1

Table of Contents

1 Introduction...............................................................................................................................2

How to use this guide ..............................................................................................2

Learn More!............................................................................................................2

Safety precautions ...................................................................................................3

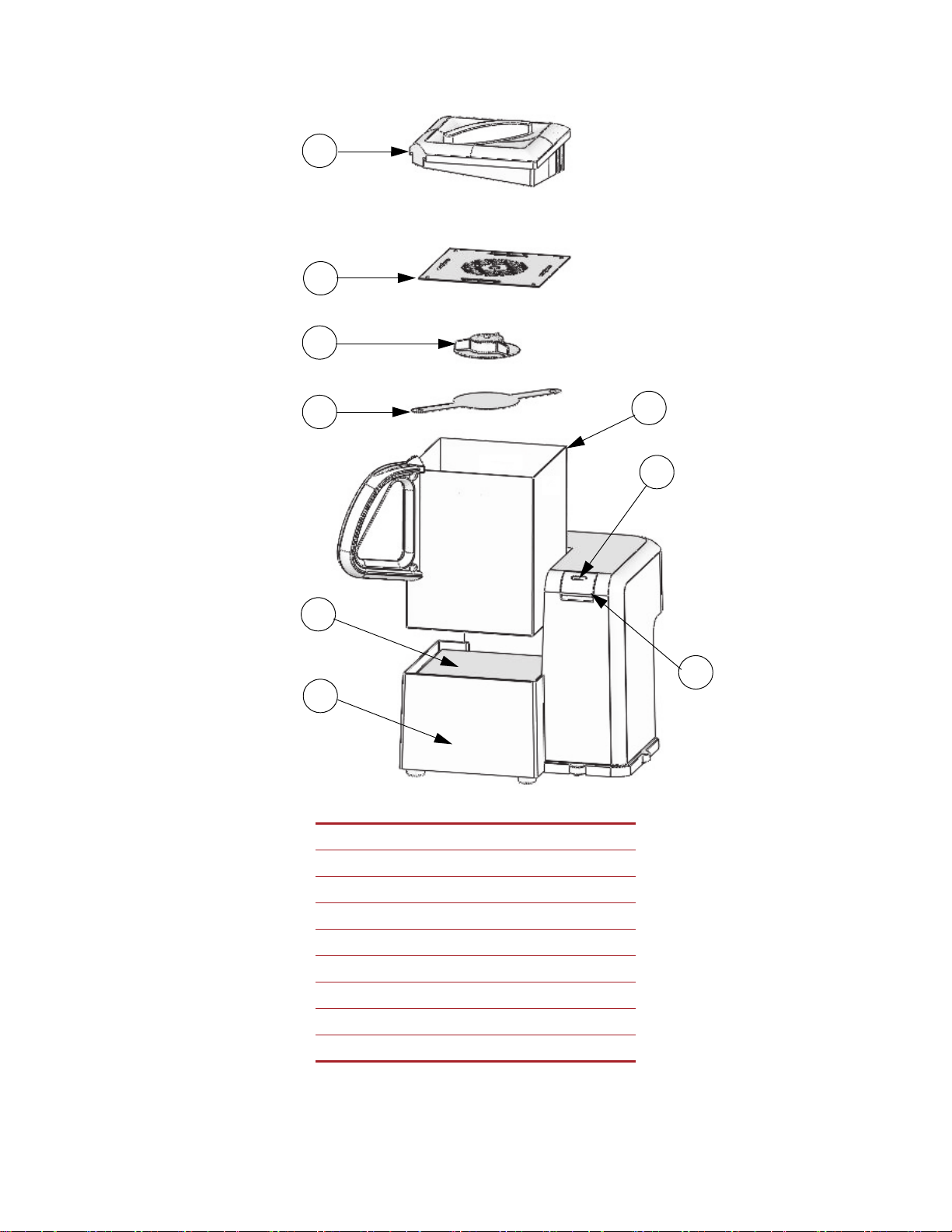

2 Overview..................................................................................................................................4

How it works ..........................................................................................................4

