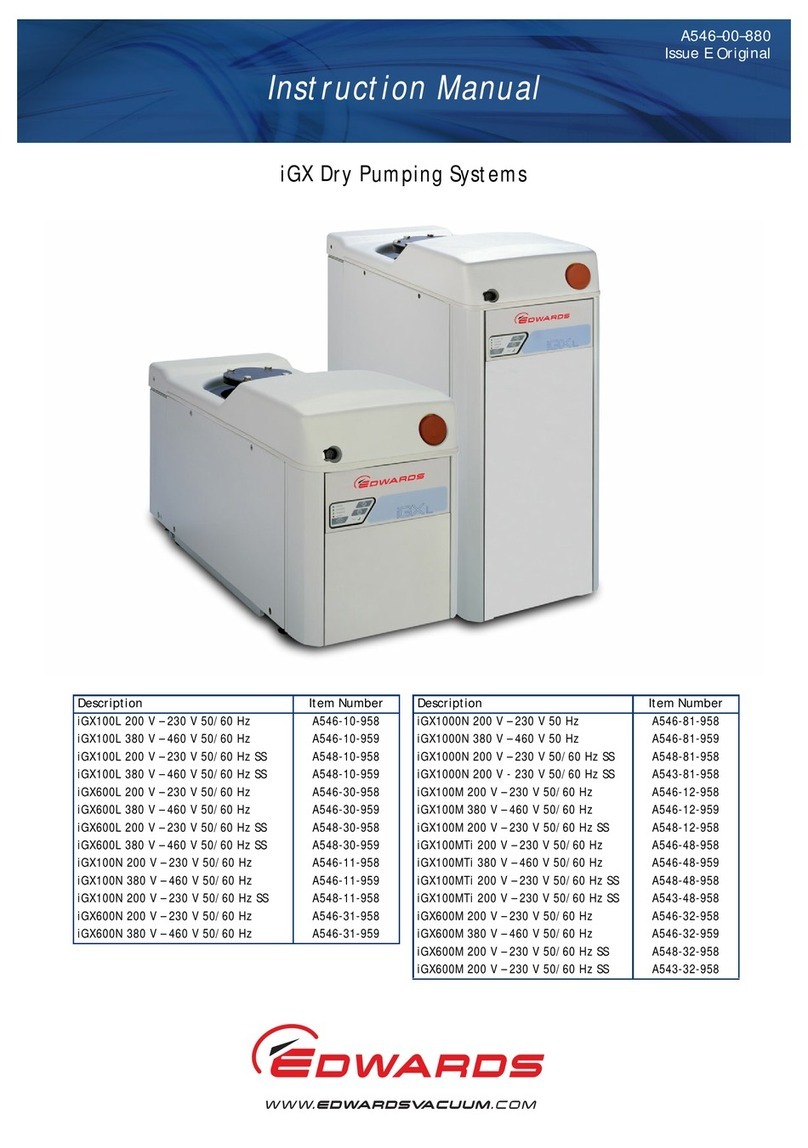

Edwards iGX Series User manual

A546–00–880

Issue C Original

Instruction Manual

iGX Dry Pumping Systems

Description Description

iGX100L 200 V – 230 V 50/60 Hz A546-10-958

iGX100L 380 V – 460 V 50/60 Hz A546-10-959

iGX100L 200 V – 230 V 50/60 Hz SS A548-10-958

iGX100L 380 V – 460 V 50/60 Hz SS A548-10-959

iGX600L 200 V – 230 V 50/60 Hz A546-30-958

iGX600L 380 V – 460 V 50/60 Hz A546-30-959

iGX600L 200 V – 230 V 50/60 Hz SS A548-30-958

iGX600L 380 V – 460 V 50/60 Hz SS A548-30-959

iGX100N 200 V – 230 V 50/60 Hz A546-11-958

iGX100N 380 V – 460 V 50/60 Hz A546-11-959

iGX100N 200 V – 230 V 50/60 Hz SS A548-11-958

iGX600N 200 V – 230 V 50/60 Hz A546-31-958

iGX600N 380 V – 460 V 50/60 Hz A546-31-959

Description Description

iGX1000N 200 V – 230 V 50 Hz A546-81-958

iGX1000N 380 V – 460 V 50 Hz A546-81-959

iGX1000N 200 V – 230 V 50/60 Hz SS A548-81-958

iGX100M 200 V – 230 V 50/60 Hz A546-12-958

iGX100M 380 V – 460 V 50/60 Hz A546-12-959

iGX100M 200 V – 230 V 50/60 Hz SS A548-12-958

iGX100MTi 200 V – 230 V 50/60 Hz A546-48-958

iGX100MTi 380 V – 460 V 50/60 Hz A546-48-959

iGX100MTi 200 V – 230 V 50/60 Hz SS A548-48-958

iGX600M 200 V – 230 V 50/60 Hz A546-32-958

iGX600M 380 V – 460 V 50/60 Hz A546-32-959

iGX600M 200 V – 230 V 50/60 Hz SS A548-32-958

Declaration of Conformity

We, Edwards,

ManorRoyal,

Crawley,

WestSussexRH109LW,UK

declare under our sole responsibility that the product(s):

