EDI CTT-2 User manual

CTT-2 Operation Manual

V1.01 04/16/14

Contents

1 Introduction

2 Swept frequency testing

3 Spot frequency testing

4 Lea age test

5 Indicator LED's

6 Data format selection

7 Baud rates

8 Command list

9 Calibration

10 Specifications

11 Warranty

CTT-2 Manual V1.01 1

1 Introduction

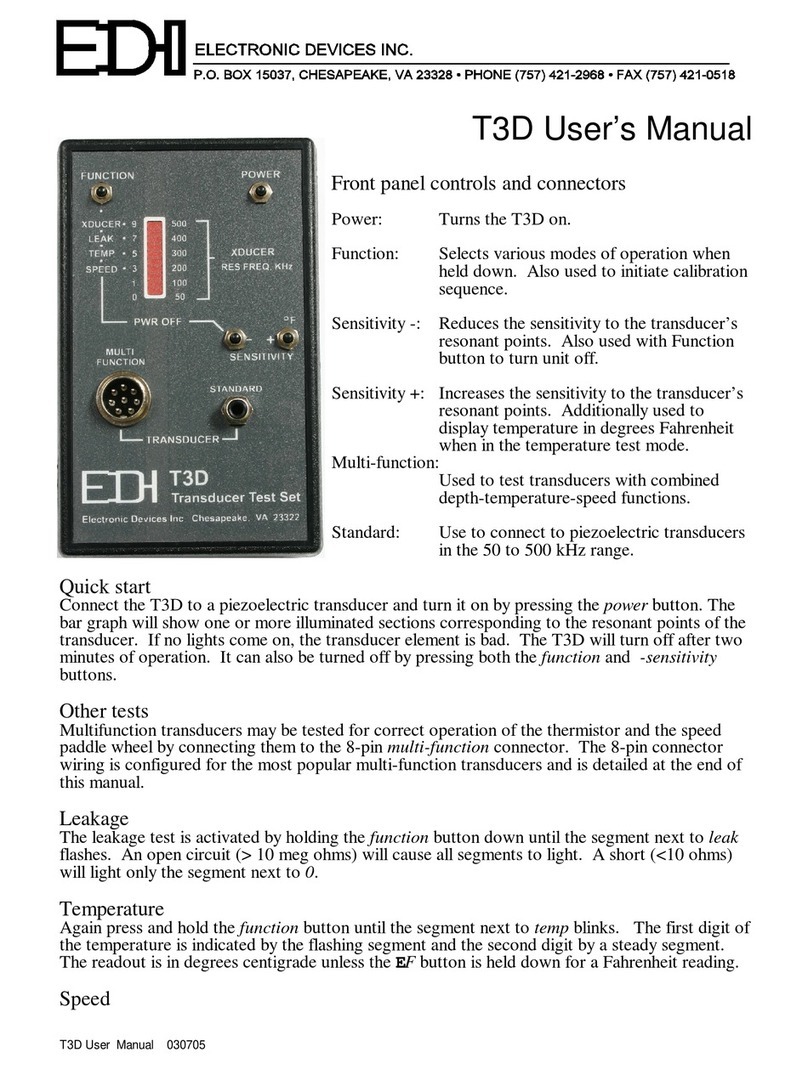

The CTT-2 is a computer controlled transducer test set designed for production line testing of

sonar transducers during manufacture. Swept frequenc tests are quickl performed. The data

returned can be impedance and relative phase for each point in the sweep, or just the minimum

and maximum impedance points found over the swept frequenc range. Leakage tests can also

be made over a range of 100 ohms to over 10 megohms.

1.1 Preliminar setup and test

Connect a terminal to the CTT-2. Set the terminal for a Baud rate of 9600, 8 data bits, 1 stop

bit, no parit , and no handshake. The supplied terminal program, DSTS_terminal.exe, is

preset to these values. Connect the power suppl to the CTT-2. The three front panel LED's

will flash briefl , indicating the CTT-2 is read to operate.

1.2 Read the power suppl voltage

T pe 'Cv' followed b the enter ke . This is the command to read the power suppl voltage.

Note that the commands are case sensitive. The power suppl voltage returned should be

between 9 and 16 volts.

1.3 Impedance check

Connect a 510 ohm resistor to the TRANSDUCER connector and t pe 'f100000' followed b

enter. The frequenc and resistance will be returned. The returned value should be within 5%

of the resistors value. This completes the preliminar test of the CTT-2's operation.

2 Sweep testing

For sweep testing a transducer, the frequenc step and the number of steps are selected to cover

the desired range of frequencies. The sweep is started b t ping the sweep command and the

starting frequenc for the test. The t pe of data returned is selected b the second character of

the sweep command. The quickest sweep test returns just the maximum and minimum

impedance points that occurred over the frequenc range. For more detail, the sweep can

return the impedance at each frequenc step; but this takes more time because of the large

amount of data returned.

