EFA 202-204 User manual

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 1

01.2021

Operating instructions

Maintenance instructions

Spare part list

EFA Vacuum unit

Type EFA 202-204

Important Informations:

Please forward these operating instructions to your

operating personnel!

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 2

01.2021

Table of contents

1. Use, scope of delivery, accessories ....................................................................3

1.1 Symbols in these instructions .........................................................................3

1.2 Intended use..............................................................................................3

1.2.1 Application area.....................................................................................3

1.2.2 Residual hazards....................................................................................3

2. Safety instructions .........................................................................................3

2.1 General safety instructions ............................................................................3

2.2 Behavior of the workspace ............................................................................4

3. Functional description and operation ..................................................................4

3.2 Operation ..................................................................................................5

3.2.1 Daily controls ........................................................................................5

3.2.2 Switch on.............................................................................................5

3.2.3 Switch off.............................................................................................5

3.2.4 Draining...............................................................................................5

3.2.5 Pneumatic Valve ....................................................................................5

3.2.6 Vacuum Control Valve .............................................................................5

4. Assembly.....................................................................................................6

4.1 Transport ..................................................................................................6

4.2 Before installing the Vacuum Extraction System for EFA 202 .................................6

4.3 Set up ......................................................................................................7

5. Cleaning and maintenance...............................................................................7

5.1 Receiving container......................................................................................7

5.2 Air filter.....................................................................................................7

5.3 Refill oil.....................................................................................................7

5.4 Oil change .................................................................................................8

5.5 Fan cover ..................................................................................................8

5.6 Vacuum ....................................................................................................8

5.7 Troubleshooting ..........................................................................................9

6. Take back of old equipment .............................................................................9

A. Appendix ................................................................................................... 10

A.1 Technical Data.......................................................................................... 10

A.2 Spare part list........................................................................................... 11

A.2 Schematics electrical and pneumatic .............................................................. 17

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 3

01.2021

1. Use, scope of delivery,

accessories

Notes, be sure to read!

These instructions are intended for the

machine operator.

Keep the operating instructions with the

vacuum unit. It must be available at all times.

The vacuum unit may only be operated:

in technically perfect condition,

in accordance with the regulations,

as well as safety- and hazard-

conscious.

with all safety devices attached.

according to the safety instructions.

after the operating personnel have

read these instructions, in particular

chapter 2 "Safety instructions" (p.2)

and chapter 3 "Functional description

and operation" (p. 3) have been read

and understood.

This is the only way to avoid operating

errors and to assess driving situations

correctly.

1.1 Symbols in these instructions

Hazard symbol:

Extreme caution and care are

required here. In case of incorrect

behavior, there is a direct risk of

injury to the operating personnel or

third parties. In addition, the

machine may be damaged.

Information symbol:

Text passages marked with this

symbol provide you with important

information and useful tips.

1.2 Intended use

1.2.1 Application area

The vacuum unit is built according to state-of-

the-art technology and recognized safety rules.

The vacuum unit is used exclusively for the

removal of animal excrement by vacuum. Any

other use or use beyond this is considered

improper. The manufacturer is not liable.

The manufacturer is not liable for any damage

resulting from this. The risk is borne solely by

the user. Intended use also includes observing

the operating instructions and complying with

the inspection and maintenance conditions.

For all other applications, the risk of accidents

or increased wear must be pointed out. The

user alone is liable in the event of non-

compliance.

1.2.2 Residual hazards

However, the use of the equipment may result

in danger to life and limb of the user or third

parties, or damage to the equipment or other

property if the user:

is not used as intended

is improperly modified or converted

the safety instructions are not

observed

2. Safety instructions

When using the vacuum aggregate, be

sure to observe the following safety

measures.

2.1 General safety instructions

It is assumed that the operating

personnel have sufficient knowledge to

work with the vacuum unit.

Make sure that the machine is always

kept in a safe operating condition and

immediately replace defective parts

that could impair operating safety.

Installation, maintenance and repair

work may only be carried out by

authorized and qualified personnel.

Only use original EFA accessories. The

use of other tools or accessories can

be dangerous for you. Failure to use

original spare parts will void the

warranty.

Technical modifications or conversions

to the equipment are generally not

permitted and release S&W from any

warranty and liability.

The system may only be operated if all

protective and safety devices are

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 4

01.2021

present and functioning properly.

The limit values for pressures and

temperatures must be permanently

marked and must not be exceeded or

fallen short of.

The warning and safety notices on the

equipment must be observed and kept

in a legible condition at all times.

2.2 Behavior of the workspace

Keep your workplace tidy. Disorder can

result in accidents.

Take environmental influences into

account. Ensure good lighting (min.