iGX100L 200-230V 50/60Hz A546-10-958 iGX100N 200-230V 50/60Hz A546-11-958 iGX100M 200-230V 50/60Hz A546-12-958

iGX100L 380-460V 50/60Hz A546-10-959 iGX100N 380-460V 50/60Hz A546-11-959 iGX100M 380-460V 50/60Hz A546-12-959

iGX100L 200-230V 50/60Hz SS A548-10-958 iGX100N 200-230V 50/60Hz SS A548-11-958 iGX100M 200-230V 50/60Hz SS A548-12-958

iGX100 380-460V 50/60Hz SS A548-10-959 iGX600N 200-230V 50/60Hz A546-31-958 iGX100MTi 200-230V 50/60Hz A546-48-958

iGX600L 200-230V 50/60Hz A546-30-958 iGX600N 380-460V 50/60Hz A546-31-959 iGX100MTi 380-460V 50/60Hz A546-48-959

iGX600L 380-460V 50/60Hz A546-30-959 iGX1000N 200-230V 50/60Hz A546-81-958 iGX100MTi 200-230V 50/60Hz SS A548-48-958

iGX600L 200-230V 50/60Hz SS A548-30-958 iGX1000N 380-460V 50/60Hz A546-81-959 iGX600M 200-230V 50/60Hz A546-32-958

iGX600L 200-230V 50/60Hz SS A548-30-959 iGX1000N 200-230V 50/60Hz SS A548-81-958 iGX600M 380-460V 50/60Hz A546-32-958

iGX600M 200-230V 50/60Hz SS A548-32-958

to which this declaration relates is in conformity with the following standard(s) or other normative document(s):

EN1012-2 (1997) Compressor and Vacuum Pumps Safety Requirements; Part 2 - Vacuum Pumps.

EN61010-1 (2001) Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use; Part 1 – General Requirements.

EN61326 (1998 + A2:2001) Electrical Equipment for Measurement, Control and Laboratory Use – EMC Requirements (Industrial locations immunity – Class A

equipment emissions).

when installed in accordance with the instruction manual supplied with the pump,

following the provisions of:

73/023/EEC Low Voltage Directive.

89/336/EECElectromagneticCompatibilityDirective.

98/37/EC MachinerySafetyDirective.

28th July 2007, Shoreham

Dr S.E. Ormrod, Technical Director Date and Place

This product has been manufactured under a quality system registered to ISO9001

P200-01-960 Issue A

P601-00-700

Issue C

Product Manual Addendum - Equipment types:

iH Vacuum Pump Range GX Vacuum Pump Range DiHxK Vacuum Pump Range

iF Vacuum Pump Range iHxK Vacuum Pump Range DiFxK Vacuum Pump Range

iGX Vacuum Pump Range iFxK Vacuum Pump Range EPX Vacuum Pump Range

IPX Vacuum Pump Range iQ/QDP/QMB Vacuum Pump

Ranges iL Vacuum Pump Range

Product Label Overshipper Label Pallet Marking

Indicates toxic or hazardous substance

contained in at least one of the homogeneous

materials used for this part is above the limit

requirement in SJ/T11363-2006.

Environmental Protection Period is 20 years

Recyclable Cardboard Recyclable Natural Wood

Materials Content Declaration & Environmental Protection Use Period

The Chinese regulatory requirement on the Control of Pollution Caused by Electronic Information

Products No. 39 (also known as ‘China RoHS’) mandates that manufacturers of certain categories of

electronic products sold in China after 1st March 2007 –

•Mark the product and packaging

•Define the Product’s Environment Protection Use Period (EPUP)

•Provide a Materials Content Declaration.

Environmental Protection Use Period (EPUP)

This is the period in years during which the toxic or hazardous substances or elements contained in

this product will not leak or mutate under normal operating conditions so that the use of such

electronic information products will not result in any severe environmental pollution, any bodily injury

or damage to any assets.

The Environmental Protection Use Period is 20 years for this product.

For the purposes of EPUP, normal operating conditions are considered to be use in accordance with

the product’s instruction manual.

Materials Content Declaration

Toxic or Hazardous Substances and Elements

Part name

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium (Cr

(VI))

Poly

brominated

biphenyls

(PBB)

Poly brominated

diphenyl ethers

(PBDE)

Cartridge O O x x O O

Enclosure O O x x O O

Electronics and

Controls X O x x O O

Cooling System O O x x O O

Purge System O O x x O O

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this

part is below the limit requirement in SJ/T11363-2006.

X: Indicates that this toxic or hazardous substance contained in at least one of the homogeneous materials

used for this part is above the limit requirement in SJ/T11363-2006.

