Ecotechnics ECK 3900 UP User manual

INSTRUCTIONS MANUAL

-2-

INSTRUCTIONS MANUAL

-3-

INDEX

INDEX .................................................................................................................................3

INTRODUCTION.................................................................................................................6

CARE OF THE MANUAL.........................................................................................................6

CONDITIONS OF WARRANTY...........................................................................................7

GENERAL INFORMATION .................................................................................................8

END-OF-LIFE......................................................................................................................9

BATTERY DISPOSAL..............................................................................................................9

SAFETY RULES................................................................................................................10

REFRIGERANT AND LUBRICANT - PERSONAL PROTECTIVE EQUIPMENT AND

PRECAUTIONS.....................................................................................................................11

HOSES CONNECTION .........................................................................................................11

PRECAUTIONS FOR HANDLING AND USE OF R134a FLUIDS..........................................12

RULES FOR WORKING WITH R1234yf FLUIDS...................................................................12

PRINCIPLES OF OPERATION.........................................................................................15

SETUP...............................................................................................................................16

Release refrigerant scale: ......................................................................................................16

Lock refrigerant scale:............................................................................................................16

THE MACHINE..................................................................................................................17

PLASTIC COVER ..................................................................................................................17

CONTROL PANEL.................................................................................................................17

FUNCTION SELECTOR KEYBOARD....................................................................................19

DISPLAY ICONS ...................................................................................................................20

BASIC COMPONENTS..........................................................................................................22

ALARMS................................................................................................................................27

ERROR CODES....................................................................................................................28

PRELIMINARY OPERATIONS..........................................................................................31

AUTOMATIC PROCEDURE..............................................................................................33

Edit VACUUM data: ...............................................................................................................34

Edit OIL data:.........................................................................................................................34

Edit UV data:..........................................................................................................................34

Edit GAS FILLING data:.........................................................................................................34

Edit GAS FILLING mode:.......................................................................................................35

START AUTOMATIC PROCEDURE:.....................................................................................35

MANUAL PROCEDURE....................................................................................................40

HIGH PRECISION RECOVERY.............................................................................................40

STANDARD RECOVERY ......................................................................................................42

VACUUM ...............................................................................................................................43

OIL+UV INJECTION ..............................................................................................................45

INSTRUCTIONS MANUAL

-4-

Edit OIL data 45

Edit UV data 45

Edit GAS FILLING data 45

Edit GAS FILLING mode 46

START procedure 46

FILLING.................................................................................................................................49

Edit GAS FILLING data 49

Edit GAS FILLING mode 49

START procedure 49

FLUSHING HOSES(optional) ......................................................................................................52

NITROGEN TEST(optional).........................................................................................................54

NITROGEN TEST (N2) 55

MIXTURE TEST (N2+H2) 57

A/C SYSTEM FLUSHING(optional) .............................................................................................60

GAS ANALYZER(optional) ..........................................................................................................62

SANITIZER(optional)...................................................................................................................63

DYNAMIC DIAGNOSIS(optional))................................................................................................64

STATIC DIAGNOSIS(optional) ....................................................................................................69

EXPRESS SERVICE .........................................................................................................71

SETUP...............................................................................................................................72

LANGUAGE...........................................................................................................................72

OPTIONS...............................................................................................................................73

VACUUM SETTINGS.............................................................................................................74

N2 TEST SETTINGS .............................................................................................................75

SETUP HEADER PRINT........................................................................................................76

INSERT OPERATOR NUMBER.............................................................................................77

COUNTERS...........................................................................................................................78

SET DATE / TIME..................................................................................................................79

OIL SETTINGS ......................................................................................................................80

MAINTENANCE.................................................................................................................81

CALIBRATION.......................................................................................................................82

BOTTLE CELL 83

OIL CELL 86

USED OIL CELL 87

BOTTLE PRESSURE 88

A/C PRESSURE 90

EVAPORATOR PRESSURE 92

TEMPERATURE 94

RESTORE CALIBRATION 95

EMPTYING HOSES...............................................................................................................96

BOTTLE FILLING...................................................................................................................97

CHANGE DRYER FILTER.....................................................................................................99

A/C PRESSURES CHECK...................................................................................................104

AIR PURGE MANUAL..........................................................................................................106

SERVICES ARCHIVE..........................................................................................................107

SEARCH BY PLATE 107

SEARCH BY DATE 108

EXTRACT ARCHIVE 109

INSTRUCTIONS MANUAL

-5-

CHANGE OIL/UV CONTAINER...........................................................................................110

VACUUM PUMP OIL CHANGE OIL.....................................................................................111

VACUUM PUMP..................................................................................................................112