500 lux).

Always switch off the device when not

in use.

Work clothing: Do not wear loose

clothing or jewelry - these can be

caught by moving parts. Wear sturdy

shoes when working. Generally wear a

hair net!

Wear the prescribed personal hearing

protection during operation of the

system, depending on the noise level.

Avoid abnormal body posture. Ensure

secure footing and maintain balance at

all times.

When working above body height, use

suitable, safety-compliant access aids

and working platforms. Do not use any

machine parts as climbing aids.

Care for your tools with care.

Do not leave any tool keys inserted.

Before switching on, check that all

keys have been removed.

3. Functional description and

operation

Only use the vacuum unit for the

extraction of animal excrement.

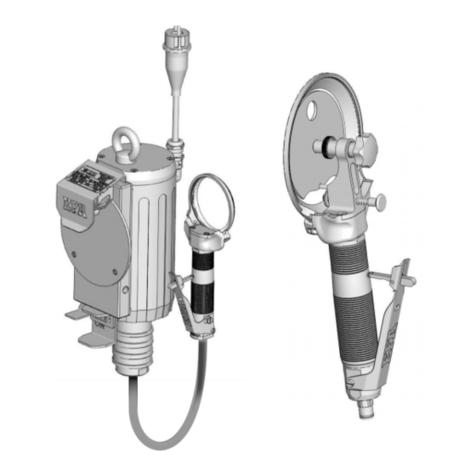

3.1 Functional description

1 –Air filter

2 –Vacuum control manometer

3 –Pump

4 –Vacuum control valve

5 –Vacuum separator cut-off valve

6 –Vacuum separator ball

7 –Vacuum separator ball valve

8 –Tank

9 –Main valve

10 –Tank lock

11 –Pneumatic manual valve

12 –Main switch

The vacuum pump (3) generates a vacuum in

the receiving tank (8) and in the suction lines

directly connected to it. As a result of the

pressure compensation, the liquid flows into

the container via the suction lines. A float

switch is located in the receiving tank (8) itself.

It switches off the vacuum pump (3) when the

filling level reaches its maximum. A suction

filter (6) and an air filter (1) are connected

upstream of the vacuum pump (3). These

prevent liquid or dirt particles from entering

the vacuum pump (3). A vacuum regulating

valve (4) is used to set the vacuum. A vacuum

gauge (2) above the vacuum pump indicates

the pressure in the vessel. A sleeve valve (5) is

located at the bottom of the receiver tank (6),

through which the contents can be drained.

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 5

01.2021

3.2 Operation

Only use the vacuum unit for the

extraction of animal excrement.

All cleaning agents for stainless

steel equipment are suitable for

cleaning the receptacle.

3.2.1 Daily controls

Check the air filter at least once a day

(1) for contamination and the oil level

of the vacuum pump.

The work steps are explained in the

following sections 5.2. and 5.3.

3.2.2 Switch on

Set the main switch (12) to 1.

3.2.3 Switch off

Set the main switch (12) to 0.

3.2.4 Draining

Empty the receiving container (8) when the

maximum filling level is reached and before

each longer downtime.

3.2.5 Pneumatic Valve

The pneumatic valve (7) has 2 modes

(ON / OFF).

For normal operation the pneumatic valve

should be switched ON (Upper position). When

the operator of the Vacuum Extraction System

finds that the vacuum is not temporarily

needed for operate, he can switch OFF (lower

position) the pneumatic valve.

3.2.6 VacuumControl Valve

By turning the Vacuum Control Valve (5)

clockwise You can increase vacuum (+sign on

the valve), by turning the valve anti-clockwise

(-sign on the valve) You can decrease the

vacuum.

To control the level of the vacuum look at the

manometer (6).

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 6

01.2021

Emptying the receiving container:

Set the main switch (12) to 0.

Open the sleeve slide (10) at the

bottom of the receptacle (9).

After emptying, close the sleeve

slide (10).

Drain the suction filter:

Unscrew the drain valve (7) at the

bottom of the Suction filter (8).

Drain the water with the dirt residues

from the suction filter (8) out of the

suction filter (8).

Screw the drain valve (7) back in

again.

4. Assembly

4.1 Transport

It is strictly forbidden to stand

underneath a lifted load! Falling

loads can cause extremely serious

injuries.

Only transport the vacuum unit bolted

to a pallet while it is upright.

Only use suitable means of transport

and lifting gear with sufficient load-

bearing capacity.

Only use load-bearing and stable

loading ramps.

Secure the vacuum unit against sliding

and tipping.

4.2 Before installing the Vacuum

Extraction System for EFA 202

Unpack the device and assemble it, as shown

on the picture below. Use the enclosed screws

for this and tighten them with a force of

12Nm.

