© 2018 United Technologies Corporation 1 / 2 P/N 3102363-EN • REV 004 • ISS 16FEB18

SIGA-PHD(B) Intelligent

Multisensor Photo-Heat

Detector Installation Sheet

Description

The Signature Series SIGA-PHD(B) Intelligent Multisensor Photo-Heat

Detector is an intelligent device that contains a photoelectric smoke

sensor and a rate-of-rise heat sensor with a fixed temperature setting.

The detector analyzes the data from both sensing devices and

determines whether an alarm should be initiated. Can be operated as a

single detector using smoke or heat to initiate an alarm or as a split

sensor with heat and smoke initiating separate signals.

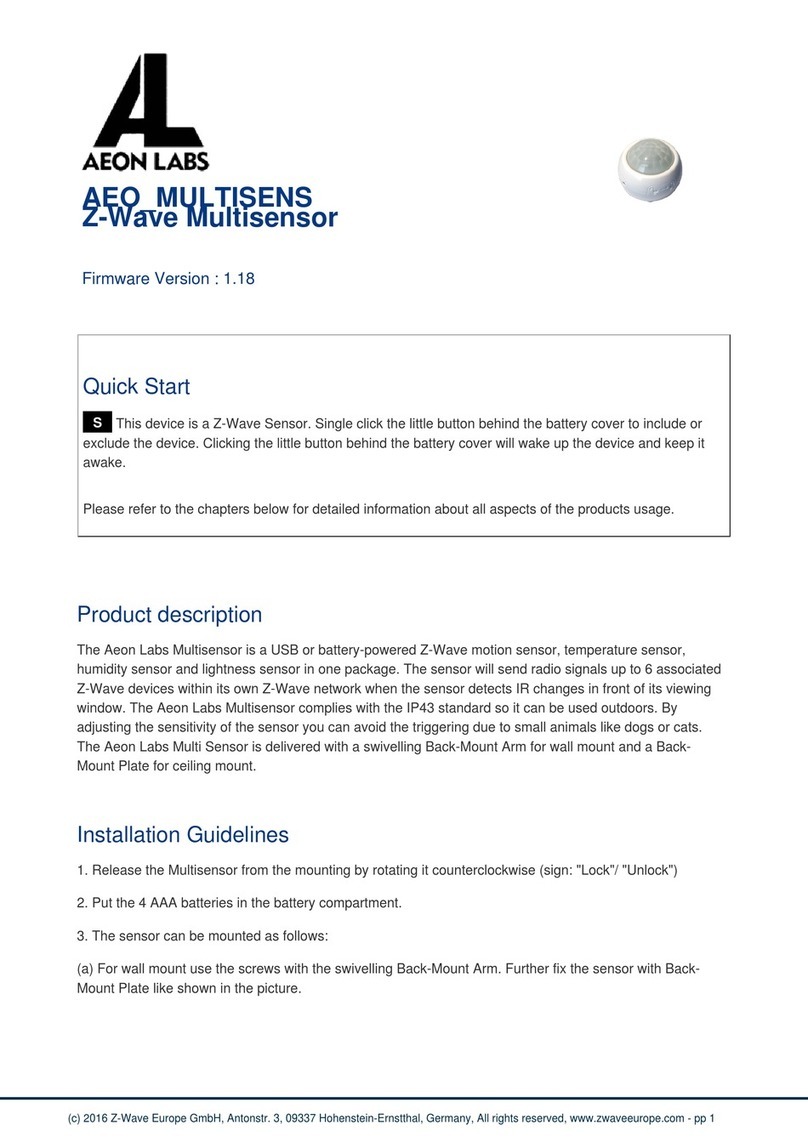

LED indicator. The LED indicator (see Figure 1 below) displays the

following states:

•Normal: Green LED indicator flashes, no action.

•Alarm/active: Red LED indicator flashes, evacuate the area.

Figure 1: SIGA-PHD(B) features

1. Self-locking tab

2. LED indicator

Installation

Notes

•This detector does not operate without electrical power. As fires

frequently cause power interruption, discuss further safeguards

with the local fire protection specialist.

•This detector does not sense fires in areas where smoke or heat

cannot reach the detector. Smoke or heat from fires in walls, roofs,

or on the opposite side of closed doors may not reach the detector.

•Photoelectric detectors have a wide range of sensing capabilities,

and are best suited for detecting slow, smoldering fires. The heat

sensor in this device provides a source of supplemental

information. The heat sensor by itself does not provide life safety

protection.

•To ensure proper operation, store the detector within the

recommended ranges. Allow the detector to stabilize to room

temperature before applying power.

•The dust cover (supplied) must remain on the detector during

installation and be removed prior to commissioning and service.

The dust cover is not a substitute for removing the detector during

new construction or heavy remodeling.

•Do not use smoke detectors with detector guards unless the

combination has been evaluated and found suitable.

•In Canada, install according to the CAN/ULC-S524 Standard for

the Installation of Fire Alarm Systems, the CSA C22.1 Canadian

Electrical Code, and the local authority having jurisdiction.

•Upon completion of the original installation and following any

modifications or additions to the system, perform a calibrated

sensitivity test per NFPA code. Signature Series devices can

perform this test and the panel can generate a system sensitivity

report.

To install the detector:

1. Install and wire the base, as described on the installation sheet

supplied with the base.

2. Remove the serial number label from the detector and attach it to

the project documentation.

3. Attach the detector to the base by rotating the detector clockwise

until it snaps into the locked position.

Testing

Before testing, notify the proper authorities that the fire alarm system is

undergoing maintenance and will be temporarily out of service.

Test each sensor in the detector.

Caution: Heat damage. Excessive heat may damage the detector

outer cover. Do not apply excessive heat when using a hair dryer.

When using a Testifire detector tester, you must install a SIGA Testifire

Adapter Assembly.

Make sure the SIGA Testifire Adapter Assembly (model

SIGA-TSTSPACER) is installed in the Testifire detector tester before

testing. Refer to the SIGA Testifire Adapter Assembly Installation

Sheet (P/N 3101942-ML) for further details.

To perform an initial installation test:

1. Remove the detector from its base and verify that the proper

detector address, trouble signals, and messages are reported.

2. For SIGA-PHD(B) detectors placed in the air ducts, verify that the

airflow is within specifications. See “Specifications” on page 2.