M.1) OIL TOP-UP 112

M.2) OIL CHANGE 114

FILLING THE RECHARGEABLE COLLAPSIBLE NEW OIL CONTAINER...........................117

FILLING THE RECHARGEABLE COLLAPSIBLE UV CONTAINER.....................................118

REPLACE THE NEW OIL CARTRIDGE ..............................................................................119

REPLACE THE NEW UV CARTRIDGE...............................................................................120

EMPTYING THE USED OIL CONTAINER...........................................................................121

REPLACING THE PRINTER PAPER...................................................................................122

DATA...............................................................................................................................123

INSTRUCTIONS MANUAL

-6-

INTRODUCTION

This machine is a pressure unit as can be seen in the CE declaration of conformity and

Data plate. The equipment supplied conforms to the Essential Safety Requirements

according to Annex I of Directive 2014/68/UE (PED). Any work involving repairs,

modifications, and/or changing pressurized components or parts make safe use of the

equipment very risky. Any tasks done must be authorized by the Manufacturer.

This manual contains important information pertinent to operator

safety. Read this manual through before beginning operation of the

machine.

The manufacturer reserves the right to modify this manual and the machine itself with no prior

notice. We therefore recommend checking any updates. This manual must accompany the

machine in case of sale or other transfer.

Any repair, modification, or changing of components not formally agreed with and authorized

by the manufacturer poses a risk of the conformity to Directive 2014/68/UE being nullified and

makes this pressure equipment a significant risk. If not authorized in writing the Manufacturer

considers the tasks indicated above to be tampering with the machine, which nullifies the initial

declaration of conformity issued, and so theydo not accept anydirect responsibility.

Braze welding of parts that contribute to the pressure strength of the equipment and the parts

directed attached to it was done by adequately qualified personnel, using adequate operating

methods. Approval of the operating methods and personnel was entrusted to a competent

outside party for category III pressure equipment, and any work on this equipment that involves

the need to carry out braze welding must comply with the requirements laid down in annex 1 of

Directive 2014/68/UE, or the Manufacturer must be contacted for the relevant information.

The pressure equipment has been inspected and tested, complete with the safety

accessories identified by the manufacturer as being of a direct discharge type with

calibrated air pressure. Testing and inspection of the accessories is not necessary prior

to starting up.

The pressure equipment must be subjected to routine inspections and checks when

operating, according to the relevant regulations and legal norms.

For the unit in question, it is hereby declared that a competent Authorized Body carried out

their part of the final check according to annex I of point 3.2.3 of Directive 2014/68/UE as well

as checking safety accessories and control devices in conformity to comma d) of art 5 of

Ministerial Decree 329 of 01/12/2004.

List of the critical components in terms of PED safety DIR 2014/68/UE

Condenser, dehydrator filters, distributor, refrigerant storage bottle, airtight compressor, safety

pressure switch, pressure transducers, and safety valves.

The operator has to check/substitute the PED critical components before their respective end

of life (according to nationallaw)

CARE OF THE MANUAL

This manual must be kept for the entire life of the machine and protected against humidity and

excessive heat. Take care not to damage this manual in any way during consultation.

INSTRUCTIONS MANUAL

-7-

CONDITIONS OF WARRANTY

Refer to CONDITIONS OF WARRANTY booklet supplied with themachine.

INSTRUCTIONS MANUAL

-8-

CE LABEL

FIG. 1

GENERAL INFORMATION

Machine model information are printed on the data plate (see Fig.1). Overall machine

dimensions:

Height: 1100 mm Width: 640 mm

Depth: 680 mm Weight: 90 kg

Operating temperature 10/50°C Storage temperature -25/+50°C

Like any equipment with moving parts, the machine inevitably produces noise. The

construction system, paneling, and special provisions adopted by the Manufacturer are such

that during work the average noise level of the machine isnot in excess of 64 dB (A).

INSTRUCTIONS MANUAL

-9-

END-OF-LIFE

The symbol on the right indicates that in accordance with Directive 2012/19/UE the

machine may not be disposed of as ordinary municipal waste but must be

delivered to a specialized center for separation and disposal of WEEE (Waste

Electrical and Electronic Equipment) or be returned to the dealer in case of

purchase of a new machine. Current legislation provides severe sanctions in the case of

disposal of WEEE into the environment. If improperly used or disposed of into the environment,

electrical and electronicequipment can release substances dangerous for the environment and

for human health.

