ECOSTAR ECO 60 Installation guide

26.03.2020 Rev. 11

www.ecostar.com.tr

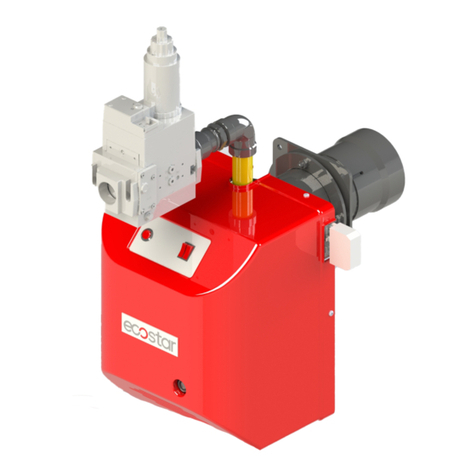

MONOBLOCK HEAVY OIL BURNERS INSTALLATION,

OPERATING AND MAINTENANCE MANUAL

TWO STAGE AND MODULATING OPERATION

ECO 50

ECO 55

ECO 60

ECO 65

ECO 70

ECO 75

26.03.2020 Rev. 11

1

DEAR USER,

ECOSTAR ECO 50, ECO 55, ECO 60, ECO 65, ECO 70, ECO 75 Heavy Oil

burners are prepared and manufactured according to the latest technical developments and

safety rules. It is easy to use for our customers.

We recommend that you read this manual and safety warnings thoroughly before the

use of the device in order to ensure safe, cost effective and environmental-friendly use.

If you encounter any issue that is not explained clearly in this manual or you could

not understand, please contact with our service department.

We thank you for choosing ECOSTAR brand.

Ecostar Heavy Oil Burners are manufactured in accordance with TS EN 267

standards.

This Operating Manual is an integral part of the burner and must be maintained in a

plastic dossier and hung at a clearly visible place in the burner room.

TERMO ISI SİSTEMLERİ SAN.VE TİC.A.Ş.

Esentepe Mah.Milangaz Cad. No:75 K:3

Kartal Monumento Plaza

Kartal/İSTANBUL/TÜRKİYE

Tel: +90 216 442 93 00

Fax: +90 216 370 45 03

www.ecostar.com.tr

e-mail:[email protected]m.tr

26.03.2020 Rev. 11

2

CONTENTS

1. WARNINGS.......................................................................................................................................... 3

1.1. Warning Symbols and Descriptions............................................................................................... 3

1.2. General Safety Rules...................................................................................................................... 4

2. TERMS OF WARRANTY.................................................................................................................... 6

2.1. Out of Warranty Conditions.......................................................................................................... 6

3. BURNER’S GENERAL FEATURES................................................................................................... 7

3.1. Purpose of Use and Work Limits of Burners................................................................................. 7

3.2. Code Key........................................................................................................................................ 7

3.3. Burner Components........................................................................................................................ 9

4. FLUE GAS AND HEATING WATER SCHEMA............................................................................. 31

5. TECHNICAL DATA........................................................................................................................... 32

5.1. Capacity Table.............................................................................................................................. 32

5.2. Back Pressure-Capacity Diagrams............................................................................................... 33

5.3. Burner Dimensions....................................................................................................................... 34

5.4. Flame Length and Diameter......................................................................................................... 35

5.5. Noise Level................................................................................................................................... 35

6. BURNER HANDLING INFORMATION.......................................................................................... 36

7. INSTALLATION................................................................................................................................ 37

7.1. Burner Installation Picture............................................................................................................ 37

7.2. In reverse flame front mirror boilers............................................................................................ 38

7.3. In cylindrical (straight flame) boilers........................................................................................... 38

8. COMMISSIONING............................................................................................................................. 39

8.1. Before Commissioning................................................................................................................. 39

8.2. General Controls........................................................................................................................... 39

8.3. Combustion Adjustment............................................................................................................... 40

8.4. Fuel Pumps................................................................................................................................... 40

8.5. Servomotor Adjustment ............................................................................................................... 44

8.6. Emission Measurement ................................................................................................................ 49

8.7. Program Relay.............................................................................................................................. 49

8.8. Heavy Oil Burner Fuel Ring Line................................................................................................ 51

9. MAINTENANCE................................................................................................................................ 52

9.1. Weekly Maintenance.................................................................................................................... 52

9.2. Monthly Maintenance................................................................................................................... 52

9.3. Seasonal Maintenance.................................................................................................................. 53

9.4. Installation and Disassembly Instructions for Maintenance Purposes......................................... 54

10. TROUBLESHOOTING................................................................................................................... 55

11. PERIODICAL FLUE GAS MEASUREMENT REPORT.............................................................. 56

12. AFTER SALES SERVICES............................................................................................................ 57

13. NOTES............................................................................................................................................. 58

26.03.2020 Rev. 11

3

1. WARNINGS

1.1. Warning Symbols and Descriptions

Symbols

Symbol Descriptions

Important information and useful hints.