2.1 Before starting the frequenc sweep, the sweep parameters must be set. There are

three parameters: the frequenc step, the number of steps, and the dwell at each step.

2.1.1 The frequenc step is the amount the frequenc will increase at each step. A

value of 100Hz is a good choice between speed and accurac for most transducers.

2.1.2 The number of steps set the range of the sweep. More steps require more time

to complete. With dual frequenc transducers, it is better to divide the sweep into two

narrower ranges than to sweep the entire range. The reason for this is to increase the test

speed b limiting the number of frequenc steps.

CTT-2 Manual V1.01 2

2.1.3 The dela is the time that the frequenc is held constant before the measurement

is made. A short dela will speed up the sweep at the expense of accurac . A dela of

1000uS is a good compromise between speed and accurac .

2.2 A t pical sweep test for a 200 KHz transducer would cover a range of 170 to 230

Khz using 100 Hz steps. The number of steps required will be the sweep width divided b

the frequenc step. In this example, the frequenc sweeps from 170 to 230 Khz for a width

of 60KHz. Using 100Hz steps this will require a total of 600 steps to cover the range. The

recommended dela should be left at 1000uS. The 'Sf' command sets the frequenc step,

'Ss' sets the number of steps, and 'Sd' sets the step dela . T ping 'S' will displa the current

frequenc step, number of steps, and dela . For this example, t pe 'Ss600' to set the

sweep for 600 steps.

2.3 To start the sweep, t pe 'sm170000' and the sweep will start at 170KHz and

continue for 600 steps to 230KHz. When the sweep is finished the maximum and minimum

impedances found will be displa ed along with the frequenc that the ocurred at. If

impedance data for each frequenc step is desired, use the command 'sa170000' and the

impedance and relative phase will be returned for each frequenc step.

3 Spot frequenc tests measure the impedance at a single frequenc . To check the impedance of

the transducer at 197KHz, t pe 'f197000'. To read both impedance and the relative phase, t pe

'fa197000'. The 'f+' command will increment the frequenc one step, and the 'f-' commad will

decrement the frequenc one step. The impedance and relative phase are returned.

4 Leakage testing is done with the 'l' command, and returns the resistance of the transducer. The

leakage test takes 3 to 10 seconds, the longer time will read higher resistances. A minimum

dela of 3000mS is required. To set a 5 second dela , t pe 'Ld5000'. Note that the commands

are case sensitive.

5 The three indicator lights on the front panel can be turned on, off , or flashed to indicate what

action is to be taken during the test. To light the left most (green) LED, t pe 'I1', to extinguish

the LED, t pe 'i1'. The LED's are numbered from left to right 1, 2, and 3. The corresponding

colors are green, ellow, and orange. T ping 'I2' lights the ellow LED, and 'I3' lights the

orange one. To make a LED1 blink, t pe 'Ib1' and the green LED will begin flashing. To stop

the LED from flashing t pe 'i1'.

6 Returned data format

Two data formats are provided, one returns descriptive data, and the other returns onl comma

separated (CSV) data. When first tr ing out the CTT232, is is easier to use the default

descriptive data that returns data in the form F= 100000, Z = 257 instead of the CSV that will

onl return 100000,257. The 'p' command switches to CSV data. To go back to the descriptive

data, t pe 'P'.

CTT-2 Manual V1.01 3

7 Baud rate

There are two commands for setting the Baud rate. The 'brxxxxx' command changes the rate

when issued, but does not store it in eeprom. The 'bsxxxxx' command stores the new Baud rate

in eeprom but does not change the rate until the next time the power is turned off and on.

8 CTT-2 Command list:

8.1 'Brxxxxx' sets baud rate. Onl 9600, 19200, 38400 allowed.

8.2 'Bs' stores baud rate for power-up default.

8.3 'faxxxxxx' returns impedance and relative at xxxxxxHz.

8.4 'f+' increments frequenc one step. See 'Sf' command.

8.5 'f-' decrements frequenc one step.

8.6 'fxxxxxx' returns impedance onl .

8.7 'Ix' turns on LED 1, 2, or 3.

8.8 'ix' turns off LED 1, 2, or 3.

8.9 'Ibx' starts LED 1, 2, or 3 flashing at a 2.5Hz rate. Use 'ix' to turn off.

8.10 'l' starts leakage test, returns ohms.

8.11 'Lxxxxx' sets the leakage test time in mS. Default is 3000mS.

8.12 'Sdxxxxx' sets dwell time in uSec. Use >1000 uS for accurac .

8.13 'Sfxxxxxx' sets sweep frequenc step in Hz.

8.14 'Ssxxxxxx' sets the number of steps used in the sweep.

8.15 'S' returns sweep frequenc start, step, number of steps, and dela .

8.16 'saxxxxxx' sweeps, returns all data for each frequenc point.