Note 1. Table applies to all product types listed above.

2020

NWNWCBCB

This page intentionally blank.

© Edwards Limited 2008. All rights reserved. Page i

Edwards and the Edwards logo are trade marks of Edwards Limited.

Contents

A546–00–880 Issue C

Contents

Section Page

1Introduction.......................................................................................1

1.1 Scope and definitions ................................................................................................... 1

1.2 Applications ............................................................................................................... 2

1.3 The iGXL system ......................................................................................................... 2

1.4 Priority of control ........................................................................................................ 4

1.5 Active utility control .................................................................................................... 5

2TechnicalData....................................................................................7

2.1 General technical data .................................................................................................. 7

2.2 Electrical Data ........................................................................................................... 8

2.3 Loading .................................................................................................................... 8

2.4 Connections ............................................................................................................... 9

2.5 General Data ............................................................................................................10

3 Installation ....................................................................................... 11

3.1 Locate the dry pumping system ......................................................................................12

3.2 Lubrication ...............................................................................................................13

3.3 Connect the iGX system to your vacuum/exhaust system and interstage connection (if fitted) ...........13

3.4 Connect to your factory extraction system (optional) ............................................................14

3.5 Connect the nitrogen supply (if provided) .......................................................................... 14

3.5.1 Flammable/pyrophoric materials ....................................................................................14

3.5.2 Gas Purges ............................................................................................................... 15

3.6 Leak-test the iGX system ..............................................................................................15

3.7 Connect the electrical supply .........................................................................................16

3.8 Connect an additional RF earth (ground) (optional) ..............................................................18

3.9 Connect to your emergency stop circuit ............................................................................18

3.10 Connect the cooling-water hoses .....................................................................................19

3.11 Accessories ...............................................................................................................19

3.12 Commission the iGX system ...........................................................................................20

3.13 Install additional safety equipment ..................................................................................22

4OPERATION......................................................................................23

4.1 Start-up ..................................................................................................................23

4.2 Status indicators ........................................................................................................24

4.3 Manual shut-down ......................................................................................................24

4.4 Automatic shut-down ..................................................................................................25

4.5 Unplanned shutdown and alarms .....................................................................................25

4.6 Emergency stop .........................................................................................................25

4.7 Restart the pump after an emergency stop or automatic shut-down ..........................................26

4.8 Single equipment monitor (SEM) .....................................................................................26

5MAINTENANCE...................................................................................27

5.1 Safety and maintenance frequency ..................................................................................27

5.2 Relocate the system for maintenance ...............................................................................28

5.3 Draining the cooling-water ............................................................................................29

5.4 Cleaning the pump ......................................................................................................30

6TRANSPORTATION,STORAGEANDDISPOSAL...............................................31

6.1 Transportation ..........................................................................................................31

6.2 Storage ...................................................................................................................31

DJD 30/05/08

A546–00–880 Issue C

Page ii © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trade marks of Edwards Limited.

Contents

6.3 Disposal ................................................................................................................... 31

7 SERVICE, SPARES AND ACCESSORIES ......................................................... 33

7.1 Introduction .............................................................................................................33

7.2 Service .................................................................................................................... 33

7.3 Ordering accessories ...................................................................................................34

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1iGXApplicationschart..................................................................................................2

2Thecontrols/connectors................................................................................................3

3TherearstatuspanelLEDindicators.................................................................................4

4Thefrontpanelcontrols................................................................................................4

5Priorityofcontrol........................................................................................................5

6Centreofgravityandlevellingfootloads...........................................................................8

7Systemarrangmenttoreduceeffective footprint (if required) .................................................12

8Highandlowvoltcodingpinarrangement.........................................................................17

9Methodforconnectingphasewires..................................................................................18

10 Connections to emergency stop circuit (systemable) .............................................................18

11 Installing 3/8" quick connect fittings (provided) ................................................................... 20

12 Gas module access panel ..............................................................................................21

13 Flow tube (14 slm) ......................................................................................................21

14 Flow tube (4 slm) .......................................................................................................22

© Edwards Limited 2008. All rights reserved. Page iii

Edwards and the Edwards logo are trade marks of Edwards Limited.

Contents

A546–00–880 Issue C

Tables

Table Page

1Technicaldata...........................................................................................................7

2Technicaldata...........................................................................................................7

3Electricaldata............................................................................................................8

4Centreofgravityandlevelling foot loads (Refer to Figure 6) .................................................... 8

5iGXconnectortypes.....................................................................................................9

6Technicaldata..........................................................................................................10

7Safetysensors...........................................................................................................25

8Accessories...............................................................................................................34

Associated publications

Publication title Publication number

Vacuum pump and vacuum system safety P300–20–000

This page has been intentionally left blank.

A546–00–880 Issue C

Page iv © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trade marks of Edwards Limited.