3 Setup........................................................................................................................................7

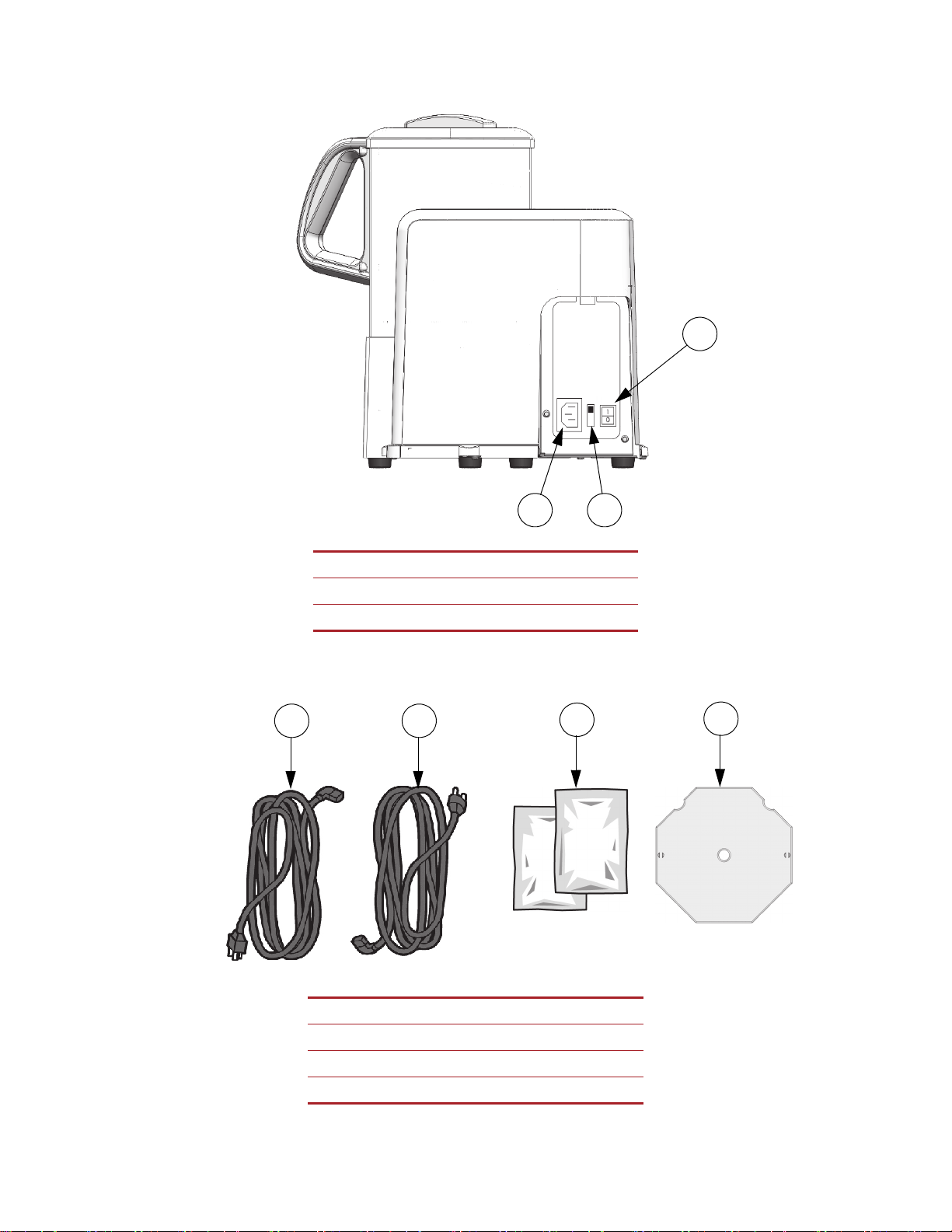

Connecting the system .............................................................................................7

4 Operation .................................................................................................................................8

