Edic CR2 User manual

CR2 COMPLETE

RESTROOM

RESTORATION

17 GALLON

PROFESSIONAL RESTROOM CLEANER

OWNER’S/OPERATOR’S MANUAL

PROUDLY DESIGNED AND MANUFACTURED BY

WWW.EDIC-USA.COM

UNPACKING YOUR NEW CR2:

When your machine is delivered, check the carton carefully

for signs of rough handling. If the machine is damaged, notify

the carrier immediately and request an inspection. Be sure

to keep the carton, packing inserts, packing lists and carrier’s

receipt until the inspector has veried your claim.

EDIC’s Liability ceases when the carrier picks up the ship-

ment. However, our customer service sta will be happy to

furnish any information needed in connection with the claim

and will attempt to expedite a resolution.

PLEASE READ BEFORE

OPERATING THE MACHINE:

Read the manual carefully and completely before attempting

to operate the unit. is manual has important information

for the use and safe operation of the machine. Keep this man-

ual handy at all times.

is machine has been engineered and manufatured to pro-

vide excellent performance and service. To ensure that your

equipment will continue to perform as intended:

• Maintain equipment regularly- following the suggested

maintenance schedule provided.

• Use only original EDIC parts when servicing.

• Operate equipment with care.

If additional information is needed, please contact EDIC at:

All information and specications printed in the manual are

current at the time of printing; however because of EDIC’s

policy of continual product development, we reserve the right

to make changes at any time without notice.

WARNING!

• e machine was designed for use on hard surfaces,

carpet, oor and upholstery extraction applications as per

instructions and recommendations written in this manu-

al. Any deviation from its proper use or purpose and the

consequential damage that may occur is the sole responsi-

bility of the end user.

• Disconnect the power cord from the outlet before ser-

vicing. Do not leave machine connected to an electrical

outlet when unattended.

• Do not immerse or use this machine in standing water.

Such use may cause electric shock.

• When using an extension cord, use only a 3-prong con-

ductor grounding cord-12 gauge wire or heavier.

• To avoid electric shock, do not expose the unit to rain or

snow. Store it indoors in a heated location only.

• Do not use the machine for dry vacuuming.

• Use defoamer at all times to prevent damage to the vacu-

um motor.

• Do not use water in excess of 130°F (54°C) in the solution

tank

• To prevent seal damage and chemical build-up to the

pump system, run clean water through the solution lines

aer each day’s use.

• Use only commercially available carpet cleaning solutions

and defoamer intended for use with machines of this type.

Do not use dyes, bleaches, ammonia, or other additives.

• e use of powdered cleaning solution, if not diluted

properly, may result in damage to the pump. Powdered

chemical is not recommended. If powdered chemicals are

used, premix in a separate container before placing in the

solution tank.

• Always read and understand your chemical’s MSDS (Ma-

terial Safety Data Sheet) before use.

• is equipment is not designed to handle or use combus-

tible/volatile substances such as gasoline or kerosene, in,

on, or near the machine. e use of such materials will

cause extreme hazardous condition.

• Do not expose machine to freezing temperatures.

• All repairs must be done by an authorized EDIC repair

station.

• Do not use replacement parts other than original EDIC

parts.

• Do not allow your spray stream to remain in one xed

location as surface damage may occur.

• Check that all spray nozzles are securely fastened. Loose

nozzles could be ejected from equipment at high speeds.

• Prevent burns by wearing gloves or using a barrier to

remove hot quick disconnects.

• is is not a toy. Keep away from children.

• Do not pull by the power or use power cord as a handle.

Always unplug by grabbing the plug and pulling, do not

unplug by pulling the power cord.

• Inspect cord for damage. Do not use damaged cords. Con-

nect only to properly grounded outlets.

• Keep hair, ngers, loose clothing, and body parts away

from moving parts and openings.

• Turn o all controls before disconnecting machine

• Use caution with ejected liquid or chemicals. High pres-

sures and temperatures could be hazardous to nearby peo-

ple or surroundings.

FAILURE TO COMPLY WITH THE ABOVE

WARNING INSTRUCTIONS WILL

VOID THE WARRANTY.

