Ecotechnics XK360 User manual

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.1 - 18/10/2005

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.2 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.3 - 18/10/2005

INDEX

INDEX...............................................................................................................................3

INTRODUCTION..............................................................................................................5

PREPARATION FOR REMOVAL AND DISASSEMBLY............................................................................5

REPLACEMENT PARTS ............................................................................................................................5

CHECKING THE CONNECTIONS .............................................................................................................6

OPERATING CYCLE .......................................................................................................7

RECOVERY-RECYCLING PHASE.............................................................................................................7

VACUUM PHASE........................................................................................................................................8

FILLING PHASE..........................................................................................................................................8

THE MACHINE.................................................................................................................8

BASIC COMPONENTS...............................................................................................................................8

CONTROLS AND CONTROL SYSTEM.....................................................................................................9

CONTROLS AND CONTROL SYSTEM...................................................................................................10

FUNCTION SELECTOR KEYBOARD......................................................................................................11

STATUS AND ALARM PANEL.................................................................................................................12

ROUTINE MAINTENANCE ............................................................................................13

FILLING THE MACHINE BOTTLE............................................................................................................13

VACUUM PUMP .......................................................................................................................................13

M.1) OIL TOP-UP..................................................................................................................................................13

M.2) OIL CHANGE ................................................................................................................................................13

M.3) DECONTAMINATION (ONLY MODEL “A”)...................................................................................................14

REPLACING THE DRYER FILTERS........................................................................................................15

FILLING THE NEW OIL TANK..................................................................................................................15

EMPTYING THE USED OIL TANK...........................................................................................................16

SPECIAL MAINTENANCE .............................................................................................17

BOTTLE SCALE CALIBRATION ..............................................................................................................17

ELECTRONIC VALVE CLEANING OR SUBSTITUTION.........................................................................18

CHANGING THE UNITS OF MEASURE (KGÆLBS OR LBSÆKG)........................................................18

TEST OF THE MACHINE...............................................................................................18

TROUBLESHOOTING ...................................................................................................19

FULL BOTTLE ALARM.............................................................................................................................19

EMPTY BOTTLE ALARM..........................................................................................................................19

SERVICE ALARM.....................................................................................................................................19

HIGH PRESSURE ALARM.......................................................................................................................19

NO DISPLAY WHEN MAIN POWER SWITCH IS ON..............................................................................19

FLUCTUATION OF THE READING OF THE REFRIGERANT................................................................19

VACUUM PUMP DOESN’T START..........................................................................................................19

VACUUM PUMP RUNS, BUT LOW SIDE GAUGE DOES NOT REGISTER AN APPROPRIATE

VACUUM...................................................................................................................................................20

THE MACHINE DOESN’T FINISH THE REFILLING................................................................................20

THE MACHINE DOESN’T REFILL THE OIL ............................................................................................20

THE MANOMETERS DON’T READ THE PRESSURE OF THE A/C SYSTEM.......................................20

PROBLEMS DURING THE DOWNLOAD OF THE SOFTWARE.............................................................20

SCALE DOESN’T READ THE WEIGHT...................................................................................................20

GAIN-OF-WEIGHT IMPLIES READING DECREASE OF THE SCALE...................................................21

THE MACHINE DOESN’T FINISH THE RECOVERY..............................................................................22

ALARM MESSAGES......................................................................................................23

ER02..........................................................................................................................................................23

ER01..........................................................................................................................................................23

HIGH PRESSURE LED.............................................................................................................................23

BOTTLE EMPTY LED..............................................................................................................................23

FULL BOTTLE LED...................................................................................................................................23

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.4 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

SERV........................................................................................................................................................ 23

HEATER (ONLY MODEL XK360)............................................................................................................ 23

SUGGESTED SPARE PARTS ...................................................................................... 24

TECHNICAL DETAILED LISTS ..................................................................................... 25

WIRING..........................................................................................................................26

30 KG LOAD CELL WIRING................................................................................................................................. 26

BOTTLE GROUND WIRING................................................................................................................................. 26

POWER SUPPLY WIRING................................................................................................................................... 27

MAIN GROUND WIRING...................................................................................................................................... 27

MAIN SWITCH WIRING + CHOKE....................................................................................................................... 28

2 ELECTRONIC VALVE WIRING (MATE_N_LOCK) ........................................................................................... 28

3 ELECTRONIC VALVE WIRING (MATE_N_LOCK) ........................................................................................... 29

HEATER PRESSURE SWITCH WIRING (PRS4075) (ONLY MODEL XK360).................................................... 29

LOW PRESSURE SWITCH WIRING (PRS4175)................................................................................................. 30

SAFETY PRESSURE SWITCH WIRING (PRS4305)........................................................................................... 30

COMPRESSOR WIRING...................................................................................................................................... 31

