INSTRUCTIONS FOR ENGINE PARTS REMOVAL

• BEFORE CAMSHAFT INSTALLATION

1. Disconnect battery.

2. For ease of installation, keep all parts in some sort of order.

WARNING: Do not remove radiator cap or radiator hose if engine is

hot.

3. Drain radiator coolant, move fan shroud back and remove fan and

spacer from water pump. Remove radiator and air conditioning con-

denser if so equipped. In some cases, the front grille may have to be

removed. Measure distance from front cover to grille or brackets that

may interfere with camshaft against the length of the camshaft.

4. Remove gas cap to relieve pressure. Disconnect fuel line at fuel

pump and plug. Replace gas cap.

5. Disconnect all linkage from carburetor such as throttle, throttle

springs, transmission, cruise control and automatic choke.

6. Tag and remove coil wires, sensor wires.and all vacuum lines.

7. Remove valve covers.

8. Remove distributor cap and wires, rotate engine until rotor points

towards number 1 terminal in cap and pointer on front cover is on

Top Dead Center (TDC) and remove distributor. Note the approximate

position of the vacuum advance canister in relation to the manifold

to assist in getting the distributor properly located during re-installa-

tion.

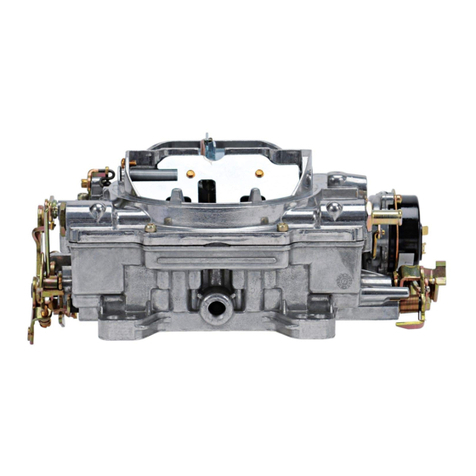

9. Remove carburetor and intake manifold.

10. Remove rocker arms and pushrods. CAUTION: Rocker arms and

rocker arm pivots must be re-installed in their original positions.

11. Remove old valve lifters.

12. Remove crankshaft pulley and, using a suitable puller, crankshaft

dampener.

13. Loosen oil pan and remove water pump, fuel pump, and front cover.

NOTE: The front cover oil seal should be replaced before the front

cover is re-installed.

14. Rotate engine until timing marks are aligned as shown in Figure 2.

15. Remove cam sprocket bolts. Slide sprocket and timing chain forward

to remove.

16. Remove camshaft. Using appropriate gear puller, remove crank

sprocket.

