efacec EFAPOWER EV HC G3 User manual

EFAPOWER

EV HC G3

HOME CHARGING STATION

Installation and User Manual

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

ii

Copyright and trademarks

©2014 EFACEC. All rights reserved. This material is protected by the copyright laws of Portugal and other

countries. It may not be modified, reproduced or distributed without the prior, express written consent of

EFACEC. All other products or services mentioned are the trademarks, service marks, registered trademarks or

registered service marks of their respective owners.

Symbols Index

The following symbols are used in this manual to prevent accidents which may occur as a result of incorrect use

of the charger.

Note

Read the notes carefully to ensure safe and proper use

Warning or safety observation

Read the instructions carefully to ensure safe and proper use

Risk of electric shock

Read the instructions carefully to ensure safe and proper use

Rua Eng. º Frederico Ulrich - Apartado 3078

4471-907 MOREIRA MAIA - PORTUGAL

Tel: (+351) 229403241 - Fax: (+351) 229403209

service[email protected]

www.electricmobility.efacec.com

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

iii

TABLE OF CONTENTS

1GENERAL PRODUCT DESCRIPTION............................................................................... 2

2GENERAL CHARACTERISTICS ....................................................................................... 3

2.1 TECHNICAL CHARACTERISTICS .......................................................................................................... 3

2.2 STANDARDS.................................................................................................................................. 4

3PRODUCT PARTS PRESENTATION ................................................................................ 5

4IMPORTANT SAFETY INSTRUCTIONS ........................................................................... 6

5INSTALLATION ............................................................................................................ 7

5.1 ENVIRONMENTAL REQUIREMENTS .................................................................................................... 7

5.1.1 Local Conditions ................................................................................................................................................... 7

5.1.2 Site Verification and Inspection............................................................................................................................ 8

5.2 SITE PREPARATION......................................................................................................................... 9

5.2.1 Upstream Wiring Information .............................................................................................................................. 9

5.2.2 Surface Preparation............................................................................................................................................ 10

5.2.3 Resources for Installation ................................................................................................................................... 10

5.2.4 Site Verification and Inspection.......................................................................................................................... 10

5.3 HANDLING AND PLACING .............................................................................................................. 11

5.3.1 Packaging........................................................................................................................................................... 11

5.3.2 Visual Inspection................................................................................................................................................. 11

5.3.3 Handling ............................................................................................................................................................. 11

5.3.4 Placing................................................................................................................................................................ 12

6START-UP ..................................................................................................................19

6.1 VERIFICATION AND INSPECTION...................................................................................................... 19

6.2 SWITCH ON................................................................................................................................ 19

7USER MANUAL ..........................................................................................................21

7.1 OUTPUT CONNECTOR ................................................................................................................... 21

7.1.1 Type 1 Connector................................................................................................................................................ 21

7.1.2 Type 2 Connector................................................................................................................................................ 21

7.1.3 Type GB Connector ............................................................................................................................................. 21

7.1.4 Type 2 outlet....................................................................................................................................................... 22

7.2 OPERATION ................................................................................................................................ 22

7.2.1 Operation Sequences (for EV-HC without Authentication) ................................................................................. 22

7.2.2 Operation Sequences (for EV-HC with Authentication) ...................................................................................... 24

8MAINTENANCE MANUAL ...........................................................................................25

8.1 PREVENTIVE MAINTENANCE .......................................................................................................... 25

8.2 TROUBLESHOOTING ..................................................................................................................... 26

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

1 | 28

The information presented in this guide is subject to change without prior notice.

The technical specifications indicated here do not constitute a contractual obligation.

No part of this document may be photocopied, reproduced or translated to other language without the written

consent from EFACEC.

In case of any doubt regarding a subject described in this manual, please contact us at:

Rua Eng. º Frederico Ulrich - Apartado 3078

4471-907 MOREIRA MAIA - PORTUGAL

Tel: (+351) 229403241 - Fax: (+351) 229403209

service[email protected]

www.electricmobility.efacec.com

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

2 | 28

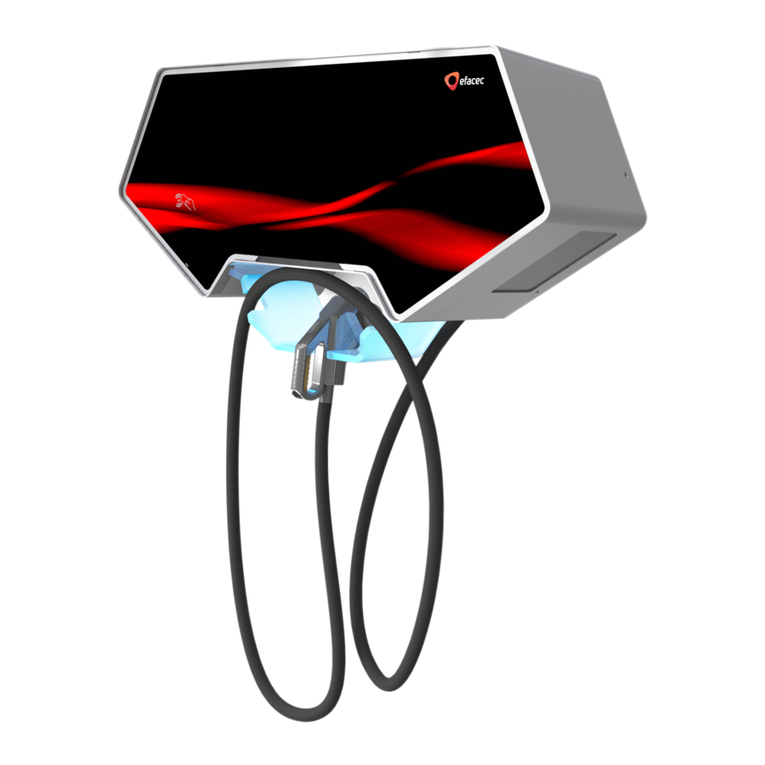

1GENERAL PRODUCT DESCRIPTION

EFAPOWER EV-Home Charger (HC) station is able to charge all electric vehicles compliant with AC charging

system standards.

The battery charging cycle finishes by itself or can be interrupted by user command.