CONDENSER FAN WIRING ................................................................................................................................ 31

VACUUM PUMP WIRING..................................................................................................................................... 32

BOTTLE HEATER WIRING (ONLY MODEL XK360)............................................................................................ 32

BOTTLE TEMPERATURE PROBE WIRING (ONLY MODEL XK360).................................................................. 33

HYDRAULICAL DIAGRAM............................................................................................ 34

WIRING DIAGRAM........................................................................................................ 35

ELECTRONIC BOARD.................................................................................................. 36

SCH4000/SCH4001 VALUE_7/9 MOTHERBOARD................................................................................ 36

EXPLODED VIEW KEY................................................................................................ 37

MODEL XK360........................................................................................................................................ 37

MODEL XK360........................................................................................................................................ 38

MODEL XK385........................................................................................................................................ 39

MANIFOLD.............................................................................................................................................. 40

PIPING..................................................................................................................................................... 42

CHECK VALVE [GRVLV05].................................................................................................................... 44

SOLENOID VALVE [VLV1550]................................................................................................................ 45

NOTE............................................................................................................................. 46

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.5 - 18/10/2005

INTRODUCTION

This manual was produced by the manufacturer primarily for use by dealers and their qualified

A/C system technicians. It is not possible to include all the knowledge of a mechanic in one

manual. Therefore, anyone who uses this book to perform maintenance and repairs on service

stations should have a basic understanding of mechanics and the techniques to repair these

types of machines. Repair and maintenance work attempted by anyone without this knowledge

is likely to render the service station unsafe and unfit for use. This model has been designed

and manufactured to perform within certain specifications in regard to performance. Proper

service with the correct tools is necessary to ensure that the service station will operate as

designed. If there is any question about a service procedure, it is imperative that you contact

the dealer for any service information changes that apply to this model. This policy is intended

to provide the customer with the most satisfaction from his service station. The manufacturer is

continually striving to improve all of its models. Modifications and significant changes in

specifications or procedures will be forwarded to all authorized dealers and will appear in future

editions of this manual where applicable. Please read this material carefully. Designs and

specifications are subject to change without notice.

PREPARATION FOR REMOVAL AND DISASSEMBLY

1. Before removal and disassembly, eliminate all dirt, mud, dust and foreign material.

2. Use only the proper tools and cleaning equipment.

3. During disassembly, clean all of the parts and place them in trays in the order of

disassembly. This will speed up assembly and allow for the correct installation of all parts.

4. Keep all parts away from any source of fire.

REPLACEMENT PARTS

Use only genuine manufacturer parts for all replacements, contact the dealer for the complete

list. Other brands may be similar in function and appearance, but inferior in quality, and not

designed for that specific use.

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.6 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

CHECKING THE CONNECTIONS

Check the leads, couplers, and connectors for stains,

rust, moisture, etc.

1.Disconnect: Lead, Coupler, Connector

2.Check: Lead, Coupler, Connector

Moisture ÆDry with an air blower.

Rust/stains ÆConnect and disconnect several

times.

3.Check: all connections

Loose connection ÆConnect properly.

If the pin 1 on the terminal is flattened, bend it up.

4.Connect: Lead, Coupler, Connector

NOTE: Make sure all connections are tight.

5.Check: continuity (with the pocket tester)

NOTE: If there is no continuity, clean the

terminals. When checking the wire harness,

perform steps (1) to (3). As a quick remedy, use a

contact revitalizer available at most part stores.

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.7 - 18/10/2005

OPERATING CYCLE

The operating cycle is divided into three distinct phases: the recovery-recycling phase with the

automatic draining of used oil, the vacuum phase, the oil and refrigerant recharging phase.

RECOVERY-RECYCLING PHASE

After carrying out the necessary connections to the vehicle’s air conditioning system and

selecting the phase, if gas is present the machine will begin recovery. There follows a detailed

description of the system. We will follow the path taken by the gas on the enclosed hydraulic

diagram: during this phase the EV1 solenoid valve is open, and the compressor (14) and

electric fan (26) are also in operation. For this to occur, it is necessary that the gas pressure,

visible on the manometer, is sufficient (+0.5 bar) to close the electrical contact at the pressure

switch (7) connected to the distributor. Under these conditions, the flow arriving from the air

conditioning system through the mechanical filters (8), which retains any solid residue, reaches

the evaporator (9) after passing through the EV1 solenoid valve.

From the evaporator, the gas moves past the check valve n°1 (11) and the low pressure filter

(12) until it reaches the compressor (14). The filter mentioned is a high capacity dehydrating

filter (between 10 and 12 ppm per kg of refrigerant in relation to the type of refrigerant and the

temperature of the fluid).

