EDTM ShowerGuard RD1661 User manual

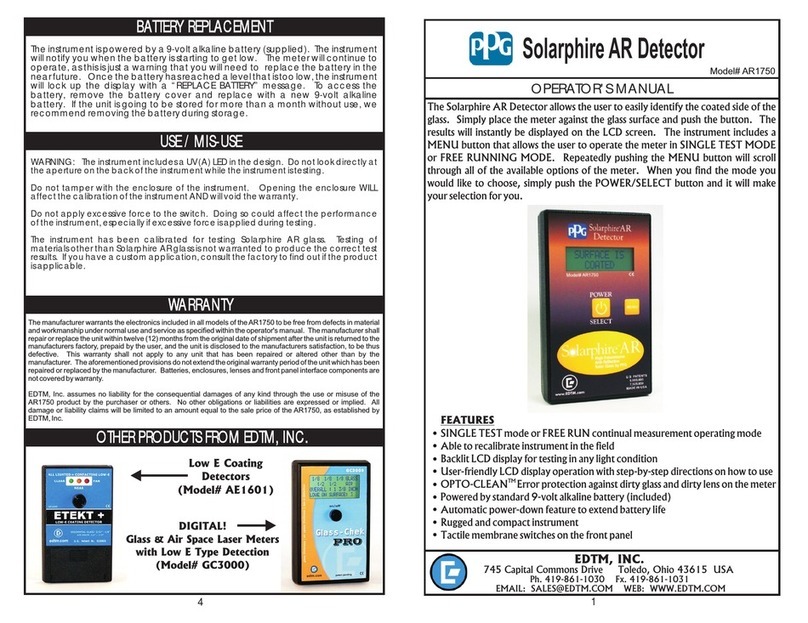

OPERATOR'S MANUAL

The instrument is powered by a 9-volt alkaline battery (supplied). The

instrument will notify you when the battery is starting to get low. The meter will

continue to operate, as this is just a warning that you will need to replace the

battery in the near future. Once the battery has reached a level that is too low,

the instrument will lock up the display with a “REPLACE BATTERY” message.

To access the battery, remove the battery cover and replace with a new 9-volt

alkaline battery. If the unit is going to be stored for more than a month without

use, we recommend removing the battery during storage.

Do not tamper with the enclosure of the instrument. Opening the enclosure

WILL affect the calibration of the instrument AND will void the warranty.

Do not apply excessive force to the switch. Doing so could affect the

performance of the instrument, especially if excessive force is applied during

testing.

The instrument has been calibrated for testing Guardian ShowerGuard

coatings. Testing of materials other than those listed is not warranted to

produce the correct test results. If you have a custom application, consult the

factory to find out if the product is applicable.

ShowerGuard

DIGITAL Coating Detector

MODEL# RD1661 MADE IN THE USA

BATTERY REPLACEMENT

WARRANTY

USE / MIS-USE

The manufacturer warrants the electronics included in all models of the RD1661 to be free from defects in material

and workmanship under normal use and service as specified within the operator's manual. The manufacturer shall

repair or replace the unit within twelve (12) months from the original date of shipment after the unit is returned to the

manufacturers factory, prepaid by the user, and the unit is disclosed to the manufacturers satisfaction, to be thus

defective. This warranty shall not apply to any unit that has been repaired or altered other than by the

manufacturer. The aforementioned provisions do not extend the original warranty period of the unit which has been

repaired or replaced by the manufacturer. Batteries, enclosures, lenses and front panel interface components are

not covered by warranty.

EDTM, Inc. assumes no liability for the consequential damages of any kind through the use or misuse of the

RD1661 product by the purchaser or others. No other obligations or liabilities are expressed or implied. All

damage or liability claims will be limited to an amount equal to the sale price of the RD1661, as established by

EDTM, Inc.

1

4

Low E Coating

Detectors

(Model# AE1601)

Tin Side

Detectors

(Model# TS1320)

Glass & Air Space

Laser Meters +

Identify Low E Type

(Model# GC3000)

EDTM, INC.