© Edwards Limited 2008. All rights reserved. Page 1

Edwards and the Edwards logo are trade marks of Edwards Limited.

Introduction

A546–00–880 Issue C

1Introduction

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards iGX dry pumping systems.

You must use your pump as specified in this manual.

Read this manual before you install and operate your pump. Important safety information is highlighted as WARNING

and CAUTION instructions; you must obey these instructions. The use of WARNINGS and CAUTIONS is defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

The units used throughout this manual conform to the SI international system of units of measurement

In accordance with the recommendations of IEC1010, the following warning labels are on the pump:

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Warning – refer to accompanying

documentation. Warning – risk of electric shock.

Warning – hot surfaces. Warning – moving parts present.

Warning – heavy object. Warning - pressurised.

RF earth (ground). Protective earth (ground).

Warning - use protective equipment. Warning - Risk of explosion.

A546–00–880 Issue C

Page 2 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trade marks of Edwards Limited.

Introduction

The Pressurised and Risk of explosion warnings only appear in this manual.

Material Safety Data Sheets for chemicals supplied by Edwards can be obtained by contacting Edwards.

1.2 Applications

If you use the iGX system on an application for which it is not suitable (refer to Figure 1), you may invalidate your

warranties. If in doubt, contact Edwards who will advise you as to the suitability of the iGX system for any particular

application.

Figure 1 - iGX Applications chart

1.3 The iGXL system

Pumping a chemical that will attack the materials in contact with these process materials may, over time, result in the

internal contents of the pump becoming exposed to the external environment, which may constitute a safety hazard.

If in doubt, contact Edwards who will advise you as to the suitability of this pump for any particular application.

It is also a feature of this pump design that process gases are contained within the gearbox. This pump is not suitable

for use with flammable, hazardous, toxic or corrosive gases or material.

© Edwards Limited 2008. All rights reserved. Page 3

Edwards and the Edwards logo are trade marks of Edwards Limited.

Introduction

A546–00–880 Issue C

Figure 2 - The controls/connectors

Item Control/connector

identification Item Control/connector

identification Item Control/connector

identification Item Control/connector

identification

1Protectiveearth(ground)

M5

8Comms2-LONmodule

connection

15 Lifting eyebolt 22 Cooling-water supply

connection

2Electricalsupply

connection

9Comms1-Systemcontrol/

PDT 2 connection

16 Pumped gas inlet

connection

23 Castors (3 off)

3Rearstatuspanel10Gatevalveinterface(EMO

on T variant)

17 RF earth (ground) cable 24 Levelling feet (4 off)

4 Comms 4 - MicroTIM

connection (if fitted)

11 EMS* 18 Interstage connection (if

fitted)

25 Cooling-water return

connection

5 Ethernet active LED 12 Accessory module

interface*

*not on T variants

19 Seismic bracket (if fitted, 4

off)

26 RF earth (ground) stud M6

6EthernetinstalledLED13 GRCinterface* 20Gas Module access panel 27 Exhaust gas outlet

connection

7Comms3Ethernet

connection

14 Extraction port 21 Nitrogen purge port 28 Leak-test port

A546–00–880 Issue C

Page 4 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trade marks of Edwards Limited.