EFAPOWER EV-HC consists on a Charging Station with one output.

Are available the following AC outputs: 3,7kVA; 7,4kVA; 11kVA and

22kVA.

EFAPOWER EV-HC station is user friendly and safe. Different models

are available, with power plug or socket. When equipped with a

socket, the power cord plug is coupled into it in the charger bay.

There is a locking mechanism on the socket that prevents the user

from disconnecting the power cord during the charging process,

without first interrupt the charging process on the system or on the

vehicle. The charger has a color warning light which shows its own

operation status.

EFAPOWER EV-Home Charger station codification and configurations are presented in chapter 3.

Figure 1 - EFAPOWER EV-HC

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

3 | 28

2GENERAL CHARACTERISTICS

2.1 TECHNICAL CHARACTERISTICS

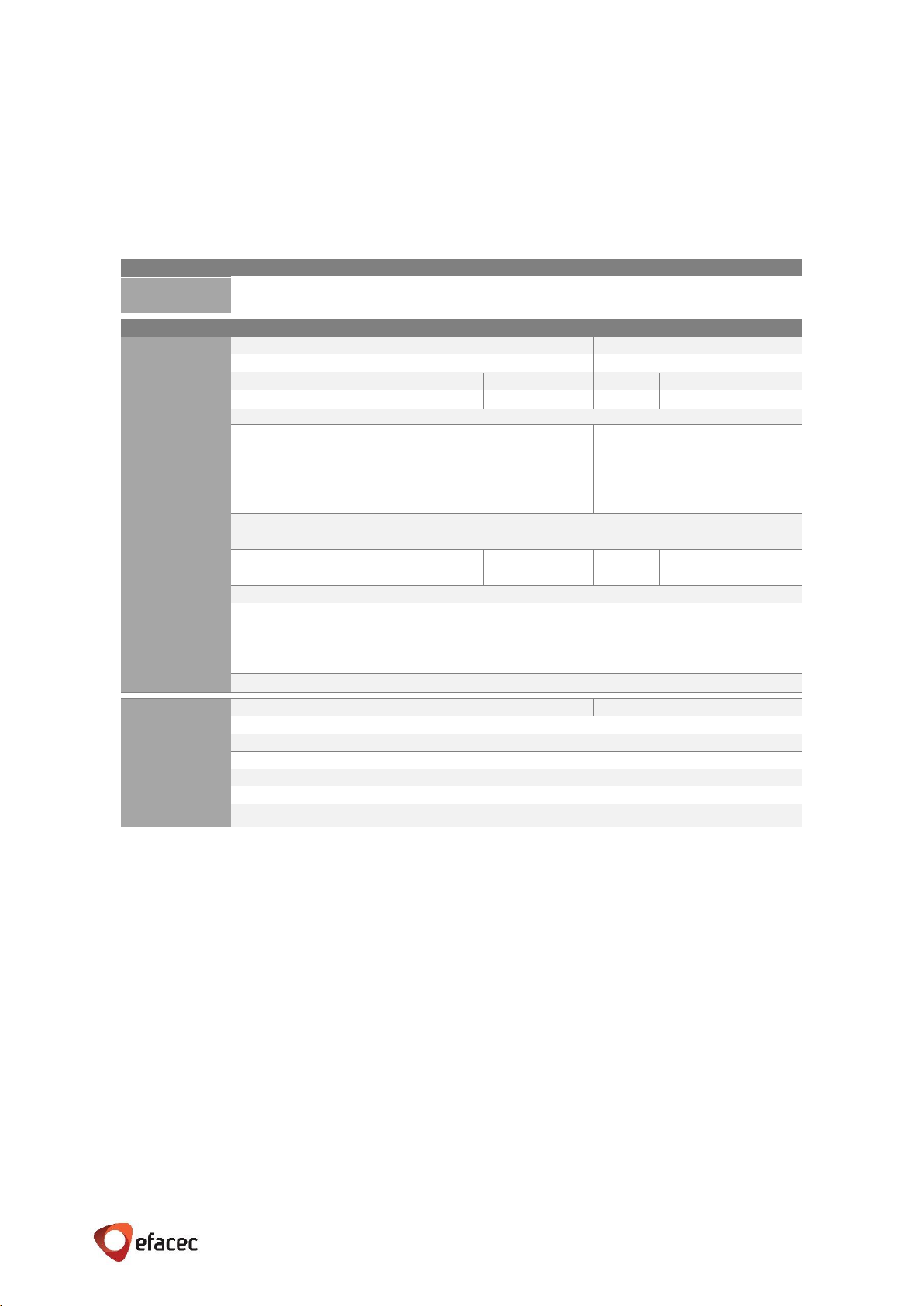

EFAPOWER EV-HC station technical characteristics are indicated in Table 1.

Table 1 –EFAPOWER EV-HC Technical Characteristics

Central Command Unit

User Interface

User Identification

(optional)

Contactless RFID Card (Mifare) ISO14443

Outputs

CE and GB Units

Nominal Input

Phases/Lines

1 line + neutral + earth

3 line + neutral + earth

Voltage

(230 ± 10%) Vac

(400 ± 10%) Vac

Current

16 A

32 A

16 A

32 A

Power

3,7 kVA

7,4 kVA

11 kVA

22 kVA

Frequency

(50 ± 10%) Hz

Output

Connector

CE Units: Type 1 according to EN 62196-1

CE Units: Type 2 according to EN 62196-2

GB Units: Mode 3 according with

GB/T20234.2

CE Units: Type 2 according to EN 62196-2

GB Units: Mode 3 according with

GB/T20234.2

EV Connection to EVSE

CE units: EN 61851-1 and IEC 61851-1 Case B and IEC 61851-1 Case C

GB units: GB/T 18487.1 Case C

Outlet Protection

Over-current (not

included)

20 A

40 A

20 A

40 A

RCD

30 mA

Charging Mode

Direct connection

between the EV and the

EVSE using the cable

supplied with the vehicle.