8.17 'smxxxxxx' sweeps for minimum, maximum Z starting at xxxxxx Hz.

8.18 'szxxxxxx' sweeps, returns onl Z for each frequenc point.

8.19 'Cfxxxxx' calibrates the output frequenc , 1 ppm/count. Nominal is 10000.

8.20 'Cm' stores the cal data to eeprom. Reads in on power-up.

8.21 'Co' calibrates readings >5K ohms. Nominal value is 2.

8.22 'Cr' calibrates for reference resistor. Nominal value is 104.

8.23 'Cs' calibrates readings for 0 ohms. Nominal value is 2022.

8.24 'Cz' prints stored and current calibration values.

8.25 'Cv' prints power suppl voltage. Range is 9 to 16 VDC.

8.26 '?' prints the firmware version and a help file.

8.27 '/' prints the firmware version.

9 Calibration

9.1 Calibration should be checked ever two ears or an time the readings are in doubt.

9.2 Equipment required: 5100 ohm 1% resistor, a 510 ohm 1% resistor, a 10 ohm 1%

resistor, and a frequenc counter capable of reading 100KHz with a 1PPM timebase.

9.3 Frequenc calibration

9.3.1 Connect a frequenc counter to the transducer connector. T pe 'f100000' and

read the counter. The frequenc should be within +/- 20Hz. If it is not, the

CTT-2 must be returned to the factor for repair.

CTT-2 Manual V1.01 4

9.4 Impedance calibration.

There are three calibration factors involved in calibration. The are the short circuit,

the the offset, and the reference resistor factors. The values in use can be read b

t ping 'Cz'. The reference resistor 'Cr' value should not be changed unless the unit

has been repaired. The calibration starts with a short circuit then a resistance test.

The 'Cs' is adjusted for 0 ohms, and the 'Co' is adjusted for correct reading of a 5K

resistor. There is interaction between the 'Cs' and 'Co' values, so the calibration ma

need to be repeated a few times for the best balance between short circuit and high

impedance readings.

9.5 Short circuit calibration.

9.5.1 Set the offset to 1 b t ping “Co1'.

9.5.2 Place a short across the transducer connector. T pe 'f100000'. The returned

impedance should be between 0 and 0.5 ohms. If not, the 'Cs' value, nominall

2022, must be changed. If the impedance is greater than 0, increase the value of

Cs slightl and read the impedance. Keep adjusting the 'Cs' until the short reads

between 0 and 0.1 ohms. If the required 'Cs' value is less than 2000 or greater

than 2040 the CTT-2 ma require repair.

9.6 5100 ohm calibration point

9.6.1 Connect a 5100 ohm 1% resistor to the transducer connector. T pe 'f100000',

the returned impedance should be 5100 +/- 250 ohms. If it is not, check the 'Co'

value. Increase 'Co' to lower the reading, decrease it to increase the reading. The

'Co' value must be between 1 and 6. If a 'Co' value over 6 is required, the CTT-2

should be returned to the factor for repair.

9.6.2 Check the readings with the 10 ohm and the 510 ohm resistor and repeat steps

9.5.2 through 9.6.2 until the results are within +/- 5% tolerance of the 10 ohm

and 510 ohm resistor values.

9.7 Storing the new calibration values is done b t ping 'Cm1234'. If 'Cm' is entered

with an other value, ou will get an error message and the values will not be

stored.

CTT-2 Manual V1.01 5

10 Specifications

10.1 Frequenc range: 10KHz to 1 MHz

10.2 Frequenc resolution: 1Hz

10.3 Frequenc accurac : .01% over -10 to +70 degrees C.

10.4 Impedance range (at resonance): 10 to 5000 ohms (to 9900 ohms with decreased

accurac ).

10.5 Impedance accurac 5% of reading for resonant (resistive) load.

10.6 Test modes: Swept and fixed frequenc

10.7 Test voltage level 5 Vpp

10.8 Data returned: Impedance, +/- phase, and leakage resistance.

10.9 Indicators: Three panel LED's controlled b test program.

10.10 Size: 3 x 7 x 7 inches

10.11 Power: External wall-plug transformer nominal 12Vdc@ 300 mA.

10.12 Interface: RS-232, 9600 to 38400 Baud, standard DB9 serial port.

11 Warrant Information

Unit will be repaired free of charge for one ear from date of purchase providing there is no

water damage or other evidence of improper use or handling. Purchaser must ship unit prepaid

to address below; EDI will pa the return freight for shipments within the contiguous United

States.

For repair, please call to obtain an RMA number, and enclose a note describing the problem and

ship to:

ATTN: EDI Service Department

BBG Incorporated

1708 South Park Court

Chesapeake, VA 23320

USA

Phone: 1-757-366-9211

1 Email: [email protected]

CTT-2 Manual V1.01 6

Table of contents

Other EDI Test Equipment manuals