BATTERY DISPOSAL

The machine uses an electronics card containing a Lithium battery (ref:1, Fig.2). When

discharged, it must be removed by expert personnel trained in machine demolition.

FIG. 2

1

0

INSTRUCTIONS MANUAL

-10-

SAFETY RULES

This machine is a piece of equipment designed to recover R134a or R1234yf (depending on

machine model) from air conditioning systems (A/C) for vehicles. The machine must be used

by qualified personnel and can only be used correctly after having read this manual that also

contains the basic safety rules listed below:

-Wear gloves and safety glasses.

-Do not expose to direct sunlight and rain.

-Before doing any task check the vehicle’s operating and maintenance handbook to

determine the type of refrigeration fluid used in the A/C system.

-No smoking in the vicinity of the machine and while working.

The ambient conditions for using the equipment are as follows:

Temperature between +10 and +50°C.

Pressure between 80 kPa (0,8 bar) and 110 kPa (1.1 bar).

Air with normal oxygen content, generally 21%by volume.

Laying-up the machine: when not in use the machine must be stored in a specific place with

the following characteristics:

1. The machine must be stored in a ventilated zone also during storage. It can be avoided

that are pit near the machine.

2. There must be no sources of ignition such as heat sources, naked flames, sparks of

mechanical origin (e.g. due to grinding), electrical material (especially the storage area for

the machine is not to have any electrical power sockets that are less than 900 mm above

floor level), stray electrical currents and cathode corrosion (check that the electrical

distribution system conforms to the relevant legal provisions), static electricity (check the

earth system for the premises' electricity distribution system), and lightning.

-Hose must be visually checked periodically, if they are damaged, or aged, substitute them.

-Use the machine away from heat sources, naked flames and/or sparks.

-Always make sure that when you switch off the engine the vehicle’s ignition key is turned to

the Fully Off position.

-Always connect the machine’s piping using the RED rapid coupling to the high pressure

branch of the A/C system.

-Always connect the machine’s piping using the BLUE rapid coupling to the low pressure

branch of the A/C system.

CAUTION: some car manufacturer on the fuel intake manifold install a

connector identical to the A/C low pressure fitting.

DANGER: DO NOT connect the recovery station to this connection; you risk to

recover petrol.

-Keep the connection pipes away from moving or rotating items or elements (cooling fan,

alternator, etc.).

-Keep the connection pipes away from hot items or elements (engine exhaust pipes, radiator,

etc.).

-Always fill the A/C system with the quantity of fluid recommended by the manufacturer.

Never exceed this quantity.

-Always check the oil levels prior to each operation.

-Always keep the oil at the correct quantity.

-Before connecting the machine to the electrical system, check that the power supply voltage

and frequencyare the same as the values indicated on the CE plate.

INSTRUCTIONS MANUAL

-11-

The bottle must be filled to 80% of its maximum capacity to leave a plenum chamber for

the gas to absorb any increases in pressure.

-Never touch the taps on the innerbottle.

-Throw the oil taken out of the A/C system and the vacuum pump into the relevant containers

for spent oils.

-Change the filters at the intervals laid down, using only filters recommended by the

manufacturer.

-Only use the oils recommended by themanufacturer.

-Only use the UV approved by the manufacturer.

-Never confuse the vacuum pump oil with the oil for the air-conditioning systems.

Failure to comply with any of these safety rules leads to any form of guarantee for the machine

being rendered null and void.

Machine is provided with class III safety valve, in case of malfunctioning it can create an

external sack of flammable gas; keep the machine in well ventilated area.

WARNING: R134a and/or R1234yf vapor/gas refrigerant are heavier than air and may thicken

on the floor or inside the cavity/pits and cause choking by reducing oxygen available for

breathing.

At high temperatures the refrigerant decomposes releasing toxic and caustic substances,

hazardous for the operator and the environment. Avoid inhalation of the refrigerants and A/C

system oils .

Exposure can irritate the eyes and airways.

WARNING: The machine must be connected to a socket with effective ground

WARNING: This is a class “A” product. In a domestic environment this product may

cause radio interference. In such cases, the user may be required to take adequate

measures.

REFRIGERANT AND LUBRICANT - PERSONAL

PROTECTIVE EQUIPMENT AND PRECAUTIONS

Handled with caution refrigerants and pressure vessels, since otherwise there could be health

risks .

The operator must wear safety glasses, gloves and suitable clothing to work , contact with

refrigerant may cause blindness (eyes), and other physical damage (frostbite) to the operator.