CE units: EN 61851-1 e IEC 61851-1 Mode 3

GB units: GB/T 18487.1 Mode 3

Energy metering

(optional)

Yes

Mechanical

Characteristics

Dimensions(WxDxH) mm

300x156x169 mm

320x156x224 mm

Architecture

Standalone box equipped with one output

Weight

from 4kg to 7kg (depending on the output)

Environmental

conditions

Degree of protection

IP 54

Temperature

Natural cooling (Range -30˚C to +50˚C)

Humidity

Range 5% to 95%

Installation site

Outdoor/Indoor

Specifications are subject to change, without prior notice.

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

4 | 28

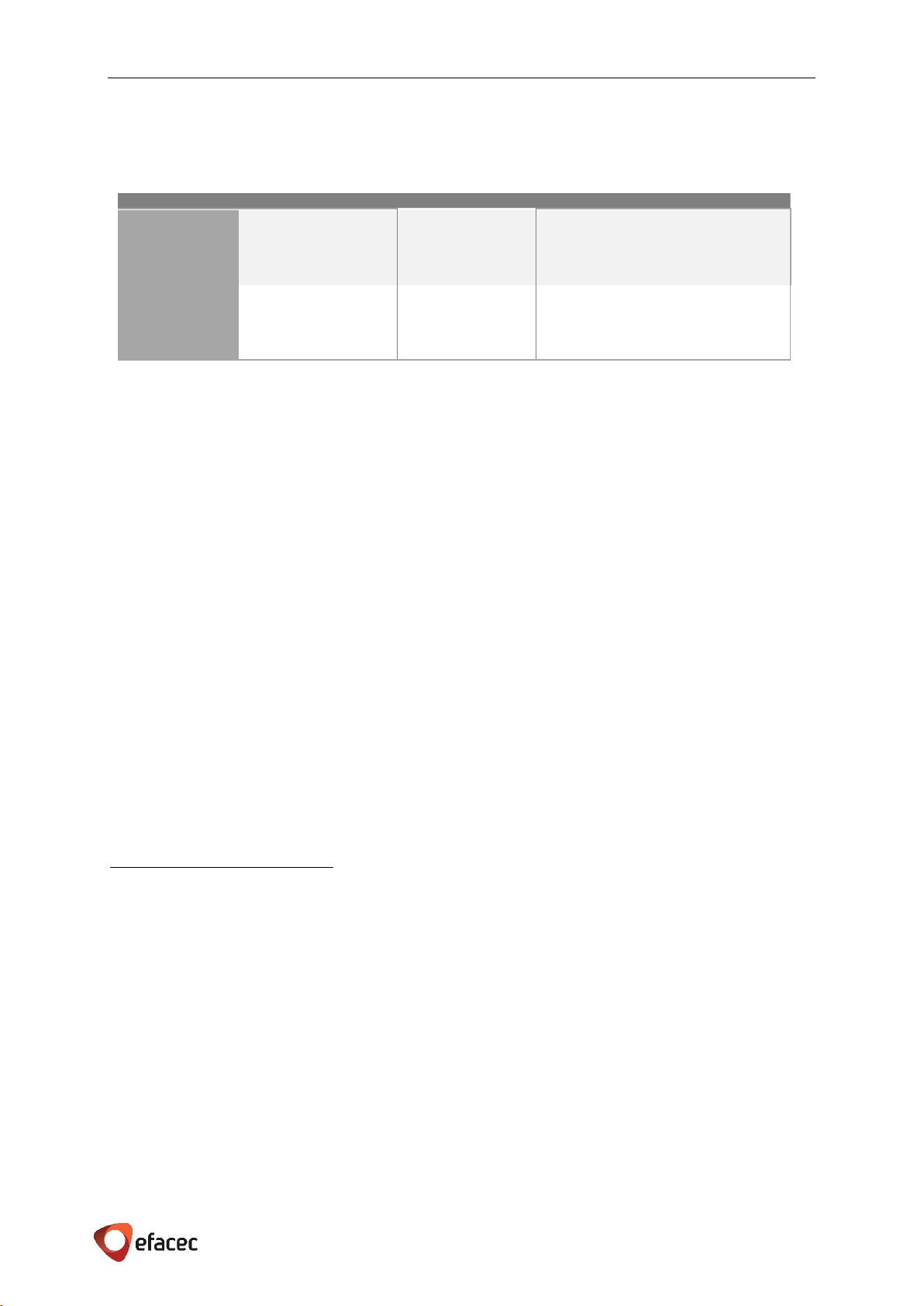

2.2 STANDARDS

The EFAPOWER EV-Public Charger station complies with the following standards:

Table 2 –EFAPOWER EV-HC Applicable Standards

1

2006/95/CE: Low Voltage Directive

2

2004/108/CE: EMC directive

3

EN/IEC 61851-1: Electric vehicle conductive charging system. Part 1: General Requirements

4

IEC 62196: Plugs, socket-outlets, vehicle connectors and vehicle inlets - Conductive charging of electric vehicles

5

GB 156-2007: Standard Voltage

6

GB/T 18487.1: Electric vehicle conductive charging system. Part 1: General Requirements

7

GB/T 20234: Connection Set of Conductive Charging for Electric Vehicles

8

GB/T 18487.3: Electric vehicle conductive charging system. AC/DC Electric Vehicle Charging Station

9

EN/IEC 61851-22: Electric vehicle conductive charging system. Part 22: AC Electric Vehicle Charging Station

10

EN/IEC 61000-6-1: Electromagnetic compatibility (EMC). Part 6-1: Generic standards - Immunity for residential,

commercial and light-industrial environments

11

EN/IEC 61000-6-3: Electromagnetic compatibility (EMC). Part 6-3: Generic standards - Emission standard for

residential, commercial and light-industrial environments

12

GB/T 17626: Electromagnetic compatibility –Immunity to Disturbance (GB/T 17626.2; GB/T 17626.3; GB/T

17626.4; GB/T 17626.5; GB/T 17626.6; GB/T 17626.11)

13

GB 4824: Industrial, scientific and medical (ISM) radio-frequency equipment. Disturbance characteristics. Limits

and methods of measurement.