745 Capital Commons Drive Toledo, Ohio 43615 USA

Ph. 419-861-1030 Fx. 419-861-1031

EMAIL: [email protected] WEB: WWW.EDTM.COM

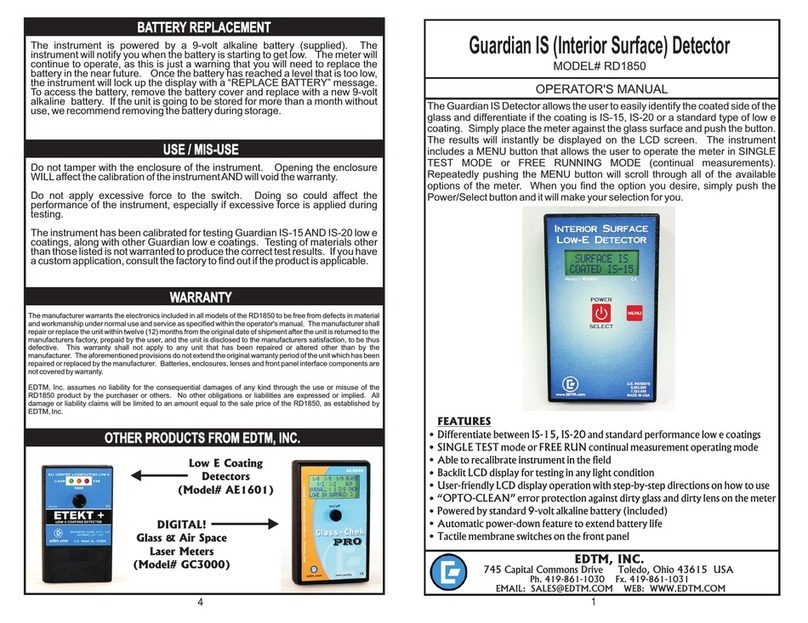

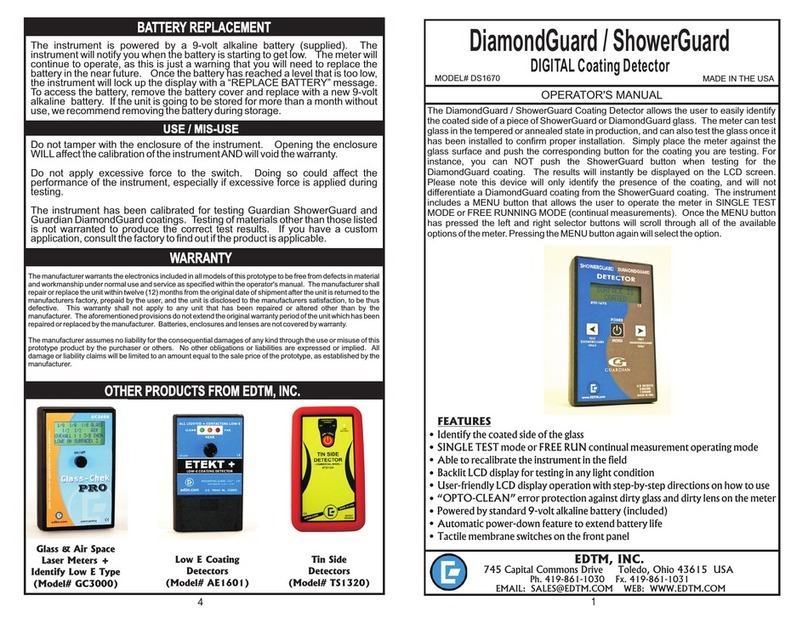

The ShowerGuard Coating Detector allows the user to easily identify the coated

side of a piece of ShowerGuard glass. The meter can test glass in the tempered

or annealed state in production, and can also test the glass once it has been

installed to confirm proper installation. Simply place the meter against the glass

surface and push the button. The results will instantly be displayed on the LCD

screen. The instrument includes a MENU button that allows the user to operate

the meter in SINGLE TEST MODE or FREE RUNNING MODE (continual

measurements). Repeatedly pushing the MENU button will scroll through all of

the available options of the meter. When you find the option you desire, simply

push the Power/Select button and your selection is made.

OTHER PRODUCTS FROM EDTM, INC.

FEATURES

Identify the coated side of the glass

SINGLE TEST mode or FREE RUN continual measurement operating mode

Able to recalibrate the instrument in the field

Backlit LCD display for testing in any light condition

User-friendly LCD display operation with step-by-step directions on how to use

“OPTO-CLEAN” error protection against dirty glass and dirty lens on the meter

Powered by standard 9-volt alkaline battery (included)

Automatic power-down feature to extend battery life

Tactile membrane switches on the front panel

MISCELLANEOUS

OPERATION TEST RESULTS - continued

23

POWER

If the user wants to turn the power off manually, you need to press AND HOLD the power button for 2

seconds. After 2 seconds the powering-down screen will appear, and the meter will begin its

countdown to shutting off. You must continue to hold the button down during the countdown to

complete the powering off sequence. If you let up on the button too early, the instrument will resume

operation.