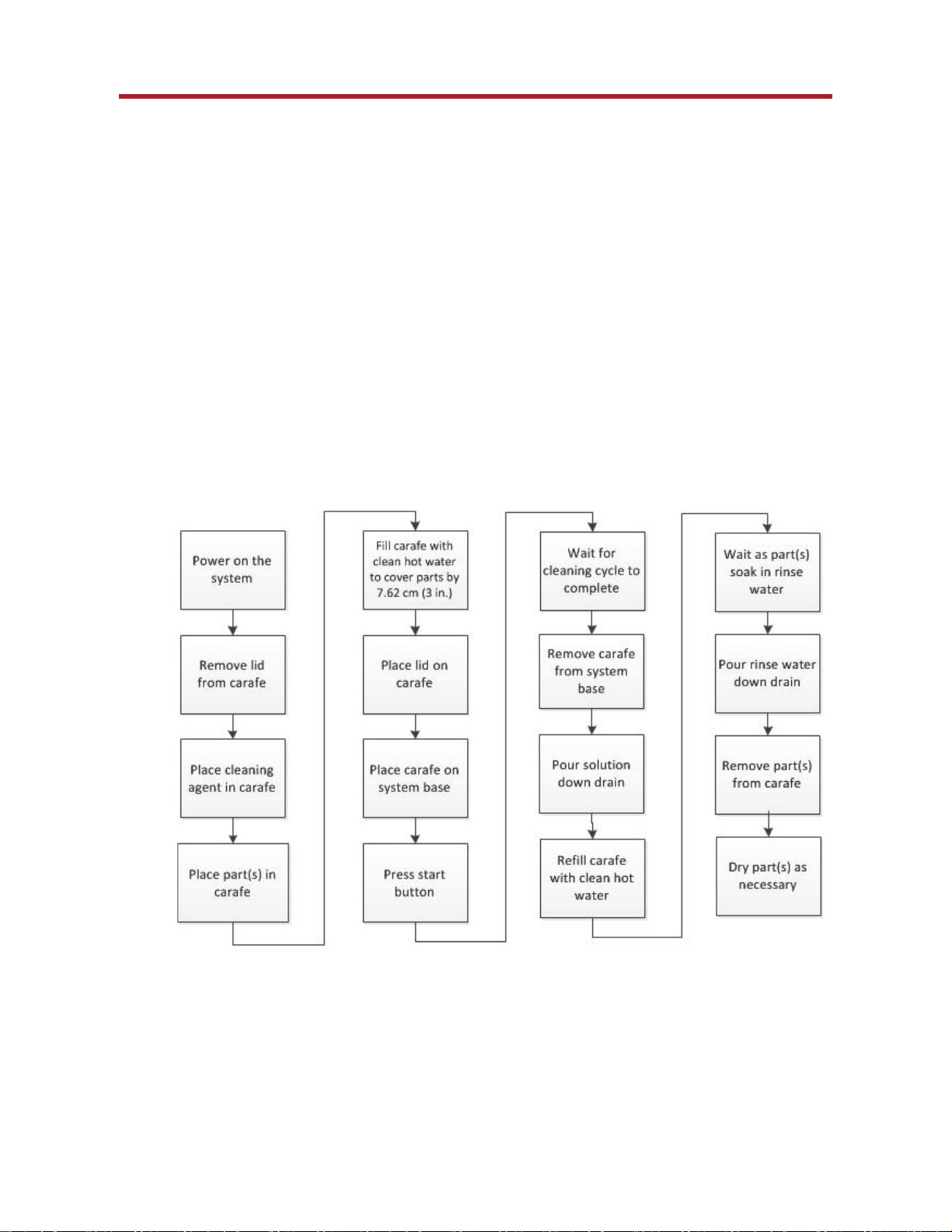

Cleaning parts ........................................................................................................8

