BOSCHSECURITYSYSTEMS,INC.

130PerintonParkway

Fairport,NY14450USA

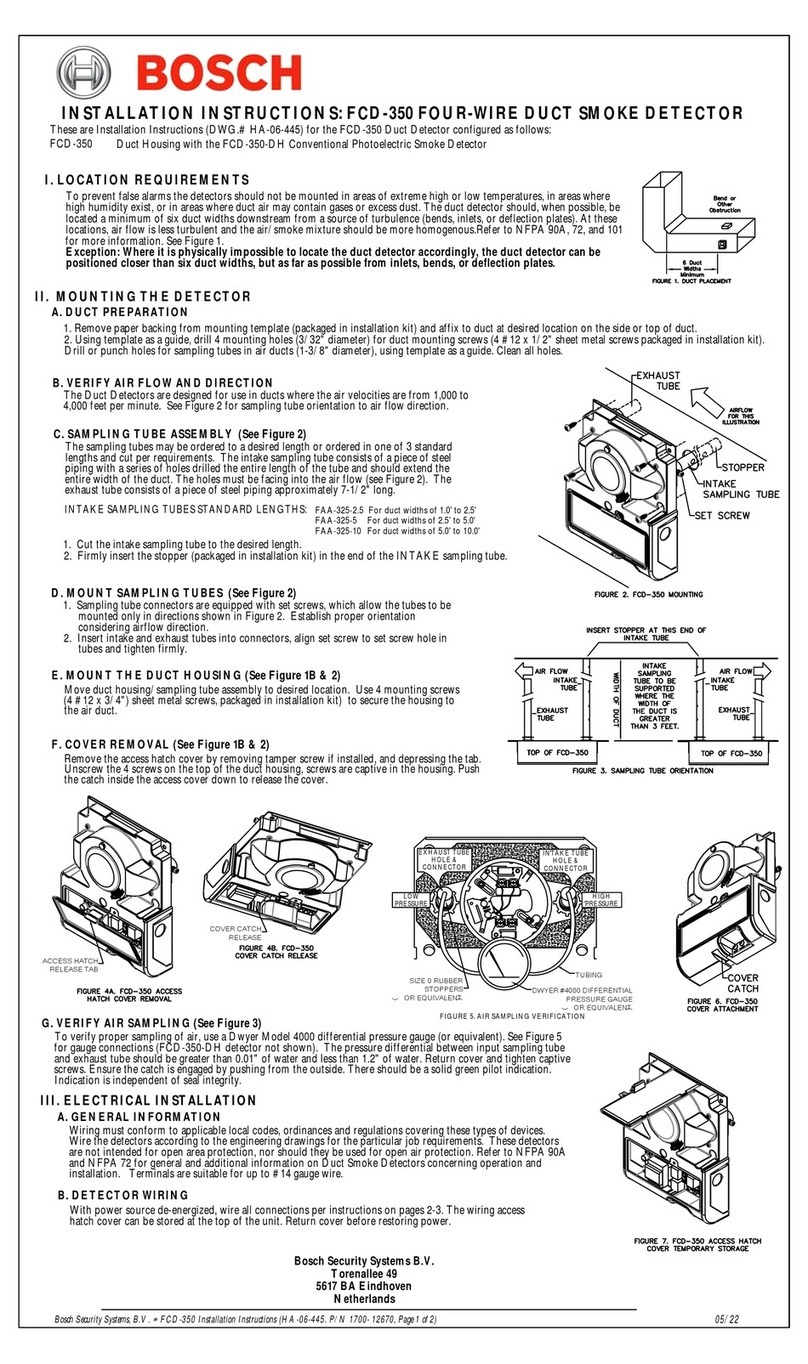

II. MOUNTING THEDETECTOR

Thesamplingtubesmaybeorderedtoa desiredlengthororderedinoneof3 standardlengthsandcut

perrequirements. Theintakesamplingtubeconsistsofapieceof steelpipingwithaseriesofholes

drilledtheentirelengthofthetubeandshouldextendtheentirewidth oftheduct.Theholesmustbe

facingintotheairflow(seeFigure2). Theexhausttubeconsistsofapieceofsteelpiping

approximately7-1/2"long.

1.Removepaper backingfrommountingtemplateAP121(packagedin installationkit)andaffixto

ductatdesiredlocation.

2.Usingtemplateasa guide, drill4mountingholes(3/32"diameter)forductmountingscrews(4#12

x1/2"sheetmetalscrewspackagedininstallationkit). Drillorpunchholesforsamplingtubesinair

ducts(1-3/8"diameter),usingtemplateasa guide. Cleanallholes.