Connect the hose (3) and secure it with the

enclosed clamps.

Connect the EFA 202 with the tank of Vacuum

Extraction System (1) with appropriate

couplings (tank side 1") and a hose.

Before use Vacuum Extraction System, start

the vacuum pump and check the rotation of

the motor. The right direction is shown on the

housing of the pump (see arrow).

In case if the direction of the rotation of motor

is opposite side than shown on the housing of

the pump, stop the pump immediately and

change the direction by switching the two

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 7

01.2021

phases (e.g. PH1 and PH2) in the plug.

NOTICE!

This operation should be done only by

qualified electrician.

Connect the pneumatic hose to the pressure

reducer.

NOTICE!

The minimal pressure for applicable

operation of the Vacuum Extraction

System is 6 bar.

After making sure, that all connections and the

direction of the rotation of the pump are

correct, turn the main switch on. The Vacuum

Extraction System is ready to operate.

4.3 Set up

The mains connection must comply

with the regulations of the local

power supply company and be

protected by a residual current

circuit breaker

(residual current <0.03 A) and fuses

(16 A, slow-blow).

Do not lay the unit on its side.

The suction connection is designed as a spigot

with a 1" female thread. A 1/2" hose nipple is

screwed into the suction connection. 1/2" hose

nipple is screwed into the suction connection.

Carry out the set-up and installation

as follows:

Set up the vacuum unit on a level,

load-bearing floor.

Anchor the vacuum unit in the floor

using hexagonal bolts (min. 8mm

diameter).

Establish a hose connection between

the unit or the system via which the

liquid is to be aspirated and the

suction connection. To do this, attach

a sufficiently long hose to the hose

nipple using hose clamps.

Have a qualified person make the

electrical connection. The socket slide

under the receiving vessel has a 2"

internal thread to which you can

connect a drain line.

Always lay the drain line with a

downward slope from the vacuum

unit.

5. Cleaning and maintenance

Disconnect the vacuum unit from

the power supply before servicing

the vacuum pump. Ventilate the

vacuum pump to ambient pressure.

5.1 Receiving container

Rinse the receptacle (8) with spray water at

least every month to remove any stuck dirt.

Proceed as follows:

Set the main switch (12) to 0.

Open the sleeve slide (10) and empty

the receiving container (8).

Close the sleeve slide (10) when the

receiving container (8) is empty.

Remove the base plate from the

receiving container (8). To do this,

loosen the fastening nuts on the base

plate.

Spray the receiving container (8) from

the underside.

All cleaning agents for stainless

steel equipment are suitable for

cleaning the receptacle.

5.2 Air filter

Check the filter element in the air filter (1) at

regular intervals (at least every three months),

as follows:

Open the retaining clips on the air

filter (1) and remove the cover.

Check the air filter (1) and replace it if

necessary.

Replace the cover on the air filter (1)

and secure it with the retaining clips.

5.3 Refill oil

Use only special vacuum pump oil

according to DIN 51506, lubricating

oil group VC. For the exact

specification, refer to the table or

enclosed operating instructions for

the vacuum pump.

When the oil level is below the MIN mark on

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 8

01.2021

the sight glass, add oil. Proceed as follows:

Open the oil filler plug.

Add oil until the oil level reaches the

MAX mark on the oil sight glass.

Close the oil filler plug.

5.4 Oil change

Change the oil:

after the first 100 hours of operation.

after every further 500 ... 2000

operating hours.

Dispose of the used oil in

accordance with the applicable

regulations.

Unscrew the oil drain plug (5) on the

vacuum pump (2) and allow the used

oil to run into a collecting pan. 2.

Screw the oil drain plug (5) back in. 3.

Unscrew the oil filler plug (3) on the

vacuum pump (2) and fill in new

vacuum pump oil. 4.

Screw the oil filler plug (3) back in.

Recommended oil

types

Ambient

temperature

VM 032

< 0 °C

VM 068

0 ... 12 °C

VM 100

12 ... 30 °C

VS 100

> 30 °C

The vacuum unit contains approx. 1 l of oil.

5.5 Fan cover

Check the fan guards of the vacuum pump for

dirt. If necessary, blow out the fan guards with

compressed air.

For further maintenance

instructions, refer to the enclosed

operating instructions for the

vacuum pump.

5.6 Vacuum

Set the vacuum via the vacuum regulating

valve (15) as follows:

By turning the Vacuum Control Valve (5)

clockwise You can increase vacuum (+sign on

the valve), by turning the valve anti-clockwise

(-sign on the valve) You can decrease the

vacuum.

To control the level of the vacuum look at the

manometer (6).