When it leaves the compressor the refrigerant, in a superheated vapour state, arrives at the

separator. In its new configuration this cylindrically-shaped component has three connectors on

the upper part, with a safety pressure switch (16) connected to one of them. This is normally

closed and will open the electrical contact, disconnecting the power supply to the compressor,

if the delivery pressure of the compressor should exceed around 17.5 bar. The compressor is

a 12 cc displacement reciprocating compressor and has three connections: on one side are the

suction and delivery connections, on the opposite side is a connection used for returning the oil

from the separator (15).

There follows a detailed description of the separator: during compressor operation obviously

part of the oil enters into circulation with the refrigerant, therefore it is necessary to make sure

that this oil returns to the compressor so that its functionality is not compromised. In

correspondence with the central connector, the separator has a pure borosilicate coalescent

filter with over 99% efficiency, which causes the oil molecules to coacervate as an effect of the

excitation produced by passing over the filter. In this way, gravity causes the drops of oil to

deposit on the bottom of the bottle and then return to the compressor, at the end of the

recovery phase, when the EV3 solenoid valve is opened.

After coming out of the separator, the superheated gas goes through the check valve n°2 (17)

and returns to the evaporator. When it comes out of the evaporator, the refrigerant goes to the

condenser (27) where it completely passes to a liquid state, transferring heat to the air flow

produced by the electric fan (26). In its now liquid state, the refrigerant then goes through filter

(30), which has the same characteristics as filter (12), and passes through the humidity

indicator (31), the check valve n°3 (32) which stop the gas from the bottle (33) returning, even if

the pressure rises to a relatively high level as an effect of the automatic heating element

resistance (ONLY MODEL XK360), not illustrated.

There is also a bottle manometer (22) and a pressure switch (21) (ONLY MODEL XK360) for

the bottle heater. When the pressure descends below 6 bar, the electrical heating element is

triggered until a pressure of 8 bar is reached.

Finally we arrive to the bottle (33) through the vapour side valve.

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.8 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

The recovery phase shuts down with the de-energising of EV1 when the pressure switch (7)

reaches a pressure of –0.3 bar, the EV2 valve is automatically opened to drain the used oil,

and the electronic valve EV3 for the return of the oil of the compressor

VACUUM PHASE

At the end of the recovery phase there is an interval of around 2 minutes during which any gas

returning from the system will result in the recovery phase being immediately restarted.

Otherwise the vacuum phase will automatically begin. During this phase only the EV4 solenoid

valve is energised so that air and non-condensable gases can be evacuated through the

vacuum pump (10). The vacuum pump is a single stage model with an involute capacity of

112l/min and a vacuum degree of 0.1 mbar.

The vacuum phase can also be selected from the keyboard as long as the air conditioning

system has been completely discharged. The vacuum phase will only start under these

conditions, otherwise the machine will sound an acoustic alarm and it will be necessary to

begin from the recovery phase.

FILLING PHASE

Once the vacuum phase has concluded, the technician will carry out the recharging of new oil,

and refrigerant. The new oil in the container (35), passes through the new oil valve (34), the

check valve n°4 (19) and reaches the distributor where there is a vacuum.

Once injection of oil is complete, the EV5 solenoid valve is energised and the refrigerant flows

from the bottle to the distributor and then into the air conditioning system, where there is a

vacuum, by simply making use of the pressure difference between the bottle and the system.

Once the required weight has been reached, the EV5 solenoid valve closes, blocking the flow

of refrigerant from the bottle.

NOTE: Numbers under bracket of this chapter are referred to the hydraulic diagram.