Introduction

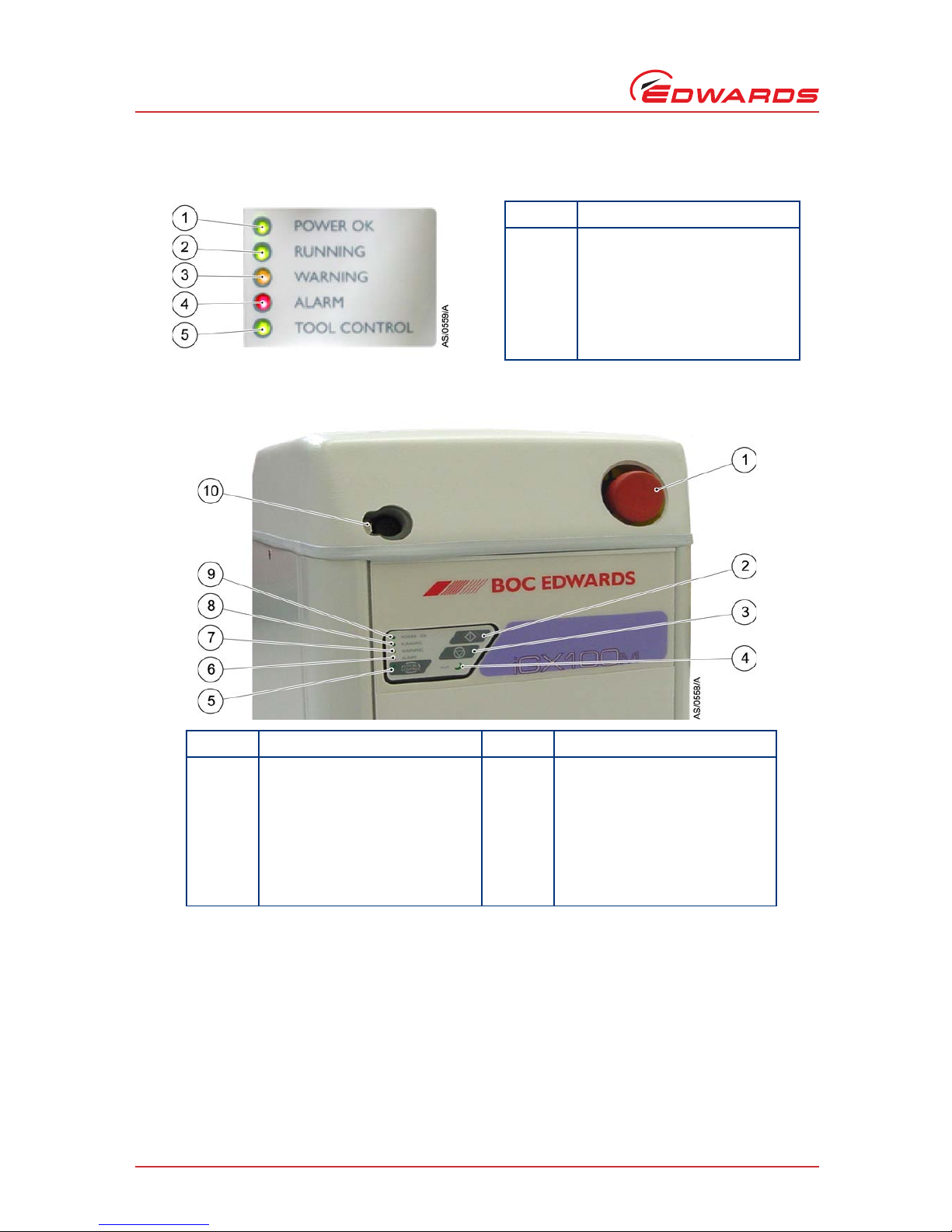

Figure 3 - The rear status panel LED indicators

Figure 4 - The front panel controls

1.4 Priority of control

The iGX system can be controlled by a number of modules: the Pump Display Terminal (PDT), from the tool through

the MicroTIM, or from the front panel local control membrane (refer to Figure 4). Only one of these can have control

of the iGX system at any one time. That is, once one of these has control of the iGX system, control requests from

the other are denied.

The PDT indicates who is in control. LEDs are also provided on the rear panel, front panel or PDT, which illuminate

to indicate 'in control'. Please refer to Figure 5.

Item Indication

1Power OK (green)

2Running (green)

3Warning (Amber)

4Alarm (Red)

5To o l c o n t r o l ( G r e e n )

Item Indication Item Indication

1EMSbutton

*

*Not on T variants

6AlarmLED(red)

2 Start button 7 Warning LED (amber)

3Stopbutton 8RunningLED(green)

4AUCLED(green) 9PowerOKLED(green)

5Localcontrolbutton/LED(green) 10Comms5pumpdisplayterminal

(PDT 1) connection

© Edwards Limited 2008. All rights reserved. Page 5

Edwards and the Edwards logo are trade marks of Edwards Limited.