The instrument also has a built-in timer that will automatically power down the product if no button

presses occur for approximately 2 minutes. This energy conservation design helps to extend the life of

the battery in the instrument in case the user forgets to turn it off. To turn the meter back on, simply

push the button.

MAINTENANCE

You will want to occasionally inspect the cleanliness of the viewing window on the back side of the

meter. If you see dust or dirt in the window, please use compressed air to blow it off. If you begin

receiving a large number of error messages during your testing, this may be a sign that the back window

needs cleaned. If there are smudges on the window that do not clean off with compressed air, use a

soft lint-free cloth to wipe the lens. Always use compressed air first to remove any particles that may

scratch the surface of the lens.

To begin, make sure the glass you are testing is clean. Dirty glass or dust and dirt on the surface of the

glass can affect the results of your test. Also make sure the lens on the back side of the meter is clean.

To turn the instrument on, press the momentary power switch on the front of the meter. The display

will direct you to place the meter on the glass you want to test. Place the meter FLAT against the glass.

Your test results will appear on the LCD screen. Here are the various operating modes and features you

can select with the MENU button:

“SINGLE TEST” MODE

Each push of the button will result in one test being done on the surface of glass you are touching. The

meter will not test the opposite side of the glass, rather only the side you are in contact with. The

display will register a measurement of “SURFACE IS COATED” or “SURFACE IS UNCOATED”.

Hold the instrument stationary while conducting the measurement. Single test mode is the most

battery-efficient operating mode and the recommended mode of operation.

“FREE RUN” MODE

In this mode, the meter will continually take measurements. There is no need to continually push the

power button when you want to take a measurement, as the meter will be continually doing so.

Measurements will be updated nearly every second. It should be noted that this operating mode will

tend to shorten the life of the battery, as the electronics are powered for a much longer period of time,

as opposed to single test mode.

CALIBRATE

If the coating you are testing has changed in chemistry, or if the warning message on the display has

encouraged you to recalibrate, select this option. Before beginning, be sure to clean the back lens of

the meter, and find a clean sample of the Guardian ShowerGuard coating.

Using an annealed piece of glass will cause an incorrect calibration to occur and the

meter will not accurately identify the coated side of tempered ShowerGuard glass. To complete the

calibration, follow the instructions on the display to take a measurement on both sides of the tempered

Guardian ShowerGuard sample. The meter will indicate if the calibration was successful or not. If the

calibration was not successful, the display will show you what error occurred during the calibration

process. If an error occurs, check to see that the meter lens is clean, and that your tempered Guardian

ShowerGuard sample is valid and clean.

USE PREV. CAL

If you do not like the new calibration that you performed, you can restore the previous calibration that

was stored in the instrument.

USE FACTORY

If you want to return the meter to the calibration that was originally shipped in the meter as new from

the factory, make this selection.

IMPORTANT NOTE:

YOU MUST USE A TEMPERED PIECE OF SHOWERGUARD GLASS FOR ANY CALIBRATION

PROCEDURE.

“PLEASE CLEAN BACK LENS”

This message will appear if the meter has determined that its back lens may be dirty. Simply use

compressed air to blow off any dirt or dust from the back lens of the meter. This message is the first

level of warning that your meter may need to be cleaned.

“MUST CLEAN BACK LENS”

This message is the second level of warning that indicates the meter has a back lens that needs to be

cleaned. The validity of your test results could be affected soon. Clean the back lens of the meter.

“MUST CLEAN AND/OR RECAL”

If the meter has been neglected and the back lens has continually been degrading in cleanliness, this

message will appear. Once this message appears, the validity of test results would be jeopardized, and

the meter will NOT allow test results to be shown. Before any re-calibration is performed, it is

pertinent that the back lens of the meter is cleaned first. This may be all that is needed to get the

meter performing correctly again. Try cleaning the lens first and then test the meter again. If the

same warning message appears, then it is necessary to recalibrate the instrument. Find a clean sample

of ShowerGuard glass and choose RECALIBRATE in the MENU system. Before re-

calibrating, make sure the glass sample is valid and clean.