2

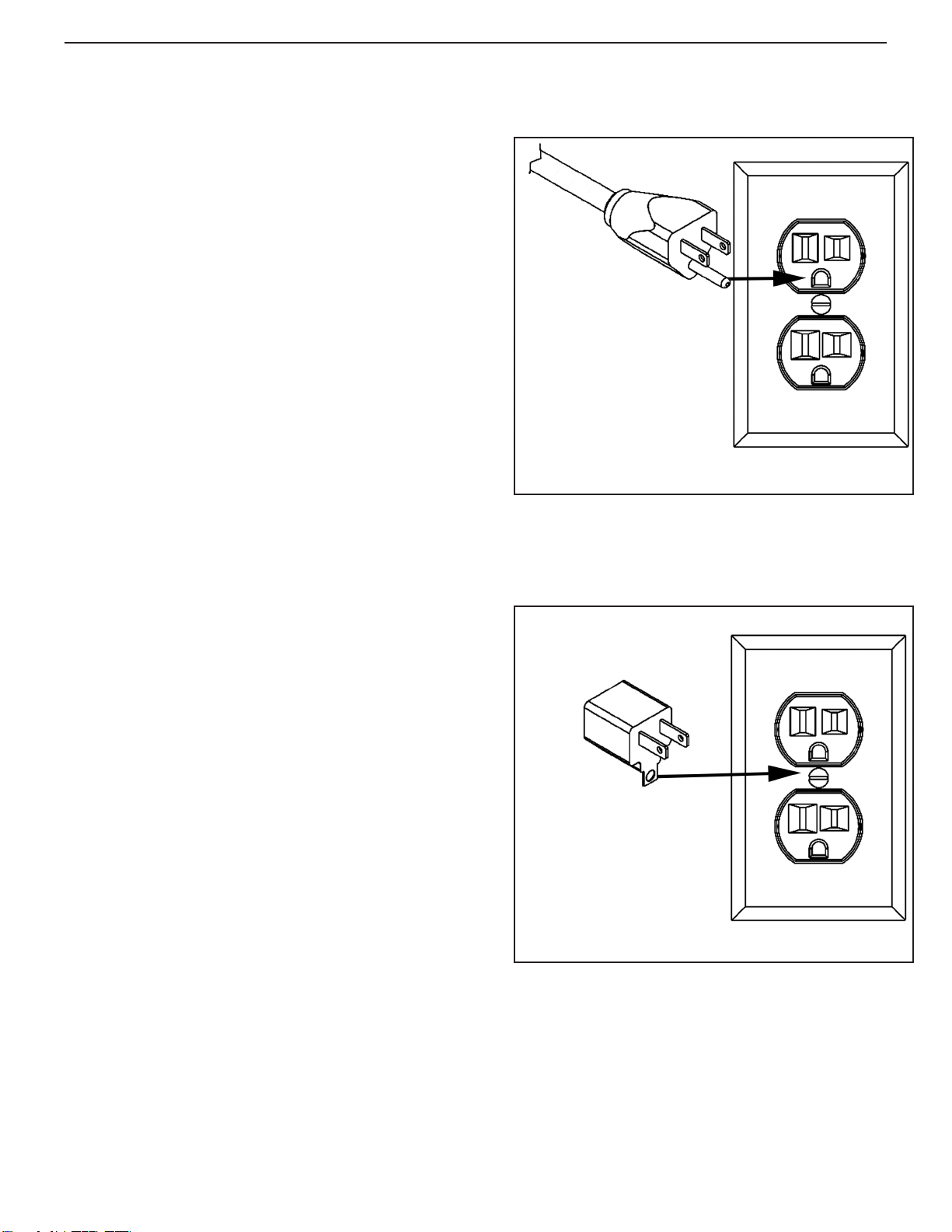

GROUNDING INSTRUCTIONS:

is piece of equipment must be grounded. Should an

electrical malfunction occur, grounding provides a path

of least resistance for electrical current- reducing the risk

of electric shock. is piece of equipment is furnished

with a cord that has a grounding conductor and ground-

ing plug. e grounded plug must only be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordi-

nances.

WARNING:

Connecting the equipment to an improperly grounded

outlet can result in an increased risk of electric shock. A

qualified electrician should be consulted if you are un-

sure that the outlet is properly grounded. Do not modify

the plug provided with the equipment. If it will not fit

the outlet, have a proper outlet installed by a qualified

electrician.

is appliance is designed for use on a 120-volt circuit.

e grounding plug provided looks like the plug illus-

trated in Figure 1.