Introduction

A546–00–880 Issue C

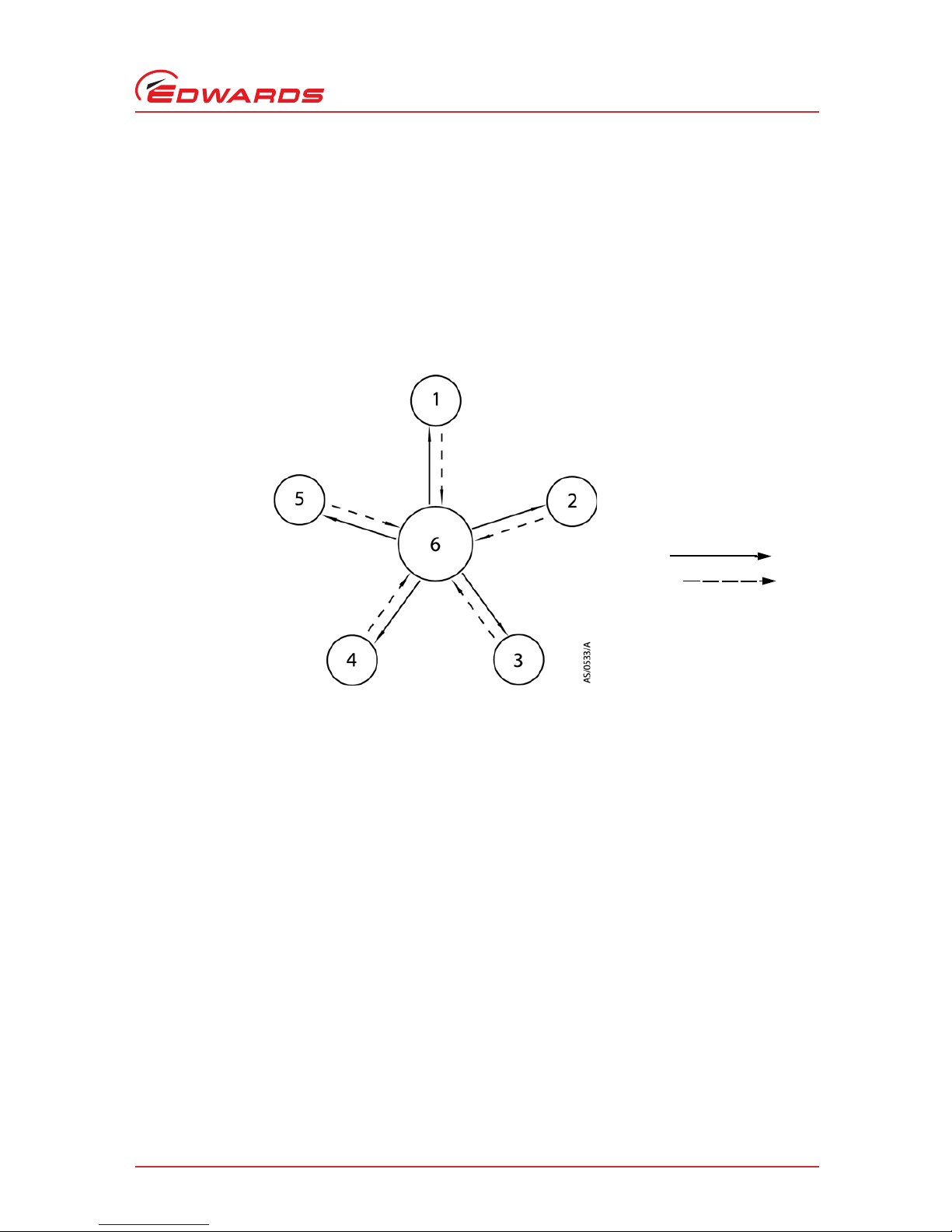

1.5 Active utility control

Active Utility Control (AUC) is available on the iGX system. This function reduces the power of the iGX system while

on stand-by. The power reduction is achieved by reducing the rotational speed of the iGX pump. This function also

reduces the nitrogen purge of M variant systems while in stand-by mode.

Advanced Active Utility Control (AAUC) is also available. This function, in addition to AUC, can reduce the water flow

of the iGX system while on stand-by, therefore allowing further reductions in power. Contact Edwards for advice.

The AUC functionality is controlled by the on/off process signal from the Tool Interface Module (TIM).

Figure 5 - Priority of control

1. PDT 1

2. PDT 2

3. System controller

4. Tool

5. Front panel

6. None in control

Take

Release

A546–00–880 Issue C

Page 6 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trade marks of Edwards Limited.

This page has been intentionally left blank.

© Edwards Limited 2008. All rights reserved. Page 7

Edwards and the Edwards logo are trade marks of Edwards Limited.

Technical Data

A546–00–880 Issue C

2TechnicalData

2.1 General technical data

Tab l e 1 - Tech n i ca l d ata

Type Characteristics 100 300 600 1000 Units

General Dimensions (L x W x H)*

*Refer to Web for installation drawings

695 x 280

x 395

695 x 280

x 695

695 x 280

x 695

695 x 280

x 695

mm

Mass (excluding packaging) 120 200 220 230 kg

Noise level (at ultimate)†

†Check valve accessory fitted

< 60 < 55 < 55 < 55 dB(A)

Vibration level at inlet < 1.5 < 1.5 < 1.5 < 1.5 mm s-1

Vibration to the floor (when docked) < 0.05 < 0.05 < 0.05 < 0.05 mm s-1

Initial force to push the pump 0.06 0.09 0.10 0.11 kN

Sustained force to push the pump 0.04 0.06 0.07 0.07 kN

Warm up time to nominal pumping

performance

15 15 15 15 minute

s

Minimum warm up time to process gas

pumping

2222hours

Performance Typical to peak pumping speed (no gas

purge/cold pump)

100 300 600 800 m3h-1

Ultimate (shaft seal purge only) 0.005 0.0007 0.0007 0.0007 mbar

Water-cooling

system

Minimum flow rate required 1222lmin

-1

Typical heat removed from the system 1 1.6 1.6 1.7 kW

Connections Pump inlet flange (bolted) ISO63 ISO63 ISO100 ISO100

Exhaust gas outlet NW25 NW25 NW25 NW25

Extraction port 50 50 50 50 mm dia

Tab l e 2 - Tech n i ca l d ata

Type Characteristics L N M Units

Gas system Nitrogen supply pressure range 2.5 to 6.9 2.5 to 6.9 bar gauge

Stability of supply 1.4 1.4 bar gauge

Nitrogen supply quality <0.01 <0.01 m

Nitrogen flow rate 14 44 slm

Gas module pressure 22bargauge

Pressure transducer accuracy 0.04 @ 0.41 bar gauge

Mass flow transducer accuracy 4.3 slm

Interstage (I) Peak pumping speed, interstage 25 25 m3h-1

Ultimate, interstage 0.1 0.5 mbar

Pump interstage flange NW16 NW16

A546–00–880 Issue C

Page 8 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trade marks of Edwards Limited.