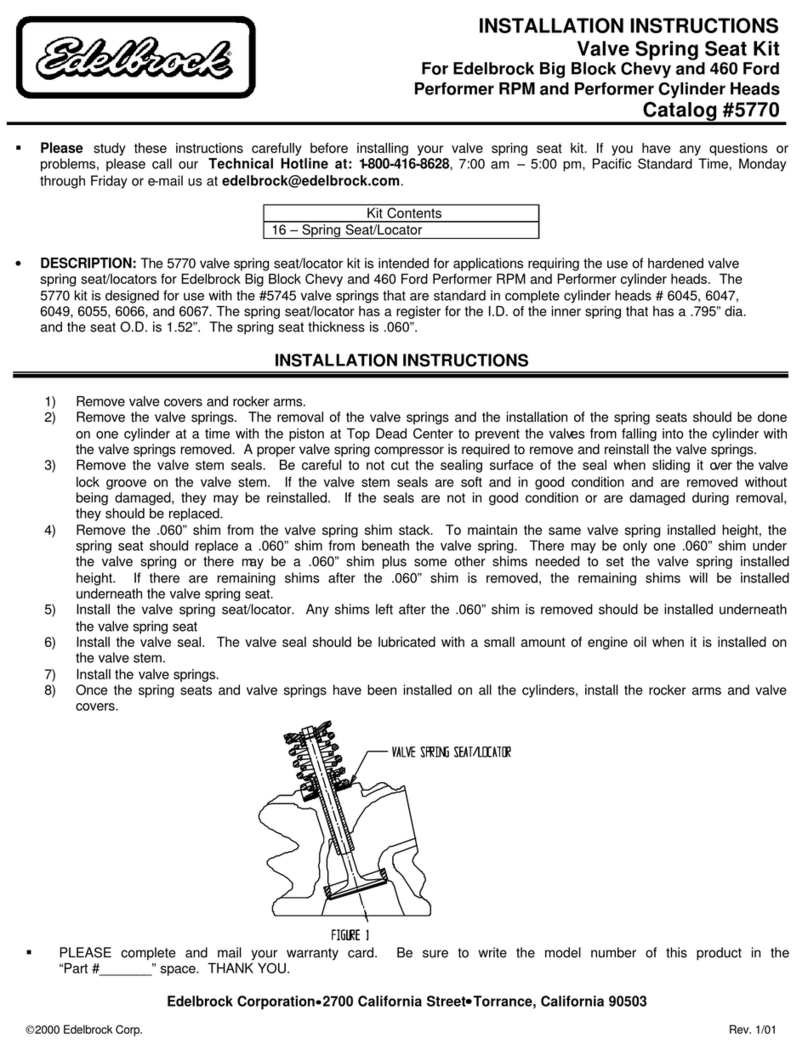

• VALVE SPRINGS

CAUTION: WARNINGS ABOUT YOUR WARRANTY

In order for this Performer-Plus cam and lifter kit to be covered

under ANY WARRANTY you MUST use the correct Edelbrock Sure

Seat Valve Springs or original equipment equivalent. Failure to install

new Edelbrock valve springs or OE equivalent with your new

Performer-Plus cam could cause the cam lobes to wear excessively

and could cause additional engine damage.

1. This camshaft is designed to function with Edelbrock Sure Seat valve

springs #5812. Do not use dual valve springs with this camshaft.

Recommended installed height for these springs is 1.670".

2. If using stock valve springs, check and set spring height to factory

specifications for correct year and model

NOTE: Due to various settings throughout the years, we advise

checking Motors, Chilton, or Oldsmobile service manuals or correct

spring height for your vehicle.

• LIFTERS

1. New lifters must be used with a new camshaft. Use only the lifters

supplied with this kit.

2. Check to be sure that all lifters fit freely in the lifter bores.

• INSTALLATION INSTRUCTIONS

1. Coat cam lobes and bottoms of each lifter with MoS2 lube (supplied)

to prevent cam lobe and lifter wear from occurring during initial

start-up. Do not "pump up" lifters before installation!

2. Install new camshaft with new sprockets, timing chain and lifters.

CAUTION: Use Edelbrock Performer-Plus True Rolling Timing Chain

and Gear Set #7813. Do not use late model timing chain & gear sets

that are designed in a retarded position and are not recommended

for this camshaft installation. Edelbrock Timing Sets feature three

keyways for specific timing selection. Use locking compound materi-

al on the bolt threads holding timing gear to cam. Torque to factory

recommendations specified in motor repair manual.

Install camshaft with timing marks lined up as recommended by fac-

tory specifications. See Figure 2.

When using Performer-Plus Timing Chain and Gear Set #7813 with

Edelbrock cam and lifter kits, straight up timing alignment is

achieved. If any other timing gear set is used, it is necessary to

check cam position for correct timing alignment. This requires index-

ing the camshaft with a degree wheel to verify timing alignment.

O.E.M. or non-Edelbrock timing gear sets are not recommended for

use with Edelbrock camshafts.

• VALVE ADJUSTMENT

1. Turn the engine over until the No. 1 cylinder is at Top Dead Center

(TDC) on the compression stroke (both lifters will be at the bottom of

their travel in the lifter bores). Install both intake and exhaust

pushrods, rocker arms, rocker arm pivot, and rocker arm bolts.

Carefully tighten bolts while feeling pushrods for vertical clearance.

As soon as all vertical clearance is gone from pushrods, count num-

ber of turns until bolts bottom out. There should be 1/2 to 1 full turn

of lifter pre-load. If vertical clearance exists after bolts bottom out,

longer-than-stock pushrods are required. Use 5/16" diameter intake

pushrods for big-block Chevrolets, which are approximately .050"

longer than Oldsmobile pushrods. They are available from GM deal-

ers (GM #14075629), TRW (#48099), or other pushrod suppliers. If

excessive lifter pre-load exists, use shims under rocker arm pivots to

achieve 1/2 to 1 turn pre-load.

2. The above procedure assures correct lifter pre-load. Repeat this pro-

cedure for each of the other seven cylinders by rotating the engine

90° and following the firing order (1-8-4-3-6-5-7-2).

3. Re-install front cover, fuel pump, water pump, and oil pan using new

gaskets.

4. Install intake manifold using new intake gasket set and torque mani-

fold bolts to 25 ft./lbs.

5. Install crankshaft dampener and torque to factory specs.

page 2

• INSTALLING PUSHRODS AND ROCKER ARMS

After the cam is installed and timed correctly (see Figure 2), it will be

necessary to check each pushrod for correct lifter pre-load. Before

installation, be sure to coat friction surfaces of pushrods, rocker

arms and pivots with a suitable lubricant such as motor oil or

assembly lube.

©2008 Edelbrock Corp. Rev. 9/08 - AJ/mc

Brochure #63-3712