DuctSmoke Detector LocationRequirements:

detectorsshouldnotbemountedinareasofextremehighorlowtemperatures,in

areaswherehigh humidityexist,orinareaswhereductairmaycontaingasesor

excessdust.Theductdetectorshould,whenpossible,belocatedaminimumofsix

duct widthsdownstreamfroma sourceofturbulence(bends,inlets,ordeflection

plates).Attheselocations,airflowislessturbulentandthe air/smokemixture

shouldbemorehomogenous.RefertoNFPA90A,72,and101formoreinformation.

SeeFigure1Aand1B.

Exception:Where itisphysically impossible tolocatetheductdetectoraccordingly,

theductdetectorcan be positioned closer thansixductwidths,butasfaras

possiblefrominlets, bends,or deflectionplates .

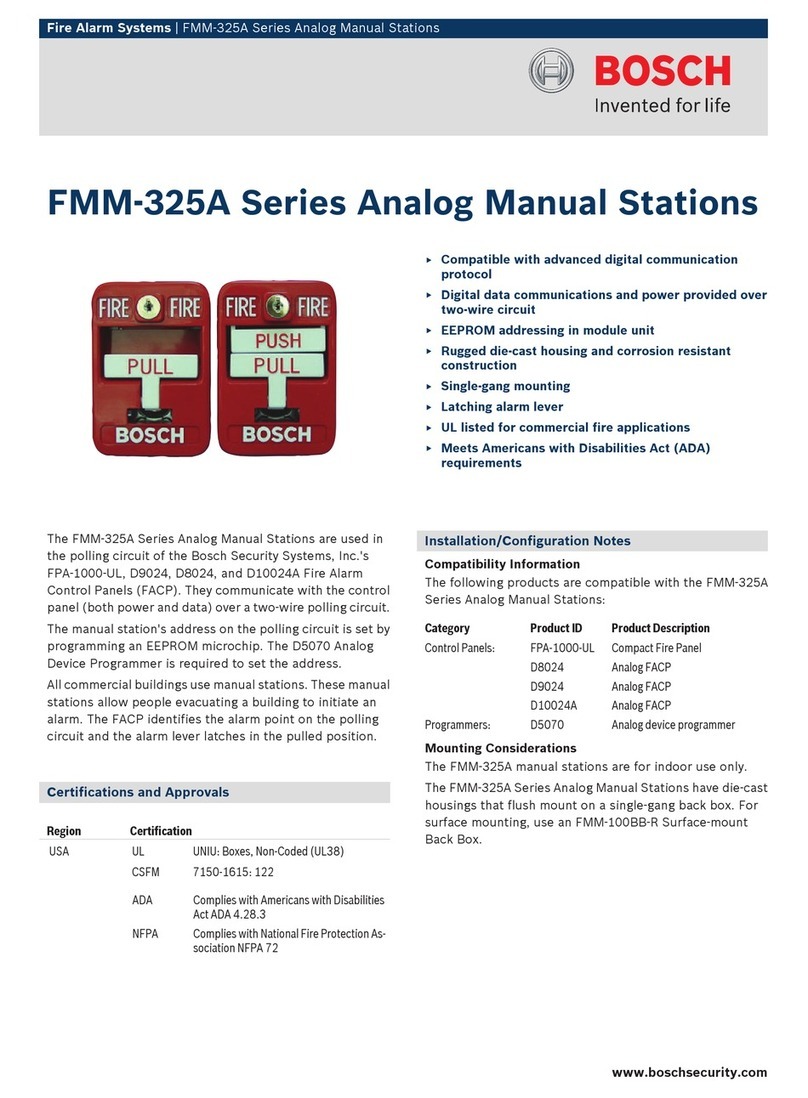

*TheseproductsarecompatibleexclusivelywithfirealarmcontrolpanelsthatutilizeBOSCH'sprotocol,DCP.

TheseareInstallationInstructions(DWG.# HA-06-184) fortheAnalogDuctHousingcustomizedasfollows:

FAD-325 DuctHousingwiththeFAD-325-DHAnalogPhotoelectricSmokeSensor*

FAD-325-V2F Duct Housingwith theFAD-325-V2F-DHAnalogPhotoelectricSmokeSensor*

FAD-325-R Duct HousingwiththeFAD-325-DHAnalogPhotoelectricSmokeSensor&Relays*

FAD-325-V2F-R DuctHousingwiththe FAD-325-V2F-DHAnalogPhotoelectricSmokeSensor&Relays*

INSTALLATIONINSTRUCTIONSFORTHEDUCTSMOKEDETECTOR

A.DUCTPREPARATION

TheDuctDetectorsaredesignedforusein ductswheretheair velocitiesare from300to4000feetper

minute. Verify this bycheckingspecificationsofinstallationandifnecessary,useanAlnorModel

6000Pvelocitymeter(orequivalent)tochecktheairvelocity.SeeFigure2forsamplingtube

orientation toairflowdirection.