Technical Data

CE

GB

Applicable

Directives /

Standards

Universal:

2006/95/CE1

2004/108/CE2

EN/IEC 61851-13

IEC 621964

GB 156-20075

GB/T 18487.16

GB/T 202347

GB/T 18487.38

AC Charging System:

EN/IEC 61851-229

EN/IEC 61000-6-110

EN/IEC 61000-6-311

EV-READY

GB/T 1762612

GB 482413

EV-READY

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

5 | 28

3PRODUCT PARTS PRESENTATION

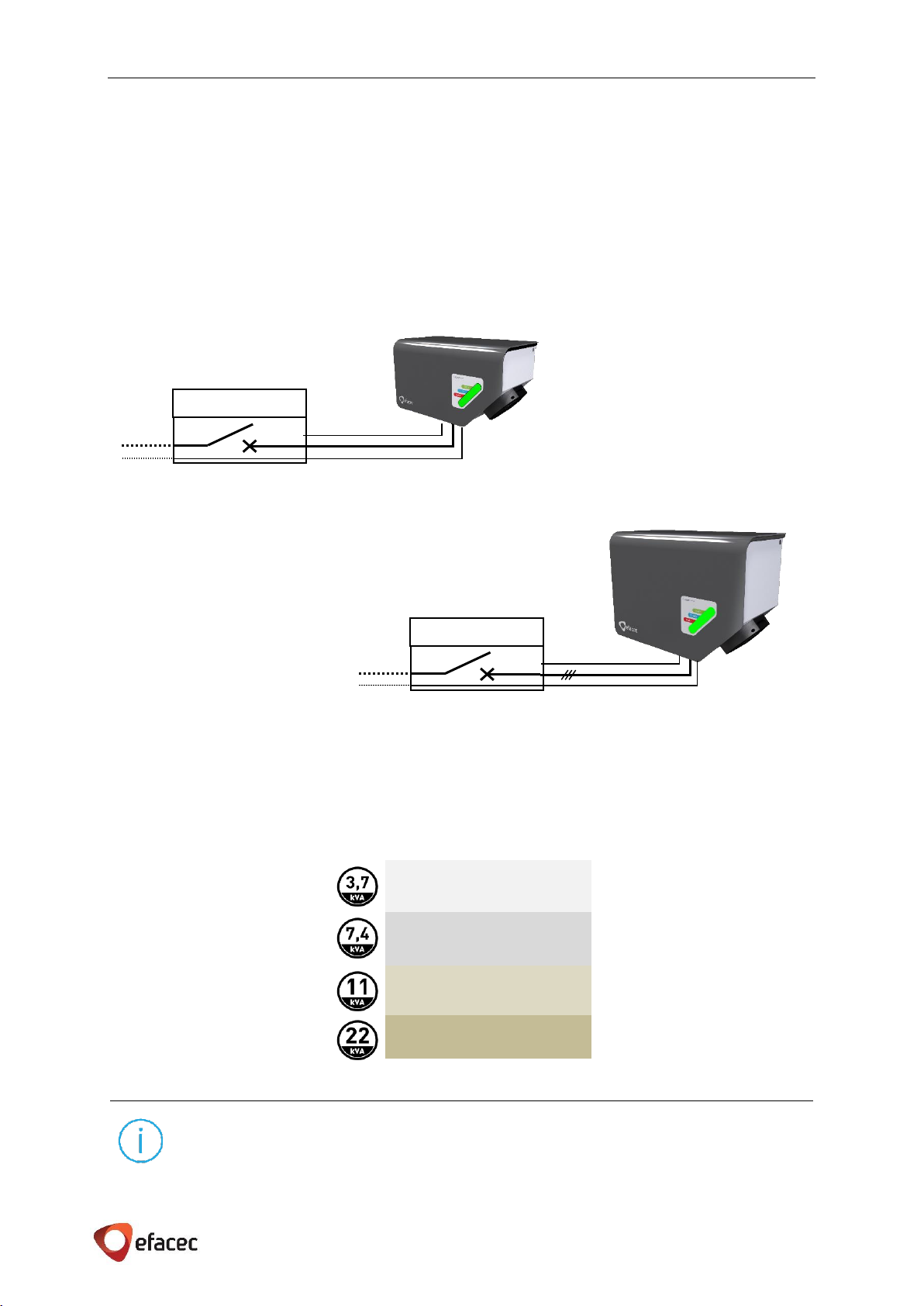

EFAPOWER EV-HC is composed by a standalone box with one output. Its codification is presented below.

