801AP

17A-05-AP

2 11/02

PAGE 2 of 10

2.2 ELECTRICAL

The 801AP can be operated with LCD backlight OFF or ON.

Batteries: 4 x rechargeable AA size

Nickel Metal Hydride

Operating Time Up to 15 hours (dependent

(Batteries only) on battery charge and usage)

The ac adaptor is required when testing high current MX

addressable devices, including the SAM800/SAB800.

2.3 ENVIRONMENTAL

Operating Temperature: 0°C to +45°C

Storage Temperature: 0°C to +50°C

Relative Humidity: 90% (non-condensing)

Battery Disposal: No special considerations are

applicable in the UK at time of

writing. (Check with local

authorities).

2.4 EMC

The 801AP MX Service Tool meets the requirements of the

EU EMC Directive 89/336/EEC.

3. OPERATION

IMPORTANT:

FULLY CHARGE THE BATTERIES FOR 10

HOURS BEFORE USING FOR THE FIRST TIME

RECHARGE THE BATTERIES AS SOON AS

THE LOW BATTERY INDICATOR APPEARS.

DO NOT OPEN BATTERY LID WHILE THE UNIT

IS SWITCHED ON.

3.1 STARTING UP

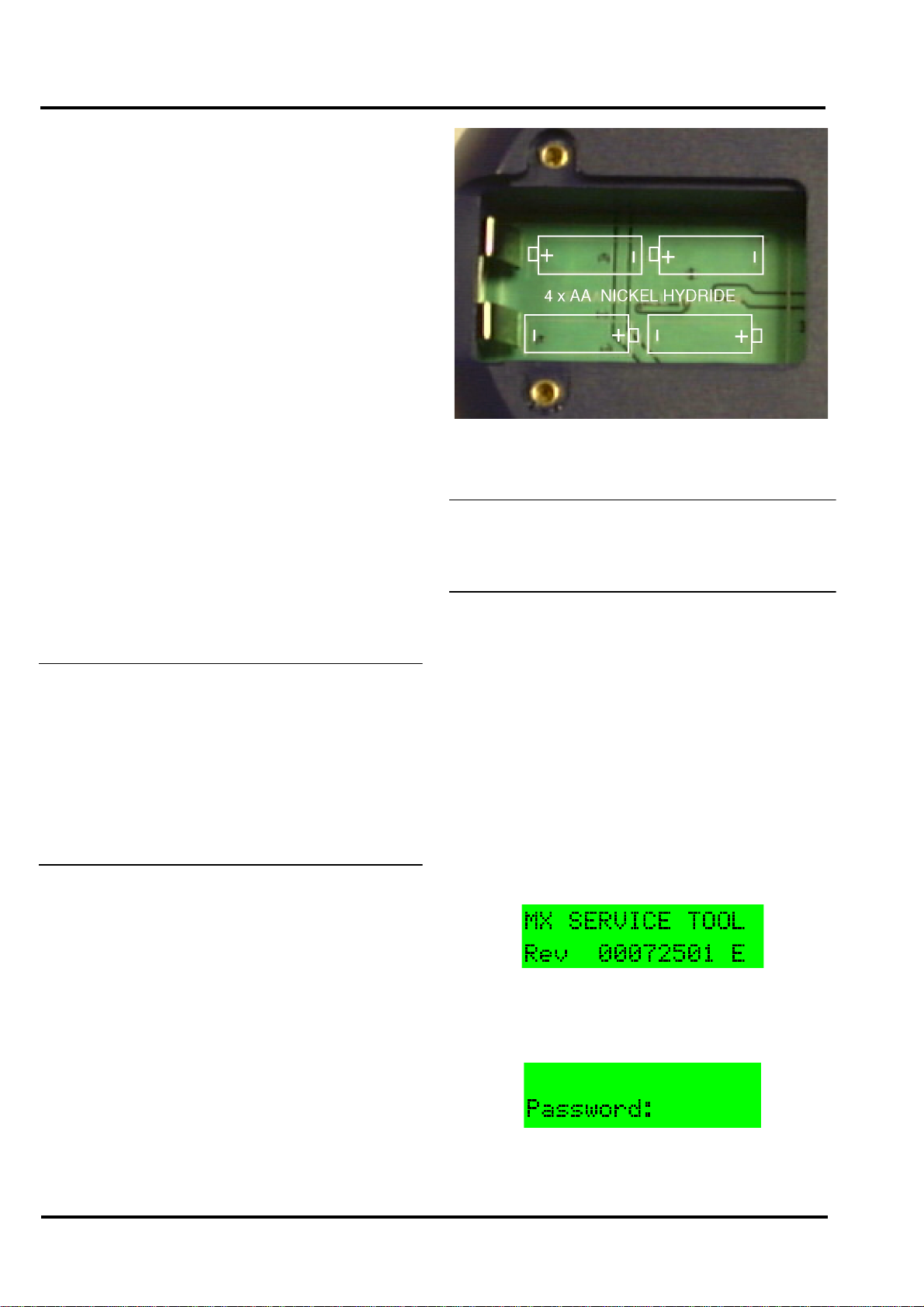

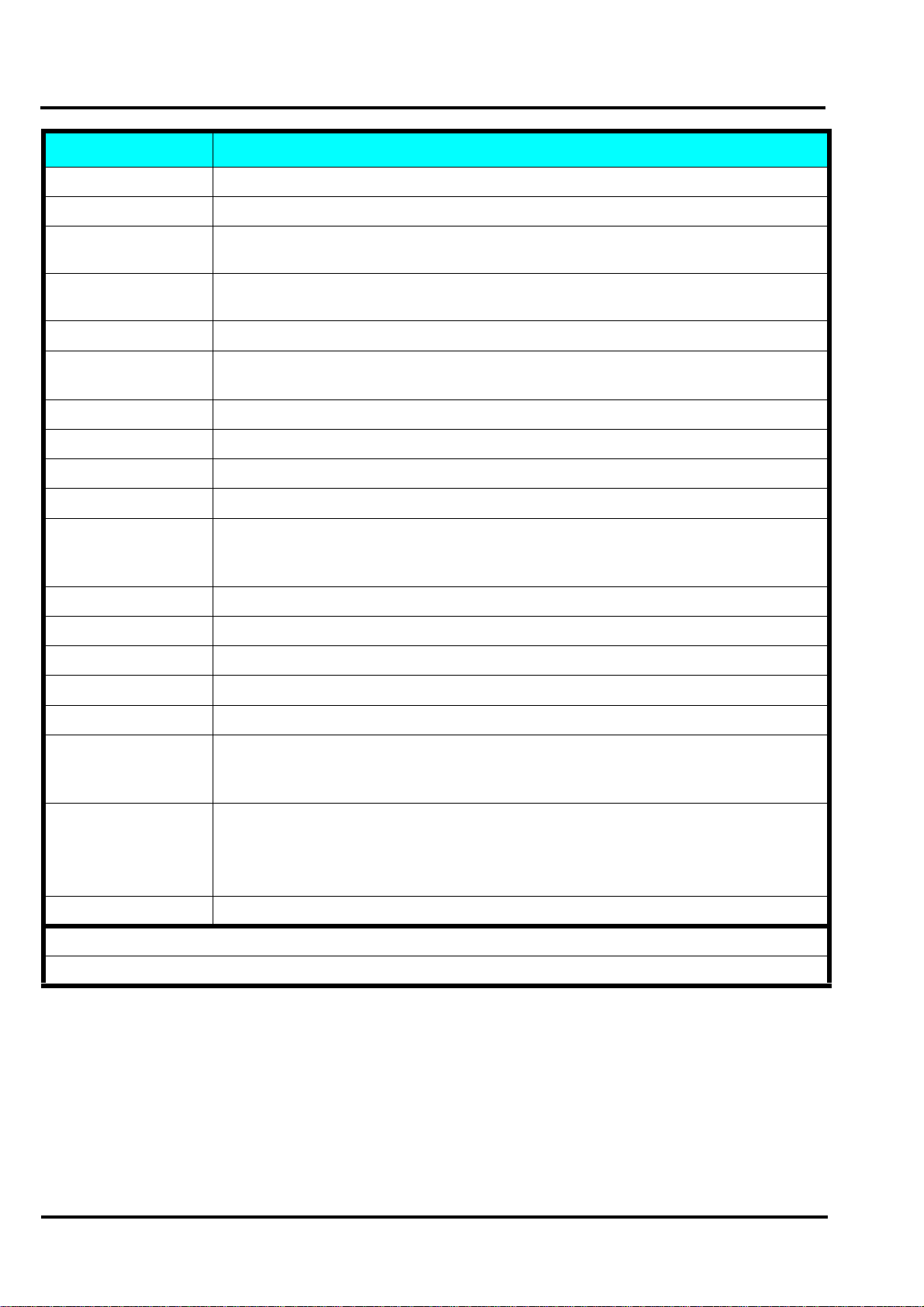

3.1.1 INSTALLING BATTERIES

To install/change the batteries, proceed as follows:

a) Unscrew the two screws on the base of the 801AP,

using a cross-point screwdriver, holding the battery

compartment cover whilst removing it.

