L4

2 x M10 x 1.5

2 x 92 mm

[3.62”]

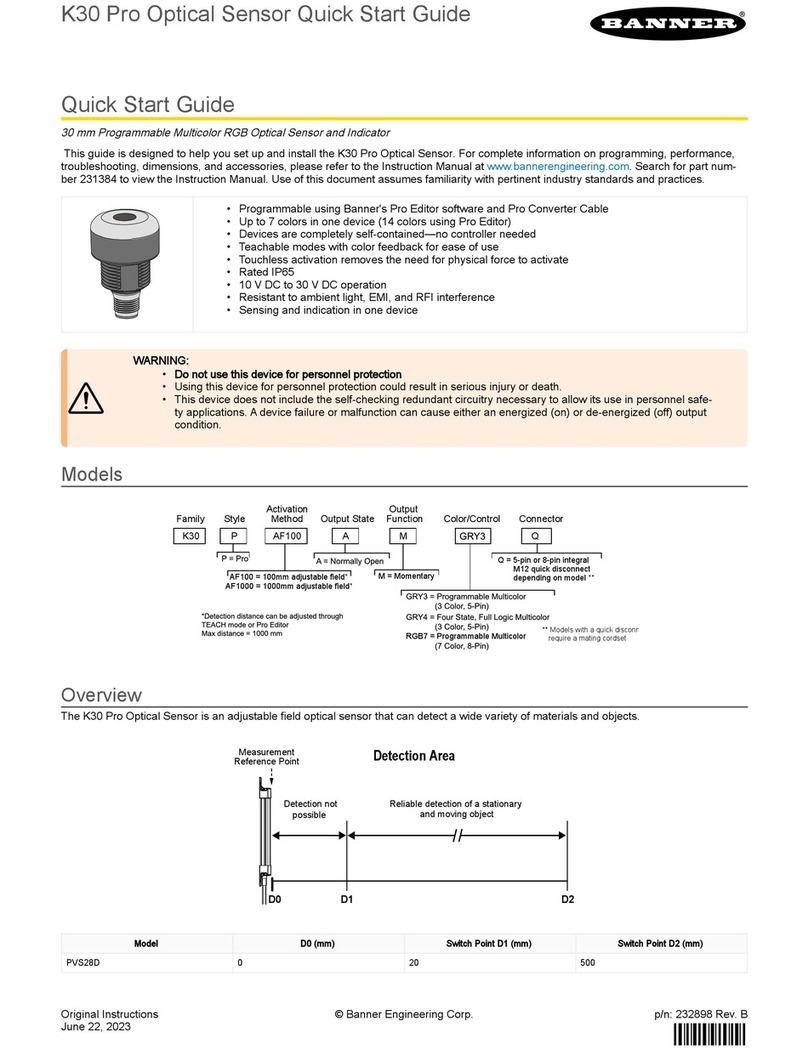

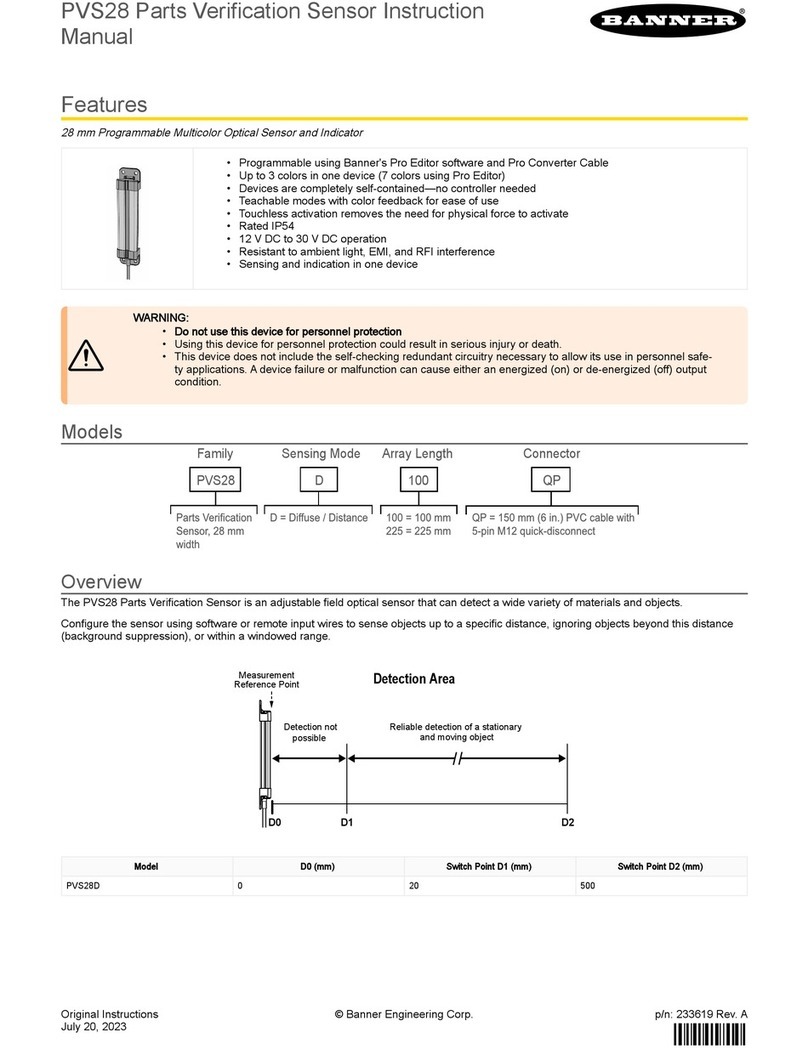

Figure 4. EZLSA-HTE with EZLSA-MBK-HTE-2 bracket

All measurements are listed in millimeters [inches], unless noted otherwise.

Enclosure Model Dened Area

(mm) L1 (mm) L2 (mm ) (1 Cable) L2 (mm) (2 Cables) (RFB

Models) L3 (mm) L4 (mm)

EZLSA-HTE-280 280 360 (14.2") 443 (17.4") 441 (17.4") 463 (18.2") 379 (14.9")

EZLSA-HTE-350 350 429 (16.9") 513 (20.2") 511 (20.1") 533 (21") 449 (17.7")

EZLSA-HTE-420 420 499 (19.7") 583 (22.9") 581 (22.9") 603 (23.7") 519 (20.4")

EZLSA-HTE-490 490 569 (22.4") 653 (25.7") 651 (25.6") 673 (26.5") 589 (23.2")

EZLSA-HTE-560 560 639 (25.2") 723 (28.4") 721 (28.4") 742 (29.2") 658 (25.9")

EZLSA-HTE-630 630 709 (27.9") 792 (31.2") 791 (31.1") 812 (32") 728 (28.7")

EZLSA-HTE-700 700 779 (30.7") 862 (33.9") 861 (33.9") 882 (34.7") 798 (31.4")

EZLSA-HTE-770 770 849 (33.4") 932 (36.7") 930 (36.6") 952 (37.5") 868 (34.2")

EZLSA-HTE-840 840 918 (36.2") 1002 (39.4") 1000 (39.4") 1022 (40.2") 938 (36.9")

EZLSA-HTE-910 910 988 (38.9") 1072 (42.2") 1070 (42.1") 1092 (43") 1008 (39.7")

EZLSA-HTE-980 980 1058 (41.7") 1142 (44.9") 1140 (44.9") 1161 (45.7") 1077 (42.4")

EZLSA-HTE-1050 1050 1128 (44.4") 1211 (47.7") 1210 (47.6") 1231 (48.5") 1147 (45.2")

Brackets

EZLSA-MBK-HTE-1

• Stamped, hygienic swivel bracket

• 304 stainless steel

• Non-metallic FDA compliant gaskets

• Two brackets included per kit

• M5 screws (8 mm socket); 65 in·lbs

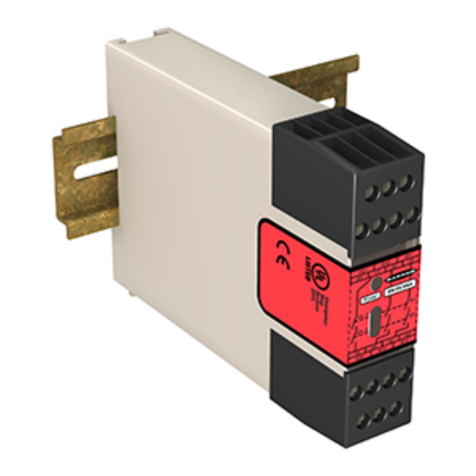

EZLSA-MBK-HTE-2

• Cast, hygienic swivel bracket

• Polished 316 stainless steel with

rounded edges for cleanliness in

demanding environments

• Non-metallic FDA compliant bushing

• M10 mount on opposite side of clamping

nuts

• Two brackets included per kit

• 5/16 inch - 18 UNC screws (9/16 inch

socket); 65 in·lbs

All measurements are listed in millimeters, unless noted otherwise.

Banner Engineering Corp. Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp. will repair or replace, free of charge, any

product of its manufacture which, at the me it is returned to the factory, is found to have been defecve during the warranty period. This warranty does not cover damage or liability for misuse, abuse, or the

improper applicaon or installaon of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discreon of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR

ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO

USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligaons or liabilies relang to any product previously manufactured by Banner

Engineering Corp. Any misuse, abuse, or improper applicaon or installaon of this product or use of the product for personal protecon applicaons when the product is idened as not intended for such purposes

will void the product warranty. Any modicaons to this product without prior express approval by Banner Engineering Corp will void the product warranes. All specicaons published in this document are subject

to change; Banner reserves the right to modify product specicaons or update documentaon at any me. Specicaons and product informaon in English supersede that which is provided in any other language.

For the most recent version of any documentaon, refer to: www.bannerengineering.com.

EZ-SCREEN LS Safety Light Curtain in an IP69K Hygienic Housing

©Banner Engineering Corp. All rights reserved