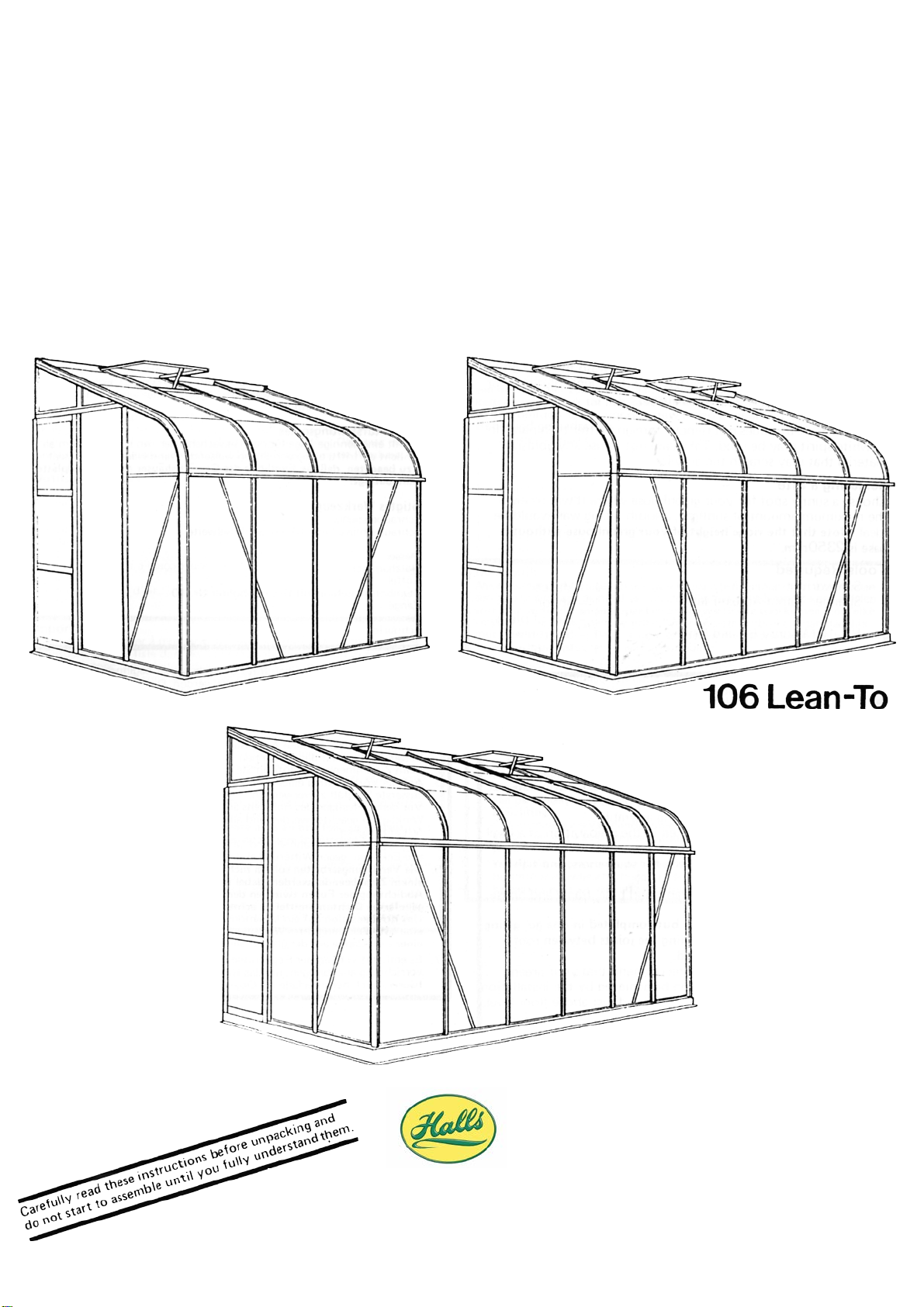

Introduction

You now own a greenhouse that is believed to be amongst the best in value on the market, and by carefully

following these assembly instructions, it will give you years of trouble-free use. We hope you will find the following

hints and explanations useful.

Your greenhouse is made of aluminium because it is the best all-round material within the price limits the average

householder can afford. It will not swell, shrink, warp or rust. In service, it should become a dull whitish-grey colour,

sometimes with a slightly rough surface on the outside which forms a self-protecting layer.