Avoid contact with the skin, the low boiling temperature (about -26°C for R134a and about -

30°C for R1234yf ) cancause cold burns.

Do not change the setting of the relevant devices for safety, do not remove the seals of the

safety valves and control systems . Do not use external tanks or other storage containers that

are not approved, or without safety valves.

During the functioning, the air vents and

ventilation equipment must not be blocked or

covered

HOSES CONNECTION

Hoses may contain refrigerant under pressure. Before substitute the quick coupler verify the

corresponding pressure in the service hoses (gauge).

The machine is equipped with the following safety devices:

SAFETY PRESSURE: stops the compressor in case of excessive

pressure

SAFETY VALVE: opens when the pressure inside the system reaches a

INSTRUCTIONS MANUAL

-12-

level of pressure above the estimated limits.

MAIN SWITCH: allows the machine’s turnoff by sectioning of the power

line. Prescribing however disconnection from the mains plug of the power

cord before servicing

IT IS NOT ALLOWED ANY KIND OF TAMPERING OF THE SAFETY

DEVICES MENTIONED ABOVE

PRECAUTIONS FOR HANDLING AND USE OF R134a

FLUIDS

Refrigerant fluids expand to the gaseous state in standard environmental conditions. In order

that they may be shipped and used they must be compressed into suitable bottles. We

therefore recommend observing all the general precautions applicable to handling of

pressurized containers. In the case of R134a in particular, we suggest the following special

precautions. Avoid inhaling highly concentrated vapors even for short periods of time, since

such vapors can cause loss of consciousness or death. R134a is not flammable, but if the

vapor is exposed to open flames or incandescent surfaces it may undergo thermal

decomposition and form acid substances. The acrid and pungent odor of these products of

decomposition is sufficient to signal their presence. We therefore recommend avoiding use of

R134a near open flames and incandescent elements. There exists no evidence of risks

deriving from transdermal absorption of R134a Nevertheless, due to the low boiling point of the

liquid, it is advisable to wear protective garments such as to ensure that no jets of liquid or gas

can come into contact with the skin. The use of goggles to avoid contact with the eyes is

especially recommended, since the refrigerant liquid or gas can cause freezing of the ocular

fluids. Moreover, we strongly advise users to avoid dispersing the R134a refrigerant fluid

utilized in the machine since it is a substance that contributes to raising the temperature of the

planet, with a global warming potential(GWP)of 1300.

RULES FOR WORKING WITH R1234yf FLUIDS

Under ambient conditions refrigerant fluids are gases. In order to be able to transport and use

them they must be compressed in specific bottles. The precautions for pressure vessels must

therefore be applied.

In particular, for R1234yf be careful of the following situations:

-Inhalation of vapours at very high concentrations, even for short periods of time, must be

avoided as it can cause unconsciousnessand sudden death.

-R1234yf is flammable and if the vapour is exposed to naked flames or red hot surfaces it

can undergo thermal decomposition with the formation of acid products. The acrid, pungent

odour of these products of decomposition is sufficient to warn of their presence. Avoid

finding yourself in the conditions just mentioned.

-There is no proof of risks resulting from the absorption of R1234yf through the skin,

however, due to its low boiling point it is advisable to wear protective clothing that can

prevent any liquid sprayed or vapour reaching the skin and especially the eyes, where they

could cause the eye fluids to congeal.

-We also recommend no dispersing the R1234yf refrigerant fluid used in the machine,

because it is a substance that contributes to heating the planet, with a global warming

potential (GWP) of 4.

INSTRUCTIONS MANUAL

-13-

ANY USE THAT DIFFERS FROM THAT JUST DESCRIBED IS NOT ALLOWED BY THE

MANUFACTURER.

Uses not allowed

This machine may not be used for tasks not envisaged or to handle products other than

those envisaged, or for uses other than those specified in paragraphs "Conditions of use

envisaged".

The following are forbidden:

1. Using the machine with a constructive configuration that differs from that envisaged by

the manufacturer.

2. Using the machine in places at risk of explosion and/or fire

3. Adding other systems and/or equipment not considered by the manufacturer in their

working design.

4. Using the machine without the perimeter protection and/or the fixed and mobile guards

tampered wit or removed.

5. Connecting the machine to energy sources other than those envisaged by the

manufacturer.

6. Using the commercial devices for a purpose other than that envisaged by the

manufacturer.