Warning of danger to life or property.

Warning of electrical voltage.

Product handling information.

Electric motor direction of rotation

Carry in an upright position. Fragile Item. Protect against water.

26.03.2020 Rev. 11

4

1.2. General Safety Rules

All personnel engaged in installation, disassembly, commissioning, operation, control,

maintenance and repair should have received the necessary training and fully read and understood

this manual.

No changes that might damage the safety of the burner unit must be made by persons and/or

organizations on the burner unit.

All operation, commissioning and installation works (except for burning adjustment) should be

carried out when the burner is not operating and after disconnecting the power supply.

Noncompliance with these rules may lead to serious bodily injuries and even death by electrical

shocks or uncontrolled flame formation.

Repairs concerned with safety elements should be carried out only by the manufacturing company.

The device should never be used by children, mentally handicapped and inexperienced persons.

Children must not be allowed to play with the device.

Keep the device away from explosive and flammable materials.

Device must intake air, ventilation and air discharge holes must not be closed.

Do not store any inflammable materials in boiler room.

Wear hearing protectors if there is noise in boiler room.

In case of fıre or other emergency;

●Switch off the main switch

●Take appropriate actions

26.03.2020 Rev. 11

5

The burner installation must be carried out in accordance with the instructions. Vibration can

damage the burner and its components.

Keep boiler doors closed while starting burner and during burner operation.

Check combustion values to be correct by using flue gas analyzer at the whole adjustment range

between minimum, full load, and ignition load.

Use lifting device or belt for lifting fan motor, if necessary

During the first commissioning of the burner or in case of any revision carried out in the electrical

system or motor cables by any reason, direction of the fan rotation must certainly be checked by

the authorized technical service.

For products that have not been comissioned or started more than 6 months, before activating the

servomotor;

In air dampers and oil regulators, servomotor and air damper connections must be checked to

ensure that they are free running in spite of immobility and oil freezing.

BURNER ROOM

Install the burner in a suitable room/floor with minimum external air openings and sufficient to

ensu re perfect combustion, in compliance with current regulations.

Never obstruct air openings of the burner room, burner fan intake vents or air ducts in order to

prevent:

a.The build up of toxic / explosive gas mixtures in the burner room,

b.Combustion with insufficient air, resulting in hazardous, anti-economical and polluting ope-

ration.

The burner must be always protected from rain, snow and frost to prevent corrosion and paint

deformations.

Keep the burner room clean and free of solid volatile substances, which could be sucked into the fan

and clog the internal burner or combustion head air ducts.

26.03.2020 Rev. 11

6

2. TERMS OF WARRANTY

Main and auxiliary equipment and all components used in Ecostar heavy oil burners are guaranteed

for 1 year by TERMO ISI SİST. A.Ş starting from the date of commissioning under the maintenance,

adjustment, operating conditions and relevant mechanic, chemical and thermal effects explained herein.

Please note that this warranty is only valid if the device(s) is commissioned and maintained by our

authorized services.

Our company reserves the right to make any modifications on the product and all instructions

thereof for improvement purposes.

2.1. Out of Warranty Conditions

Any damage arising out of or in relation to customers’ non-compliance to their responsibilities

with regards to installation, commissioning, operation and maintenance,

Any damage arising out of or in relation to commissioning, repairs and maintenance carried out by

unauthorized services,

Any damage that may occur during transportation or storage of the product,

Not preserving the product in its original packaging until the installation stage,

Incorrect and poor electrical connections, Failures due to incorrect voltage applications, frequent

repetition of voltage fluctuations,

Any damage that may occur as a result of incorrect fuel usage or, foreign substances in the fuel

used or using of the product without any fuel,

Any damage that may occur due to foreign particles entered into the product during installation

and operation,

Failures due to incorrect device selection,

Any damage to unit due to natural disasters,

Devices without any warranty certificates,

Warranty Certificates without the stamp and signature of the authorized dealer or service,

Devices with any falsification on the warranty certificate or without an original serial number.