b) Insert the batteries ensuring correct polarity as shown

inside the battery compartment.

c) Replace the battery compartment cover and screw

down.

CAUTION:

ENSURE ONLY NICKEL METAL HYDRIDE

RECHARGEABLE BATTERIES ARE USED.

3.1.2 CHARGING AND MAINS USE

The 801AP has its own built-in charging circuit, powered by

the mains adaptor. The batteries are boost-charged for 4-5

hours and reach full charge within 10 hours.

The 801AP can be powered from the mains supply using the

DC adaptor. If batteries are installed, this allows them to be

charged at the same time. For low battery indicator, see page 9.

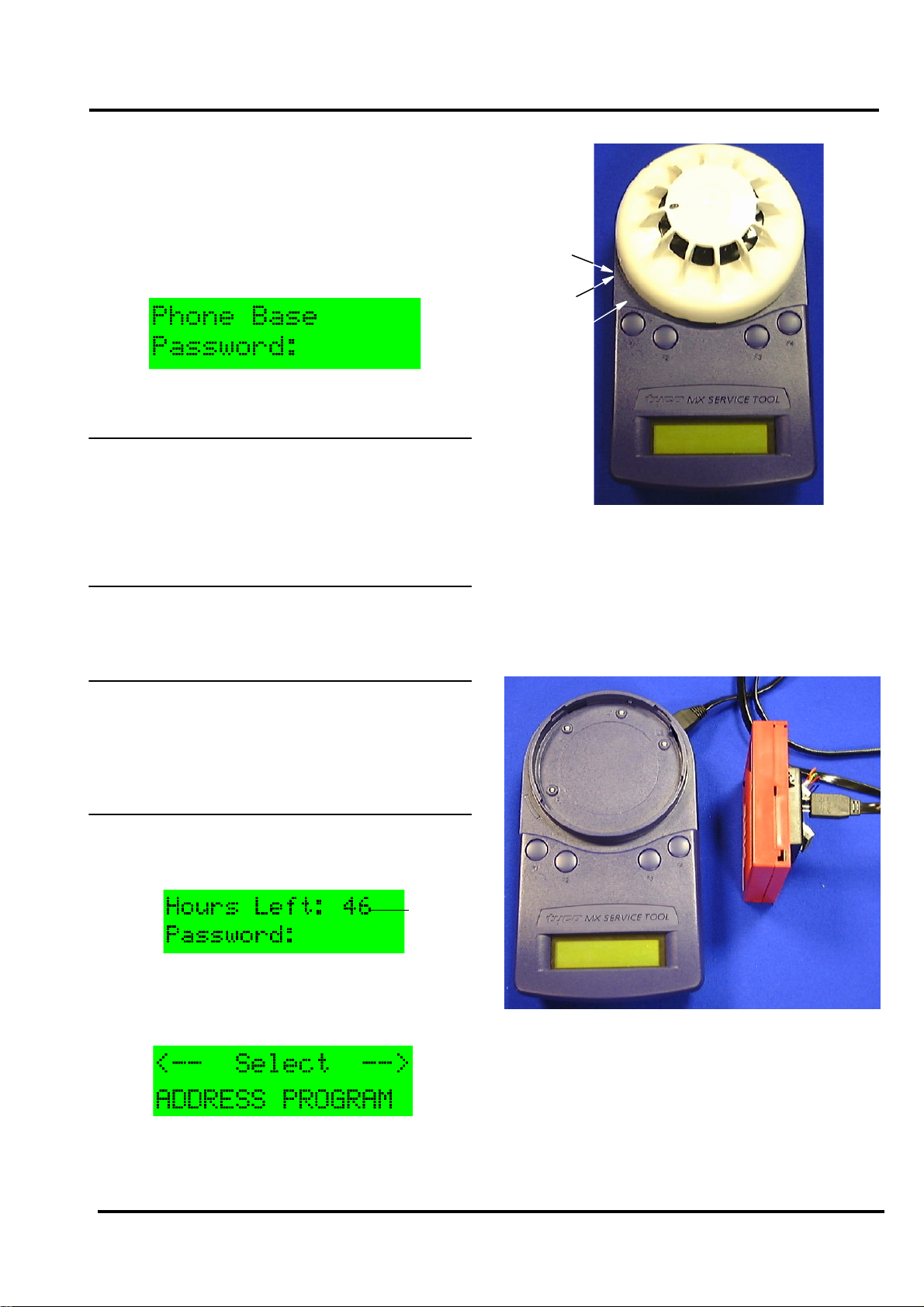