Actions not allowed on the part of the operator

The operator tasked with operating, supervising, and maintaining the machine must not:

1. Use the machine if they have not been trained and informed beforehand as called for

by the law on safety in the workplace

2. Fail to act as described in the operating instructions.

3. Allow unauthorized people to approach and/or use the machine.

4. Tamper with the moving and fixed guards that provide perimeter protection, thereby

also exposing other operators and people to risks of a residual nature.

5. Remove or alter the safety signs (such as pictograms, warning signs, and others) on

the machine.

6. Use the machine without having first read and understood the behavioral, operating

and maintenance information contained in the operating instructions.

7. Leave the maneuvering keys on the electromechanical controls (selectors), pneumatic

controls, and doors of the housings for electrical and electronic materials (electrical

panels and derivation boxes).

8. Carry out the following operations as they pose residual risks:

Adjust the mechanical, pneumatic, or electrical parts on the machine while it is

working.

Remove the mechanical, pneumatic, or electrical parts on the machine while it is

working.

Remove the protective devices for mechanical, pneumatic, or electrical parts on the

machine while it is working.

Allow the machine to run when the electrical panels are open.

These uses, that cannot be avoided by way of construction, must not be allowed.

9. If service station fall down, or is hit, or in case of big leakage, or sounds of flowing gas:

WARNING

The employer (or safety manager) is obliged to see to it that the machine is not

used in an improper manner, putting the health of the operator and people

exposed first.

The operator is obliged to inform their employer (or the system safety manager)

if there is a danger of improper use of the machine since, as an instructed

person, the operator is responsible for the use that is to be made of the

machine.

INSTRUCTIONS MANUAL

-14-

an internal damage could happen, also if externally the machine seems good, and it

is still working;

the machine must be taken outdoor or in a very ventilated place.

No fire, no smoke, no workers, no cars nearby this service station.

The service station must be fully tested by a trained technician before to be used

again.

INSTRUCTIONS MANUAL

-15-

PRINCIPLES OF OPERATION

In a single series of operations, the machine permits recovering and recycling refrigerant fluids

(R134a or R1234yf, depending on machine model) with no risk of releasing the fluids into the

environment, and also permits purging the A/C system of humidity and deposits contained in

the oil.

The machine is in fact equipped with a built-in evaporator/separator that removes oil and other

impurities from the refrigerant fluid recovered from the A/C system and collects them in a

container for that purpose.

The fluid is then filteredand returned perfectly recycled to the bottle installed on the machine.

The machine also permits running certain operational and seal tests on the A/C system.