A temporary adapter such as the one illustrated in

Figure 2 may be used to connect this plug to a 2-pole

receptacle (see Figure 2), if a properly grounded outlet

is not available. Temporary grounding adapters should

only be used until a properly grounded outlet (see

Figure 1) can be installed by a qualified electrician. e

green-colored rigid ear, tab, or similar, extending from

the adapter must be connected to a permanent ground

such as a properly grounded outlet box cover. Whenever

an adapter is being used, it must be secured by a metal

screw. ese temporary grounding adapters are not

approved for use in Canada.

Replace the plug if the grounding pin is damaged or

broken.

e Green (or Green/Yellow) wire in the cord is the

grounding wire. When replacing a plug, this wire must

be attached to the grounding pin only.

Extension cords connected to this machine should be

12 gauge, three-wire cords with three-prong plugs and

outlets. DO NOT use extension cords more than 25 feet

(7.6 m) long.

Fig. 1

Fig. 2

3

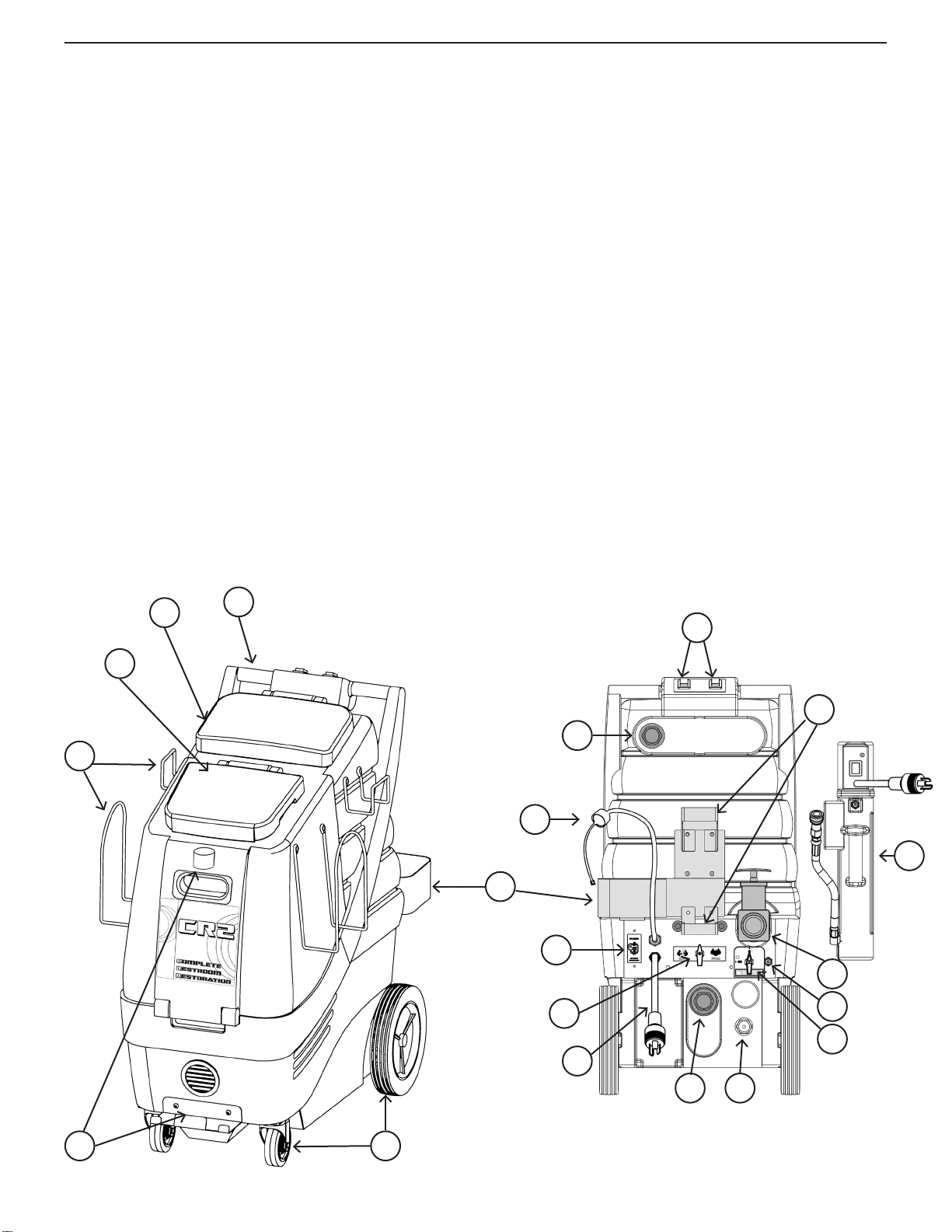

1. Handle- Used to maneuver and position the CR2

2. Recovery tank lid- Allows access to recovery tank

and creates a seal to ensure suction

3. Solution tank lid- Allows access to the solution tank

and prevents external contamination of solution tank

4. Accessory racks for hoses, cords, tools etc.- One large