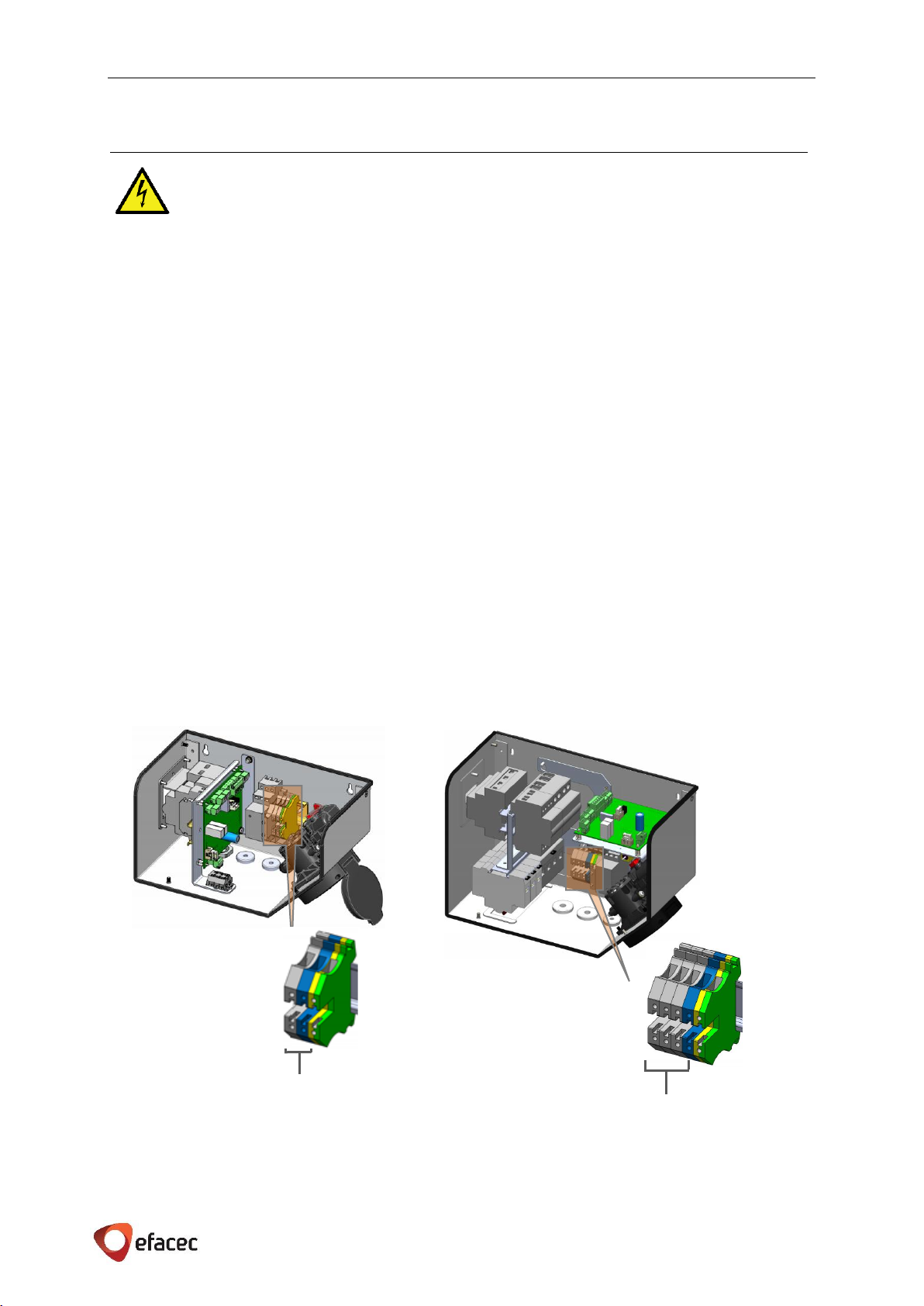

EFAPOWER EV-HC has two boxes depending on the power rate. For 3,7kVA and 7,4kVA the box is represented

in Figure 3.

CE marked units can be supplied with socket or cable and GB marked units are supplied only with cable.

In Figure 4 is presented the box for 11kVA and 22kVA.

Figure 2 - EFAPOWER EV-HC Codes

Figure 3 - EFAPOWER EV-HC 3 / 7 Parts

RFID (if applicable)

Output connection

(3,7kVA –7,4kVA)

Output

signaling

Meter (if applicable)

RCD and

CB (if applicable)

left side

front side

EV-XX G3 YY 0F-00-G-KK ZZP

ZZ

Meter

MS

Simple Meter

--

wo Meter

P

Card Reader

C

RFID

--

wo Card Reader

0F

Number of Phases

1F

One-phase

3F

Three-phase

00

Current

16

16 A

32

32 A

G

Plug/Socket

P

Plug

S

Socket

KK

Mode

T2

Type T2

GB

Type GB

Home Charger 3kW –

HC3

Home Charger 7kW –

HC7

Home Charger 11kW –

HC11

Home Charger 22kW –

HC22

Figure 4 - EFAPOWER EV-HC 11 / 22 Parts

RFID (if applicable)

Output connection

(11kVA –22kVA)

Output

signaling

Meter

(if applicable)

left side

front side

RCD and

CB (if applicable)

bottom side

CE European markets

GB China market

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

6 | 28

4IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that must be followed during installation of the EFAPOWER EV-HC

Station.

Grounding instructions

The EFAPOWER EV-HC Station must be connected to a grounded, metal, permanent wiring system; or an

equipment-grounding conductor is to be run with circuit conductors and connected to the equipment grounding

terminal or lead on the Electric Vehicle Supply Equipment (EVSE). Connections to the EVSE shall comply with all

local codes and ordinances.

Safety and compliance

This document provides instructions to install the EFAPOWER EV-HC Station and should not be used for any other

product. Before installing the EFAPOWER EV-HC Station, you should review this manual carefully and consult

with a licensed contractor, licensed electrician and trained installation expert to ensure compliance with local

building practices, climate conditions, safety standards, and state and local codes. The EFAPOWER EV-HC Station

should be installed only by a licensed contractor and a licensed electrician and in accordance with all local and

national codes and standards. The EFAPOWER EV-HC Station should be inspected by a qualified installer prior to

the initial use. Under no circumstances will compliance with the information in this manual relieve the user of

his/her responsibility to comply with all applicable codes or safety standards. This document describes the most

commonly-used installation and mounting scenarios. If situations arise in which it is not possible to perform an

installation following the procedures provided in this document, contact EFACEC. EFACEC is not responsible for

any damages that may occur resulting from custom installations that are not described in this document.

No accuracy guarantee

Reasonable effort was made to ensure that the specifications and other information in this manual are accurate

and complete at the time of its publication. However, the specifications and other information in this manual are

subject to change at any time without prior notice.

Warranty information and disclaimer

Your use of, or modification to, the EFAPOWER EV-HC Station in a manner in which the EFAPOWER EV-HC Station

is not intended to be used or modified will void the limited warranty. Other than any such limited warranty, the

EFACEC products are provided “AS IS,” and EFACEC and its distributors expressly disclaim all implied warranties,

including any warranty of design, merchantability, fitness for a particular purposes and non-infringement, to the

maximum extent permitted by law.

Limitation of liability

IN NO EVENT SHALL EFACEC OR ITS AUTHORIZED DISTRIBUTORS BE LIABLE FOR ANY INDIRECT, INCIDENTAL,

SPECIAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION, LOST PROFITS, LOST

DATA, LOSS OF USE, COST OF COVER, OR LOSS OR DAMAGE TO THE EFAPOWER EV-HC STATION, ARISING OUT

OF OR RELATING TO THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF EFACEC OR ITS AUTHORIZED

DISTRIBUTORS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

7 | 28

5INSTALLATION

All matters for installing the EFAPOWER EV-HC are described in this chapter.

