• VALVE SPRINGS

CAUTION: WARNINGS ABOUT YOUR WARRANTY

In order for this Performer-Plus cam and lifter kit to be covered

under ANY WARRANTY you MUST use the correct Edelbrock Sure

Seat Valve Springs or original equipment springs. Failure to install

new Edelbrock valve springs or original specification springs with

your new Performer-Plus cam could cause the cam lobes to wear

excessively and could cause additional engine damage.

1. This camshaft is designed to function with Edelbrock Sure Seat

valve springs #5867 (non-rotators) or OE valve springs. Do not use

dual valve springs with this camshaft.

2. Check and set spring height to factory specifications for your year

and model. If using Edelbrock #5867, set to 1.820". NOTE: Due to

the various settings through the years, we advise checking Mitchell,

Motors, Chilton, or Ford service manuals for correct spring height

setting for your vehicle.

3. For 1969 & later non-rotator engines, you may want to install

Edelbrock Valve Spring Retainer Kit #9724.

• LIFTERS

1. New lifters must be used with new camshaft. Use only the lifters

supplied with this kit.

2. Check to be sure that all lifters fit freely in the lifter bores.

• INSTALLATION INSTRUCTIONS

1. Coat cam lobes and bottom of each lifter with MoS2 lube (supplied)

to prevent cam lobe and lifter wear from occurring during initial

start-up.

2. Install new camshaft with new sprockets, timing chain and lifters.

CAUTION: Use Edelbrock Performer-Plus True Rolling Timing Chain

and Gear Set #7830. Do not use late model timing chain & gear sets

that are designed in a retarded position and are not recommended

for this camshaft installation. Edelbrock Timing Sets feature three

keyways for specific timing selection. Use locking compound mater-

ial on the bolt threads holding timing gear to cam. Torque to factory

recommendations specified in motor repair manual.

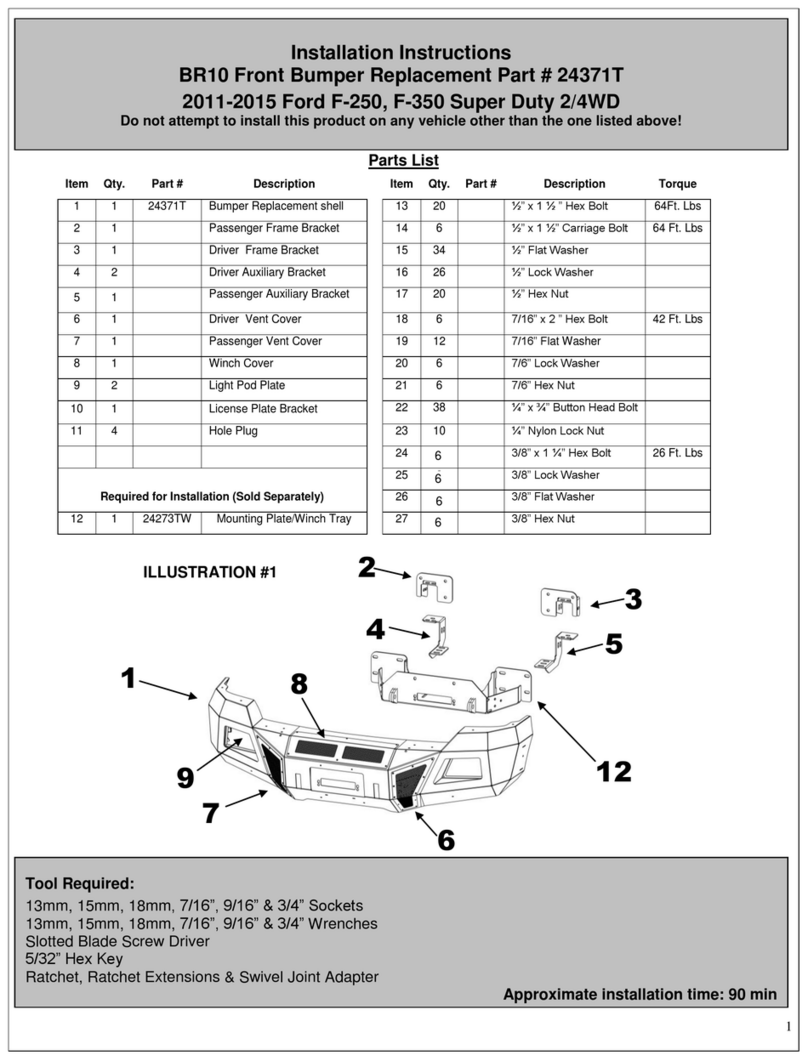

Install camshaft with timing marks lined up as recommended by

factory specifications. See Figure 1.