rack and one small rack on each side of the machine.

4 total

5. Wand storage bracket and velcro strap- Allows the

operator to secure a wand attachment to the machine

for ease of transport

6. Non-marking front 4” locking casters and rear 10”

wheels

7. Recovery/vacuum hose inlet barb- connect your

recovery vacuum hose to this barb

8. Feed hose line for chemical with threaded bottle cap-

secures the feed hose line to the chemical bottle

9. Bottle holder for chemical feed system- Holds up to a

one gallon chemical bottle

10. GFCI breaker- Interrupts and disables the electrical

system if a ground leak is detected.

11. Chemical dispensing valve- Select between chemical

and no chemical by turning to le or right as marked

12. Male twist lock pigtail- Connects to 50 cord

13. Exhaust port hose barb- Used to connect to hose

with blower attachment.

14. Pressure regulator- Decrease pressure by turning

counter-clockwise or increase pressure by turning

clockwise

15. Priming/pressure relief valve- Prime system in the

event of air lock. Relieves pressure in the event of

pressure lock

16. Solution line Q.D.- Pressurized connection for solu-

tion line

17. Recovery tank dump valve- Pull up to open

18. Accessory Heater (Available separately)

19. Heater mounting brackets- for accessory heater

20. Switch box- one switch marked “PUMP” and one

switch marked “VACUUM”. Switches light up when

powered on.