INSTRUCTIONS MANUAL

-16-

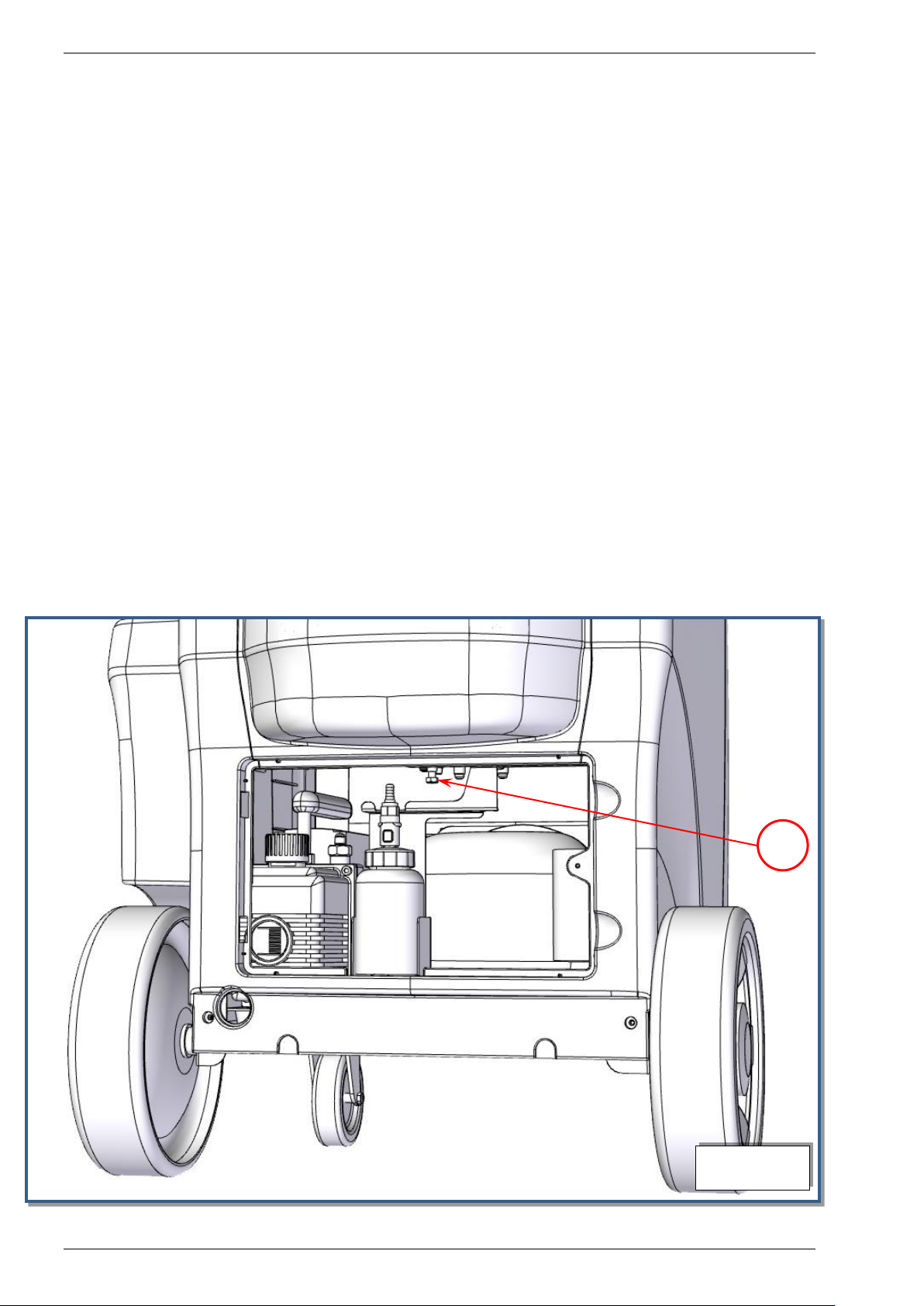

FIG. 3

BOTTLE

RE

LE

AS

E

1

SETUP

The machine is supplied fully assembled and tested.

Remove the protections under the refrigerant scales as follows:

Release refrigerant scale:

- In order to remove the protections under the refrigerant scale the screw (ref.1, Fig.3)

has to be unscrewed until it full stops

- Connect the machine to the electrical supply and switch it on

- Check if the value of refrigerant scale is correct.

Lock refrigerant scale:

NOTE: in the event that the equipment has to be transported, the refrigerant bottle scale

should be locked in place as follows:

1. Switch the machine on.

2. Tighten the screw (ref.1, Fig.3) until the display signals ZERO availability.

NOTE: Check that the oil containers are properly placed in their housing

INSTRUCTIONS MANUAL

-17-

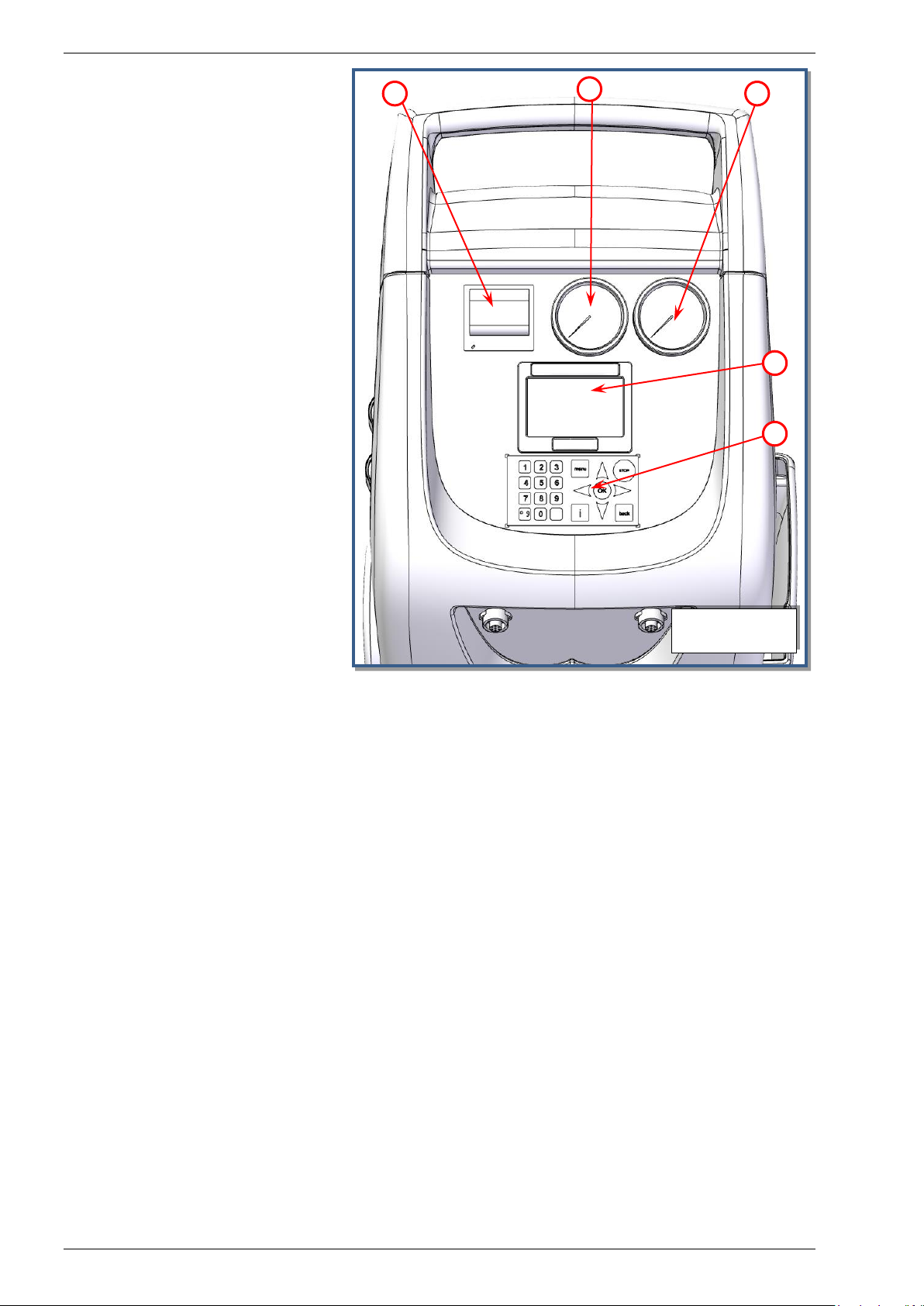

FIG. 4

2

1 3

THE MACHINE

PLASTIC COVER

Refer to Fig.4 .

1. Front plastic cover

2. Rear plastic cover

3. Upper plastic cover

Disassembly: Screw off screws marked (+)

INSTRUCTIONS MANUAL

-18-

FIG. 5

BOTTLE

REL

EAS

E

BOT

TLE

SCA

LE

REL

EAS

E

BOT

TLE

TOOLS:

Screw

driver

+

Box

spann

er

n°10

4

2

1

5

3

CONTROL PANEL

Refer to Fig.5 :