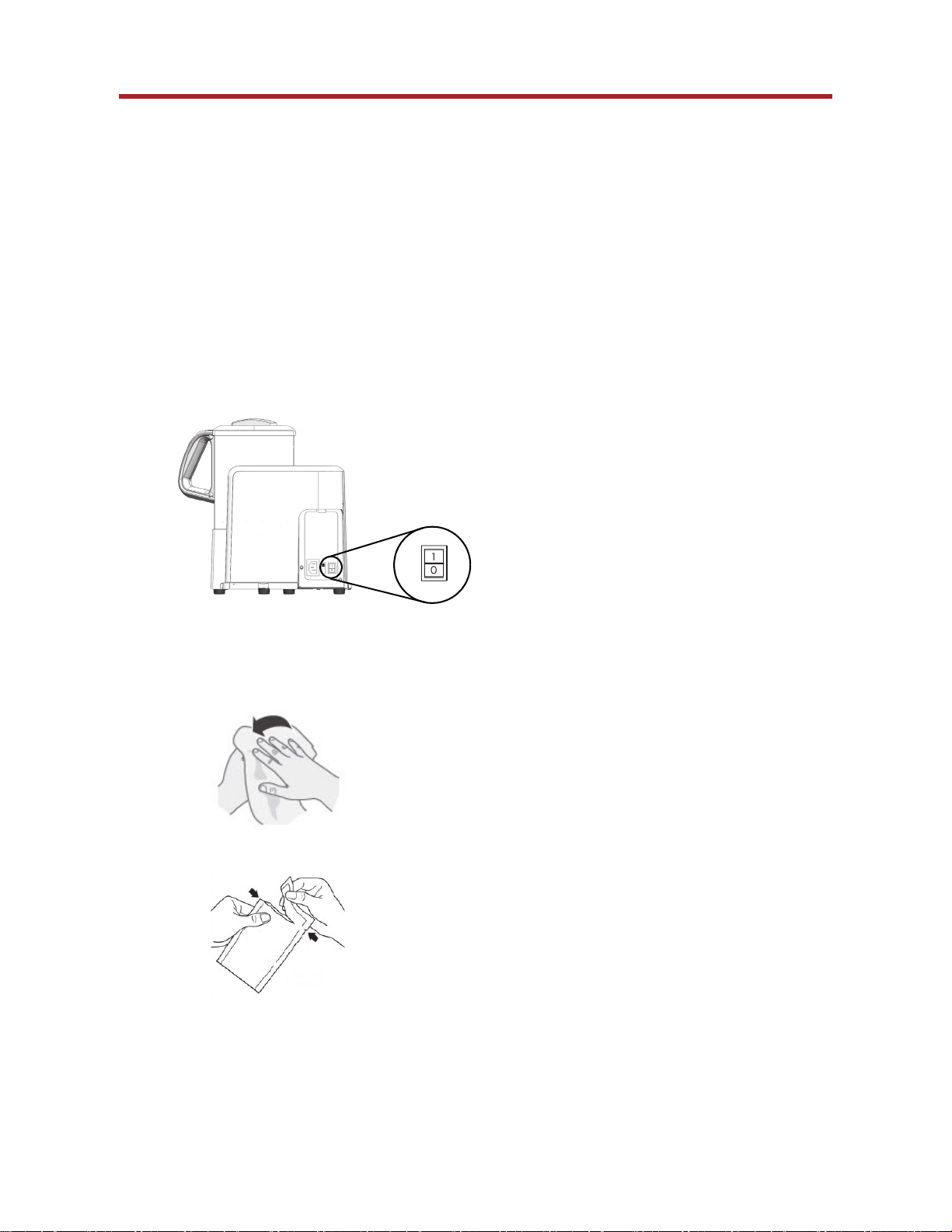

Powering off .........................................................................................................11

5 Maintenance ...........................................................................................................................12

Every cleaning cycle ..............................................................................................12

As needed............................................................................................................12

Yearly..................................................................................................................12

6 Troubleshooting ......................................................................................................................13

Troubleshooting ....................................................................................................13

7 Support...................................................................................................................................14

Registration ..........................................................................................................14

Customer Support..................................................................................................14