3

21

4

8

65

9

10

11

12

13 14

15

16

17

18

20

7

19

4

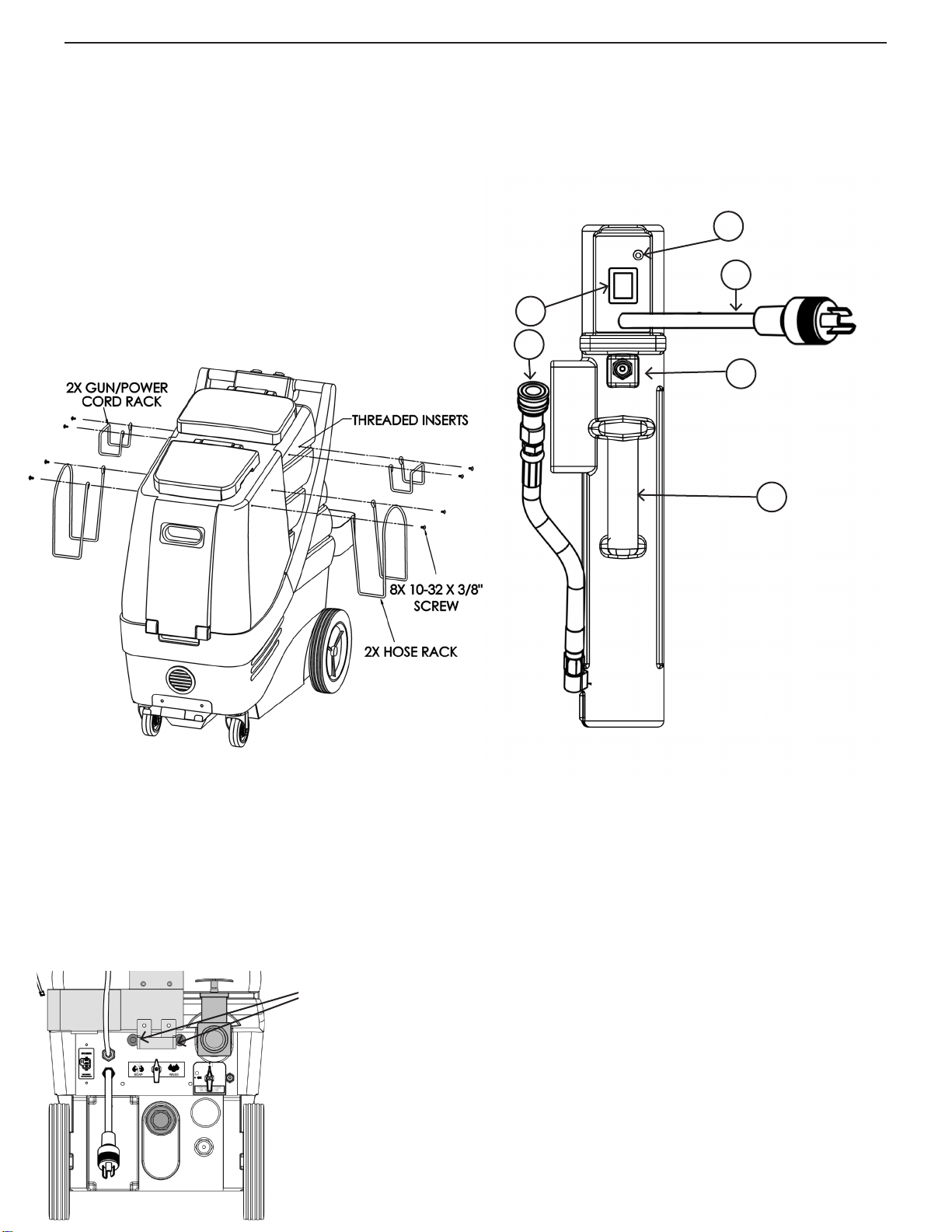

Assembling the accessory racks:

e CR2 is shipped with the accessory racks and hard-

ware in the solution tank. When you receive your CR2,

it is necessary to secure the racks to the body. e only

tool required to complete this action is a Phillips head

screwdriver.

e CR2 comes equipped with threaded inserts pre-in-

stalled in the body. e two larger racks are installed

toward the front of the machine- one per side and the

two smaller racks are installed toward the rear, also one

per side.

Installing an accessory heater:

If a 600HR Heat “n” Run heater system has been pur-

chased for the CR2, use the following illustration to

familiarize yourself with the heater.

Opening the machine:

is unit can be opened by simply removing two bolts

located on the back of the machine. e unit will open

forward by liing up on the handle. If you need to open

the unit further, you may release the vacuum hose going

from the base of the vacuum plate to the bottom of the

recovery tank by loosening the hose clamp.

2 BOLTS

1

2

4

5

3

6

1. Power switch- Lights up when switched to power

“ON”

2. “IN” hose connect to male Q.D. (Number 16 on page

4)

3. Lamp will turn on anytime the heat element is ac-

tivated. Lamp will turn o any time max temp is

reached.

4. Male twist lock Pigtail- connects to 50 cord

5. “Out” male Q.D.- Connect to your 35 solution line

6. Handle

5

How to use an accessory heater:

1. Mount the Heater by lining up the two “legs” to the

two mounting brackets on the rear of the machine.

(19 on page 4)

2. Fill the solution tank of your CR2 with sucient

water for the task at hand

3. Connect your heater’s in hose (#2 on page 5) to #16

on page 4

4. Connect your 35 solution hose to #5 on page 5

5. Connect your 35 vacuum hose to number 7 on

page 4.

6. Connect your wand or upholstery tool to the end of

your 35 solution hose

7. Connect the power cord on the machine and the

power cord to the heater to two separate plugs on

two separate circuits.

8. Turn the priming/pressure relief valve (15 on page

4) 45 degrees to the le to the open position

9. Turn the pump to the on position

10. Allow pump to prime

11. Close priming valve

12. Turn heater on and allow up to 3 minutes for the unit

to heat up.

You will know the heater is ready for use once the green

lamp shuts o the rst time. Once you start cleaning car-

pet, the green lamp will turn on and o throughout your

job as the thermostats regulate the temperature.