If you have the horticultural glass, the small panes are less likely to crack due to movement of the greenhouse, are

easier to transport and cheaper to replace in the event of accidental damage.

The acrylic sheet has been selected for its flexibility to form the curved part of the roof, its weather resistance and

lasting clarity.

We recommend that you give your greenhouse all round protection by including it in your house insurance.

Maintenance

To keep your greenhouse clean, occasionally wash the glass and aluminium frame thoroughly with a mild detergent

solution. For difficult stains, white spirit may be used.

The acrylic may be cleaned using warm soapy water applied with a soft cloth. If this does not remove foreign matter

then paraffin or white spirit may be used. Take care not to use any abrasive material that may scratch the acrylic.

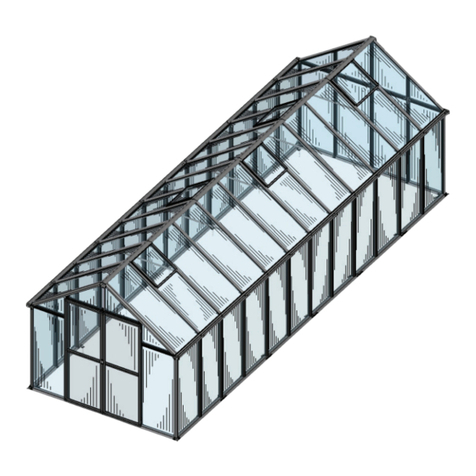

Selecting a Site

Choose a sunny spot for your greenhouse where it will receive a fair amount ofsunlight.

Note that the ridge height of your greenhouse without the base is2350mm.