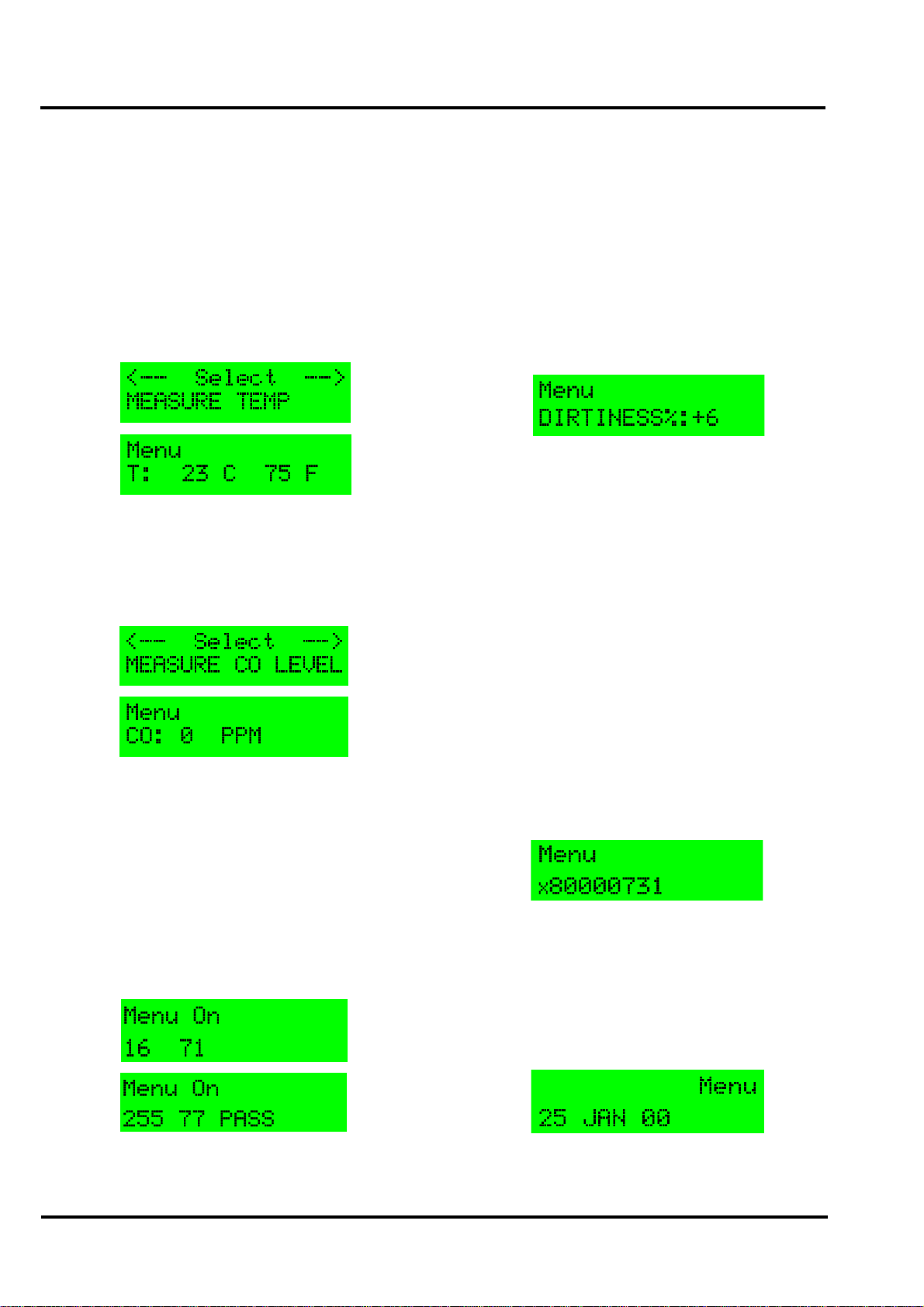

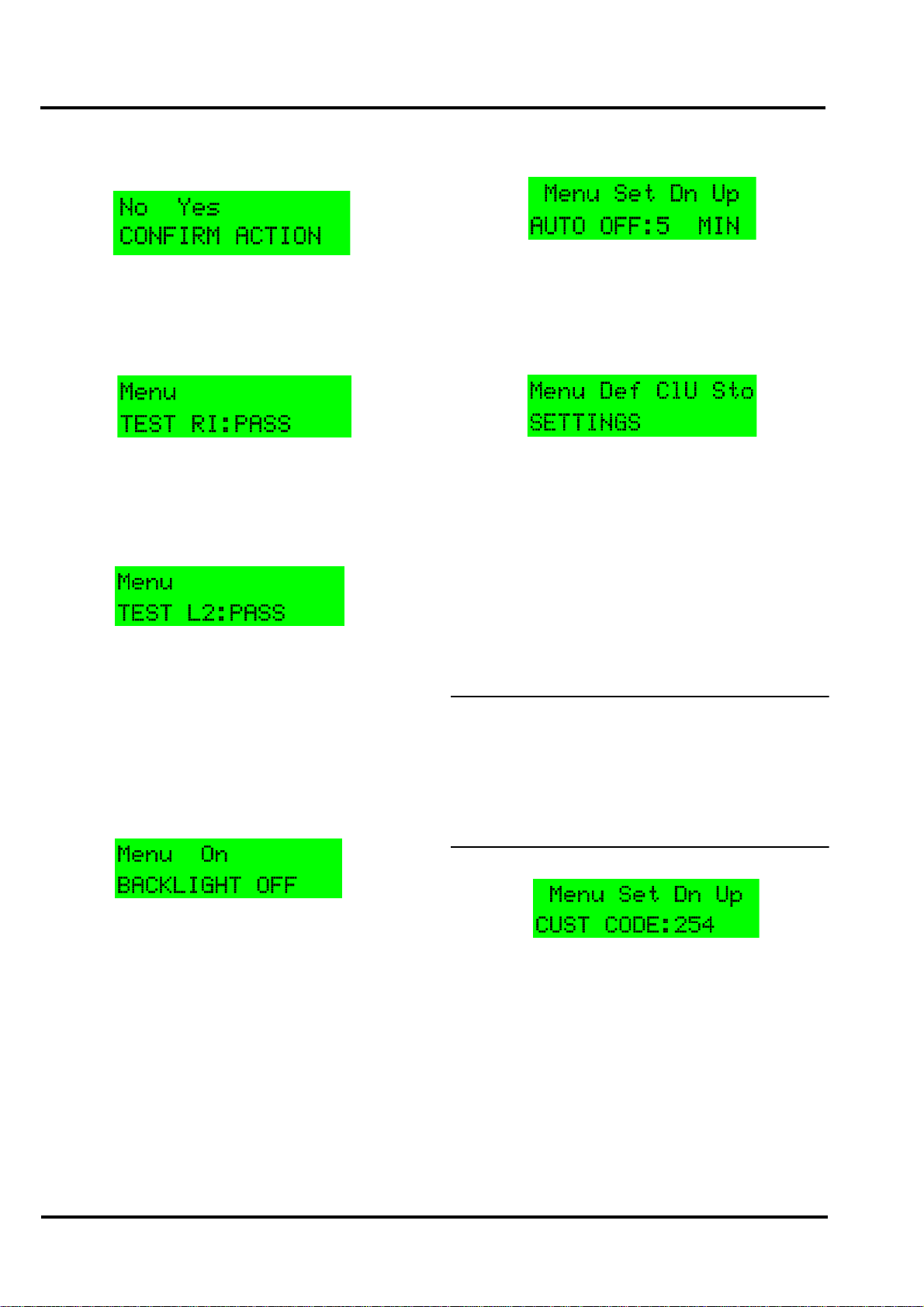

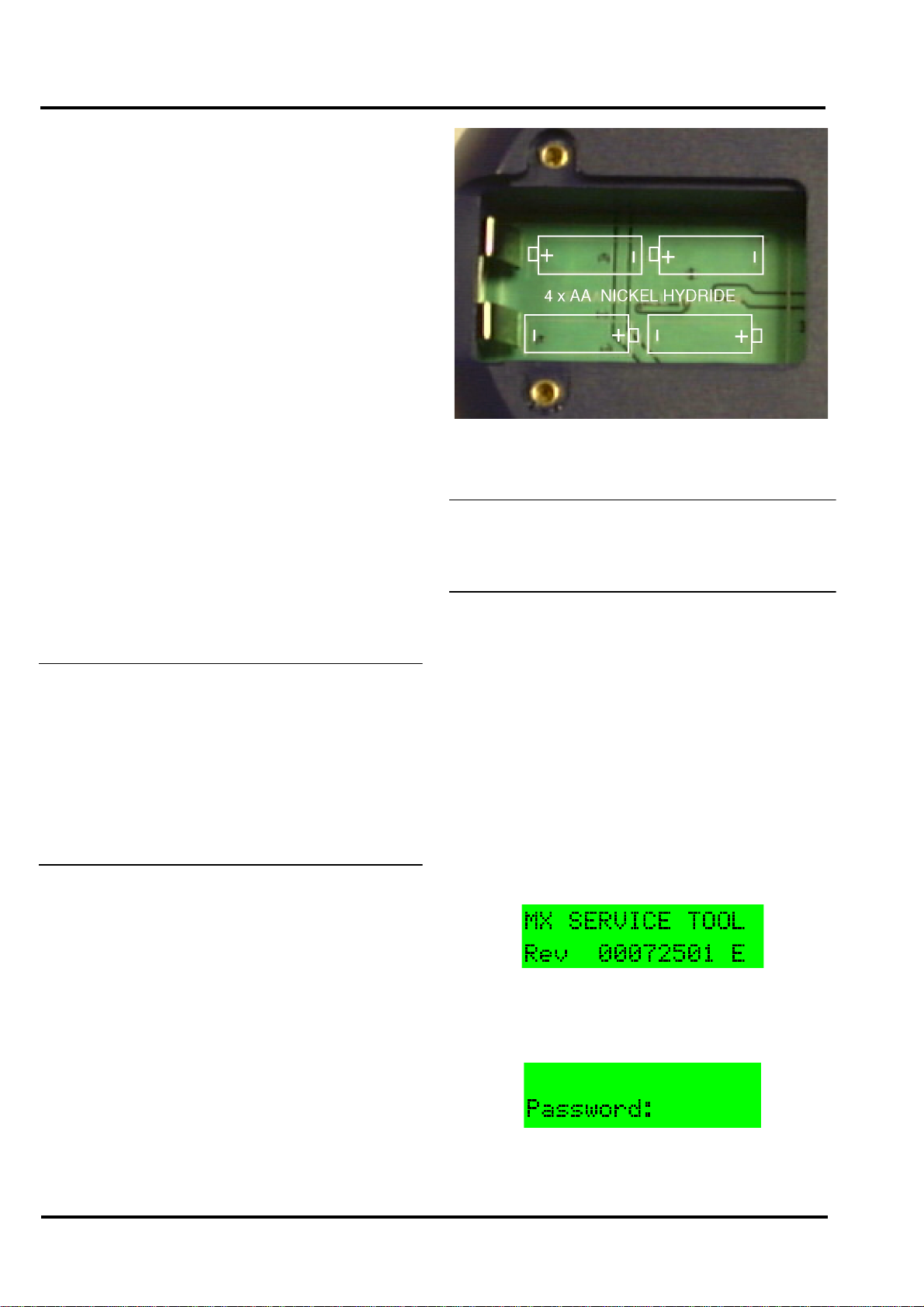

3.2 PASSWORD PROTECTION

The 801AP MX Service Tool is switched ON/OFF by pressing

any button for more than 3 seconds. The following example

screen showing the software revision number, is displayed for

2 seconds when the Service Tool is switched on:

Note that the ‘E’displayed stands for English version.

(appropriate letters are used for other languages). The Service

Tool then displays:

Note: The following information on Password

Protection is CRUCIAL to the operation of the

MX Service Tool.

Fig. 2 Battery Compartment