Note: e heater is mainly to be used for carpet cleaning.

While the heater may provide some heat during chem-

ical application, it is unlikely to reach desired tempera-

tures during continous spray conditions.

Installing metering tips for the Chemical feed

system:

Remove the semi-clear hose from the bottle cap (8 on

page 4). Select the appropriate metering tip for the dilu-

tion required and push it into the tube on the bottle cap.

Metering tip color guide:

Tan 1.25oz/Gal

Turquoise 2.00oz/Gal

Pink 3.00oz/Gal

Brown 4.00oz/Gal

White 5.00oz/Gal

Chemical feed system and hard surface clean-

ing:

e chemical feed system is designed to deliver accu-

rate chemical dilution for touchless surface cleaning.

e chemical feed system is activated by low pressure

spraying and is not suited for chemical dispensing while

performing carpet cleaning. To clean hard surfaces:

1. Fill the solution tank of your CR2 with sucient

water for the task at hand

2. Connect hoses and accessory pressure gun

3. Select the appropriate tip and install on the cap of

the chemical feed (number 8 on page 4)

4. Place a bottle into bottle holder (number 9 on page

4)

5. Take the feed tube attached to the cap (number 8 on

page 4) and place it inside the bottle.

6. Take the cap from number 8 on page 4 and thread it

onto the bottle of chemical to secure it in place

7. Turn the chemical dispensing valve (11 on page 4)

to the le to the word “SOAP”

8. Chemical will only draw in the “Low pressure”

setting of your pressure gun. To activate the Low

pressure setting, pop the collar of the gun out.

9. While in the low pressure setting, apply chemical to

the walls and xtures starting from the lowest point

to the highest.

10. Spray the oor as you make your way out of the

room

11. Allow the chemical to dwell according to the chemi-

cal manufacturers recommendations

12. You may use the brush on your squeegee/brush

wand to agitate particularly soiled areas

13. When you are ready to rinse away chemical, simply

turn the Chemical dispensing valve to the right to

the word “RINSE”

14. Set your pressure gun to “high” pressure by pulling

the collar back in. Rinse surfaces starting from the

top down.

15. See “Recovering liquid” for nal steps

6

Recovering liquid:

e CR2 is equipped with two dedicated tools for liquid

recovery: the squeegee/brush wand and the Gulper tool.

Other accessories are available for the CR2.

1. Connect recovery vacuum hose to the recovery inlet

barb (number 7 on page 4)

2. Turn the vacuum switch (19 on page 4) into the on

position

3. Using either the squeegee/brush wand or the Gulper

tool, extract the liquid from the surface.

4. Monitor the levels in the recovery tank and empty

as necessary. Use defoamer to ensure your vacuum

motor does not take in uid

Using the blower hose:

e CR2 has a hose barb (13 on page 4) tted to the vac-

uum motor’s exhaust. By attaching a hose to this tting,

the energy from the exhaust is redirected and allows the

operator to use the accessory hose as a blower.

Convenient for:

• Blowing uid o countertops and walls onto the

oor

• Drying Faucets and other xtures

Cleaning carpet or upholstery:

e CR2 can be used as a cold or hot water extractor.

If you do not have an accessory heater, then perform e

steps below 1-12. If you do have a heater, read the heater

steps on page 6 and continue at step 10 below.

1. Prespray the area of carpet to be cleaned

2. Connect your solution line

3. Connect your recovery vacuum hose

4. Connect your wand or upholstery tool to the solu-

tion and vacuum hoses

5. Fill the solution tank of your cr2 with water

6. Turn the pump switch to the “on” position

7. Turn the priming valve to the le to the open posi-

tion if pump needs to be primed

8. Allow pump to prime

9. Close the Priming valve

10. Turn on the vacuum motor

11. Spray on the backstroke and do a dry stroke when

pushing forward.

12. Overlap your previous path slightly when you pull

back.

Maintenance:

• Use only chemicals safe for extractors

• Adhere to the appropriate mix ratios for all chemi-

cals

• Do not add chemical to the solution tank- use the

chemical feed system

• For optimal performance, it is suggested that the

operator ush the system aer every job or at the end

of the day.