The risks during transportation of device under the responsibility of customer belong to the

customer.

Presence of misuse faults are indicated in the reports issued by authorized service stations or our

authorized agent, dealer, representative or our factory in case of unavailability of authorized

service stations.

Customers may apply consumer protection arbitrator committee with regards to this report and

request for an expert report.

26.03.2020 Rev. 11

7

3. BURNER’S GENERAL FEATURES

ECOSTAR Heavy Oil burners are designed to operate with oil at 2.5 –20 Cst (mm²/s) viscosity, at

rated capacity and pressure ranges and -15% to +10% nominal voltage.

3.1. Purpose of Use and Work Limits of Burners

This product works at any load value equivalent to its max. capacity or covered by its capacity

range;

-In hot water and steam boilers,

-In direct and indirect hot air generators,

-Industrial appliances operating at temperature below 600 0C,

--15 0C…+60 0C ambient temperature range,

-1N 230 VAC/3N 380VAC /50 Hz feed voltage (-%15…+%10) values,

-Max. 95% relative humidity,

-In well-ventilated open and closed spaces compatible with protection class IP 40.

This device must never be operated with open flame!

3.2. Code Key

26.03.2020 Rev. 11

8

Temperature change of fuel used in ECOSTAR heavy oil burners dependent on viscosity