Technical Data

2.2 Electrical Data

2.3 Loading

Figure 6 - Centre of gravity and levelling foot loads

Tab l e 3 - E lec t ric a l dat a

Supply voltage and frequency 200/230 50/60 Hz 380/460 50/60Hz

100 300 600 1000 100 300 600 1000

Full load (A) 12 22 22 22 8 14 14 14

Booster motor rating (kW) 1.9 1.9 1.9 1.9 1.9 1.9

Pump motor rating (kW) 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.9

Tab l e 4 - Cen t re of g rav i t y and l e ve lling foot loads (Refer to Figure 6)

100 300 600 1000

Centre of gravity

A510 510 510 510

B246 266 243 243

C103 107 108 108

D216 216 216 216

E167 287 311 310

Levelling foot loads

126 45 56 56

235 58 55 55

328 43 61 61

431 54 48 48

© Edwards Limited 2008. All rights reserved. Page 9

Edwards and the Edwards logo are trade marks of Edwards Limited.

Technical Data

A546–00–880 Issue C

2.4 Connections

Table 5 - iGX connector types

Description Mating connector description/

external supply rating Internal supply rating

PDT1 XLR type 5-way plug 24 V d.c. 0.75 A

Mains connection Weidmuller HDC 16D free socket, PG21, 6

mm2

stranded wire, 13-18 mm cable OD

Ethernet connection Standard RJ45 type or Neutrik Ethercon

RJ45

IEE802.3 10BaseT Ethernet

LON module connection XLR type 4-way plug 24 V d.c. 0.75 A

PDT2 XLR type 5-way plug 24 V d.c. 0.75 A

Gate valve interface* CPC 9-way plug, standard gender, socket

contacts

24 V d.c. (48 V peak), 100 mA

EMO (on T variant only)

6 - common and 7 - normally closed

CPC 7-way plug, standard gender, socket

contacts 30 V d.c. 0.5 A

EMS* XLR type 6-way plug

External emergency stop switch

1 - supply, 2 - return

24 V d.c. 100 mA

Internal emergency stop switch

3 - common, 4 - normally open

30 V a.c. 1 A

60 V d.c. 0.55 A

Comms supply

5 - supply, 6 - return

24 V d.c. 0.5 A

Accessory module interface* Preh locking DIN 8-way plug 24 V d.c. 1.3 A

GRC interface* DIN type 6-way plug

1 - Normally open and 3 - common 30 V a.c. 1 A

2 - Normally open and 4 - normally

closed

30 V d.c. 1 A

5 - Normally open and 6 - common 60 V d.c. 0.5 A

A546–00–880 Issue C

Page 10 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trade marks of Edwards Limited.

Technical Data

2.5 General Data

Tab l e 6 - Tech n i ca l d ata

Item Description Rating Units

Electrical Supply voltage 3-phase 200/230 V, 50/60 Hz a.c. 380/460 V,

50/60 Hz a.c.

V

Recommended fuse/isolator rating Full load current rating, refer to

Ta b l e 3 .

Class CC fuse rated to 600 V.

Voltage tolerance range + 10% V

Installation category II (IEC 664)

Earth leakage 6 mA

Harmonic voltage distortion factor 5%

Water-cooling system Maximum supply pressure 100 psig

Minimum supply pressure 36 psig

Minimum flow rate required Refer to Ta b l e 1 l min-1

Cooling-water supply temperature

range

10 - 30 °C

Maximum particle size 0.03 mm2

Acidity 6.5 to 8.0 pH

Hardness < 100 ppm

Resistivity > 1 k cm

Solids (turbidity) < 100 ppm

Materials in contact with cooling-

water

Stainless steel, PTFE, copper, brass

and fluoroelastomer.

Connections Cooling-water ¼” BSPT male

Nitrogen ¼” tube fitting

Materials in contact with

process gas

Pump, shafts and rotors Cast SG iron, steel, aluminium

Seals PTFE and fluoroelastomer

Operating conditions Intended Use: Indoor use

Ambient temperature range:

Operating +5 to +40 °C

Storage -45 to +55 °C

Relative humidity 10 to 90 %

Maximum operating altitude 2000 m

Pollution degree 2 (IEC 61010)

© Edwards Limited 2008. All rights reserved. Page 11

Edwards and the Edwards logo are trade marks of Edwards Limited.