• Pump seals and valves may need to be replaced at the

1000 hour mark if a loss in pressure is noted

e pressure regulator may require servicing should a

pressure drop be noted

Daily:

• Flush chemical lines

• Check and clean vacuum lter

Wee kly :

• Check and clean solution lter

• Check for obstructions in vacuum pathways

Quarterly:

• Check pump, plumbing and ttings for leaks

• Check power cords and hoses for tears

7

Other manuals for CR2

1

Table of contents

Other Edic Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Profigold

Profigold PROC9001 user manual

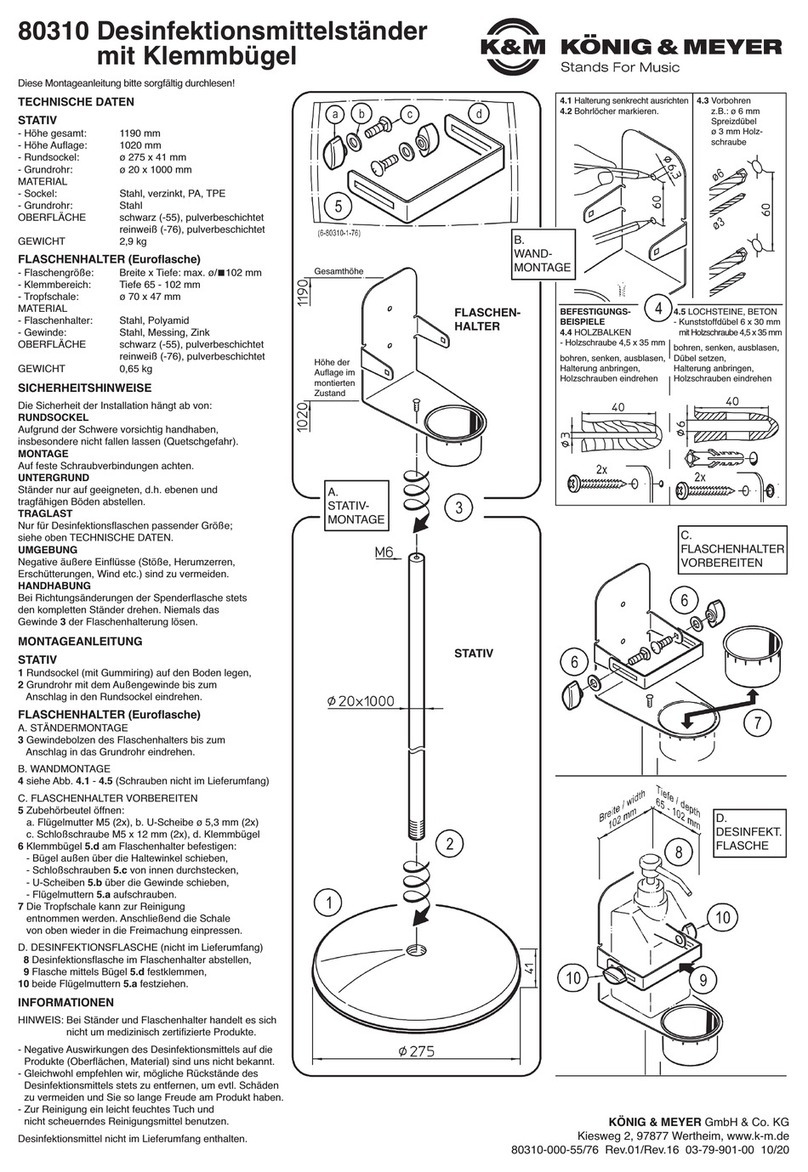

Konig & Meyer

Konig & Meyer 80310 instructions

PREMIER AUTOMATION

PREMIER AUTOMATION HydroCleaner Operator's manual

HydraMaster

HydraMaster Boxxer 318 owner's manual

Clarus Technologies

Clarus Technologies PCS-35 Operator's manual

Stratasys

Stratasys WaveWash 55 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Victrola

Victrola VA-55 instruction manual

Elma

Elma Elmasonic xtra ST operating instructions

Elma

Elma Elmasonic Select Translation of the original manual

Westfalia

Westfalia 92 12 79 Original instructions

Dane Technologies

Dane Technologies QuicKLEEN Owner's manual & operating instructions