The vacuum must not exceed

75 kPa! Higher negative pressures

can cause damage to the receiving

container.

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 9

01.2021

5.7 Troubleshooting

Malfunction

Possible reason

Remediation

Vacuum unit does not run

Level control indicator is

out

Power supply interrupted.

Check the mains connection

and fuses. Notify the customer

service if none of the above

errors are present.

Motor protection tripped due to

overload of vacuum pump (3).

Open the switch box (12) and

check whether the motor

protection switch has tripped.

Suction filter (6) clogged and

air filter (1) wet. -> Vacuum

pump has sucked in water.

Notify customer service.

Suction filter (6) clogged.

Empty the suction filter (6)

(section 3.2).

Press the "Reset" button on the

motor protection switch.

Vacuum unit does not run

Level indicator is on

Receptacle (8) is full.

Empty the receiving container

(8) (section 3.2).

Low flow rate

Intake filter clogged

Clean/renew intake filter

Vacuum too high

Suction filter (6) clogged.

Drain the suction filter (6)

(section 3.2).

Regulating valve (4) set

incorrectly.

Readjust the vacuum

(section 5.6).

Vacuum too low

Sleeve gate valve (10) open or

not properly closed.

Close the sleeve slider (10)

Hose line at suction connection

leaking.

Check the hose line and the

devices connected to it.

Eliminate the leaks.

If necessary, replace the

leaking parts.

Regulating valve (4) set

incorrectly.

Readjust the vacuum

(section 5.6).

Leakage at the receiver (8) or

other parts of the vacuum unit.

Defective vacuum pump (3).

Notify customer service.

6. Take back of old equipment

Return old equipment to the parent company for disposal.

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 10

01.2021

A. Appendix

A.1 Technical Data

Description

Value

Voltage

3 x 400 V /50 Hz / N / PE

Current

3,2A

Rated power

0,75kW

Flow rate

25 m3/h

Contents of the receptacle

90 L

Mass (net)

115 kg

Ambient temperature

+5°C - +35°C

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 11

01.2021

A.2 Spare part list

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 12

01.2021

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 13

01.2021

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 14

01.2021

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 15

01.2021

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 16

01.2021

Page

Part number

Part

Index

11

1

Tank

2

Vacuum separator

3

Hose

Z084015

8

Pneumatic hose

Z084194

9

Pneumatic hose

Z084194

12

7

Pneumatic manual valve

Z083927

9

Pneumatic exhaust filter

Z084193

12

5

Vacuum control valve

Z093583

6

Vacuum manometer

Z093543

13

2

Vacuum pump

Z084014

5

Main switch

Z084018

7

Pneumatic manual valve

Z083927

9

Pneumatic exhaust filter

Z084193

11

Pneumatic manometer

Z084195

12

Hose

Z084016

13

Pump filter

26 - 27

Pneumatic hoses

Z084194

29

Pneumatic hose

Z084194

34

Vacuum control unit

Z093583+

Z093543

35

Electrical box –OPTION

36

Pneumatic tee

Z013998

37

Pneumatic hose

Z084194

38

Pneumatic hose

Z084194

14

5

Vacuum separator cut-off valve

Z083809

7

Vacuum separator ball valve

Z083850

9

Vacuum separator ball

Z084022

15

4

Tank lock

Z083847

2

Tank gasket

Z084044

16

Main valve - OPTION

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 17

01.2021

A.2 Schematics electrical and pneumatic

Schmid & Wezel

Execution

D 75433 Maulbronn

Page 18

01.2021

Chorzów, 19.01.2021

DECLARATION OF CONFORMITY

2006/42/EC MACHINERY

Manufacturer: Weindich Sp. J., ul. Adamieckiego 8, 41-503 Chorzów

Declare that the product described below is in conformity with the relevant provisions

of the following directives and the National Laws and Regulations adopting these

directives.

Machinery Directive: 2006/42/EC

Low Voltage Directive: 2014/35/EC

EMC Directive: 2014/30/EU

Product type: Vacuum Extraction System

Model: W0279.23.06.20

Serial Number: W0279.23.06.20 No. 001

The product has been tested and assessed by application of the following standards

or specifications. Together with all relevant National Technical Standards and

Specifications as applicable.

Applied standards:

DIN EN ISO 12100:2012

DIN EN ISO 13850:2016-03

EN 60204-1:2018-12

EN 60529:2003

EN 1672-2+A1:2009

EN 55014-1:2017-06/A11:2020-07

EN 55014-2:2015-06

DIN EN 61000-6-3:2008/A1:2012

DIN EN 61000-6-4:2019-12

Head of Technical department

Board member

Table of contents

Other EFA Industrial Equipment manuals