THE MACHINE

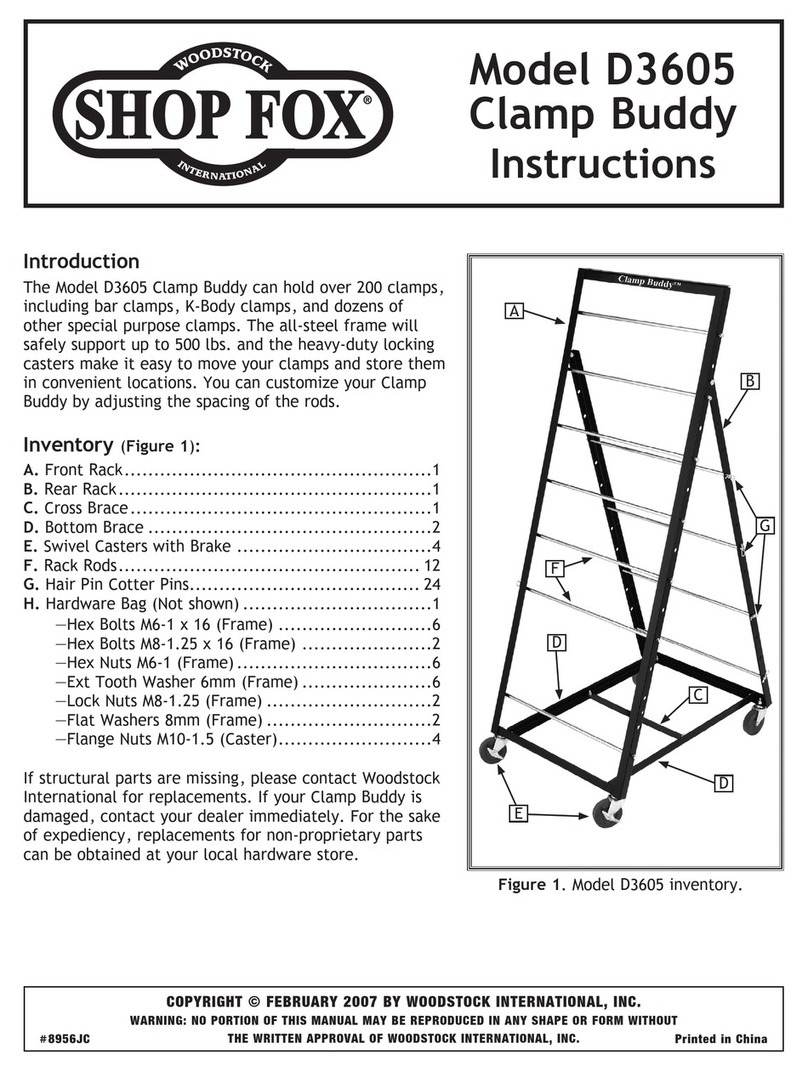

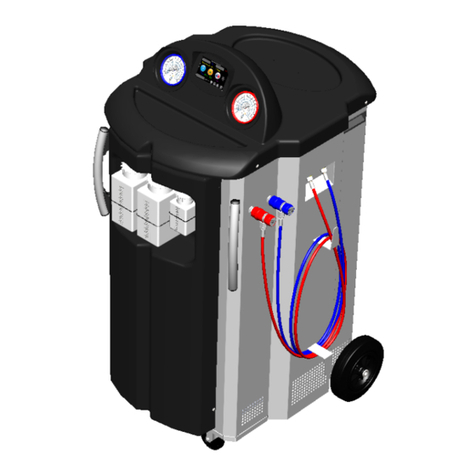

BASIC COMPONENTS

a) Control console b)Taps

c) Handle d) High/Low Pressure threaded connectors

e) Top-up oil container f) Bottle

g) Drying filters h)Electronic scale

j) Main switch i) Heating resistance (ONLY MODEL XK360)

k) Socket for electrical supply plug l) Fuse

m) Used oil container n) Serial port

o) Humidity gauge p) Vacuum pump

q) Wheels

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.9 - 18/10/2005

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.10 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

CONTROLS AND CONTROL SYSTEM

(A1) High pressure gauge for A/C system

(A2) Low pressure gauge for A/C system

(A4) Pressure gauge for bottle refrigerant pressure

(A6) Emergency/alarms panel

(A7) Display

(A8) Pushbuttons for modifying and starting/stopping operations

(A9) Operations selector panel

A1 A2

A9

A4

A6

A7 A8

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.11 - 18/10/2005

T1 T3 T8

T6

T9

T5

T4 T7 T12 T10 T11

T2T13

FUNCTION SELECTOR KEYBOARD

(T1) Availability LED indicator: when lit, the display reports the quantity of refrigerant fluid

contained in the bottle.

(T2) Charging LED indicator (flashes during the CHARGING phase).

(T3) Recovery LED indicator (flashes during the RECOVERY phase).

(T4) Vacuum LED indicator (flashes during the VACUUM phase).

(T5) Oil Discharge indicator (flashes during the OIL DISCHARGE phase).

(T6) SEL key: Selects the operation to be performed. Every time this key is pressed one of the

LEDs from T1 through T4 will light in sequence; the LED alongside each operation indicates

that the operation may be started or that it is being performed (flashing LED).

(T7) + key: Each time this key is pressed during the operations relative to setting the time and

the quantity, the value of the flashing digit on the display will be increased by one unit.

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.12 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

(T8) ARROW key: Each time this key is pressed while a display value is flashing during the

operations relative to setting the time and the quantity, a different digit will be selected for

modification (selected digit will flash).

(T9) ENTER key: Pressing this key when a LED corresponding to an operation is lit but not

flashing will permit modifying the times and the fluid quantities. Upon completion of

modification, press the key again to confirm the datum

(T10) START key: Pressing this key will start the operation indicated by the lighted LED

(T11) STOP key: Pressing this key will stop the operation indicated by the flashing LED.

(T12) TEMPERATURE key: Pressing this key the display will show the bottle temperature in

Celsius degree and Fahrenheit degree. (ONLY MODEL XK360)

(T13) Display: According to the operation selected, displays the time or refrigerant quantity

values.