5.1 ENVIRONMENTAL REQUIREMENTS

EFAPOWER EV-HC Station reliability is dependent upon compliance of environmental specifications. The design

of the environmental control system for your EFAPOWER EV-HC Station, in case of extreme environmental

conditions, must ensure that the Unit can operate reliably while remaining within the range of its operating

specifications.

5.1.1 LOCAL CONDITIONS

EFAPOWER EV-HC Station has a protection degree of IP54. This Unit is intended to work below 50ᵒC ambient

temperature.

Clearance around the unit

There should be enough space to operate the unit in the front and both sides. For EV-HC 11 / 22 please ensure

also clearance in the bottom to access to the RCD.

Input Power Cables

AC input cables must be copper with appropriate power rating.

EFAPOWER EV-HC is intended to be placed on the wall, as showed in Figure 5.

Figure 5 - EFAPOWER EV-HC Station –placing

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

8 | 28

On locations with harsh weather conditions (high temperatures, heavy dust, snow and/or very low temperatures)

it’s recommended to provide additional protection, either inside a building or a shelter, or providing a roof

protection for the Unit. See example in Figure 6.

Figure 6 - EFAPOWER EV-HC with roof protection

5.1.2 SITE VERIFICATION AND INSPECTION

Check if Home Charger Station layout site is compliant with the specified clearance around the box;

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

9 | 28

5.2 SITE PREPARATION

Once the local conditions are verified is time to set up the site in order to be ready for the installation of the

EFAPOWER EV-HC Station.

5.2.1 UPSTREAM WIRING INFORMATION

The power feeding of the EFAPOWER EV-HC with origin on the LVDB (low voltage distribution board) must be

done with dedicated wiring (line(s), neutral and earth conductors only used to supply the equipment) and

protected by a circuit breaker and a voltage suppressor, please refer Figure 7 and Figure 8.

Depending on the output of the Unit, we can have several scenarios for the circuit breaker to be installed in the

distribution board for each Unit. The appropriate circuit breaker is represented in Table 3.

NOTES

Unless it’s required by local code it’s not necessary to install a residual-current device (RCD) for

EFAPOWER EV-HC Station as it is already installed inside the unit.

Circuit Breaker 20A 1P C

Circuit Breaker 40A 1P C

Circuit Breaker 20A 3P C

Circuit Breaker 40A 3P C

Table 3 - Overcurrent protection upstream

Figure 7 - EFAPOWER EV-HC 3 / 7 Wiring Information

Figure 8 - EFAPOWER EV-HC 11 / 22 Wiring Information

Distribution Board

Ground

Neutral

Distribution Board

Ground

Neutral

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

10 | 28

5.2.2 SURFACE PREPARATION

Each Charging Station must be fixed to a pole or a wall by a fixing plate.

5.2.3 RESOURCES FOR INSTALLATION

For the installation of EFAPOWER EV-HC Station the following resources are going to be needed:

Fasteners:

3x Screws M4 + 3x matching Anchors

If EV-HC with cable, for cable holder: 2x Screw M4 + 2x matching Anchor

End terminals for input wiring by Unit:

EV-HC 3 / 7

3 (three) end terminals for cable according to Table 5 or according to local codes (1 phase + neutral +

protective ground)

EV-HC 11 / 22

5 (five) end terminals for cable according to Table 5 or according to local codes (3 phases + neutral +

protective ground)

16A

32A

16A

32A

Table 5 - Input lines –cross-section range

*These cross-sections are applied to copper cable length up

to 50m or according to local codes. For higher distances

contact the manufacturer.

max A

Min cross-section*

Terminal block section

16 A

2,5mm2

4mm2

32 A

4mm2

4mm2

Tools:

Screwdriver - for wall mount

Crimping tool - for power and earth cables

Torque screwdriver with flat blade - for input terminal blocks

5.2.4 SITE VERIFICATION AND INSPECTION

Check if Home Charger has the appropriate upstream protection depending on the configuration of it

Verify if the neutral is of type TT or TN. Only these two regimes guarantee a good and correct

functioning of the EFAPOWER EV-HC residual current device

Verify the earth circuit resistance: it should be according to IEC 60364/GB 16895.3, and other applicable

standards. In either case it must be under 150 Ω

Verify if the main distribution board has conditions to support one more circuit with the characteristics

required depending on the model

Execute and test the installation according to IEC 60364 standard or local regulations for CE marked

units and according to GB 16895.3, GB/T 16895.10, GB16895.5 standards or local regulations for GB

marked units

A test document will be issued by the installer responsible as a guarantee to the user that the

Homecharger was properly installed and ready to supply energy to charge the EV battery

Table 4 –Max current by phase

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

11 | 28

5.3 HANDLING AND PLACING

Before installing stations

The instructions provided in this manual assume that the appropriate wiring, circuit protection, and

metering are in place at the installation location.

To assist in the process of preparing the installation site, it is recommended that before you begin

installing the Charging Station, you thoroughly review the contents of this document to familiarize

yourself with the required installation steps.

In case of any doubt regarding items described in this guide, please contact us at:

5.3.1 PACKAGING

EFAPOWER EV-HC Station is shipped in a personalized package (493x400x187mm), please refer to Figure 9. The Unit

dimension is in Technical characteristics - 2.1.

5.3.2 VISUAL INSPECTION

Check if the exterior case has been damaged by mechanical impacts or any accidents during transportation

If applicable, check if the EFAPOWER EV-HC Station decor is in perfect condition

Check for proper Unit(s) protective ground connection point, which should be interconnected with the low

voltage switchboard ground connection during the installation

5.3.3 HANDLING

Due to its weight (max 7kg), this Charging Station can be placed by one person.

Rua Eng. º Frederico Ulrich - Apartado 3078

4471-907 MOREIRA MAIA - PORTUGAL

Tel: (+351) 229403241 - Fax: (+351) 229403209

service[email protected]

www.electricmobility.efacec.com

Figure 9 - EFAPOWER EV-HC Package

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

12 | 28

5.3.4 PLACING

5.3.4.1 FIXING ON THE WALL

Each unit must be installed by using 3 (three) screw anchors, M4 –length must comply with local codes.

The fixation of the EV-HC should assure that no part of it is under 0,8m or above 1,5m from ground thus

permitting a comfortable handling of the equipment and charging cable.