Tools Required

1 – Screwdriver

1 – Spanner 10mm Across Flats

1 – No. 10 Masonry Bit and Drill

1 – Knife

1 – Spoon

1 – Pair of Pliers

1 – Spirit Level

Important

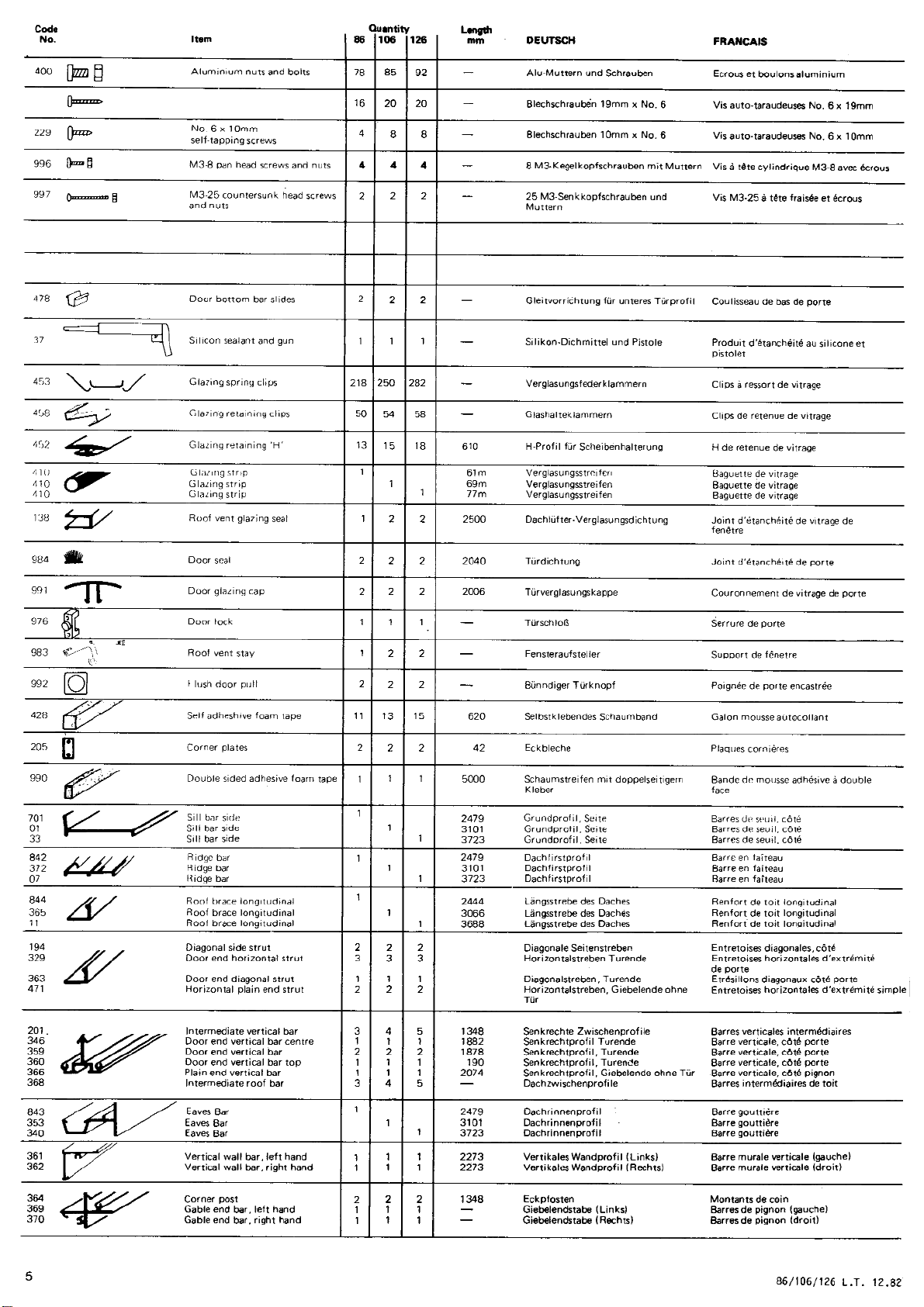

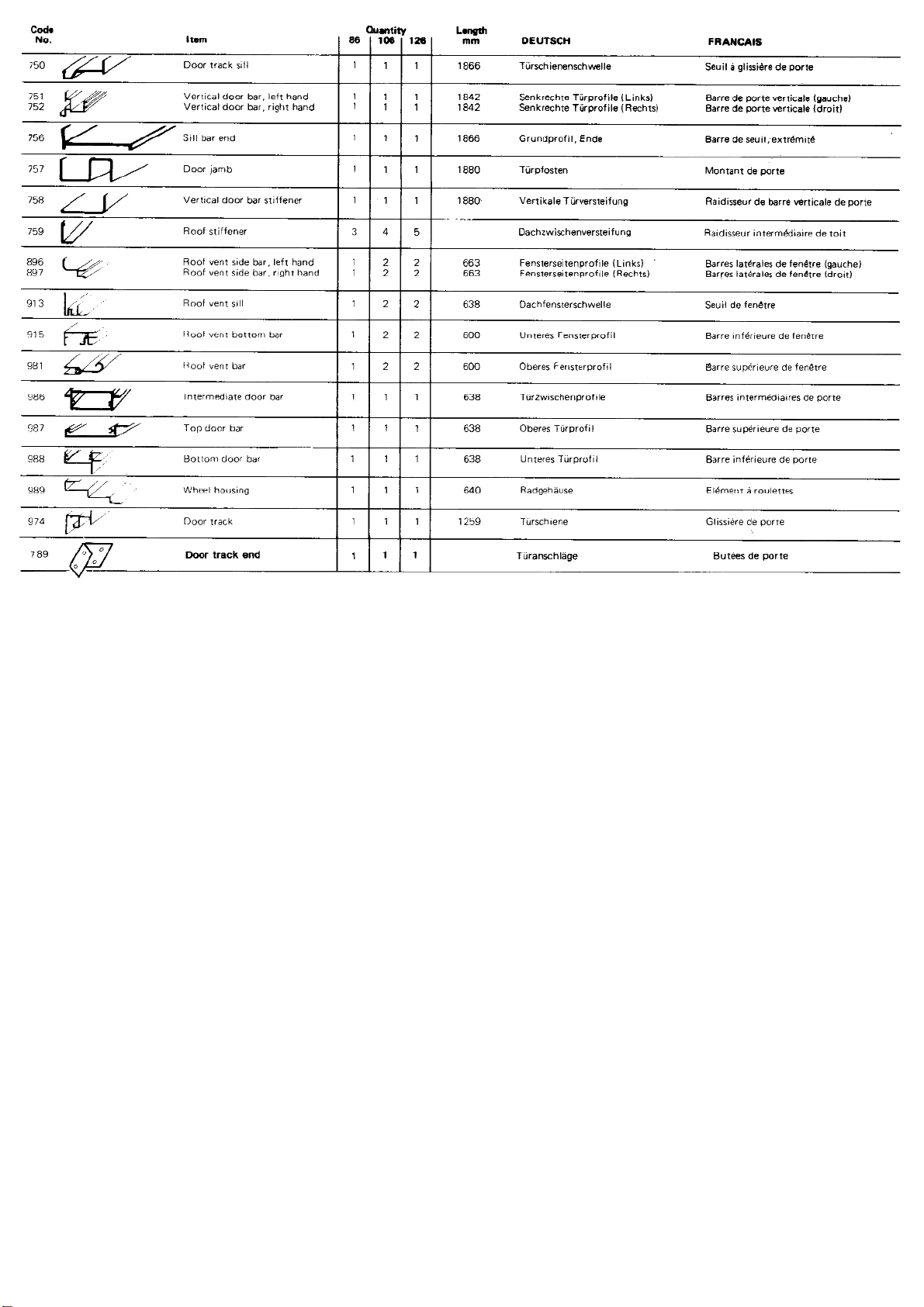

Before starting the assembly of your greenhouse, please check all the contents against the parts list. The parts for

each section are bundled together, so to avoid mixing them up, open each bundle separately. If anything is missing,

please contact Customer Service Dept., using the reply form included in these instructions.

1. Carefully read these instructions before unpacking and do not start to assemble until you fully understand

them.