STATUS AND ALARM PANEL

(C1) HEATER ON: Lights to indicate that the electrical resistance of the machine is heating the

bottle to maintain fluid pressure between 5.5 and 8,5 bar. The resistance does not operate

during the RECOVERY phase of operation (ONLY MODEL XK360)

(C2) HIGH PRESSURE: Lights and emits an acoustic signal when the pressure of the fluid in

the circuit catch up 17.5 bar. The RECOVERY operation is automatically interrupted.

(C3) FULL BOTTLE: Lights and emits an acoustic signal when the bottle is full to more than

80% capacity (that is, 10 kg). The Recovery operation is automatically interrupted.

(C4) EMPTY BOTTLE: Lights and emits an acoustic signal when the quantity of refrigerant fluid

contained in the bottle is low (2 kg). in order to avoid the emission of non-condensable gases.

Fill the bottle according to the procedure described in the ROUTINE MAINTENANCE section.

C3

C4

C2

C1

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.13 - 18/10/2005

ROUTINE MAINTENANCE

FILLING THE MACHINE BOTTLE

This operation must be performed whenever the available refrigerant in the bottle is less than 3

kg and must in any case be performed when the “empty bottle” indicator lights on the control

console.

IMPORTANT: Never tamper with the taps on the machine bottle. Procure a bottle of R134a

gas; connect it to the high-pressure hose of the MACHINE. Open the tap of the external bottle

and the high-pressure tap of the MACHINE. If the external bottle is not supplied with a suction

device, turn it upside down to obtain a higher delivery rate. Switch the machine on, then hold

down the SEL key until the LED corresponding to “Recovery” lights. Press the START key to

start the MACHINE. The display will indicate the quantity of refrigerant transferred to the bottle

on board the machine. Close the tap of the external bottle when the quantity transferred is 0.50

kg less than the final quantity desired. Allow the machine to recover the fluid remaining in the

hose. The “oil discharge” LED will light when the machine will have recovered all the fluid from

the hose. The machine will stop automatically. Close the high-pressure tap on the MACHINE,

press the STOP key, and disconnect the external bottle.

VACUUM PUMP

Perform the operations listed below on a routine basis in order to ensure good operation of the

vacuum pump.

M.1) Oil top-up

M.2) Oil change

M.3) Decontamination (only Model “A”)

When topping-up or replacing the pump oil, use only the oil recommended by the

manufacturer. Contact the distributor for information concerning the correct type of oil.

NOTE: in order to correctly check the oil level it is suggested to run a 1 minutes of vacuum, and

the verify the oil level.

M.1) Oil top-up

This operation must be performed when the level of the oil falls to less than half on the indicator

(4). To refill the oil, perform the steps listed below in the order given. Disconnect the machine

from the mains supply. Locate the oil cap (3) and screw it off. The oil will be added through the

hole in which the oil cap was lodged (3). Add oil a little at a time, waiting for the level to rise

before each successive addition, until the oil level is about ½ cm above the red mark on the

indicator (4). Replace the oil cap (3) and tighten down.

M.2) Oil change

The vacuum pump oil must be replaced every 150 working hours and in any case every time

the refrigerant filters are replaced. The oil must also be changed whenever it changes color

due to absorption of humidity. Before beginning the oil change procedure, procure a container

of at least 500 cc capacity in which to collect the used oil. The pump contains about 500 cc of

oil. Use only suitable ISO68 oils (Contact your vacuum pump distributor for specific

information).

1) Disconnect the machine from the mains supply.

2) Unscrew the filling cap (3).

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.14 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

3) Unscrew the drain cap (5).

4) Allow all the oil to run out into a disposal

container (with height < 10 cm)

5) Close the drain cap (5).

6) Pour in new oil through the filling hole (3

- opened previously) until the level rises

to the midpoint on the indicator (4).

7) Replace and tighten the filling cap (3).

M.3) Decontamination (only Model “A”)

Dark or turbid oil or an increase in the oil level

are signs that the oil has been contaminated

by foreign substances. In these cases proceed

as outlined below.

1) Disconnect the machine from the mains

supply.

2) Unscrew the ballast valve (2) by 2 (two)

turns.

3) Reconnect the machine to mains

supply.

4) Run the vacuum phase for one hour on

the hoses, with the taps open, and with

the quick coupler connected.

5) Disconnect the machine from mains supply.

Should decontamination not return the oil to its original state (light color and no traces of

emulsion), change the oil.

NOTE: vacuum pump maintenance procedure described into the users manual ed.0 is non

correct, decontamination is available only for vacuum pumps model “A”.