“CLEAN & RE-TEST”

This result screen will show up if the measurement was not in the range anticipated by the meter. This

typically happens when the glass is dirty. Clean the glass and test again. If this does not correct the

problem, you may want to clean the back lens of the instrument by using compressed air to blow off

the lens. If smudges still remain, use a lint-free cloth to wipe the smudges from the lens.

“KEEP METER FLAT ON GLASS DURING TEST”

If you pick up the meter or the instrument is not setting flat against the glass during the test, this error

message will occur. The instrument is monitoring the measurement and if it determines that the

meter has been pulled away from the surface of glass, it will display this message and ask you to start a

new test.

TEMPERED

“SURFACE IS” . . . . . . . .

One of the following screens will appear after a successful test:

SURFACE IS COATED: surface 1 contains Guardian ShowerGuard coating

SURFACE IS UNCOATED: surface 1 does not contain Guardian ShowerGuard coating

Please note, the meter will make NO attempt to identify any coatings on surface #2.

TEST RESULTS

Other EDTM Security Sensor manuals

Popular Security Sensor manuals by other brands

Tecnoalarm

Tecnoalarm MINIEXPLORER manual

Aritech

Aritech ATS 500A Series Installation sheet

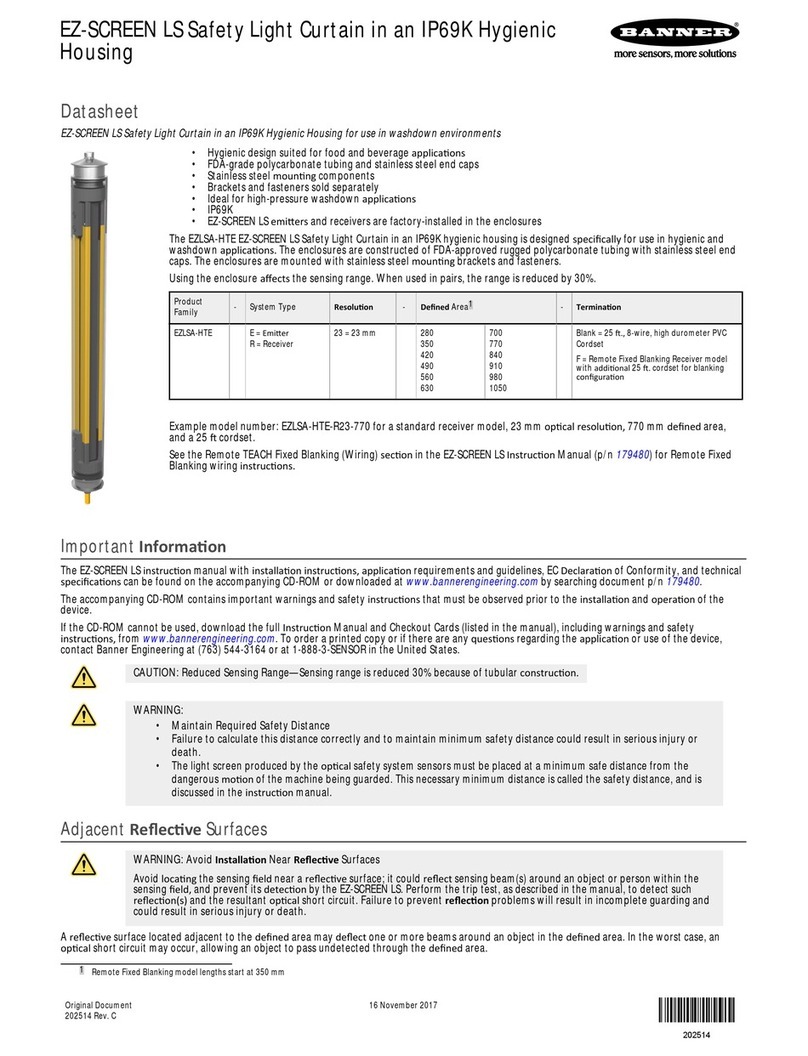

Banner

Banner EZ-SCREEN LS instruction manual

Honeywell

Honeywell Ex-Or Digital Gold Series Installation and commissioning instructions

Eminent

Eminent EM8650 manual

Orno

Orno OR-AK-1202 Operating and installation instructions