When using Performer-Plus Timing Chain and Gear Sets (7800

series) with Edelbrock cam and lifter kits, straight up timing align-

ment is achieved. If any other timing gear set is used, it is neces-

sary to check cam position for correct timing alignment. This

requires indexing the camshaft with a degree wheel to verify timing

alignment. O.E.M. or non-Edelbrock timing gear sets are not recom-

mended for use with Edelbrock camshafts.

• INSTALLING PUSHRODS AND ROCKER ARMS

After the cam is installed and timed correctly (see Figure 1), it will

be necessary to check each pushrod for correct lifter pre-load.

• VALVE ADJUSTMENT

1. Turn the engine over until the No. 1 cylinder exhaust lifter starts to

move up. At this point install pushrod and adjusting nut on intake

rocker arm and adjust to zero clearance between rocker arm and

valve tip. For engines equipped with adjustable rocker arms, contin-

ue tightening the adjusting nut one-half turn. Check to make sure

that the slot in the rocker arm has clearance at the stud in the full

open and closed positions. If there is no clearance in the closed

position a 0.060" longer pushrod is required. For engines with non-

adjustable rocker arms, continue to tighten the adjusting nut until it

bottoms out. If this adjustment is less than one-half turn, you will

need to purchase the 0.060" longer pushrods from your Ford dealer.

2. Turn the engine over again until the intake lifter just stops coming

down. At this point install pushrod and adjusting nut on exhaust

rocker arm and repeat the same procedure as above.

3. The above procedure assures correct hydraulic lifter pre-load.

Repeat this procedure for each of the other seven cylinders. For

non-adjustable rockers only, torque rocker arm nuts to

20-25 ft./lbs.

4. Re-install front cover, fuel pump, water pump, and oil pan using

new gaskets.

5. Install intake manifold using new intake gasket set and torque man-

ifold bolts to 25 ft./lbs.

6. Install crankshaft dampener and torque to factory specification.

• INSTALLING DISTRIBUTOR AND TIMING ENGINE

NOTE: Before installing your distributor, check the gear drive on the

distributor and oil pump for any signs of wear. If worn, be sure to

replace with new or you may wear out your camshaft prematurely.

This is especially true when rebuilding your engine and a high per-

formance oil system is used, which generates a heavier load on the

camshaft gear system.

Edelbrock camshafts are designed to use OEM-type gears and oil

pumps only.

1. Turn the engine over in the direction of rotation until the No. 1

intake valve closes and continue until the pointer on the front cover

is approximately 5 degrees BTDC.

2. Re-install the distributor with the rotor pointing towards No. 1 termi-

nal in the cap, and with the vacuum advance canister in its original

position.

3. Lightly tighten the hold-down clamp so that the distributor can still

be turned to determine final setting using a timing light with the

engine running.

4. Replace valve covers, carburetor linkage and remaining vacuum and

electrical connections.

5. Re-install air conditioner, if so equipped.

6. Re-install radiator, fan shroud, and belts (if removed), fill radiator

with coolant and re-connect battery.

7. Double check all connections, fuel lines, etc. before starting engine.

• CAMSHAFT/LIFTER RUN-IN

CAUTION: Change the engine oil and filter before start-up and again

after break-in. Do not allow the engine to run under 2000 rpm for

the first 1/2 hour. Vary engine speed between 2000 and 2500 rpm.

Slow idle speeds will result in severe cam and lifter wear. Start the

engine and bring to break-in rpm.

IMPORTANT INSTRUCTIONS

AFFECTING YOUR WARRANTY

• CAM LOBE WEAR- Cam lobe wear is almost non-existent unless

mismatched parts are used or installation of the cam and lifters is

done improperly. Most cam damage is caused by the timing gear

coming loose due to improper torque on bolts. Bolts holding gear to

camshaft should be torqued carefully and a locking compound

applied to bolt threads.

• CAUTION: Use Edelbrock Performer-Plus Timing Chain and Gear Set

#7830. Do not use late model timing chain and gear sets that are

designed for emission-controlled engines. These timing sets are

machined in a retarded position and are not recommended for this

camshaft installation. Edelbrock Timing Sets feature three keyways

for specific timing selection.

©2008 Edelbrock Corp. Rev. 9/08 - AJ/mc

Brochure #63-2167