2 1

3

4

MA

X

min

5

5

4

MA

X

min

3

1

Model “

A

”

Model “B”

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.15 - 18/10/2005

REPLACING THE DRYER FILTERS

Replace the filters whenever the machine gives

the service alarm during the first ten seconds of

operation or whenever the humidity gage signals

the presence of humidity in the circuit (inner circle

yellow). Before performing any operation, check

that the replacement filters are the same types as

those installed on the machine. Then proceed as

described below:

1) Disconnect the machine from the electrical

supply

2) Wear protective gloves and glasses

3) Remove the rear plastic cover from the

machine.

4) Close the taps on the bottle.

5) Close the tap (1) on the filter (4)

6) Connect the low pressure quick-connect

coupling to the male connector (2) of the

filter (4)

7) Connect the machine to the electrical

supply

8) Carry out a recovery operation (note: the

low pressure tap should be open)

9) When zero bar is reached, immediately

close the tap (3) on the filter (5) and press

Stop or Reset

10)Disconnect the machine from the electrical supply

11)Disconnect the low pressure quick-connect coupling from the connector (2) on the filter

(4)

12)Dismantle the old filters and mount new ones, carefully noting the direction of the

arrows.

IMPORTANT: replace the old filter with a new one as quickly as possible to avoid

possible contamination by moisture in the ambient air.

13)Open the tap (1) under the filter (4) and the tap (3) on the filter (5)

14)Open the taps on the bottle

15)Replace the rear plastic cover on the machine

16)Reconnect to the electrical supply and switch the machine on.

17)Select NEXT MENU, and enter into SERVICE ALARM.

18)Key in the filter code to cancel the alarm; if the filter code is not available, telephone the

Service Center.

19)Recover around 500g of gas to charge the machine circuit.

20)Switch off the machine

21)Disconnect the machine from the electrical supply

FILLING THE NEW OIL TANK

It is good practice to fill the oil tank whenever the oil level falls below 100 cc in order to

guarantee that there will be sufficient oil for topping up during successive operations. Types of

1

2

3

4

5

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.16 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

oil: use only synthetic (polyester) oils or the oils recommended by the A/C system manufacturer

(ISO 68 density). Always refer to the information provided by the system manufacturer.

Procedure: Lift the oil tank out of its lodging. Hold the cap and unscrew the tank. Fill with the

correct quantity of suitable type and grade oil for compressors. Screw the tank back into the

cap while holding the latter in place.

EMPTYING THE USED OIL TANK

This operation must be performed whenever the oil level exceeds 200 cc. Procedure. Remove

the tank from its lodging very carefully. Hold the cap and unscrew the tank. Empty the contents

into a container for used oils. Screw the tank back into the cap while holding the latter in place.

Replace the tank.

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.17 - 18/10/2005

SPECIAL MAINTENANCE

BOTTLE SCALE CALIBRATION

This operation should be performed when the scale values displayed are out of line with known

values. The operations listed below must be performed with the maximum attention and care.

Always observe the precautions outlined in this section. Always place the weights carefully on

the scale plate, one at a time. Always place the weights the center of the scale plate. Proceed

as explained below to calibrate the scale (see fig.3). Disconnect the machine from mains

supply. Procure a known reference weight (16 or 18 kg). Remove the plastic cover on the rear

of the machine (ONLY MODEL XK360) to access the machine bottle. Close the blue and red

taps on the bottle. Unscrew the bottle lock nut (3). Separate the heating coil (4) from the bottle

(do not touch or disconnect the wires of the resistance coil).

Remove the bottle (5) from its seat, leaving the resistance around the scale plate(ONLY

MODEL XK360). Rest the bottle on a stand at least 40 cm in height. Switch on the MACHINE.

Be careful not to touch any electrical wires. Wait at least 10 seconds. Press the + and ARROW

keys simultaneously and hold down for about 5 seconds. The value displayed at this point will

correspond to the scale zero value. Press down lightly on the scale plate; the value should

increase. If it does not, replace the charge cell. Press the ENTER key to memorize the value.

In this phase, take care that nothing touches the scale plate). Place the reference weight (16 or

18 kg) carefully at the center of the scale plate and check that the displayed value increases

accordingly. Press the SEL key and use the + e ARROW keys to type in the 4 figures of the

reference weight. Press ENTER. The display reading should be the reference weight minus the

weight of the empty bottle (ca. 6.1 kg).

Remove the reference weight. Switch off the machine and disconnect from mains supply.

Replace the bottle in its seat on the scale plate. Switch on the MACHINE, taking care not to

touch any electrical wires. Check calibration: place a known 0.5 kg or 1 kg reference weight on

the bottle and check that the displayed availability value increases by the value of the known

reference weight ±2%. Remove the reference weight. Switch off the machine and disconnect

from mains supply. Screw down the bottle lock nut (3). Open the red and blue bottle taps.