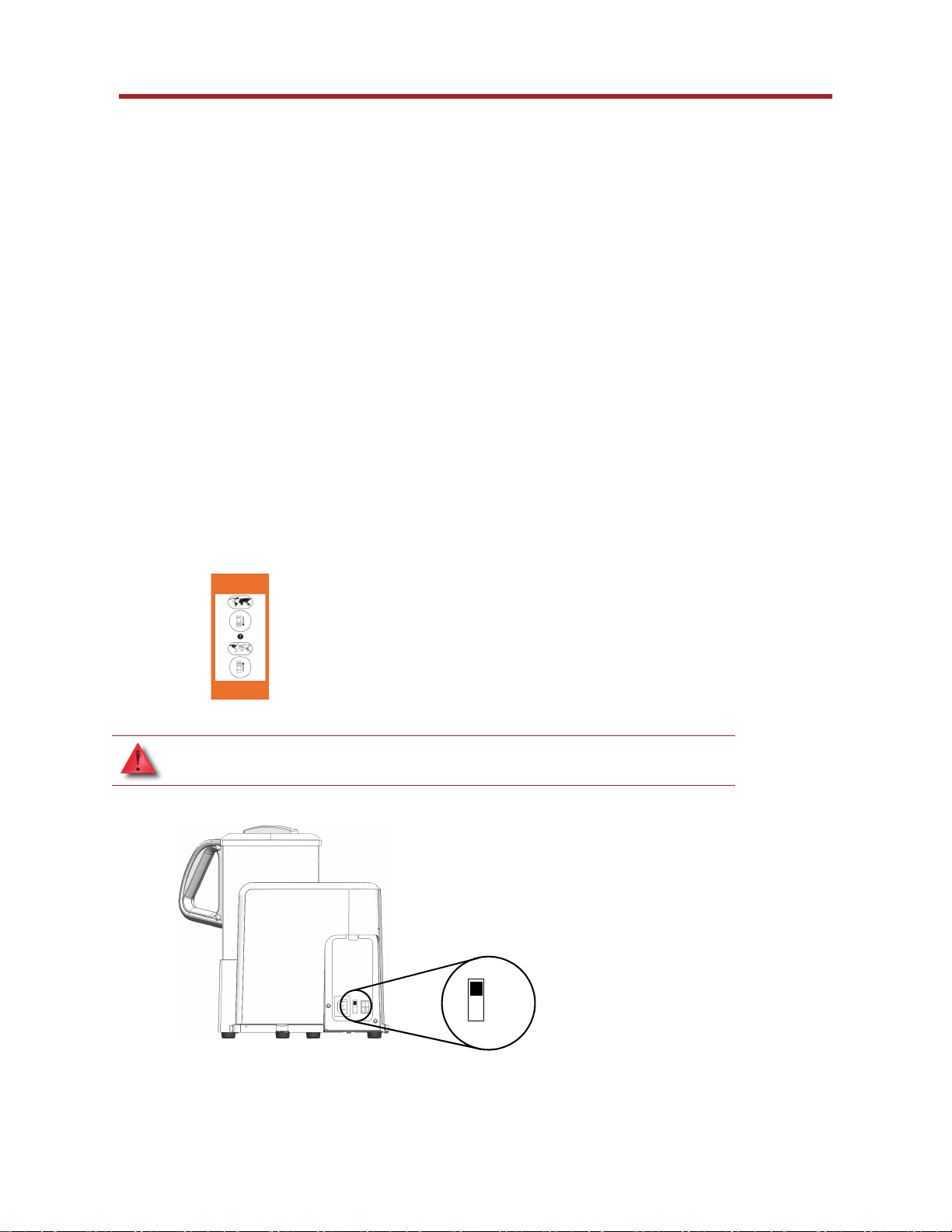

8 Recycling ................................................................................................................................15

9 System specifications...............................................................................................................16

Physical specifications............................................................................................16

Facility specifications .............................................................................................16

Power specifications ..............................................................................................16

Environmental specifications ...................................................................................16

Acoustic specifications ...........................................................................................16

10 Supplemental Information........................................................................................................17

Stratasys Limited Warranty Statement ......................................................................17

Declaration of Conformity ......................................................................................19

Regulatory and environmental information................................................................20

11 Glossary .................................................................................................................................22