Fans

IP65

Environment

Ambient Temperature

Storage Temperature

Humidity

Warranty

Certification

Safety

-25~65℃( Derating from 45℃)

-40℃~+85℃

100% Non-Condensing

3 Years

CE and UL

Support off-grid operation and battery mode operation without mains power

Dimensions 232*301*90 MM

Model Tribune-EMS 1.6KWTribune-EMS 2.4KW

MPPT Solar Charger

Number of MPPT Trackers

PV Operating Voltage

MPPT Operating Voltage Range

Max. PV Open Circuit Voltage

Max. PV Array Power

Max. Charging Current

Max. DC Load Current

Self Consumption

MPPT Tracking Efficiency

Conversion Efficiency

Protection

3

20-60V

25-50V

60Vdc

2W

99.9%

98%

Overload, Reverse Connection, Short Circuit, High voltage ,High Temperature Protection

Battery

Battery Type

Battery Voltage

Battery Voltage Range

Customized Discharge Time

Sealed , AGM, Gel, Flooded, Lithium , Lithium carbonate, User-defined

Standard 24VStandard 36V

20V-60V

Set Up the Discharge Time by APP

Communication

Communication Port RS485

Energy Management

Input Power from Microinverter

Qty of Microinverter

AC Loading (Back-up)

Loading Peak Power (Back-up)

AC Output (On-grid)

Output Power Factor (Adjustable)

UPS Switch Time

Level of Harmonics Distortion

Protection

1.6KW2.4KW

1pc Tiger-2KW;2pcs Tiger-1.2KW;

7.2KW (with 2pcs Tiger-1.2KW)

2.4KW 230Vac@2pcs Tiger-1.2KW

3.6KW (with 1pc Tiger-1.2KW)

1.2KW 230Vac@1pc Tiger-1.2KW

2.4KW 230Vac@2pcs Tiger-1.2KW 1.2KW 230Vac@1pc Tiger-1.2KW

>0.99 Default, 0.8 Leading...0.8 Lagging...

<10mS

THD <3%

Overload, Short Circuit, Battery Low Voltage, Battery Reverse Polarity, Lsland Protection

Mechanical

Net Weight 4.5KG 4.2KG

2 x 1 Tracker 800W3 x 1 Tracker 800W

2

67A

2 x 30A3 x 30A

1pc Tiger-1.2KW;2pcs Tiger-800W

Storage Mode Zero Feed-in Mode

In storage mode, user can choose:

a) Batte Charge Priority

1.Default batte charging priority is established to

maintain the batte in a saturated state for emer-

gency usage during a main grid outage.

2.Batte charging occurs until it reaches full capaci-

ty, ensuring its readiness for unexpected power

outages.

3.Once the batte is fully charged, any surplus

electricity generated by the PV system is directed

towards powering loads or supplying the main grid.

c) Grid Feed-in Priority

1.When PV power sucient. all PV inputs will be

feed-in to the main grid through microinveer.

2.When the photovoltaic power is insucient, the

batte simultaneously supplies power to the micro-

inveer to ensure full power operation until batte

low voltage protection.

3.When there is surplus PV power (if controller

output > microinveer output), if there is surplus PV

power, the remaining electricity will be used to

charge the batte.

b) Loading Priority

1.PV are sucient to meet the loading, and surplus

power is used to charge the batte.

2.Insucient PV power, both batte and PV power

supply to loading.

3. Under the loading priority, only the PV system has

surplus power to charge the batte.

4. After the batte is discharged. the PV and main

power are combined to drive the microinveer

ensure the normal operation of the loading.

In Zero Feed-in mode, user can choose:

a) Batte Charge Priority

b) Default Loading Priority

This work mode prioritizes loading to make the most

of solar energy for personal consumption.

When there is sucient PV energy available, it will be

utilized to power the loads directly.

If the PV energy is insucient to meet the load

demand, the batte will provide compensation and

supply the additional required power.

In the absence of a batte, both PV and the grid will

work together to power the loads, ensuring uninter-

rupted supply.

The batte will only be charged when there is surplus

PV power available. AC charging is disabled by default

in this mode to optimize the utilization of solar energy.

Now time to enjoy your solar haest in dierent way. Users have the exibility to choose the desired mode based on their

energy requirements and preferences. The T-Shine cloud monitoring APP facilitates easy control and management of these

work modes, allowing users to optimize their energy consumption and reduce reliance on the grid. For better understand-

ing of our T-Shine APP please check our T-Shine APP user manual. Here is brief description of ‘Storage Mode’ and ‘Zero

Feed-in Mode’ functions.

Technical Data Sheet

17 18

Scan the QR code for quick installation

T- Shine APP

Please dowload the T-Shine APP and sta to run your

solar storage system.

This manual suits for next models

2

Table of contents

Other TENTEK Inverter manuals

Popular Inverter manuals by other brands

Power One

Power One AURORA PVI-6000-OUTD-AU Series Installation and operator's manual

Generac Power Systems

Generac Power Systems 006180-0 owner's manual

Goodwe

Goodwe GW3600S-BP user manual

Siemens

Siemens SINAMICS G120P instruction manual

SolarEdge

SolarEdge Power Harvesting System installation guide

Case IH

Case IH BC12000ER Operation manual