© 2019 United Technologies Corporation 1 / 3 P/N P-047550-1788-EN • REV 013 • ISS 08SEP19

SIGA-IM Isolator Module

Installation Sheet

Description

The SIGA-IM Isolator Module is an addressable device that protects a

signaling line circuit (SLC) from a wire-to-wire short. The SIGA-IM

module monitors line voltages and opens the SLC when a short is

detected, effectively isolating the short between the two isolator

modules located electrically closest to the short.

The SIGA-IM module requires one detector address on the SLC.

Addresses are assigned electronically. There are no address switches.

An LED provides visible indication of the status of the module:

• Normal: Green LED flashes

Installation

Install this device in accordance with applicable national and local

codes, ordinances, and regulations.

• NFPA 72 2013 – A single fault on a pathway connected to the

addressable devices shall not cause the loss of more than 50

addressable devices.

• NFPA 72 2016 – A single fault on a pathway connected to the

addressable devices shall not cause the loss of the devices in

more than one zone.

Notes

• The module is shipped from the factory as an assembled unit; it

contains no user-serviceable parts and should not be

disassembled.

• This module does not operate without electrical power. As fires

frequently cause power interruption, discuss further safeguards

with your local fire protection specialist.

To install the module:

1. Write the address assigned to the module on the label provided,

and then apply the label to the module. Remove the serial number

label from the module, and then attach it to the project

documentation.

2. Wire the module as shown in Figure 2 on page 2.

3. Using the self-tapping screw provided, attach the wall plate to the

module. See Figure 1.

4. Using the four machine screws provided, attach the wall plate and

module to the electrical box.