Replace the rear plastic cover(ONLY MODEL XK360).

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.18 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

ELECTRONIC VALVE CLEANING OR

SUBSTITUTION

Disconnect the machine from mains supply.

Remove the rear plastic cover. Identify the

solenoid valve referring to the PIPING

paragraph of the EXPLODED VIEW KEY. Close

the blue and red taps of the machine bottle.

Unscrew the nut (2), extract the lock washer (3)

and the coil (1). ATTENTION: The coil must

remain inside the machine, with the wires

attached.

NOTE: if the valve to be cleaned is EV2 or EV3,

it will be necessary to also remove the front

plastic cover and the front panel.

Unscrew the body of the solenoid valve (4). Use

a jet of compressed air to clean the plunger

gasket (5) and the orifice (6). Reassemble.

Open the blue and red taps of the machine

bottle. Replace the rear plastic cover. Test the

machine. If the problem persists, disconnect the

machine from main supply and replace the

solenoid valve

CHANGING THE UNITS OF

MEASURE (KGÆLBS OR LBSÆKG)

Press the SEL, START, and ENTER keys

simultaneously. Switch on the machine. The

machine will change from one system of units of

measurement to the other.

TEST OF THE MACHINE

Not available

1

23

4

5

6

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc pag.19 - 18/10/2005

TROUBLESHOOTING

FULL BOTTLE ALARM

- Transfer refrigerant from unit tank to approved refrigerant storage tank.

- Check the scale calibration

- Check if the max=10.000g

EMPTY BOTTLE ALARM

- Transfer refrigerant from approved refrigerant storage tank to unit tank.

- Check the scale calibration

- Check if the min=2.000g

SERVICE ALARM

- Remove and replace the filter-drier. See REPLACING THE FILTER-DRIER and change

the oil of the vacuum pump

HIGH PRESSURE ALARM

- remove the air from the bottle as describe into “purge non condensable gas” paragraph

of the user manual. Repeat another recovery phase, if air accumulate again into the

bottle it means that the machine is sucking air, please verify leaks on the piping.

- Open the machine, verify that the valve under the high pressure dryer filter and the two

valves over the refrigerant bottle are all open

- Gaskets of the hose (s) connected to the internal bottle are distorted. Substitutes with

new ones, cod. GUA0002

NO DISPLAY WHEN MAIN POWER SWITCH IS ON

- Blown main fuse, Replace fuse 8A

- verify connection LINE IN into the motherboard

- verify the voltage into the LINE IN wiring,

a. it is 230 +/-10%: substitute the motherboard

b. it is NOT 230 +/-10%: substitute the LINE IN wiring

FLUCTUATION OF THE READING OF THE REFRIGERANT

- verify the power supply voltage must be 220 +/-10%:

- verify bottle load cell connection J15 to the motherboard

- verify wiring connection to bottle load cell

- replace refrigerant bottle load cell

- replace motherboard

VACUUM PUMP DOESN’T START

- ERROR: “02”; make another recovery phase, if the recovery phase doesn’t finish,

please refer “the machine doesn’t finish the recovery” paragraph

The data, information and descriptions, and the technology described herein are the exclusive intellectual property of Ecotechnics S.p.A. and constitute industrial

secrets. Said information is communicated in strict confidentiality; said information may be used only for the purpose for which it is communicated; said information

may not be divulged, communicated, or revealed to third parties and/or reproduced by any means for any reason whatsoever; said information is protected under

applicable Italian competition and industrial property law.

pag.20 - 18/10/2005 Service manual VA500-VA750 ed.1 ver.5.05 [MANU360.SA0].doc

VACUUM PUMP RUNS, BUT LOW SIDE GAUGE DOES NOT REGISTER AN

APPROPRIATE VACUUM

- Possible leak into the A/C system, close both quick coupler, if the now the vacuum is

reached it means there is a leak into the A/C system of the car.

- Pump oil insufficient or contaminated: refill or decontaminate the vacuum pump oil

- If the pump start and the immediately stops visualizing ERROR “02", verify and if

necessary substitute the check valve n°1

THE MACHINE DOESN’T FINISH THE REFILLING

- Close HP valve, left open the LP valve in front of the machine, start the engine of the

car, turn on the A/C system, let the compressor of the A/C system suck the remaining

refrigerant.