Mounting steps:

1. Unscrew the lid

All 4 screws must be untighten to take off the lid.

2. Disconnect the lid

The lid shall not be hanging on the wires!

a. Unplug the earth cable on it (faston terminal)

b. Unplug the flat cable on the board (X14)

c. Unplug the card reader cable on the board (X6) –if applicable

3. Fix the Unit to the wall (use the drilling layout template)

In the following figures some details are shown regarding the drilling layout for both boxes.

Only 3(three) points are needed to fix each Unit on the wall (marked with a red circle) with M4 bolt.

To make easier the wall mounting, a drilling layout template, 1:1 scale, is supplied with the unit.

Additional 2(two) screws and matching anchors are need if the EV-HC has charging cable (for cable

holder).

Figure 10 - EFAPOWER EV-HC 3 / 7 Drilling Layout

Figure 11 - EFAPOWER EV-HC 11 / 22 Drilling Layout

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

13 | 28

4. Connect the cables

The cables entrance shall respect the place that was assigned to it at the bottom of the Unit:

EV-HC3 / EV-HC7

Left grommet –Charging Cable

(if applicable)

Middle grommet –Communications

(refer chapter 5.3.4.4)

Right grommet –Input power cables

(refer chapters 5.3.4.2 and

5.3.4.3).

EV-HC11 / EV-HC22

Left grommet –Charging Cable

(if applicable)

Middle grommet –Input power cables

(refer chapters 5.3.4.2 and

5.3.4.3).

Right grommet –Communications

(refer chapter 5.3.4.4)

5. Connect the lid

Do not forget to re-connect the cables!

a. Plug the earth cable on it (faston terminal)

b. Plug the flat cable on the board (X14)

c. Plug the card reader cable on the board (X6) –if applicable

6. Screw the lid

First, tighten all 4 screws only to the point where they are snug.

Then, tighten the screws all the way starting with the lower screws.

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

14 | 28

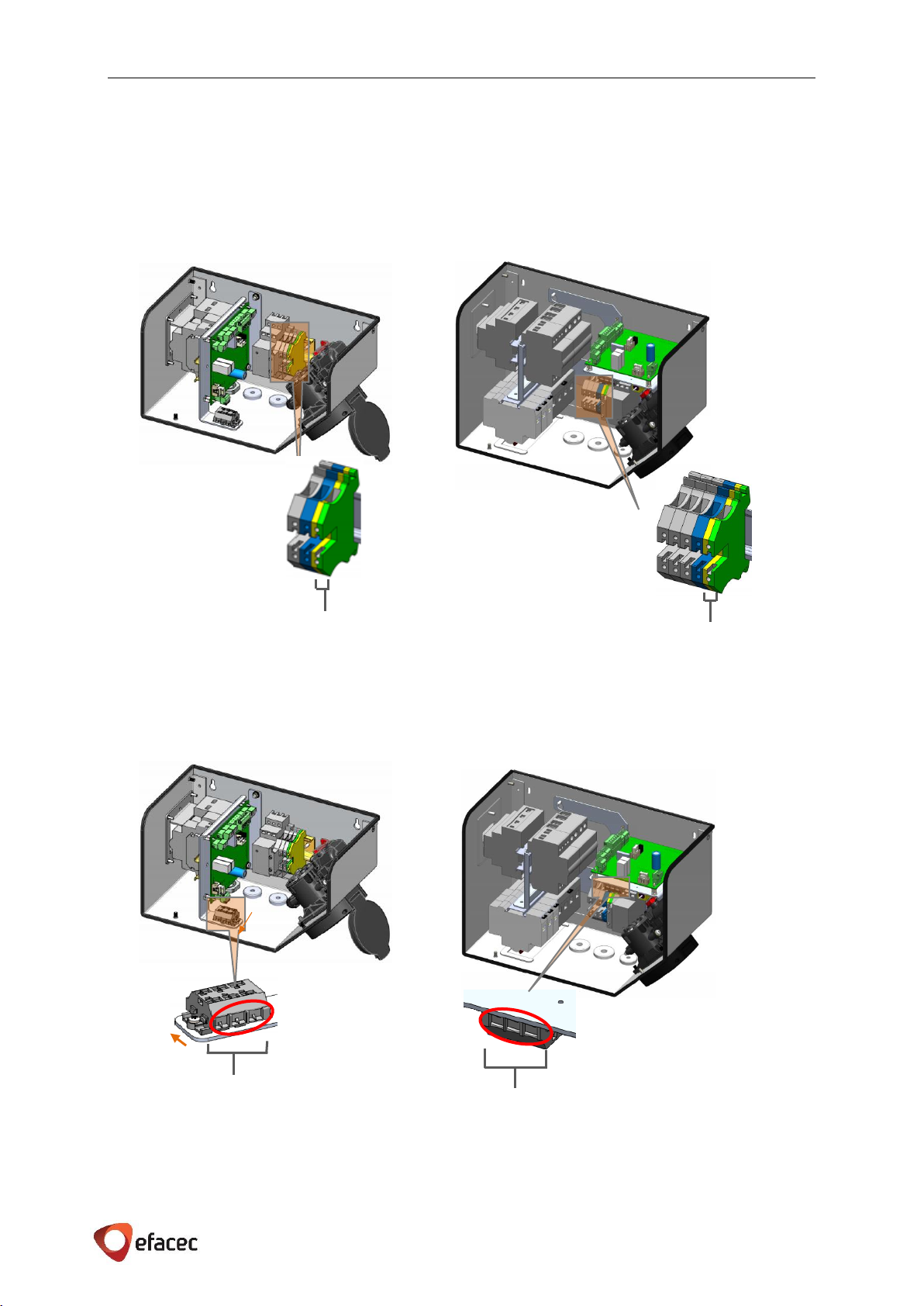

5.3.4.2 POWER CABLES CONNECTION

EVERY OPERATION ON THE EFAPOWER EV-HC MUST BE EXECUTED BY QUALIFIED PERSONNEL AND

PROPERLY AUTHORIZED. DO NOT OPERATE IN CASE OF WATER PRESENT OR HUMIDITY.