Installation

A546–00–880 Issue C

3 Installation

Potential hazards on the dry pumping system include electricity, hot surfaces, process chemicals, Fomblin®oil,

nitrogen and water under pressure.

Detailed safety information is given in Edwards Publication Number P300-20-000 'Vacuum Pump and Vacuum System

Safety'.

Only Edwards engineers may install the dry pumping system. Users can be trained by Edwards to conduct the

tasks described in this manual, contact your local service centre or Edwards for more information.

Do not remove the temporary cover or blanking plate from the dry pumping system inlet and exhaust until

you are ready to connect the dry pumping system to your vacuum or exhaust-extraction system. Do not

operate the dry pumping system unless the inlet and exhaust are connected to your vacuum and exhaust-

extraction system.

Vent and purge the process system (if the dry pumping system is to replace an existing pumping system) with

nitrogen for 15 minutes before you start installation work. Refer to Section 4.

Disconnect the other components in the process system from the electrical supply so that they cannot be

operated accidentally.

Electrical, nitrogen and water supplies are all potentially hazardous energy sources. Before carrying out any

maintenance the supply of these sources should be locked and tagged out.

Route and secure cables, hoses and pipework during installation to avoid possible trip hazards.

The pump system includes provision for ventilation extraction and secondary containment of oil and water

leaks. Any unintended overflows or spills must be removed immediately to avoid risk of slips.

Obey all national and local rules and safety regulations when you install the dry pumping system. Consult

Edwards Publication Number P300-20-000 (Vacuum Pump and Vacuum System Safety) before you pump

hazardous materials. This publication is available on request: contact your supplier or Edwards.

WARNING

Obey the safety instructions given below and take the appropriate precautions. If you do not, you

can cause injury to people and damage to equipment.

WARNING

The system should not be operated with the Edwards panels removed.

A546–00–880 Issue C

Page 12 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trade marks of Edwards Limited.

Installation

3.1 Locate the dry pumping system

Use the following procedure to locate the iGX system in its operating position. The iGX system must be located on a

firm, level surface, to ensure that the system is not damaged.

1. Use suitable lifting equipment (refer to Figure 2) attached to the lifting eyebolt (15) to move the iGX system

close to its final operating position.

2. Adjust the levelling feet (24) to make sure that the iGX system is level and is not supported by the castors. The

lifting eyebolt must be retained for future use with this system.

3. If required, the iGX system can be secured to the floor by fitting suitable bolts or studs (not supplied) through

the M10 docking points on the chassis.

If vibration transmission to the floor is a concern, suitable vibration isolators (not supplied) should be fitted

between the docking points and the bolt or stud, if doing this the levelling feet will need to be removed.

4. If preferred, the lifting eyebolt can be removed and replaced with the lifting eyebolt hole plug supplied with the

systems.

5. Ensure that access is possible to the emergency stop button (refer to Figure 4, item 1), if not use an iGX

Disconnect Box (refer to Section 7.3).

Figure 7 - System arrangment to reduce effective footprint (if required)

If you want to secure the iGX in place to prevent inadvertent movement (for example, during an earthquake), take

note of the following:

The iGX system seismic brackets (Figure 2, item 19) are designed to withstand a level 4 earthquake in a

ground floor installation.

WARNING

You must use suitable lifting equipment to move the system. It is too heavy to lift by hand.

WARNING

Do not exceed the topple angle of 10 ° when moving the pump. Wheel the system on its castors to

move it into its operating position. The system should only be wheeled short distances over flat

surfaces. If the floor surface is uneven or has obstacles the system should be lifted with suitable

lifting equipment.

This manual suits for next models

8

Table of contents

Other Edwards Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Pacific Image Electronics

Pacific Image Electronics RapidScan ST-5 Series user manual

Sartorius

Sartorius Vivacon 500 operating instructions

Conviron

Conviron GEN1000-GE Operator's manual

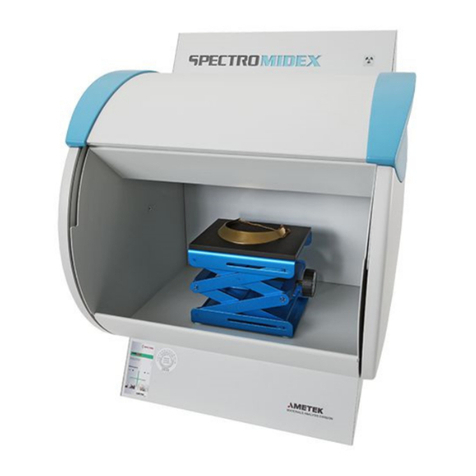

Ametek

Ametek SPECTRO MIDEX MID04 Original operating instructions

Deltec

Deltec AR 2000 Operating instruction

Mi-T-M

Mi-T-M AW-3000-0000 manual