SET

SCREW CONNECTORS

FIGURE 1B:DUCT HOUSINGMOUNTING

TOPOF DUCTHOUSING

DUCT MOUNTING

SCREWS

FIGURE 2 SAMPLING TUBE ORIENTATION

INSERT STOPPERAT THISENDOF

INTAKETUBE

TOP OF DUCT HOUSING

EXHAUST

TUBE

AIRFLOW

INTAKE

TUBE

INTAKE

SAMPLING

TUBETOBE

SUPPORTED

WHERETHE

WIDTHOF

THEDUCTIS

GREATER

THAN 3FEET.

WIDTHOFDUCT

TOP OF DUCT HOUSING

EXHAUST

TUBE

INTAKE

TUBE

AIRFLOW

EXHAUST

TUBE

Bendor

Other

Obstruction

6Duct

Widths

Minimum

FIGURE1A

TEMPLATE

AIRFLOW

FORTHIS

ILLUSTRATION

INTAKE

SAMPLING

TUBE

STOPPER

1.Withpowersourcede-energizedandthesmokedetectornotinstalled,wire allconnectionsperengineeringdrawings.

Referto theapplicablefiguresbelowdependingonyourducthousingmodelnumber.

2.Withallwiringinplace,installthedetectorhead.

3.Energizetheductdetector.

Wiring must conformtoapplicable localcodes, ordinancesand regulations covering thesetypesofdevices. Wirethedetectorsaccordingtotheengineeringdrawingsforthe

particularjobrequirements. Thesedetectorsare notintendedforopenarea protection,norshouldtheybeusedfor openairprotection.Referto NFPA90AandNFPA72for

generalandadditionalinformationonDuctSmoke Detectorsconcerningoperationandinstallation. Terminalsaresuitableforupto#14gaugewire.

Toverifypropersamplingofair,usea DwyerModel4000 differentialpressuregauge(orequivalent).

SeeFigure3forgauge connections. Thepressuredifferentialbetweeninputsamplingtubeand

exhausttubeshouldbegreaterthan0.01"of waterandlessthan1.2"ofwater.

Moveducthousing/samplingtubeassemblytodesiredlocation. Use4 mountingscrews(4#12x1/2"sheet

metalscrews,packagedininstallationkit) tosecurethehousingtotheairduct.

1. Samplingtubeconnectorsareequippedwith setscrews,which allowthetubestobemounted

onlyindirectionsshown in Figure 2. Establish properorientationconsideringairflowdirection.

2. Insertintakeandexhausttubesintoconnectors,alignsetscrewtosetscrewholeintubesand

tightenfirmly.

1. Cuttheintakesamplingtube tothedesiredlength.

2. Firmlyinsertthestopper(packagedininstallationkit) intheendof theINTAKEsamplingtube.

INTAKESAMPLINGTUBESSTANDARDLENGTHS:

III.ELECTRICAL INSTALLATION

FIG. 3AIRSAMPLING

VERIFICATION

For duct widths of 1.0' to 2.5'

For duct widths of 2.5' to 5.0'

For duct widths of 5.0' to 10.0'

EXHAUSTTUBE

HOLE&

CONNECTOR

LOWPRESSURE

SIDE

FAA-325-2.5

FAA-325-5

FAA-325-10

DWYER#4000DIFFERENTIAL

PRESSURE GAUGE(OR

EQUIVALENT)WITH TUBING

AND SIZE0RUBBERSTOPPERS

(HA PART#0700-01118).

HIGHPRESSURE

SIDE

INTAKETUBE

HOLE&

CONNECTOR

Note: Allductdetectormodelscanbetestedwith actualsmoke. Removetheductdetector cover. Testthedetectorheadbylightingapieceofcotton

clothesline.andplacingitapproximately3 inchesfromthedetectorhead. Blowacrossthelitendoftheclothesline towardthedetector. TheLEDsonthe

detectorshouldilluminatewithinoneminute. Afterperformingthistest sequence,reinstalltheductdetectorcover.

Theseductsensors areanalogaddressableandcanbecalibratedbyaU.L.Listedanalogcontrolpanel. SeetheFACPInstallation

Instructions for specificdirections.

Models FAD-325/FAD-325-V2F/FAD-325-R andFAD-325-V2F-R

BOSCHSecuritySystems,Inc. * FAD-325Installation Instructions(HA-06-184.P/N1700-11140Page1of2) Specifications subject tochangewithoutnotice.*February2017

B. VERIFY AIR FLOW ANDDIRECTION

C. SAMPLINGTUBE ASSEMBLY (See Figure2)

D. MOUNTSAMPLING TUBES (SeeFigure2)

E.MOUNT THE DUCTHOUSING (See Figure 1B&2)

F. VERIFY AIR SAMPLING (See Figure3)

A. GENERAL INFORMATION

B. DETECTORWIRING

I.LOCATION REQUIREMENTS Toprevent falsealarmsthe