- If the problem reiterate continuously, proceed with the following verification:

1. bottle pressure > LP and HP

a. verify if the needle of the HP and LP quick coupler reach the valve

inside the male fitting

b. verify if hose or the capillary for the refilling (the one under the refilling

electronic valve EV5) is obstructed

2. bottle pressure < LP and HP

a. verify the calibration of the refrigerant load cell, it could possible a shift

of the “zero” (that is the availability displayed > of the real one)

THE MACHINE DOESN’T REFILL THE OIL

- Verify the functioning of the new oil manual valve

- New oil hose (Ton) obstructed or restricted

THE MANOMETERS DON’T READ THE PRESSURE OF THE A/C SYSTEM

- the quick coupler is closed, verify the corresponding stinger inside of the quick coupler

- service hoses gasket obstructed

- manometer capillary line obstructed (rare)

PROBLEMS DURING THE DOWNLOAD OF THE SOFTWARE

- The software “ECKPC” doesn’t find the machine:

1.The serial cable RS232 isn’t direct (pit to pin), turn off the machine and check the

serial wiring

2.wrong connection port

3.wrong bit rate, set up to 19200 baud rate

SCALE DOESN’T READ THE WEIGHT

- the bottle fix bolt touches the bottle plate, remove it (only for refrigerant scale)

- the scale pin-connector isn’t correctly plugged to the motherboard

- during calibration electrical level is always 4096:

1. verify the right sequence (refer to WIRING paragraph) of the colour of the wire into

the pin-connector of the scale

2.verify that the pin-connector “AMP MOD II” of the motherboard aren’t short-

circuited: check the voltage between PIN 2 and PIN 3, if the voltage is > 100 mV

clear the pin-connector or replace the motherboard

This manual suits for next models

3

Table of contents

Other Ecotechnics Service Equipment manuals

Popular Service Equipment manuals by other brands

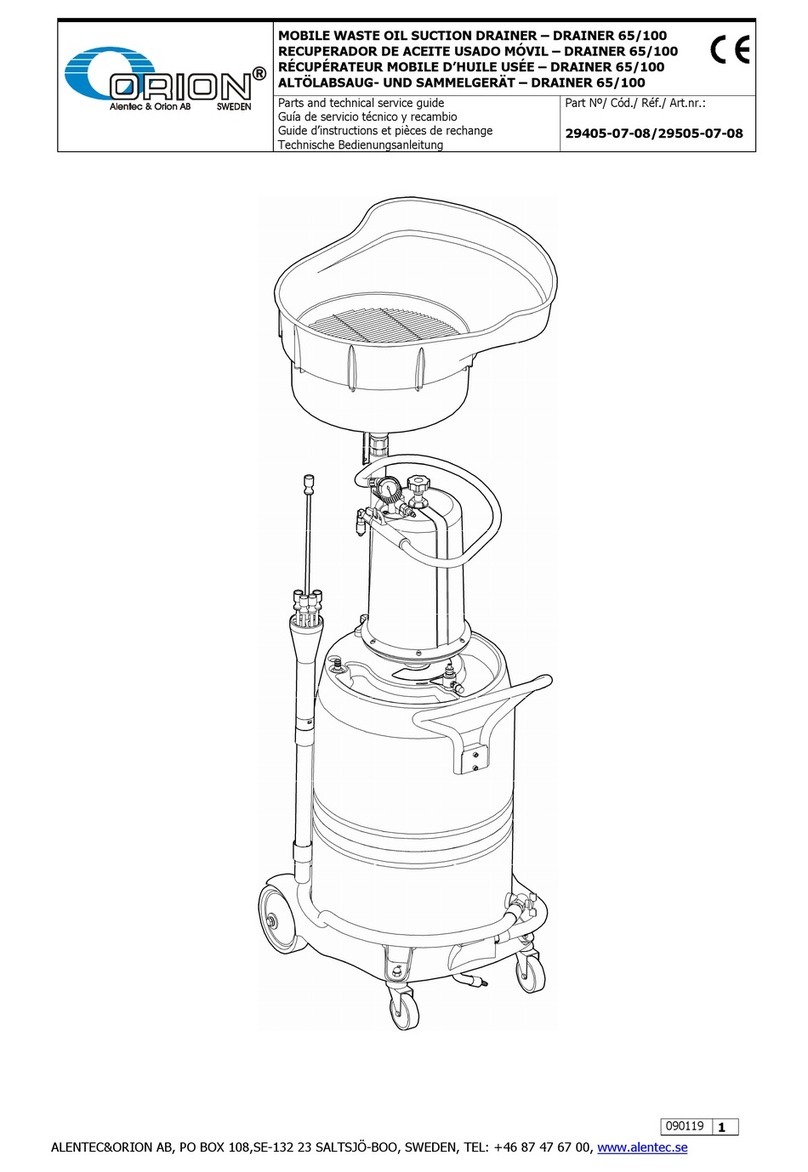

Orion

Orion 29405-07-08 Parts and technical service guide

Master cool

Master cool 53376 operating instructions

Master cool

Master cool COMMANDER4000-E Operation instructions

parktool

parktool 100-3D quick start guide

Brain Bee

Brain Bee 9000 Bus Plus User and maintenance manual

Heal-Tech

Heal-Tech FI Cleaner user manual