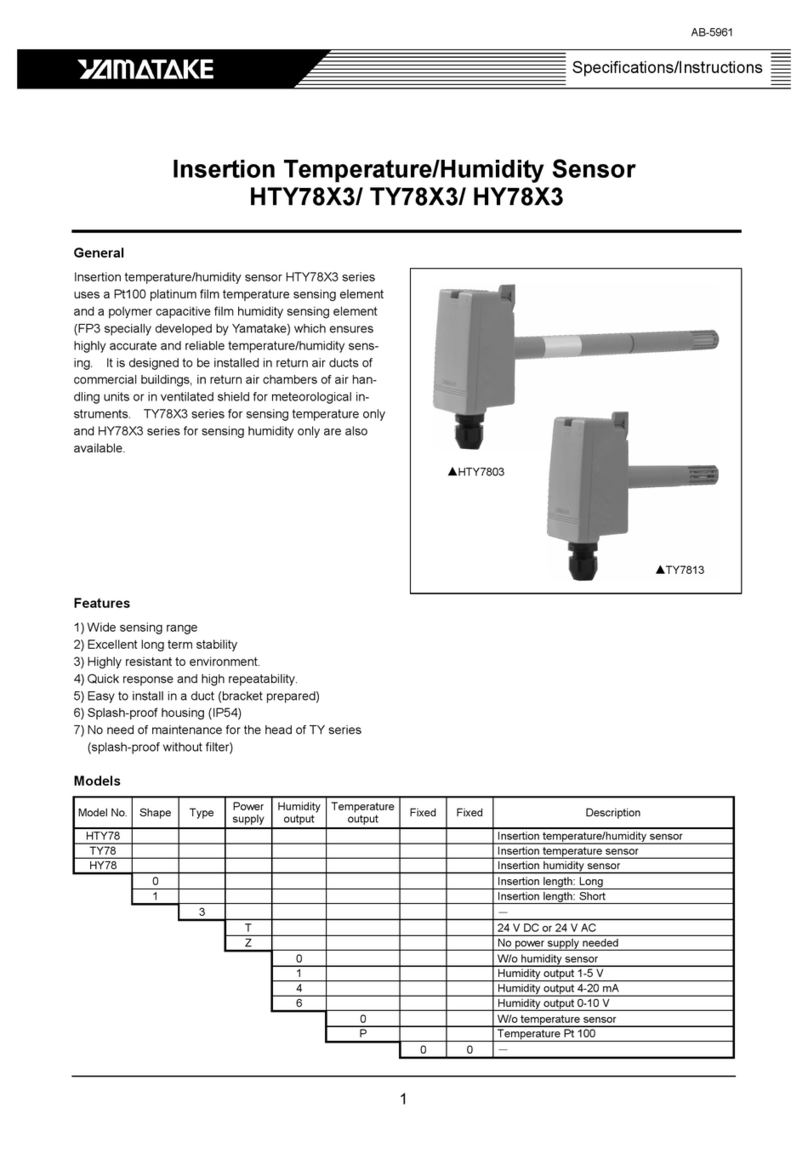

Figure 1: Installation diagram

(1) Compatible electrical box

(2) SIGA-IM module

(3) Wall plate

(4) #6-32 × 5/8 machine screws (4X)

(5) #4 × 1/2 self-tapping screw

Wiring

Wire this device in accordance with applicable national and local

codes, ordinances, and regulations.

Notes

• Refer to the Signature loop controller installation sheet for SLC

wiring specifications for additional details.

• All wiring is power-limited and supervised.

To wire the module:

1. Verify that all field wiring is free of opens, shorts, and ground

faults.

2. Strip 1/4 in. (about 6 mm) from the ends of all wires that connect to

the terminal block of the module.

When stripping wire ends, exposing more wire may cause a

ground fault; exposing less wire may result in a faulty connection.

3. Make all wiring connections as shown in Figure 2.

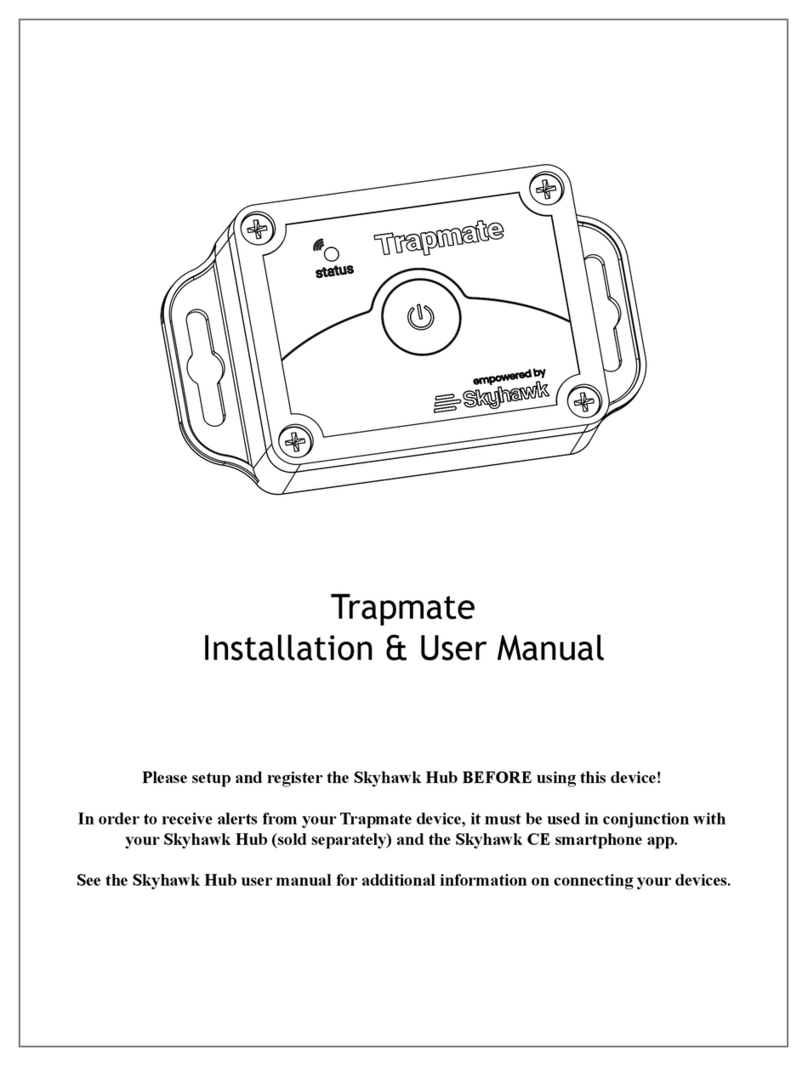

Figure 2: Wiring diagram

(1)

(2)

(3)

(4)

(5)

SLC