BY OPENING THE EFAPOWER EV-HC STATION’S COVERS YOU RUN RISK OF EXPOSURE TO DANGEROUS

VOLTAGES!

After unpacking and physically installing, the authorized technician must start installing the input cables.

Before connecting the EFAPOWER EV-HC must be assured:

The Grid Voltage level and frequency match the specifications on the EFAPOWER EV-HC

characteristics label

The Ground connection is connected in accordance with the harmonized standards or local regulation

The upstream protection is provided for the Unit

To ensure protection to technicians during installation of the EFAPOWER EV-HC, please verify the connections

are done according to the following conditions:

There is no input Voltage (not connected to the Grid);

No connection to Loads from the EFAPOWER EV-HC

The EFAPOWER EV-HC is OFF.

The input AC connections are done on the Charging Station as represented in Figure 12 through the grommet

mentioned below:

For 3,7kW/ 7,4kW - 1Ph+N+PE, 50/60Hz, and shall come through the right grommet

For 11kW/ 22kW - 3Ph+N+PE, 50/60Hz, and shall come through the middle grommet

Cable section of each line, depending on the power rate of EV-HC, can be consulted in Table 3 on page 9.

Figure 12 –Home Charger (front view) - Input Terminals

X1

HC 11 or HC 22

X1

HC 3 or HC 7

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

15 | 28

5.3.4.3 PROTECTIVE GROUND

The metallic structure is connected to the protective earth connection, as shown in Figure 13, which should be

interconnected with the low voltage switchboard earth connection.

Cable section of protective earth line, depending on the power rate of EV-HC, can be consulted in Table 3 on

page 9.

5.3.4.4 COMMUNICATIONS (IF APPLICABLE)

When applicable, the communications on the EV-HC shall be done through X2 double terminal (marked with a

red circle), represented in both EV-HC boxes on the next figure.

NOTE: The following communication scenarios are going to be represented on the one phase EV-HC box,

although they are valid also for the three phase EV-HC box.

Earth Terminal

HC 11 or HC 22

Figure 13 –Home Charger (front view) - Earth Terminals

Earth Terminal

HC 3 or HC 7

Figure 14 –Home Charger (front view) –X2 Terminals

X2 (rotated 90ᵒ)

HC 3 or HC 7

X2

HC 11 or HC 22

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

16 | 28

EV-HC Standalone connected to a Local PC

This scenario includes an EV-HC with RFID card reader and/or meter, with a port for communication with the PC

program Efacec Communication Manager. For more information on the Efacec Communication Manager, please

contact Efacec Electric Mobility commercial team.

If the charger isn’t equipped with an Energy Meter, the energy field on the transactions will be zero.

This communication is based on RS-485 and shall be used a USB-RS485 converter.

The Figure 16 represents the USB-RS485-WE FTDI converter.

The converter has several lines, although only 3 are needed for this communication, as referred in the following

table.

Table 6 - USB-RS485-WE FTDI converter - Connections

Cable Color

Function

X2 Terminal

Black

GND

X2.3

Orange

RS-485 D+

X2.1

Yellow

RS-485 D-

X2.2

A. Converter connected to a pre-installation outside EV-HC

If it’s not suitable the USB-RS485 converter connected directly to the EV-HC, due to distance constraints,

alternative pre-installation it’s allowed (Figure 15):

A shielded communication cable of at least 3 conductors can be connected to the EV-HC (through X2)

and end into a 3 pin panel outlet connector near a suitable place to connect the PC.

ATTENTION: This panel connector shall not be standard in order to prevent anyone to connect an

everyday use cable to the charger. USB, RJ45 adapter should not be used. This connector can also be

somehow locked to prevent inadequate use.

The mate male connector shall be assembled to the USB-RS485 FTDI converter, refer Table 6.

The panel outlet connector can now be installed in a suitable place, without length constrains, where the PC is

located. The USB-RS485 converter will link between the panel connector and the PC providing full access to the

Home Charger.

Figure 15 - Converter connected to a pre-installation outside EV-HC

Shielded communication cable of ate least

3 conductors –no length constrains

3 pin Panel Outlet Connector

USB-RS485 FTDI converter with mate

male connector

E F A P O W E R EV- H C - I N S T A L L A T I O N A N D U S E R M A N U A L

17 | 28

B. Converter directly connected to EV-HC

In this case the converter is directly connected to the X2 terminal of EV-HC, as represented in Figure 16.

The USB connection point can now be installed in a fixed location where the PC is located, providing full access

to the Home Charger.

A Network of EV-HCs connected to a Local PC

This scenario is a development of the previous. In this situation, all the chargers are connected together through

the X2 connector in Unit, and each charger is equipped with a RFID card reader and/or meter.

If the charger isn’t equipped with an Energy Meter, the energy field on the transactions will be zero.

The transactions can be saved in an excel file ant therefore reports of charge associated to a specific RFID card

can be generated.

ATTENTION: There is a Maximum limit of the number of the chargers that can be connected this way: 127

chargers in the network.

A USB-RS485 converter is used to connect all the chargers to a Local PC, refer Table 6.

The USB converter is connected between the Local PC and the first/closest charger (through X2). The pre-

installation presented above can be implemented.

Thereafter each charger is connected through the same X2 terminal till the last. A shielded communication cable

of at least 3 conductors shall be used, as represented in the following figure.

Shielded communication cable of ate least

3 conductors –no length constrains

3 pin Panel Outlet Connector

USB-RS485 FTDI

converter with

mate male

connector

Figure 17 - Network of EV-HCs connected to a local PC

Figure 16 - Converter directly connected to EV-HC

Cable length should be 5 meters

maximum

Table of contents

Other efacec Batteries Charger manuals

Popular Batteries Charger manuals by other brands

Schumacher

Schumacher SE-40225 owner's manual

Universal Power Group

Universal Power Group 12BC2000T-1 Specification sheet

Hitachi

Hitachi UC 18YGL Safety instructions and instruction manual

CS-Electronic

CS-Electronic Professional X2 Charger manual

Panasonic

Panasonic FZ-VCBN141 operating instructions

ECTIVE

ECTIVE Multiload PRO operating instructions