26.03.2020 Rev. 11

9

3.3. Burner Components

ECO 50 OSC2

26.03.2020 Rev. 11

10

Assembly No

Part Number

Assembly No

Part Number

1

Body

23

Purger

2

Air Intake

24

Electrical Panel Mounting Plate

3

Flame Tube

25

Electrical Panel

4

Boiler Connection Flange Sheet Metal

26

Observation Glass

5

Flame Tube Extension

27

Handling Shaft

6

Lance

28

Handling Shaft Fixing Plate

7

Combustion Head

29

Pump

8

Fuel Nozzle

30

Pump Coupling

9

Ignition Electrode

31

Servomotor

10

Electrode Connection Sheet Metal

32

Servomotor Coupling

11

Pot Heater Connection

33

Air Damper

12

Lance Centering Console

34

Air Damper

13

Klingerit Gasket

35

Air Damper Motion Rod

14

Gasket

36

Air Damper Motion Transfer Rod

15

Fan Motor

37

Pot Heater

16

Fan Motor Connection Flange

38

Pot Heater Protection Cover

17

Fan

39

Thermometer

18

Fan Coupling

40

Thermometer Connection Adaptor

19

Coupling Connection Pipe

41

Solenoid Valve

20

Ignition Transformer

42

Ball Valve

21

Transformer Mounting Plate

43

Manometer

22

Photocell

44

Fuel Pipes

26.03.2020 Rev. 11

11

ECO 50 OSC3

26.03.2020 Rev. 11

12

Assembly No

Part Number

Assembly No

Part Number

1

Body

25

Electrical Panel

2

Air Intake

26

Observation Glass

3

Flame Tube

27

Handling Shaft

4

Boiler Connection Flange sac

28

Handling Shaft Fixing Plate

5

Flame Tube Extension

29

Solenoid Valve Connection Plate

6

Lance

30

Pump

7

Combustion Head

31

Pump Coupling

8

Fuel Nozzle

32

Disc Control Group

9

Ignition Electrode

33

Servomotor

10

Electrode Connection Sheet Metal

34

Air Damper Modulating Motion Rod

11

Pot Heater Connection

35

Air Damper Modulating Spring

12

Lance Centering Console

36

Servomotor Coupling

13

Klingerit Gasket

37

Air Damper

14

Gasket

38

Air Damper

15

Fan Motor

39

Air Damper Motion Rod

16

Fan Motor Connection Flange

40

Air Damper Motion Transfer Rod

17

Fan

41

Pot Heater

18

Fan Coupling

42

Pot Heater Protection Cover

19

Coupling Connection Pipe

43

Thermometer

20

Ignition Transformer

44

Thermometer Connection Adaptor

21

Transformer Mounting Plate

45

Solenoid Valve

22

Photocell

46

Ball Valve

23

Purger

47

Manometer

24

Electrical Panel Mounting Plate

48

Fuel Pipes

26.03.2020 Rev. 11

13

ECO 55 OSC2

26.03.2020 Rev. 11

14

Assembly No

Part Number

Assembly No

Part Number

1

Body

23

Electrical Panel Mounting Plate

2

Air Intake

24

Electrical Panel

3

Flame Tube

25

Observation Glass

4

Boiler Connection Flange sac

26

Handling Shaft

5

Flame Tube Extension

27

Handling Shaft Fixing Plate

6

Lance

28

Pump

7

Combustion Head

29

Pump Coupling

8

Fuel Nozzle

30

Servomotor

9

Ignition Electrode

31

Servomotor Coupling

10

Electrode Connection Sheet

Metal

32

Air Damper

11

Pot Heater Connection

33

Air Damper

12

Lance Centering Console

34

Air Damper Motion Rod

13

Klingerit Gasket

35

Air Damper Air Damper Motion

Transfer Rod

14

Gasket

36

Pot Heater

15

Fan Motor

37

Pot Heater Protection Cover

16

Fan

38

Thermometer

17

Fan Coupling

39

Thermometer Connection Adaptor

18

Coupling Connection Pipe

40

Solenoid Valve

19

Ignition Transformer

41

Ball Valve

20

Transformer Mounting Plate

42

Manometer

21

Photocell

43

Fuel Pipes

22

Purger

26.03.2020 Rev. 11

15

ECO 55 OSC3-3a

26.03.2020 Rev. 11

16

Assembly No

Part Number

Assembly No

Part Number

1

Body

25

Handling Shaft

2

Air Intake

26

Handling Shaft Fixing Plate

3

Flame Tube

27

Solenoid Valve Connection Plate

4

Boiler Connection Flange

28

Pump

5

Flame Tube Extension

29

Disc Control Group

6

Lance

30

Pump Coupling

7

Combustion Head

31

Air Damper Modulating Motion Rod

8

Fuel Nozzle

32

Air Damper Modulating Spring

9

Ignition Electrode

33

Servomotor Coupling

10

Pot Heater Connection

34

Air Damper

11

Lance Centering Console

35

Air Damper

12

Klingerit Gasket

36

Air Damper Motion Rod

13

Gasket

37

Air Damper Air Damper Motion Transfer Rod

14

Fan Motor

38

Pot Heater

15

Fan

39

Pot Heater Protection Cover

16

Fan Coupling

40

Thermometer

17

Coupling Connection Pipe

41

Thermometer Connection Adaptor

18

Ignition Transformer

42

Solenoid Valve

19

Transformer Mounting Plate

43

Ball Valve

20

Photocell

44

Manometer

21

Purger

45

Fuel Pipes

22

Electrical Panel Mounting Plate

46

Electrode Connection Plate

23

Electrical Panel

47

Servomotor

24

Observation Glass

26.03.2020 Rev. 11

17

ECO 60 OSC2

26.03.2020 Rev. 11

18

Assembly No

Part Number

Assembly No

Part Number

1

Body Group

20

Purger

2

Flame Tube

21

Eye Bolt

3

Lance

22

Gas Solenoid Valve

4

Klingerit Gasket

23

Servomotor

5

Combustion Head

24

Servomotor Coupling

6

Air Adjustment Mechanism

25

Air Damper

7

Boiler Connection Flange

26

Air Damper

8

Gasket

27

Air Damper Motion Rod

9

Fan Motor

28

Air Damper Air Damper Motion Transfer

Rod

10

Fan Motor Connection Flange

29

Air Damper Modulating Spring

11

Fan

30

Pump Housing Cover

12

Observation Glass

31

Photocell

13

Observation Glass Frame

32

Liquid Fuel Solenoid Valve

14

Handling Shaft

33

Lance Centering Console

15

Handling Shaft Fixing Plate

34

Ignition Electrode

16

Electrical Panel

35

Electrode Connection Plate

17

Electrical Panel Mounting Plate

36

Pilot Ignition

18

Transformer Mounting Plate

37

Pilot Ignition Pipe

19

Ignition Transformer

38

Fuel Nozzle

26.03.2020 Rev. 11

19

ECO 60 OSC3

This manual suits for next models

5

Table of contents

Other ECOSTAR Industrial Equipment manuals