2. Assistance will be necessary during assembly.

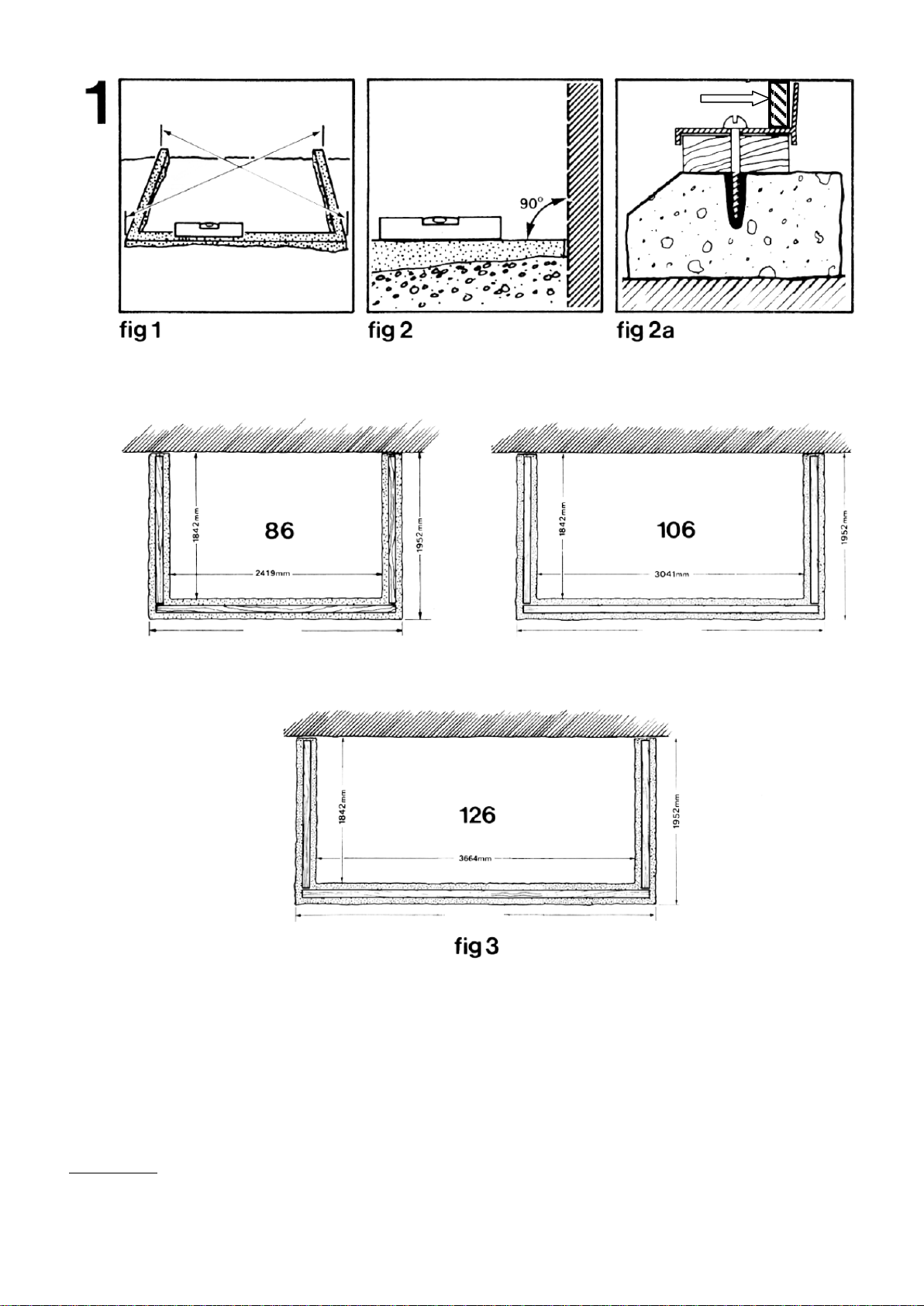

3. Considerable care should be taken in the preparation of a level and square base.

4. Before fixing frame to base, check for squareness and tighten all nuts and bolts. Weatherseal the join

between frame and base, frame and house and all other corner joints.

5. Glazing should not be hurried, but completed in one go, giving great care and attention to sealing the joints

between roof and panes with the sealant provided.

6. To minimise the condensation, werecommend that your greenhouse iswell ventilated. This can beachieved

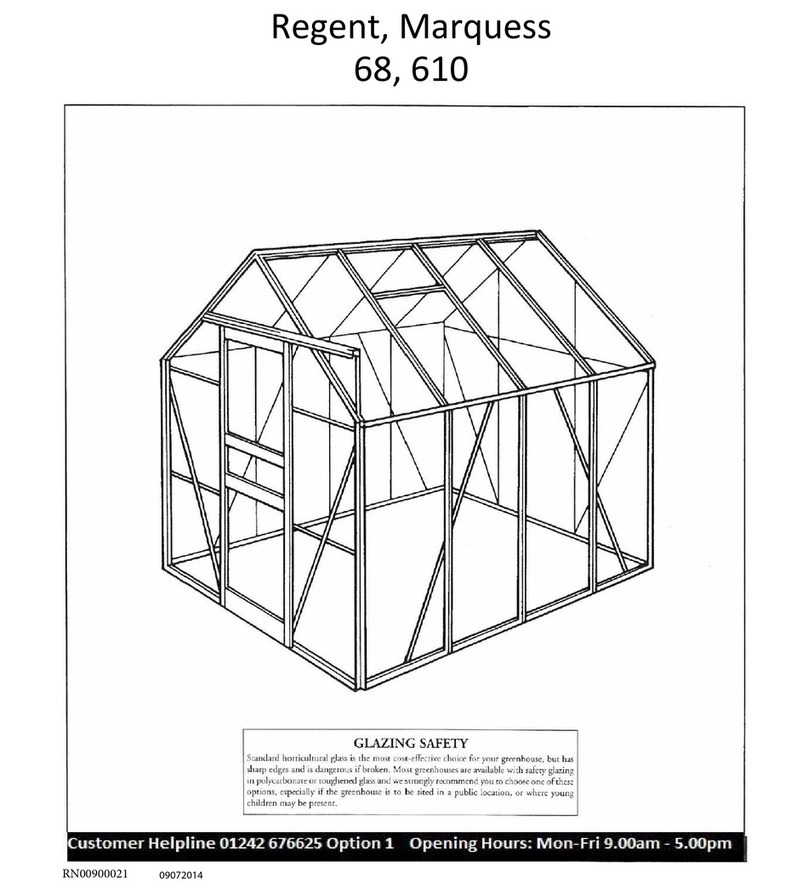

by the installation ofa louvre vent. A louvre vent can only be fitted in the 106 and the 126 models.

7. It is recommended that a snow guard befitted tothehouse gutter above the greenhouse if there is a risk

of falling debris damaging the greenhouse.