1) High pressure gauge

2) Low pressure gauge

3) Printer

4) 5” Graphic color display

5) Keypad

INSTRUCTIONS MANUAL

-19-

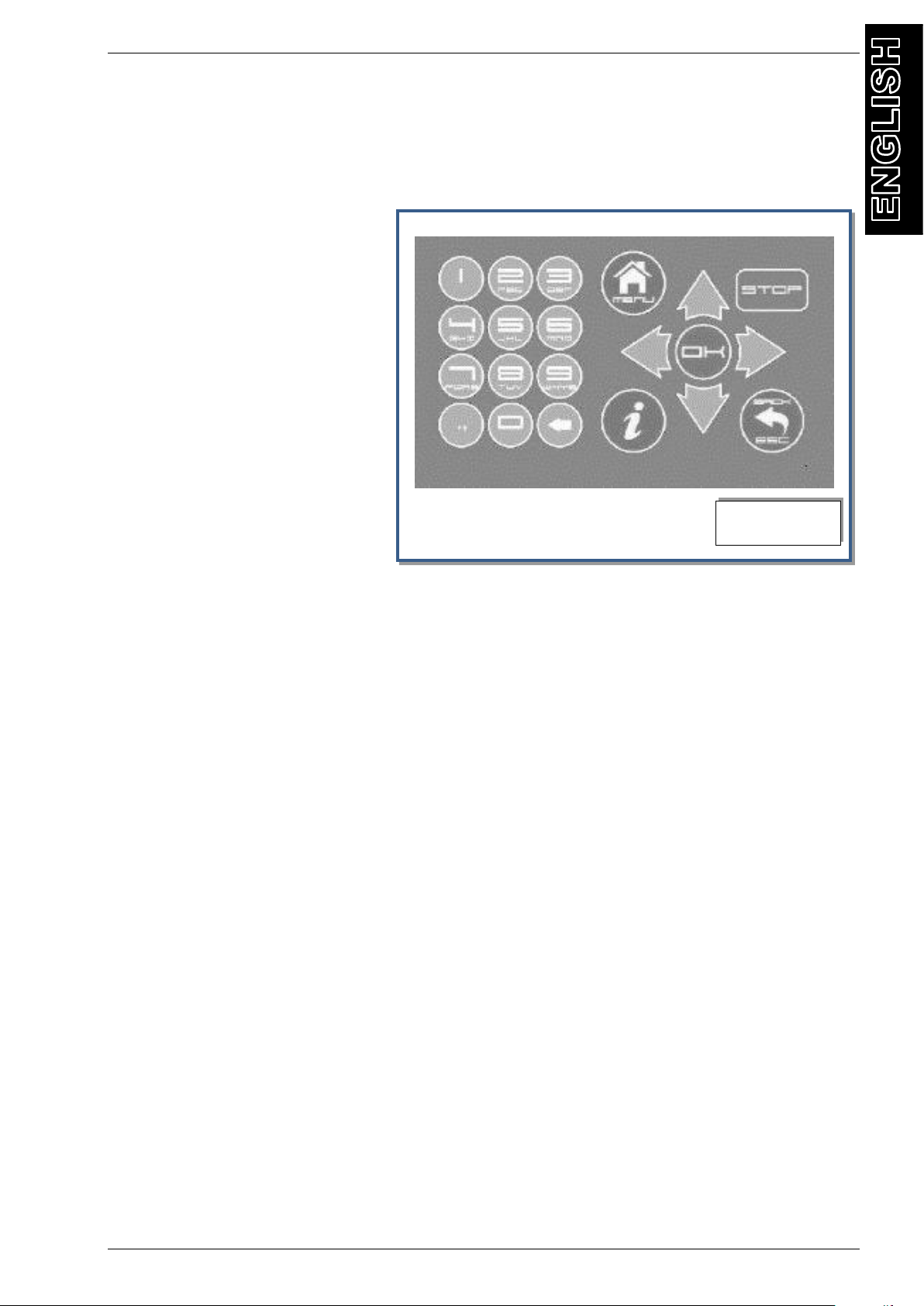

FIG. 6

BOTTLE

REL

EAS

E

BOT

TLE

SCA

LE

REL

EAS

E

BOT

TLE

TOOLS:

Screw

driver

+

Box

spann

er

n°10

FUNCTION SELECTOR KEYBOARD

Refer to Fig.6 :

STOP: interrupt and pause a operation (could be used in case of emergency)

OK: confirm or finish a procedure

or operation shown on the display,

: used for scrolling down through

menu items..

: used for scrolling up through

menu items.

: used for scrolling right through

menu items.

: used for scrolling left through

menu items.

BACK: Return back to previous

menu, orto exit from a procedure

i: visualize data information or

restore default values when

requested

MENU: to return to main menu

KEYPAD: Numerical keypad (includes an alphabet that is used similarto text messaging)

KEYPAD : key to cancel during the input of a parameter, value, plate or code

INSTRUCTIONS MANUAL

-20-

DISPLAY ICONS

ICON DESCRIPTION FUNCTION

AUTOMATIC

PROCEDURE activates a menu that helps the user set up an automatic

recover/vacuum/leak test/charge sequence.

MANUAL

PROCEDURE activates a menu that helps the user to perform a

manual operation:

HIGH PRECISION

RECOVERY activates a menu that helps the user to perform an high precision

recovery/recycling phase

STANDARD

RECOVERY activates a menu that helps the user to perform a recovery/recycling

phase (without SAE J-2788 or SAE J-2843 compliance)

VACUUM activates a menu that helps the user to perform a vacuum phase

OIL / UV INJECTION activates a menu that helps the user to perform a oil/uv injection

followed by a gas filling phase

GAS FILLING activates a menu that helps the user to perform a gas filling phase

DEVICES activates devices menu

FLUSHING HOSES activates a menu that helps the user to perform a FLUSHING HOSES

NITROGEN TEST activates a menu that helps the user to perform a NITROGEN TEST

A/C FLUSHING activates a menu that helps the user to perform a A/C FLUSHING

GAS ANALYZER activates a menu that helps the user to perform a GAS ANALYSIS

SANITIZER activates a menu that helps the user to perform a A/C SYSTEM PURIFICATION

DIAGNOSIS activates a menu that helps the user to perform a A/C SYSTEM DIAGNOSIS

This manual suits for next models

1

Table of contents

Other Ecotechnics Service Equipment manuals